7

ELECTRICAL INSTALLATION

This equipment system has been100% factory tested for quality and reliability prior to

shipping. Care should be taken on all electrical connections to avoid damage to the system

circuit board, and added components. Damaged caused by accidents, improper wiring

configurations and/or abuse voids your warranty.

Start by having your electrician select a wiring configuration that best fits your total system

needs, from the GFCI breaker sizing matrix on page 8.

Due to the availability of GFCI breaker sizes, and your electrical supply requirement, some

systems require a second independent or “dual” power source, to supply the electric heater

separately. Diagrams for independent heater wiring is provided in this manual.

Note; 5.5kw systems using a single source power supply will not allow electric heater

operation, when pumps are in high speed. See system programming to change operation if

available.

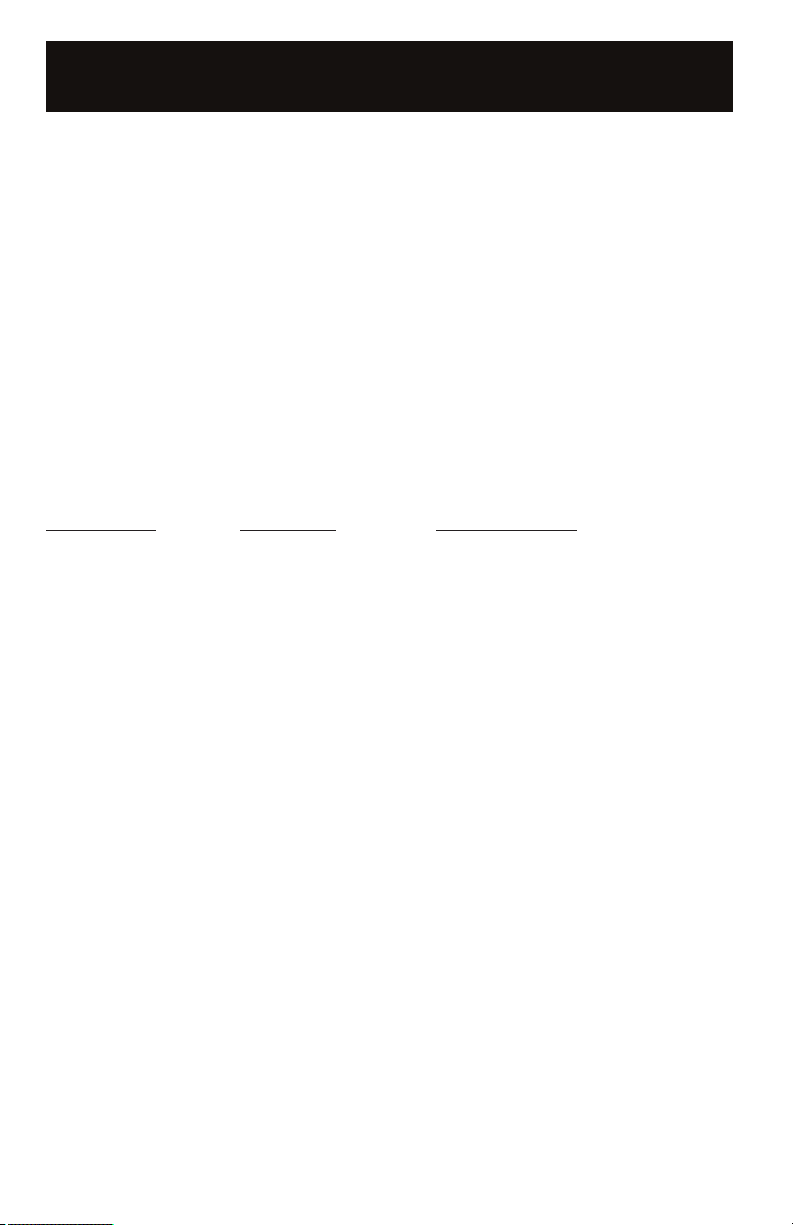

System Type Heater size Connection type

Gas heat none Single source power supply

Electrical heat 5.5kw Single source power supply

Electrical heat 5.5kw Dual source power supply

Electrical heat 11.0kw Dual source power supply

Gas/Electric Combo 5.5 or 11kw/Gas Single Source power supply

All Hydro-Quip 8000 series control systems require a 4 wire electrical supply, incorporating

a “Neutral” wire for operation. Electric heaters being powered independently in the “dual”

circuit configuration does not require a neutral wire supply. This is clearly explained in the

wiring diagrams.

For gas heaters electrical connection, consult your gas heaters supplier manual, and note

in this manual contains important wiring instructions for control and operation of the gas

heaters fireman circuit.

Gas and electric heater combination

When faster heat recovery is desired, or a redundant heat source is a priority, it’s possible

to install both a gas and electric heater on the same 8000 series system.

Default programming allows both the gas heater control circuit (page 15) and electric

heater circuit to operate simultaneously. Input from both heat sources will speed up heating

times, and also provide an operating alternate if one source becomes disabled. You must

follow all installations instructions for both the gas heater, and electric heater plumbing and

wiring requirements to successfully connect. No PCB programming change is required.