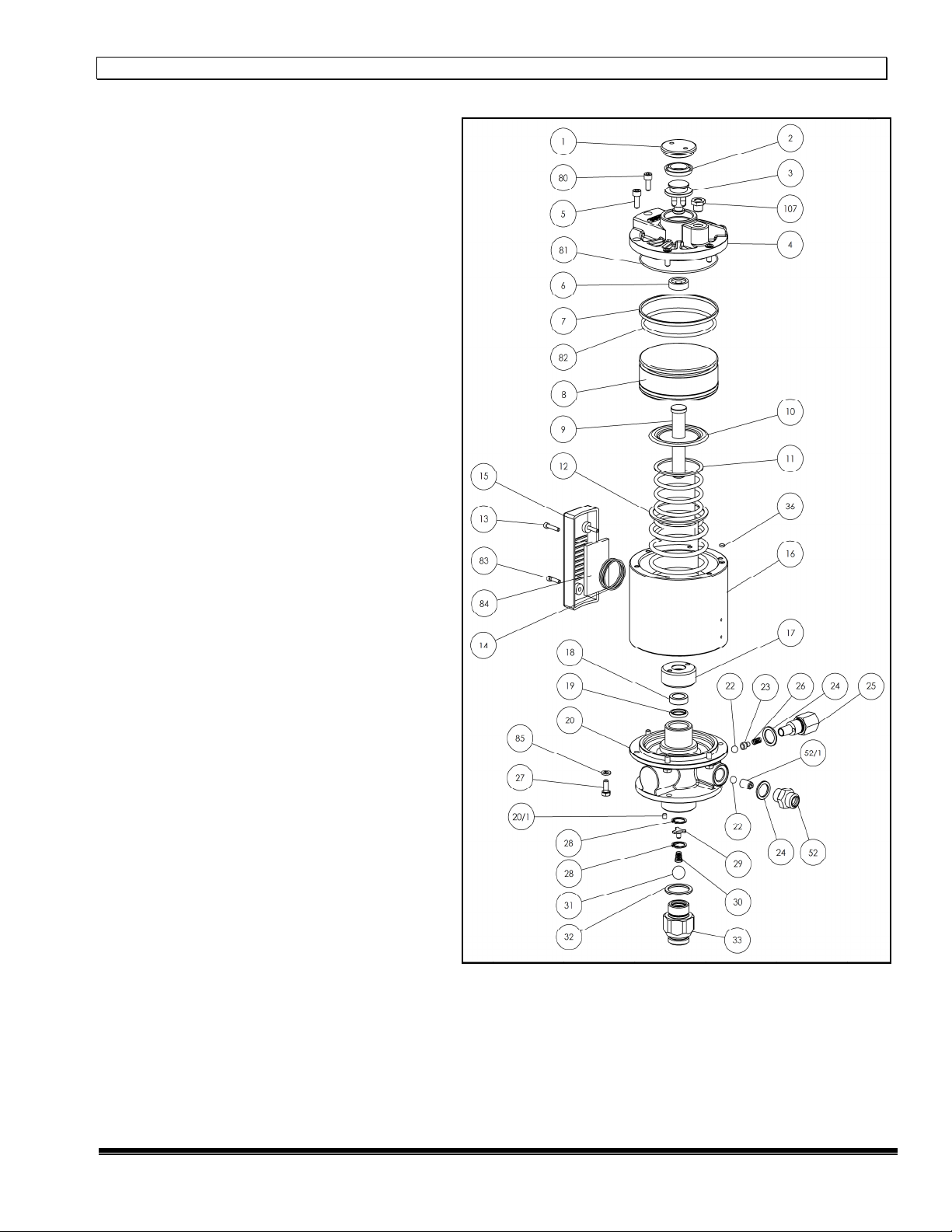

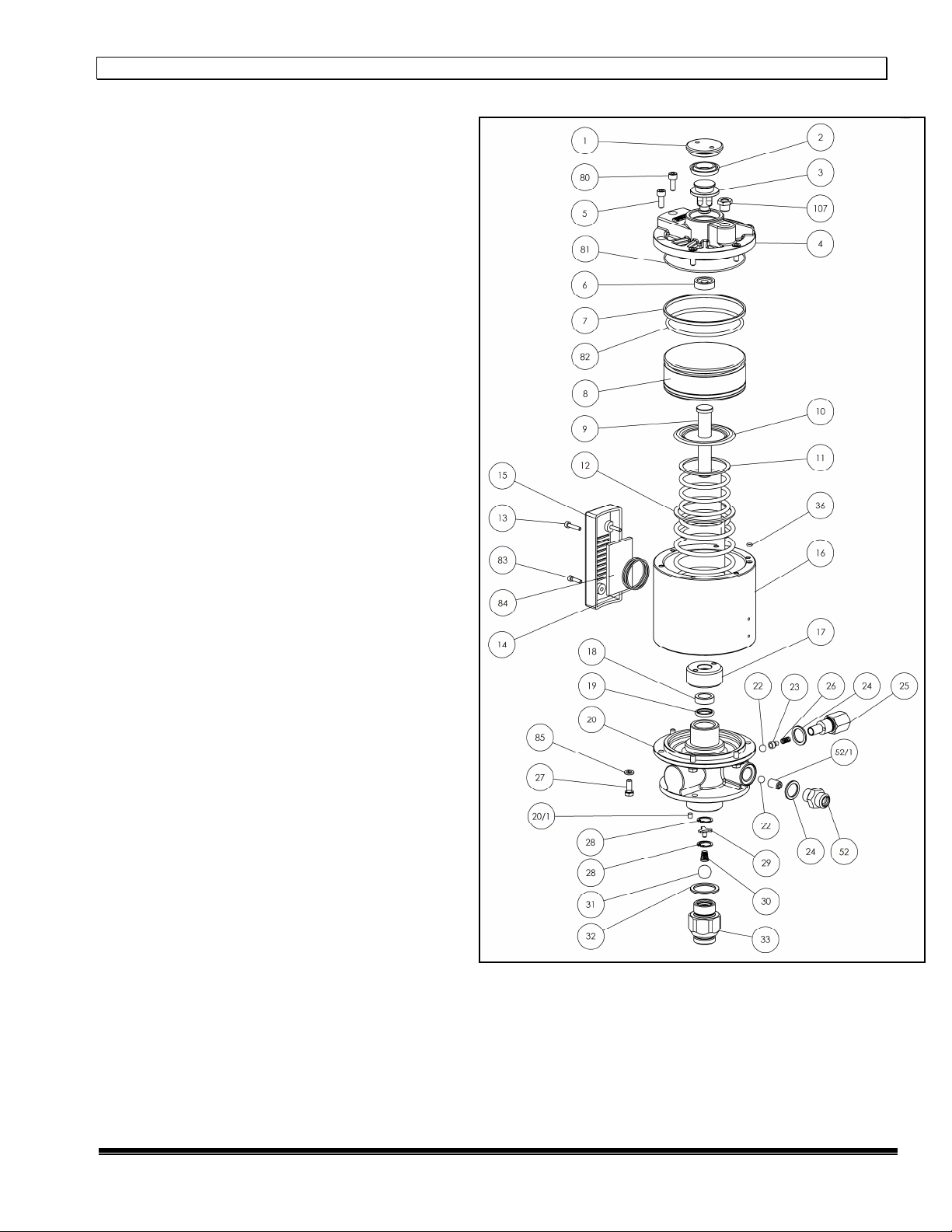

Hydronic Air Driven Pumps & Intensifiers P720 Installation, Use and Maintenance Booklet 08-21-09

Page 3

Installation Guide

Pumps should be installed in a vertical position or optimum unctioning o suction and

delivery valves. Suction, pressure and airlines should be ¼” bore. Basic pumps can be

controlled by a hydraulic directional valve. The manual pressure release version will stop

and start the pump at the same time as opening and closing the pressure to tank line.

The air-operated version will require a pneumatic our-way valve to direct air to the

pump or the air-operated pressure to tank line. It may be use ul in certain applications

to add lubrication oil to the air inlet. I this action is taken, the ollowing speci ications

are advised:

•Hydraulic oil having viscosity o 150 to 250 SSU

•Oil temperature 32º F to 150º F

•Air temperature 40º F to 100º F

•Room temperature 40º F to 100º F

Compressed Air System

It will be advisable to it an air ilter/regulator unit having minimum low capacity o 30

sc m plus a pressure gauge in order to ensure the pump has su icient air energy to work

correctly and provide the hydraulic per ormance you expect.

Hydraulic System

Valves, pipes, hoses and accessories should all correspond to maximum working

pressure o the pump used and be o a size that will ul ill low requirements. Bear in mind

the minimum o ¼” bore or the suction line.

Application

Hydronic air driven hydraulic pumps are designed or operating oil hydraulic circuits.

The pump operates simply, a large sur ace area piston actuated by compressed air.

Attached to it is a piston with a smaller sur ace area in a hydraulic chamber generating

high hydraulic pressures. The continuous pumping action is produced by the

compressed air being switched by a special valve assembly. By regulating the air

pressure rom 30 psi to 100 psi, the maximum hydraulic pressure can be adjusted by the

ratio o the pump used. As the hydraulic load o the circuit increases and the oil

pressure rises, the pump will slow down and eventually stop. In this way, the maximum

load o the circuit will be maintained without air consumption.