6

2.2.2 Demineralization on a mixed ion exchange bed

Filter H5 – filter contains beds of mixed ion exchange resins in ionic form H+/OHˉ

situated in the housing. Water is purified on the deionization columns, where remaining

mineral salts are captured. In the ion exchange process ions existing water and particles

with a specified current are bound by ionites. After this process, the conductivity

decreases < 1 μS/cm.

3. Technical specification

The device is equipped with:

sediment prefilter 5 μm

module A (sediment-carbon)

ion exchange module H6

conductometer measuring demineralized water conductivity, equipped with an

alarm informing about necessity to replace ion exchange resins

manometer measuring feed water parameters

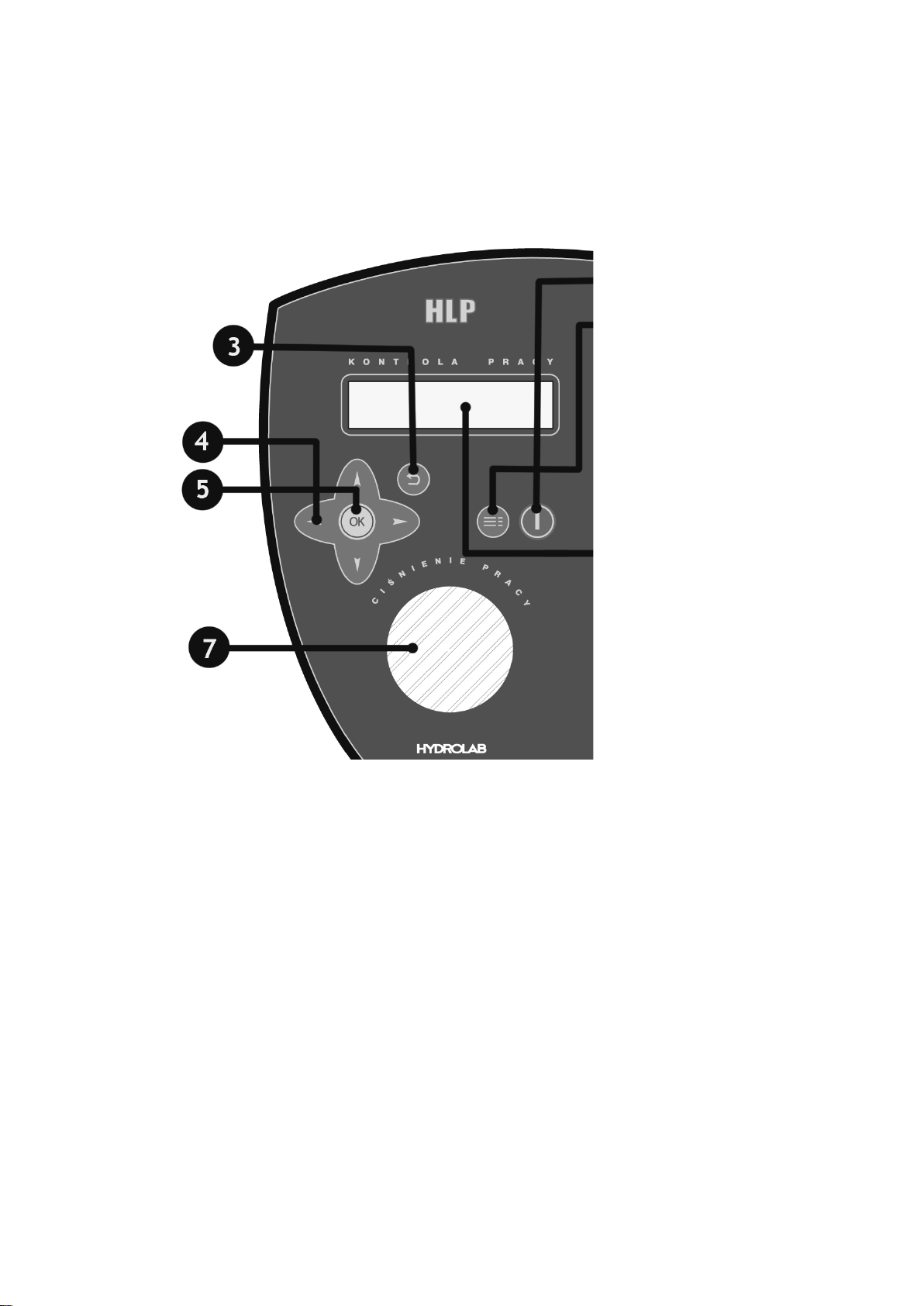

control system

…………………………………

…………………………………

…………………………………

3.1. Materials

All used materials are inert with water:

