CSM 1000 Series

HYDAC Filtertechnik GmbH en Page 3

BeWa CSM1000 3265074d en 2012-09-20.doc 2012-09-20

Contents

Preface ....................................................................................................................................5

Customer Service ................................................................................................................6

Product modification ............................................................................................................6

Warranty .............................................................................................................................. 6

Using the documentation.....................................................................................................7

1. General safety guidelines .......................................................................................... 8

1.1. Obligations and liability.................................................................................................8

1.2. Explanation of symbols and warnings ..........................................................................9

1.3. Intended use ................................................................................................................. 9

1.4. Improper use................................................................................................................. 9

1.5. Safety devices ............................................................................................................10

1.6. Informal safety precautions......................................................................................... 10

1.7. Training and instruction of personnel.......................................................................... 10

1.8. Safety precautions for normal operation.....................................................................11

1.9. Electrical hazards .......................................................................................................11

1.10. CSM modification .....................................................................................................11

2. Packing, storage ....................................................................................................... 12

2.1. Unpacking CSM..........................................................................................................12

2.2. Storing the CSM .........................................................................................................12

3. Checking the scope of delivery............................................................................... 13

4. Technical description...............................................................................................14

4.1. Application restrictions................................................................................................14

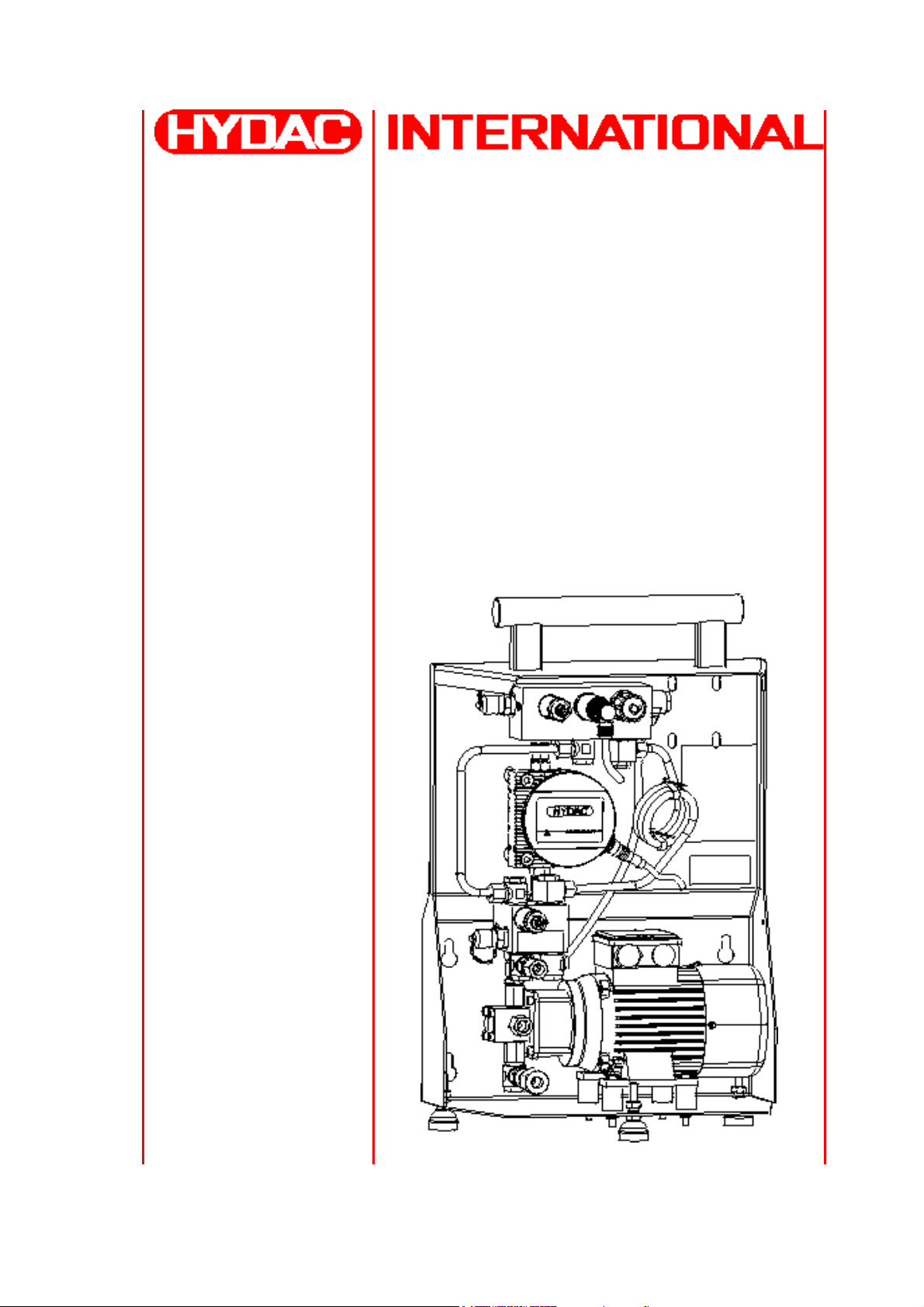

4.2. CSM components .......................................................................................................15

4.3. Hydraulic diagram.......................................................................................................16

4.4. Dimensions CTU 1xxx-1 ... .........................................................................................17

4.5. Dimensions CTU 1xxx-2... ..........................................................................................17

4.6. Drilling template .......................................................................................................... 18

5. Connecting the CSM hydraulically and electrically...............................................18

5.1. Hydraulic connection ..................................................................................................18

5.2. Notes on piping / hosing .............................................................................................19

5.2.1. Suction port - IN .............................................................................................. 20

5.2.2. Return port connection - OUT ......................................................................... 20

5.2.3. Leakage connection - LEAKAGE (only with CSM 1xxx-2....) .......................... 20

5.3. Electrical connection................................................................................................... 21

5.4. Electrical connection of the ContaminationSensor CS1000 ....................................... 22

5.5. Electrical connection of the AquaSensor AS1000 ...................................................... 22