EN

6– English

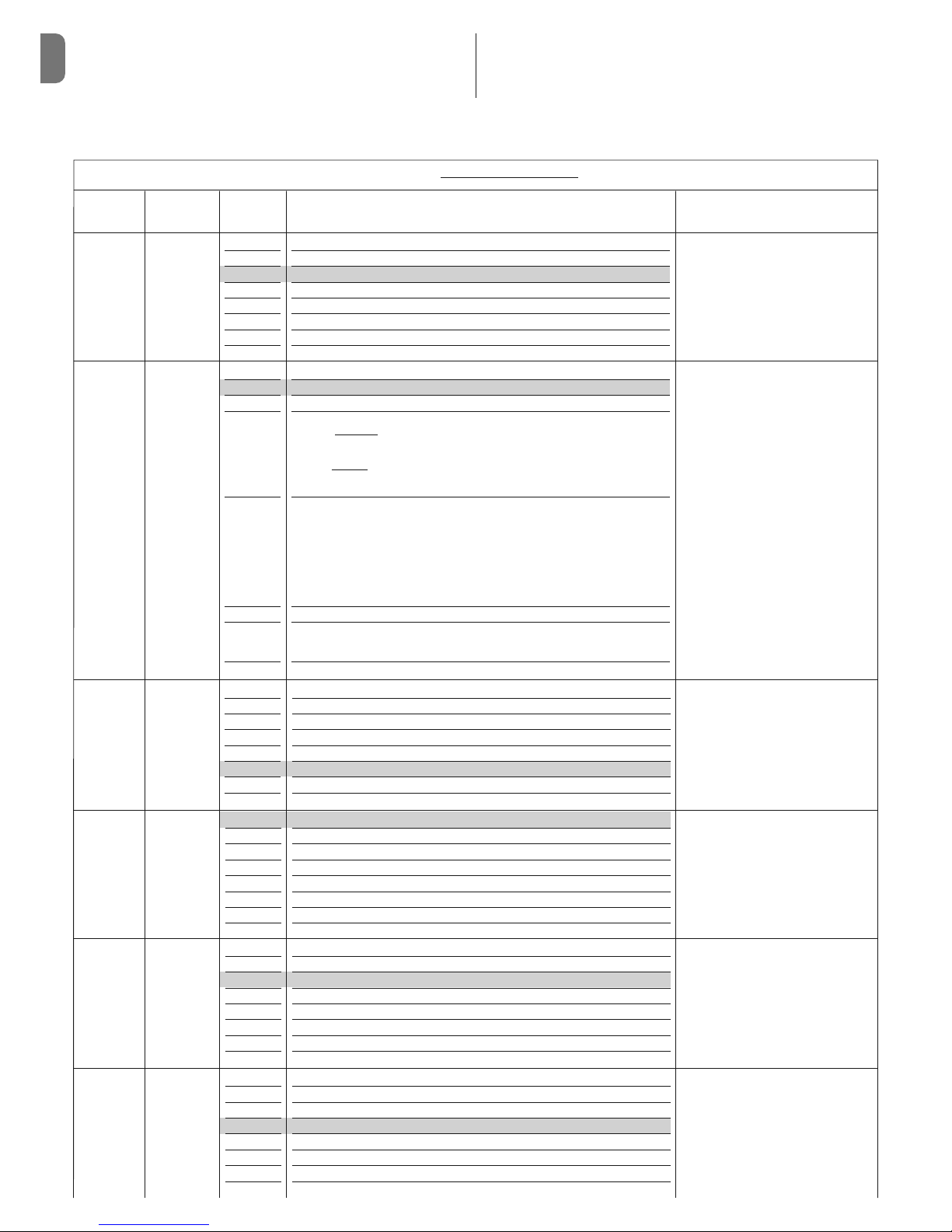

01. Press and hold keys “Set” and “” at the same time.

02. Release the keys when led “L1” starts flashing (after approx. 1 second);

Note – After 3 seconds have elapsed, if the keys “Set” and “” are not

released, the “automatic learning” procedure is started up, and not the

manual procedure.