- all wires are made of polyurethane

- connectors and fittings – polyethylene or polyvinylchloride,

- ion exchange column – polypropylene,

- distributors and column filtration nozzles – polyethylene,

- conductometric probe – polyethylene and stainless steel

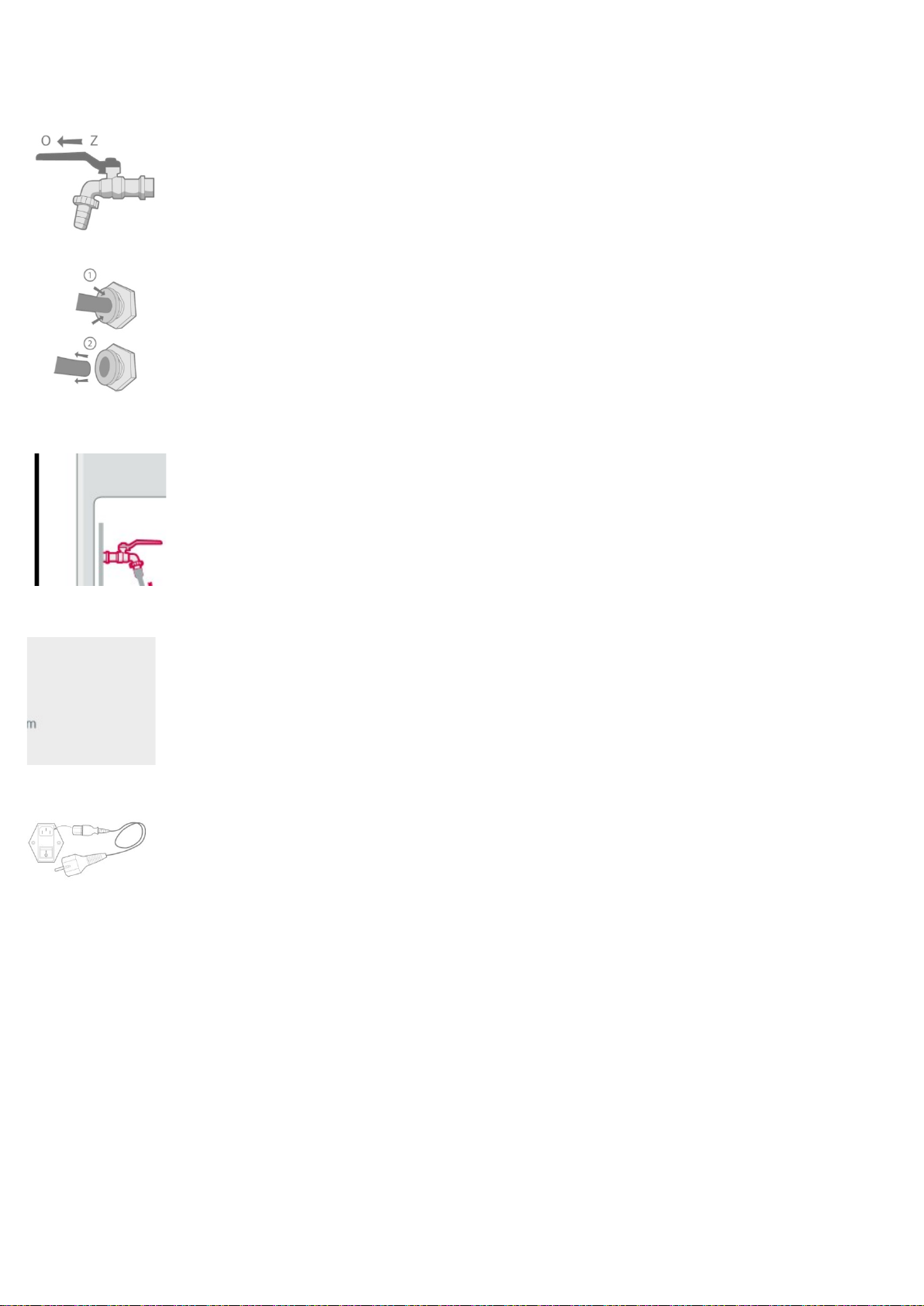

4. Installation

GENERAL INFORMATION BEFORE INSTALLATION

• Best results are achieved when the demineralizer is fed by softened water.

• Feed water should match the requirements defined in 1.3 (temperature, pressure,

etc.)

• Performing quality analysis of feed water allows for matching a right initial

purification.

Cartidges should be replaced with a frequency that is recommended further in this

manual.

4.1 Demineralizer installation

Remember to place the fillers in the wires (connected by the caps). In case of quick

couplings, just plug in the wire to the connector (make sure it is evenly cut).

Step 1

Put the device in a suitable place.