SECTION 4 - ELECTRICAL SYSTEM

General Information.................................................................................................................... 4.1

Photos of Standard Electrical Components................................................................................. 4.1

Photos of Optional Electrical Components.................................................................................. 4.3

List of Electrical Components For An S-25A With the Optioanl PLC100.................................... 4.4

List of Electrical Components For A Standard S-25A.................................................................. 4.7

Standard Electrical Schematic S25-7-00-1.......................................................... 4.12

Standard Electrical Wiring Diagram S25-70-02 pg.1............................................... .... 4.13

Wiring Diagram S25-70-02 pg. 2 ................................................. 4.14

Wiring Diagram ( Contol Box) S25-70-02 pg.3.................................................... 4.15

Electrical Schematic (PLC Option) S25A-7-00-1A ..................................................... 4.16

Electrical Wiring Diagram PLC S25A-7-00-2A pg.1 ............................................. 4.17

Electical Wiring Diagram PLC (Control Box) S25A-7-00-2A2 pg.2 ........................................... 4.18

SECTION 5 - HYDRAULIC SYSTEM

General Information.................................................................................................................... 5.1

Parts List and Photos of Hydraulic Components.......................................................................... 5.1

Cylinder Components .................................................................................................................. 5.2

Positive Downfeed Valve Components ...................................................................................... 5.3

Hydraulic Schematic S25A-6-00-1 ...................................................... 5.4

Hydraulic Plumbing Diagram S25A-6-00-2 ....................................................... 5.5

Plumbing Diagram (VVP Option) S25A-6-00-2....................................................... 5.6

SECTION 6 - MECHANICAL ASSEMBLIES

Parts List and Photos:

Blade Guide Arm Assembly........................................................................................................ 6.1

Guide Arm Rack Assembly......................................................................................................... 6.2

Blade Brush Assembly................................................................................................................ 6.3

Drive Assembly.......................................................................................................................... 6.4

Idler Wheel Assembly................................................................................................................. 6.5

Vise Cylinder Mounting Assembly............................................................................................... 6.6

Front Table Assembly ................................................................................................................ 6.7

Gearbox Assembly.................................................................................................................... 6.8

Auxiliary Table Assembly............................................................................................................ 6.9

Shuttle Guide Assembly.............................................................................................................. 6.10

Infeed Conveyor assembly......................................................................................................... 6.11

Pivot Link Assembly.................................................................................................................. 6.12

Head Swing Assembly............................................................................................................... 6.13

Coolant System Assembly.......................................................................................................... 6.14

Outfeed Table Assembly............................................................................................................. 6.15

Length Control Assembly............................................................................................................ 6.16

SECTION 7 - OPTIONAL SAW EQUIPMENT

Overhead Bundling Attachment.................................................................................................. 7.1

Variable Vise Pressure................................................................................................................ 7.2

Blade Breakage Switch............................................................................................................... 7.3

Out of Stock Limit Switch............................................................................................................ 7.4

Remote Blade Speed Adjustment............................................................................................... 7.5

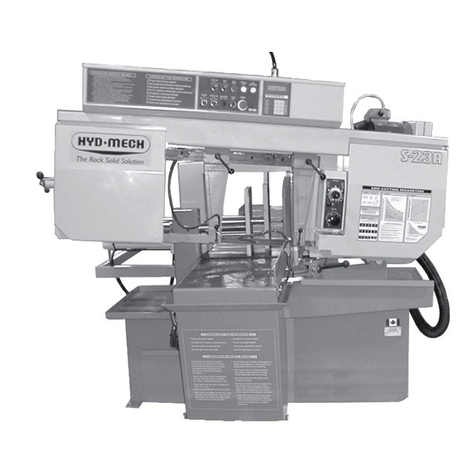

SECTION 8 - SPECIFICATIONS

Specification List........................................................................................................................ 8.1

Dimensional Drawings................................................................................................................ 8.2

SECTION 9 - WARRANTY

Warranty..................................................................................................................................... 9.1