SB Wire Sawing System

SB_0107_e.mif Page 3

7DEOHRIFRQWHQWV

6DIHW\LQVWUXFWLRQV

1.1 Fundamentals 4

1.2 Inherent dangers of wire saws 6

1.3 Intended purpose 7

1.4 Before starting work 8

1.5 After work 8

7HFKQLFDOGDWD

2.1 Possible cutting capacity 9

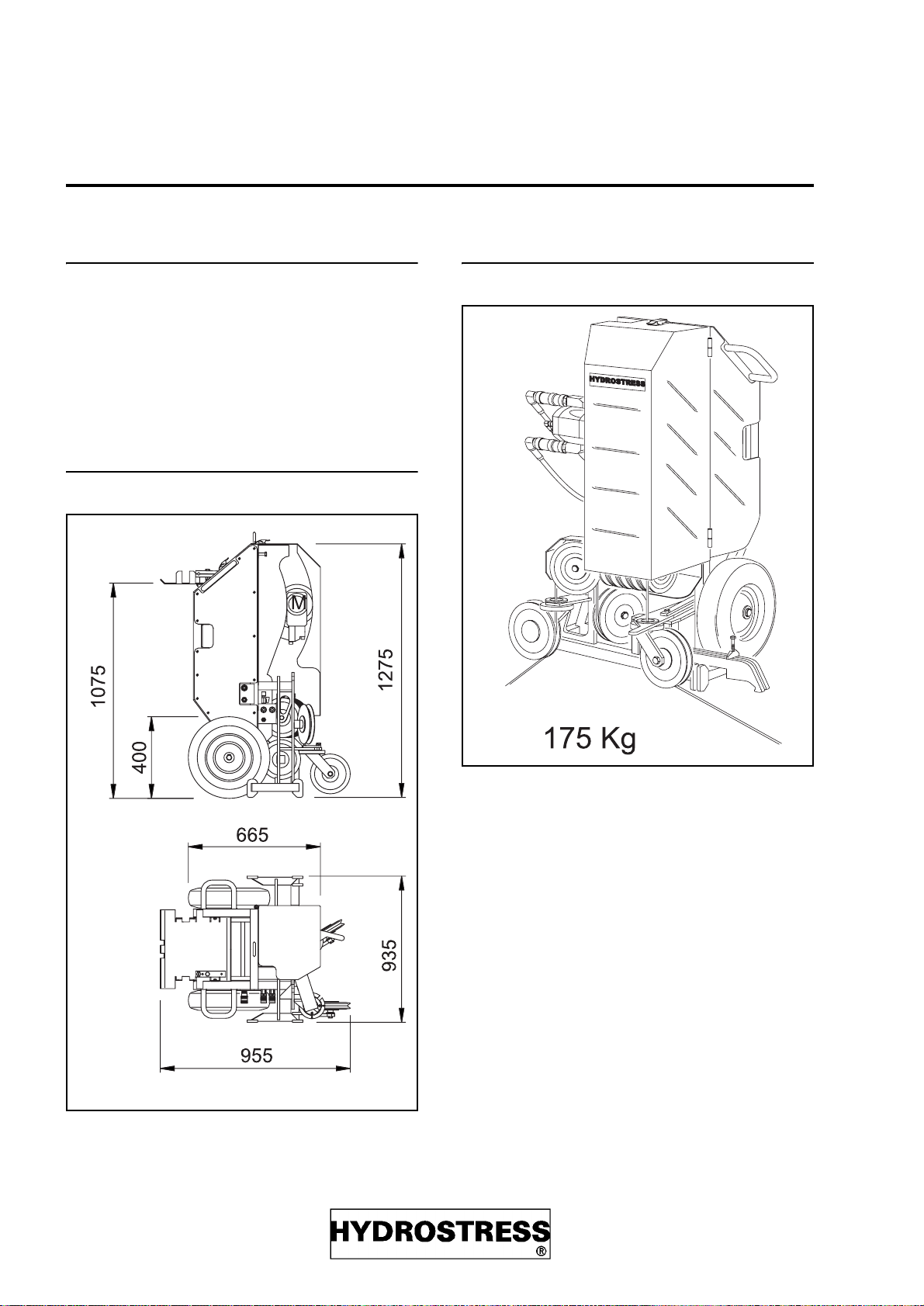

2.2 Dimensions 9

2.3 Weight 9

2.4 Wire drive 10

2.5 Connectable drives 10

2.6 Wire running direction 10

2.7 Wire cutting speed 11

2.8 Wire lengths 12

6DIHDQGHIILFLHQWRSHUDWLRQ

&RQVWUXFWLRQ

&RQWUROHOHPHQWV

:DWHU

$SSOLFDWLRQDODGYLFH

7.1 Setting up the SB 17

7.2 The correct cutting direction 18

7.3 Finish cutting 18

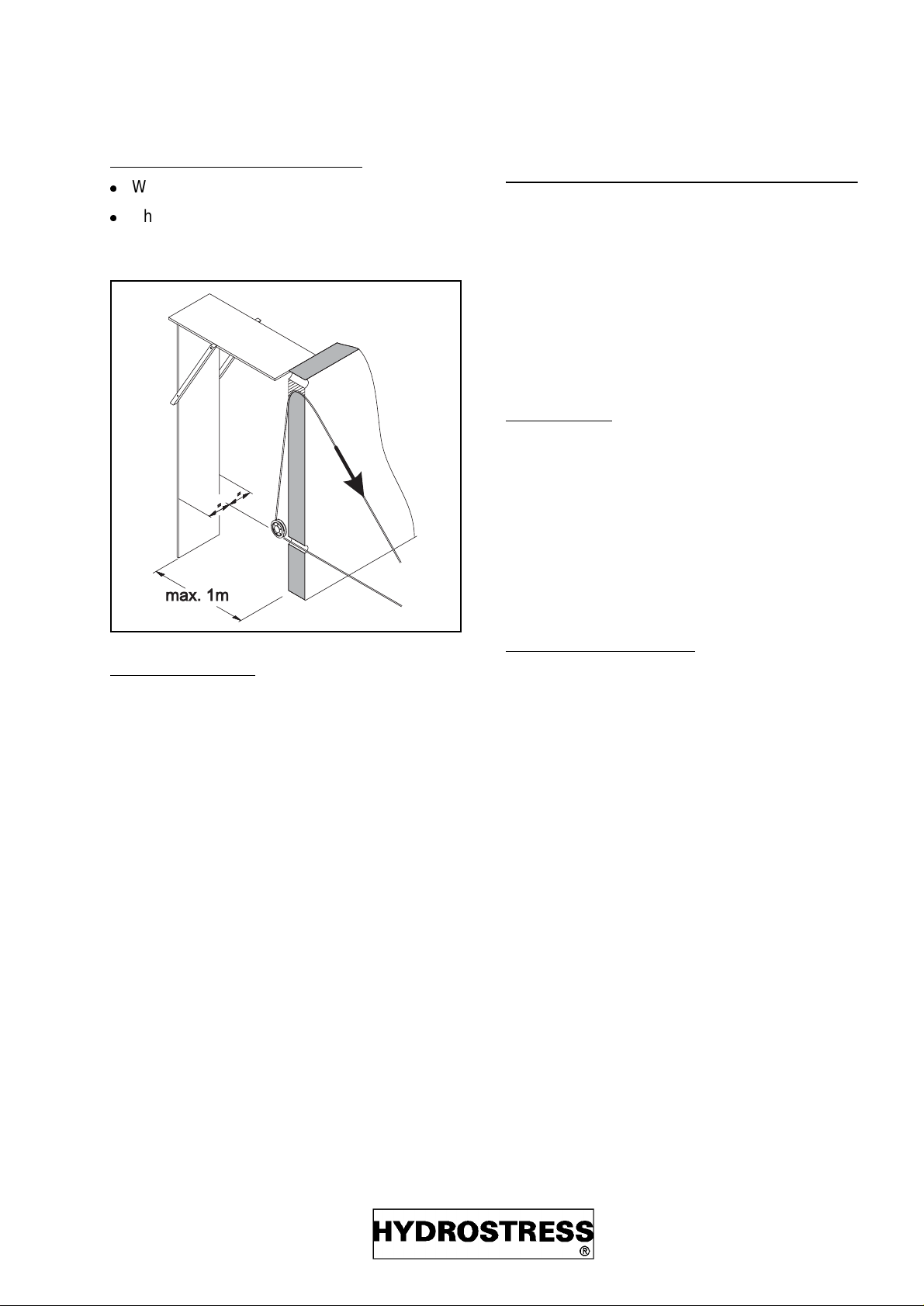

7.4 Flush cutting against a wall 19

7.5 Flush cutting against the floor 19

7.6 End of cut 19

7.7 Establish removal direction 19

7.8 Rounding off the structural body 20

7.9 The cutting sequence 20

&RQQHFWLRQRIK\GUDXOLFVDQGZDWHU

8.1 Example of CR-5 RC 21

7KHGLDPRQGZLUH

9.1 Types of diamond wire 24

