✆

01268 205 121

| www.hydraev.co.uk | sales@hydraev.co.uk

2

CONTENTS

SAFETY ...................................................................................................................................................................................3

Safety Identication .......................................................................................................................................................3

INTRODUCTION.....................................................................................................................................................................6

Serial Number Identication.........................................................................................................................................6

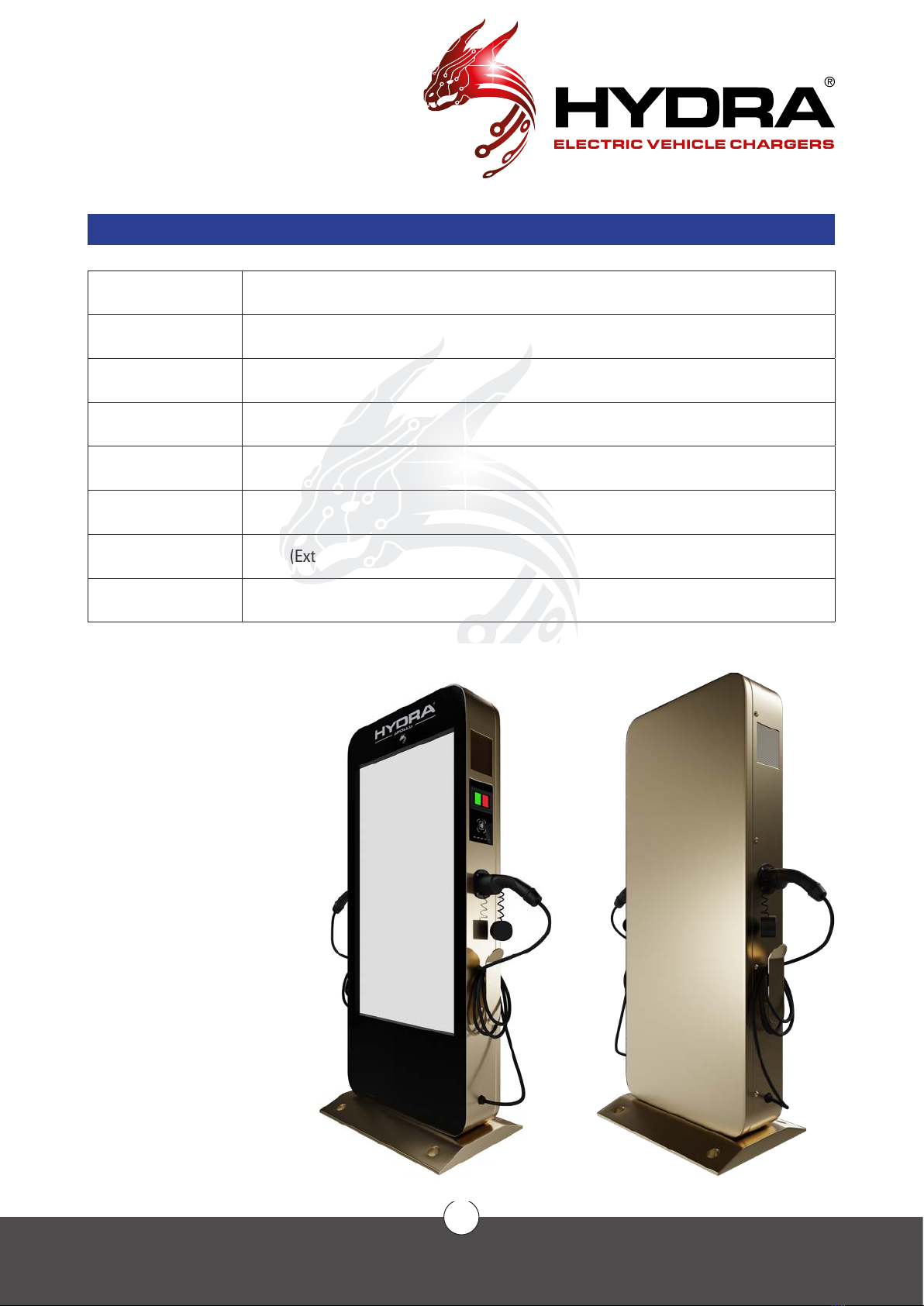

Appearance .....................................................................................................................................................................7

Technical Specications................................................................................................................................................8

Product Features...........................................................................................................................................................10

SYSTEM ARCHITECTURE ..................................................................................................................................................11

Electric............................................................................................................................................................................11

System Communications .............................................................................................................................................11

INSTALLATION ....................................................................................................................................................................12

Procedure.......................................................................................................................................................................12

Network connectivity requirements ..........................................................................................................................13

Tool preparation ............................................................................................................................................................14

Internal structure ..........................................................................................................................................................15

Site Space Requirements ............................................................................................................................................16

Installation Instructions ...............................................................................................................................................17

Electrical Requirements...............................................................................................................................................18

Connect the Power Cable............................................................................................................................................19

COMMISSIONING ..............................................................................................................................................................20

Power on standby owchart.......................................................................................................................................21

Charging Operation.......................................................................................................................................................22

Charging Operation Flowchart....................................................................................................................................22

Non-Operational mode owchart ..............................................................................................................................23

Emergency Operation...................................................................................................................................................24

Setup ...............................................................................................................................................................................25

Ethernet Mode...............................................................................................................................................................26

Using a Static IP address ............................................................................................................................................26

Wi Mode.......................................................................................................................................................................26

WIFI mode ......................................................................................................................................................................27

Set DNS ..........................................................................................................................................................................27

Change the URL.............................................................................................................................................................27

PLATFORM CONECTIVITY .................................................................................................................................................28

Connect to the Chargecore Platform.........................................................................................................................28

AFTERSALES........................................................................................................................................................................29

Aftersales Service ........................................................................................................................................................29

Disclaimer ......................................................................................................................................................................29

Maintenance..................................................................................................................................................................29

Procedures.....................................................................................................................................................................31

During Installation.........................................................................................................................................................31

After Installation............................................................................................................................................................31

APPENDIX............................................................................................................................................................................32

Screen Icon Key............................................................................................................................................................32

Fault Diagnosis ..............................................................................................................................................................33

Electrical Diagram ........................................................................................................................................................34

Restriction of Hazardous substances........................................................................................................................35

Authentication ...............................................................................................................................................................36