Viscolite VL7

10 U01-04-013 R1 08/13

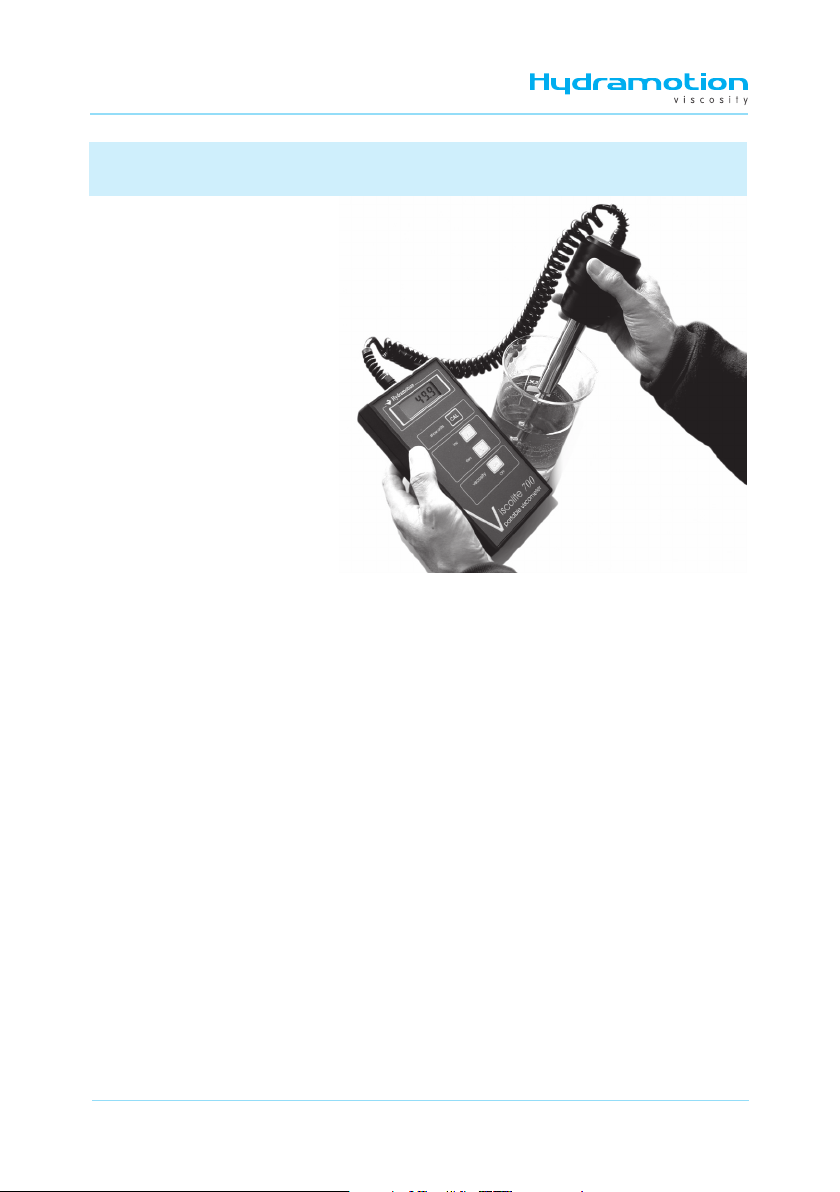

2 Measuring viscosity

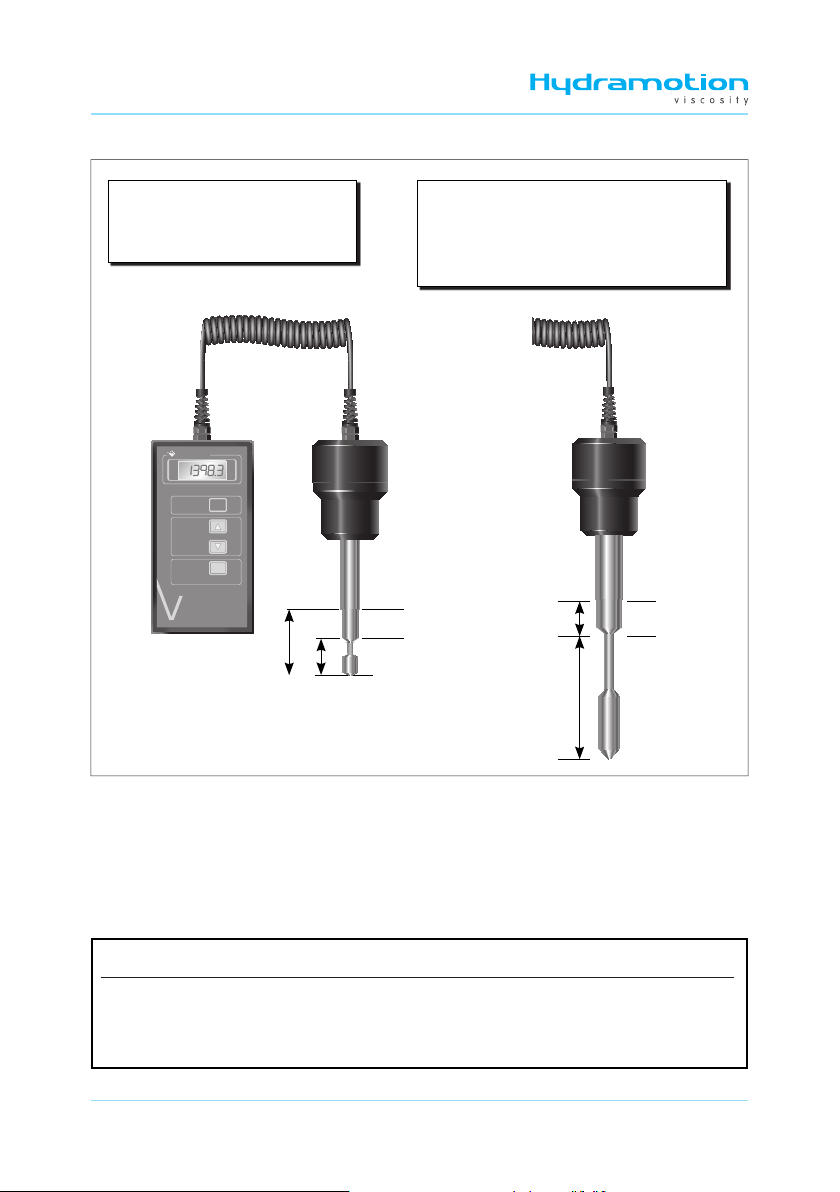

Figure 4

Display unit

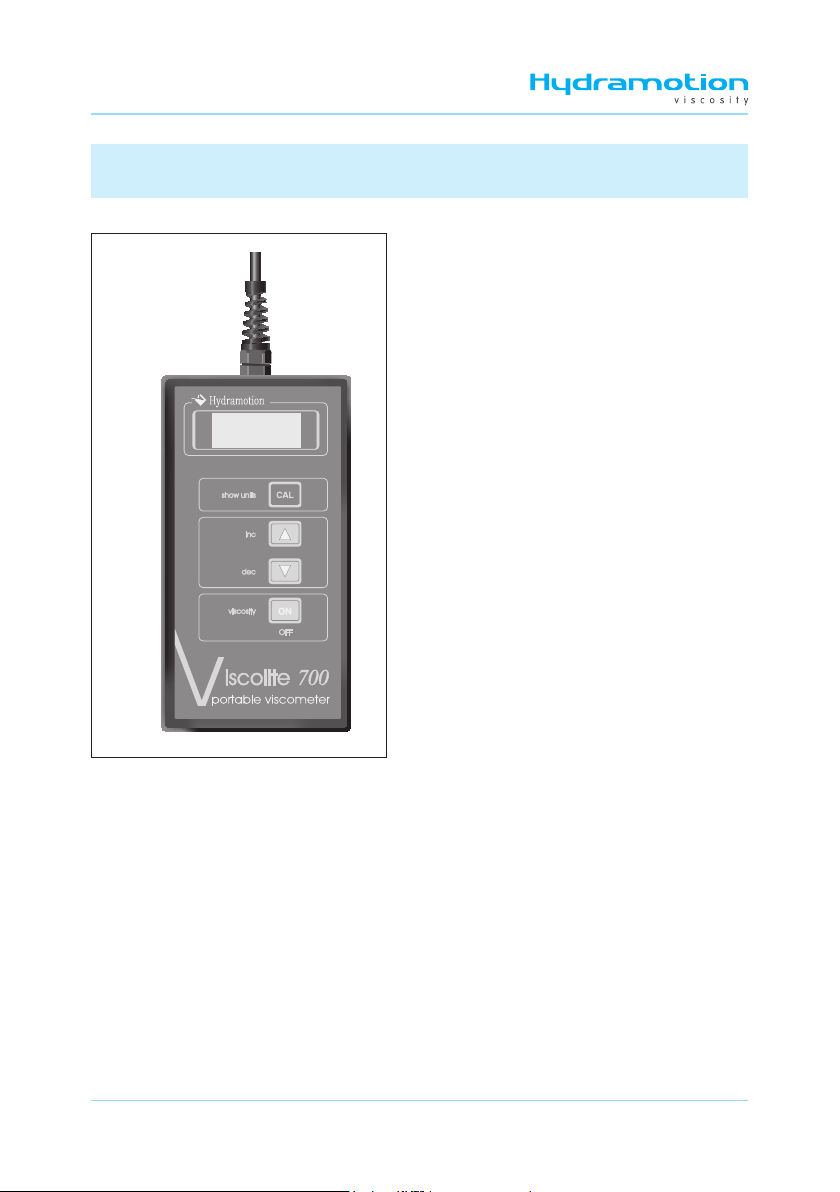

2.1 Turning on

• Press the *key on the display unit and

hold it down for a second or two.

• The display shows a succession of digits

while the microprocessor goes through a

start-up routine. It will then show “VL”

briefly before settling on the “live viscosity”

reading. This is the dynamic viscosity

in centipoise (cP) of whatever fluid is

surrounding the sensor.

• The reading is updated every 1.5 seconds

approximately.

• Pressing the )or (keys will bring up two

other measurements, “t” (temperature) and

“VC” (temperature-corrected viscosity). For

more details, see pages 12 and 13.

• A beeper sounds each time a key is pressed.

• To switch off, press the *key again.

2.2 Operation check

• The display unit should read 0.0(zero) so long as the sensor is

(i) perfectly clean, dry and

(ii) wholly in air and not touching anything.

• The display should show 1.0 (exactly one) if the sensor is immersed in water at 20 °C.

For details of the checking procedure, see Section 5.2.

• If the air reading is not exactly zero:

(1) check that the sensor is perfectly clean, dry and not in contact with anything.

(2) if necessary, perform a “minor null adjustment” as described in Section 4.4 (p. 22).