9.2 Preparation of wire ends 25

9.3 Avoiding out-of-round wear 25

9.4 Connect wire 30

,QVHUWZLUH

10.1 Insert wire, general. 32

10.2 Insert wire, 1st step 33

10.3 Insert wire, 2nd step 33

10.4 Insert wire, 3rd step 33

10.5 Insert wire, 4th step 33

6WRUHZLUH

11.1 Store wire, 1st step 34

11.2 Store wire, 2nd step 34

11.3 Store wire, 3rd step 34

11.4 Store wire, 4th step 34

5XQXSZLUHVDZ

12.1 Pull wire through by hand 36

12.2 Switch on drive unit 36

12.3 Presetting the feed 36

12.4 Letting the wire run 36

12.5 Operation 37

12.6 Interruption of cut 37

12.7 End of cut 37

12.8 Terminate operation 37

5HFWLI\LQJIDXOWV

0DLQWHQDQFH

14.1 Maintenance table 41

14.2 Repairs 41

7UDQVSRUWSXWWLQJRXWRIRSHUDWLRQ

VWRUDJHDQGGLVSRVDO

15.1 Transport 42

15.2 Putting out of operation, storage 42

15.3 Disposal 42

$FFHVVRULHVVSDUHSDUWVOLVWV

16.1 Accessories delivered together

with the SB 43

16.2 Accessories which can be ordered 43

16.3 Spare parts lists, ordering details 43