6

Terms of Guarantee

Hydraram provides a warranty of 12 months from the date of delivery.

All defective parts proven to be caused by faults in either manufacture, production or

material are covered by the warranty.

Defective parts that are replaced and fall under guarantee become property of Hydraram.

They must be kept available and returned immediately, in complete and unaltered

condition, upon the first request from Hydraram.

Any claim made under guarantee will only be taken into consideration once a written

appeal is made to the dealer or Hydraram. This must be done directly after the damage or

fault occurs and at least within 24 hours of any irregularities and problems arising.

All claims under conditions of the warranty must contain the following data; the type of

machine the product has been mounted on, the serial number of the grab, the record of

the defective part(s and a description of the fault, photographs, copy of the delivery

papers and invoice and a copy of the invoice of the piece of equipment concerned.

Minor repairs can be carried out in consultation with the dealer; the necessary parts

which fall under the warrantee, will be delivered without charge. For larger repairs the

grab should be sent to your dealer or Hydraram for repairs or modifications. The work and

necessary parts are free of charge. However, transport costs and call-out charges to and

from your dealer or Hydraram are not covered.

The Hydraram is not liable for consequential loss caused by a defective demolition

Grab (consequential loss to excavators, consequential loss due to a stationary excavator

or the suspending of work activity).

Excluded from Guarantee:

•Damage caused by faulty assembly of a machine and or the hydraulic system,

improper maintenance without expertise and transport damage.

•Defects resulting from improper repairs and/or maintenance including that carried

out by an unauthorised third party.

•Defects arising from neglect or improper execution of preventive maintenance

procedures e.g. regular lubrication or greasing.

•Defects to parts which are subject to normal wear like blades.

•Consequential loss caused by failure to replace normal wearing parts in time

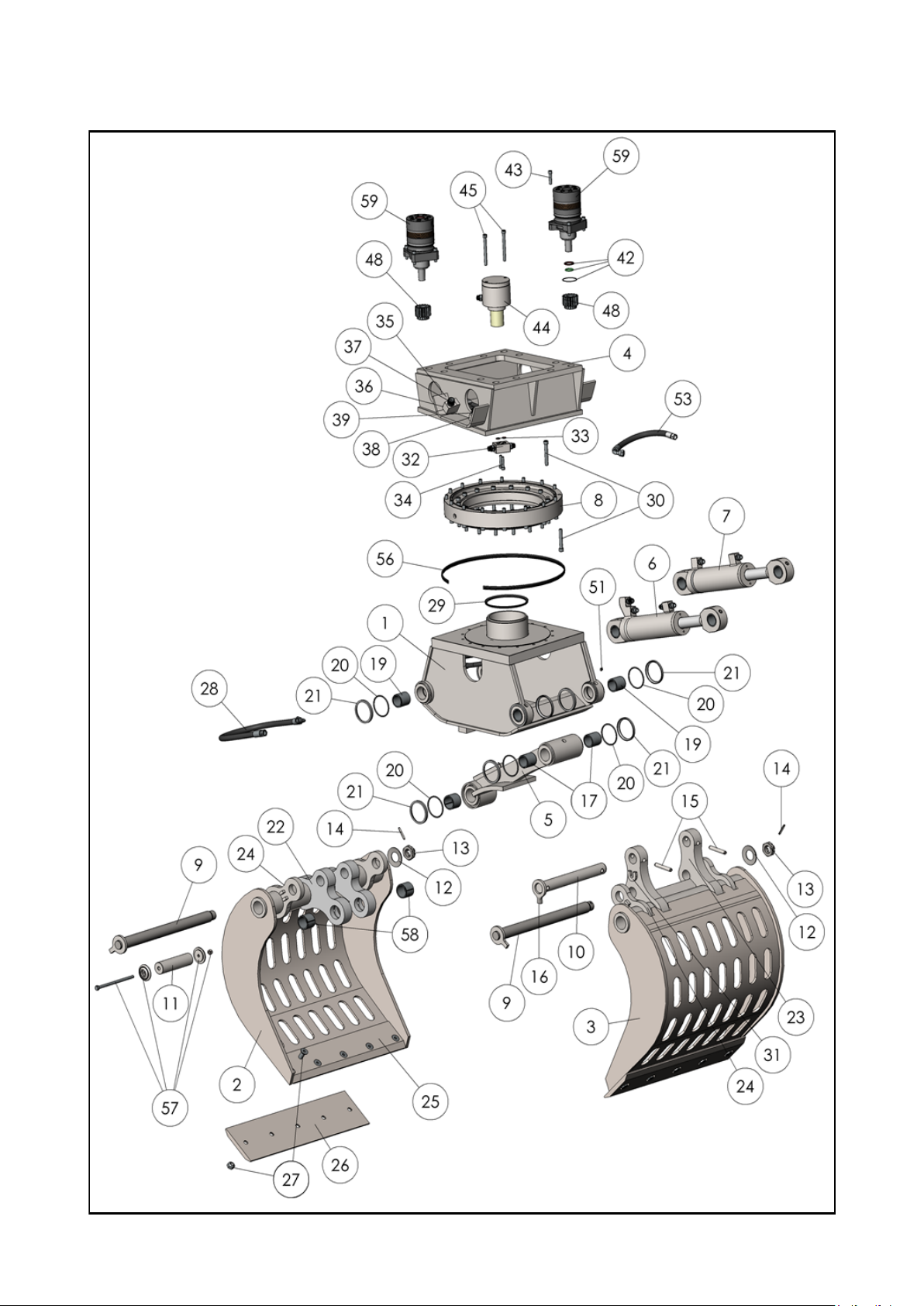

N.B. If defective or worn down parts are replaced by non-original parts, the entire

warranty and liability will cease to apply.