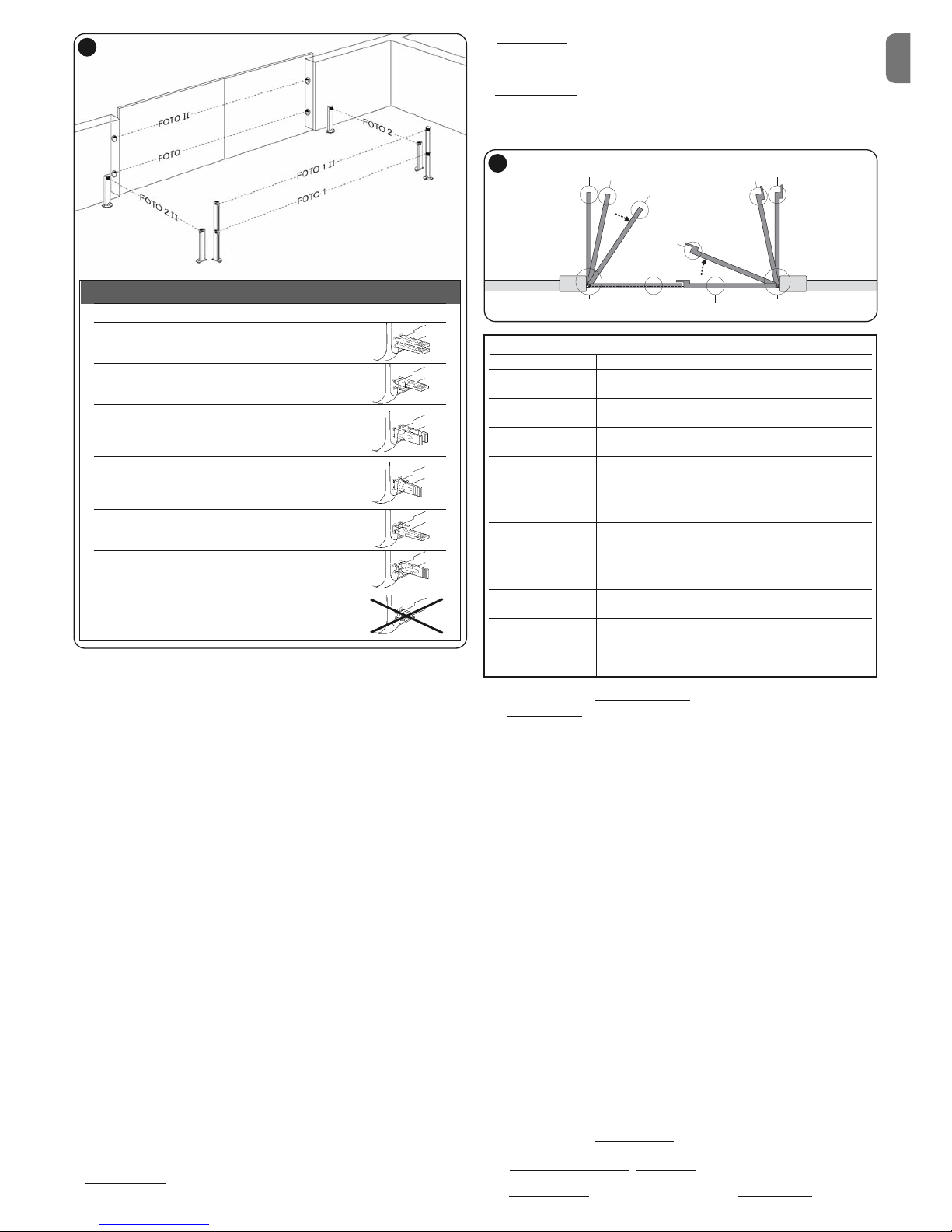

03. • LED L1 flashes: position 0 of M1

To bring motor 1 to position 0 (fig. C): press and hold down the or

keys. On reaching the position, release the key to stop the manoeuvre.

