TABLE

OF

CONTENTS

Page

CHA

PTB

sicnticw

un

cad

iunriwan

ihe

ckniieateneaiels

idebdiniesecuteeiaioneenttriceaten

1-1

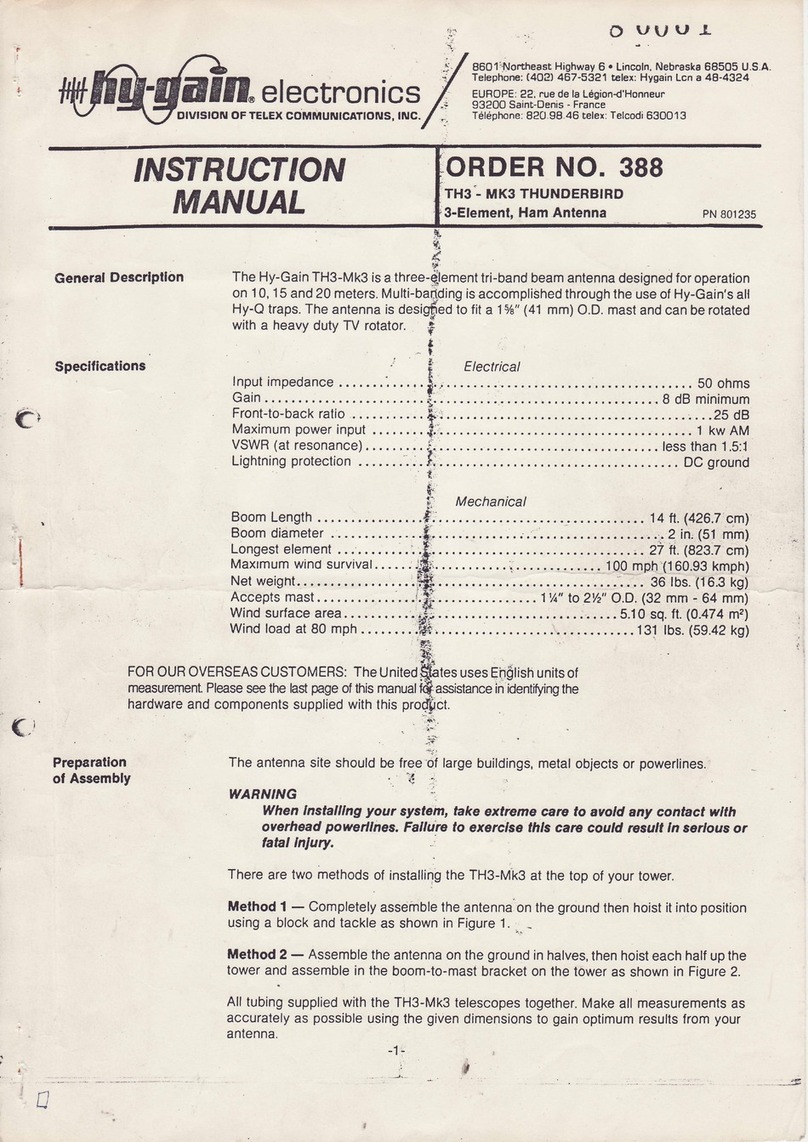

General

Description

............c.ccccccsssssessssssssssessesseseees

gdestectenedesececetarcess

Iutgons

wen

gatlca

ieee

aah

1-1.

PEC

MIC

ANON

Ss

scitessital

ides

actesttverstascecce

icxstchtale

delves

bes

seceauledasitatshsvactansatdesdesicusatiubusestevedeomiscteveceaeteens

1-1

Theory

Of

Operation..............cccsccscscessceseresecesseesseecesseees

ere

Ta

er

eT

UT

aR

ene

ee

Rudedars

1-2

CHARTER

2

vcs

sescccecstvesspasciearnsacentotsnsceess

BS

eens

wescesa

yeu

ecusoneteaas

i

aseeeeca

yeaa

MaNelisesh

ies

ee

ee

en

ere

2-1

Pete

par

aliors

Or

ASSO

EY

sce

w,

Soa

zeshceve

oconeste

tector

ccc

tea

eda

doatesaeteaaeo

eons

GlsdeLicb

a

eseeneean

2-1

CHA

POEL

SD

srecsscsecssdnsotvsecsceastetetnaces

acest

dik

tN

eccu

east

cosines

os

hire

Maecenas

3-1

Assembly

of

the

Boom

and

Boom-to-Mast

Brackets

..............:.cccsscssccssscsscsessssssccsscessssssesccsessscesceneees

3-1

Assembly

of

the

Element-to-Boom

Brackets

on

the

Boom............

