i

TABLE OF CONTENTS

SECTION 0 - SAFETY INSTRUCTIONS

SUMMARY .......................................................................................................................................0.1

BASIC RULES .................................................................................................................................0.4

RESPONSIBILITIES OF THE OWNER ...........................................................................................0.5

RESPONSIBILITIES OF THE OPERATOR AND MAINTENANCE PERSONNEL .........................0.6

SAFETY HAZARD LABELS............................................................................................................0.9

LOCATION AND PART NUMBERS OF SAFETY HAZARD LABELS...........................................0.10

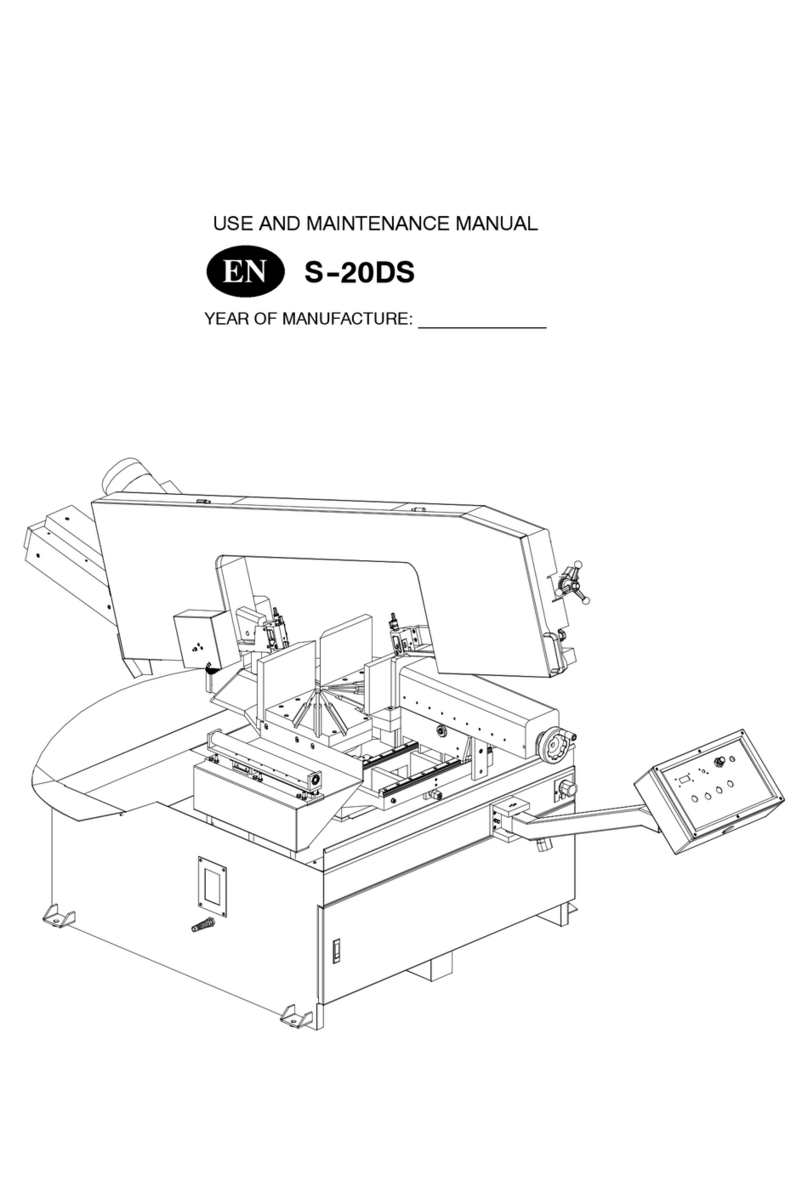

SECTION 1 - INSTALLATION

SAFETY PRECAUTIONS ................................................................................................................1.1

LIFTING THE S20A WITH A FORK LIFT ........................................................................................1.2

FOUNDATION, LEVELLING AND ANCHORING............................................................................1.3

EARTH GROUNDING PROCEDURE..............................................................................................1.3

POWER WIRING CONNECTIONS..................................................................................................1.4

HYDRAULIC OIL .............................................................................................................................1.4

CUTTING FLUID..............................................................................................................................1.4

SECTION 2 - OPERATING INSTRUCTIONS

OPERATOR CONTROL PANEL......................................................................................................2.1

START-UP........................................................................................................................................2.1

CONTROL CONSOLE .....................................................................................................................2.2

OPERATION CONTROLS ...............................................................................................................2.2

HYDRAULIC FEED CONTROL.......................................................................................................2.2

STARTING THE MACHINE ............................................................................................................2.10

MANUAL MODE Machine Operation............................................................................................2.12

SETTING HEAD UP AND HEAD DOWN LIMITS...........................................................................2.13

PROGRAMMING JOBS..................................................................................................................2.13

PROGRAMMING THE QUEUE .....................................................................................................2.14

BLADE KERF ................................................................................................................................2.15

AUTOMATIC MODE Machine Operation ......................................................................................2.16

STEP ...............................................................................................................................................2.22

BLADE CHANGE MODE (BCM) ....................................................................................................2.23