5

How does the Chemical Free AIO Iron Filter

work?

This filter works by adding oxygen to the incoming wa-

ter by passing it through a bubble of compressed air.

The water is then passed through a special filter bed.

The special media not only increases the pH of the

water to enhance iron removal but also acts as a

physical barrier to trap iron precipitate.

As more water passes through this iron filter, the oxy-

gen in the unit is used up, and the media gets loaded

with iron. The regeneration process then begins in

order to replenish the supply of oxygen, and to back-

wash the precipitated iron trapped in the media bed.

The iron removal efficiency will be more effective with

high pH water.

Optional Media Beds:

• Birm - Removes iron and manganese from water.

Recommended for high pH water.

• nextSand or Multimedia- Traps precipitated iron

from the water. Recommended for high pH water.

AIO Standard Chemfree Filter

This special media not only increases the pH of the

water to enhance iron, manganese and hydrogen sul-

fide removal but also acts as a physical barrier to trap

iron precipitate.

The filter will automatically adjust the pH to neutral or

higher on acid water without an acid neutralizer. The

ability to raise pH greatly enhances the filter’s ability to

remove iron efficiently.

Replenishment of this media that raises pH will be re-

quired periodically, depending on how low the raw wa-

ter pH is the amount of manganese (Mn) present in

the water and usage rate.

AIO Birm Filter

This media acts as a catalyst for the removal of iron

and manganese from the water but require pre-

oxidation. The water is pre-oxidized from the air bub-

ble on the top of the tank and this media removes the

iron and manganese from the water. This is not rec-

ommended to remove hydrogen sulfide from the water

and requires high pH water.

The media is not sacrificial hence no replenishment is

required

IRON (Fe)

Iron concentrations as low as 0.3 ppm will

cause staining. The iron concentration, to-

gether with the flow rate demand and the

consumption rate of the water determines

the basic size filter system. The higher these

factors are, the larger the required system.

The filter system is capable of filtering out

the three main types of iron found in water

supplies: Soluble iron (also known as “clear

water” or ferrous iron), precipitated iron (also

known as “red water” or ferric iron) and bac-

terial iron (also known as iron bacteria).

There is no apparent upper limit of iron con-

centration for the filter, but special care must

be taken when selecting a filter model if your

water has a combination of high iron, very

low pH and/or manganese.

MANGANESE (Mn)

The presence of manganese can be bother-

some, even for a chemical free iron filter. As

little as 0.05 ppm of manganese can produce

a brownish or black stain. The ability of the

filter to remove manganese depends on its

concentration and the pH of the water.

Manganese tends to “coat” the filter media,

rendering it incapable of increasing the pH,

and therefore ineffective in removing either

the iron or the manganese. Manganese, how-

ever, will precipitate in the filter bed when

the pH is increased. To accomplish this a spe-

cial “MN” type media can be provided that

contains additional quantities of the pH rais-

ing component (“MN adder”). The use of

“MN” type media is for applications where

the manganese is not more than 1.5 ppm,

and the pH is at least 6.5.

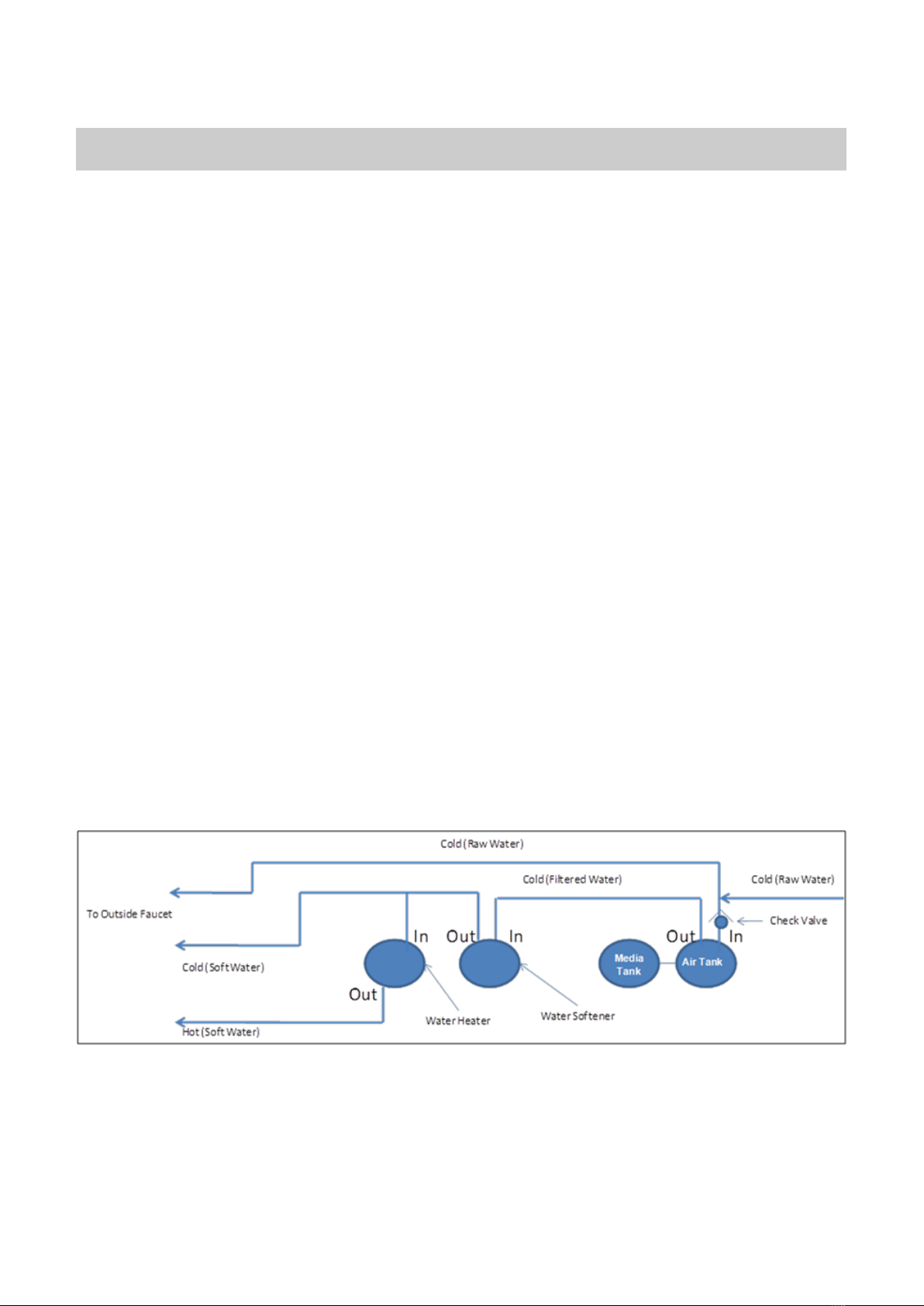

How The System Works