erecaieee

eels

s

aL

hai

thst

eetins

3-2

Installation

of

Tubing

Clamps

on

Element...............cccccccssessesccsceseceseescesccssccssessecscsssccsssecsesscesscssssssees

3-3

BC

Ie

REA

SSE

BLY

spies

coasts

sees

nceahs

ize

At

cae

Sacsaet

ects

oeAvansiocseessveeiieasausaseteiceateean

sed

bsttes

aust

een

3-5

Installing

Elements

On

the

Boom

<cccvises.

sexcacaed

siocecscieketece

s50a5oes

tutescuceutcecsdecacutesitdeledusk

avedaivecsndeebeateaates

3-9

Plrasing:

Tid

be

ASseim

Bly

csisce

cuts

oe

cd

osteateeasched

av

tte

sects

ecsarsans

ohsdaneaghas

at

oeeciews

ted

masculine,

3-9

Boom

Support

Assembly

..............ccssscssccssessescececesssssesccesscseseseees

Paceline

ata

cn

a

eee

3-13

6

V9

ool

5

ee

ean

PRO

ee

SEE

een

Pe

st

eR

eae

DMP

PD

OTE

ree

ER

OTT

4-1

PEN

Ma

INSTA

AON

xs

scstecsa

sate

Socancethe

saizedc

us

cous

vartecdoenchd

cueuiesvtniesietelucasabusthatencs

Gaeiee

ieee

ae

4-]

Installavon

oma

Crank-Up

POW:

cccciccassjesscceccesssttesesesescrsecdsaneceu

lets

daviesnystoeetextcn

Sndbsaandenteatiasesuteenuee

4-]

OMREE

EVES

OF

RO

WETS

se

ccsctses

casi

ee

pad

ass cad

eum

es

ced

ened

es

osctods

Sespteea

ds

icaes

cates

basboce

oars

acne

nascoed

lata

te

testes

4-1

Atiachinent

Of

Pee

line:

s.gsescicasacactesteusiceaxesacsatin

tzesotes

os

ccesce

Sessuavstnssecee

secuisehel

teseua

rave

donated

ania

4-1

Attaching

the

Antenna

to

the

MaSt..............cccsssssesccesesseeesensessecsecesesnsssecsccsscsecsecccceeccsaceaccresccascecesavess

4-]

TETSU

PEO

VECO

Mi

eae

acc

nda

icesatace

eu

co

ec

ss

eas

acca

auc

eecas

tse

Pata

Uaessts

ips

ve

lusc

eee

anone

cath

ake:

4-2

VSWR

Curves............

batguasgaceataeet

a

camaavees

Mtcnashat

cesarean

Doss

eosin

less

vbadad

Nance

eae

vaetente

eeeee

eee

4-2

VOW

ER

CATS

oo

cette

vo

sttnve

cated

che

uattsueasiaueadairuncetwasud

saeasieodaenssaass

acoead

us

vatgasosn

deacon

geceeclosstidendaates

4-3

a

oF)

a

BO

|

ae

erreur

ee

em

OT

DenRA

ee

CER

INTE

Tree

PEST

RE

ENS

ae

Ee

5-1

CPE

GAOT

yeas

esccqnses

areas

se

arauetecuvereacsman

er

taebaecuducieses

ata

tet

eta

sale

es

edhe

tis

asked

raat

det

5-1

IAAI

ADCS

soc

ctceoctlaceectysee.wsnatccececestcastect

nasaususiaax

Oiewlsiauyosvsnluasae

conmttuastseacaaancestescuses

ecu

cueel

audasocasauesntes

5-2

CHAPTER

6.

BR

als

ate

eal

ac

tah inh

eras

Sean

ale

nals

iit

e

ad

seen

caus

ca

ete

uRe

cna

been

teas

dod

Masuda

bvaceadsaosiacenaies

6-1

TROUDICSNOOUNG

iin

nteostnien

laces

lice

data

eivebsensudareete

auhad

car

cacadcan

ceva

ouauacuae

wa

leniueaacs

deat

ils

6-1

AP

TOUDICSMOOUM

DAC

NRE

act

18

coke

lee

hh

ce

ha

ala

chenas

Lyle

Siete

es

andl

ach

l

es

rate

eaten

te

canaasceices

duane

6-1