To memorise the position, press and hold down the “Set” key for at least

3 seconds and then release it (after 2 seconds LED L1 remains on and on

releasing the “Set” key LED L2 begins flashing).

• LED L2 flashes: position 0 of M2

To bring motor 2 to position 0 (fig. C): press and hold down the or

keys. On reaching the position, release the key to stop the manoeuvre.

To memorise the position, press and hold down the “Set” key for at least

3 seconds and then release it (after 2 seconds LED L2 remains on and on

releasing the “Set” key LED L3 begins flashing).

• LED L3 flashes: position SA of M2

To bring motor 2 to position SA (fig. C): press and hold down the or

keys. On reaching the position, release the key to stop the manoeuvre.

To memorise the position, press and hold down the “Set” key for at least

3 seconds and then release it (after 2 seconds LED L3 remains on and on

releasing the “Set” key LED L4 begins flashing).

• LED L4 flashes: position A of M1

To bring motor 1 to position A (fig. C): press and hold down the or

keys. On reaching the position, release the key to stop the manoeuvre.

To memorise the position, press and hold down the “Set” key for at least

3 seconds and then release it (after 2 seconds LED L4 remains on and on

releasing the “Set” key LED L5 begins flashing).

• LED L5 flashes: position A of M2

To bring motor 2 to position A (fig. C): press and hold down the or

keys. On reaching the position, release the key to stop the manoeuvre.

To memorise the position, press and hold down the “Set” key for at least

3 seconds and then release it (after 2 seconds LED L5 remains on and on

releasing the “Set” key LED L6 begins flashing).

• LED L6 flashes: position SC of M1

To bring motor 1 to position SA (fig. C): press and hold down the or

keys. On reaching the position, release the key to stop the manoeuvre.

To memorise the position, press and hold down the “Set” key for at least

3 seconds and then release it (after 2 seconds LED L6 remains on and on

releasing the “Set” key LED L7 begins flashing).

• LED L7 flashes: position 1 of M1

To bring motor 1 to position 1 (fig. C): press and hold down the or

keys. On reaching the position, release the key to stop the manoeuvre.

To memorise the position, press and hold down the “Set” key for at least

3 seconds and then release it (after 2 seconds LED L7 remains on and on

releasing the “Set” key LED L8 begins flashing).

• LED L8 flashes: position 1 of M2

To bring motor 2 to position 1 (fig. C): press and hold down the or

keys. On reaching the position, release the key to stop the manoeuvre.

To memorise the position, press and hold down the “Set” key for at least

3 seconds and then release it to exit programming (after 2 seconds LED

L8 remains on until the “Set” key is released).

Note – To perform manual programming in a system with a single gear-

motor, proceed as described in paragraph 4.7.2 and at step 03 program posi-

tions “0” and then “1” of M1, ignoring the part related to keys “” and “”, and

using the “Set” key only, as described. Important! – In the manual proce-

dure, positions “SA” of M2; “A” of M1; “SC” of M1 must not be pro-

grammed.

4.7.3 - Learning in combined mode

Perform this procedure after completing the automatic learning cycle:

01. Press and hold keys “Set” and “” at the same time.

02. Release the keys when led “L1” starts flashing (after approx. 1 second);

Note – After 3 seconds have elapsed, if the keys “Set” and “” are not

released, the “automatic learning” procedure is started up, and not the

manual procedure.

03. Briefly press key “” or “” to move the flashing led (L1-L8) to the position

to be programmed and proceed for each position, as described in step 03

of the manual learning procedure (paragraph 4.7.2).

Repeat this operation for all other positions to be modified.

To complete the manual learning process, press key “” repeatedly to move

the led that flashing beyond position L8.

4.8 - Checking movement of gate leafs

At the end of the learning procedure, it is advisable to make the control unit per-

form a few opening and closing manoeuvres to ensure that the gate moves cor-

rectly and to check for installation or setting defects.

01. Press the “Open” key. Check for the correct leaf opening offset and check

that the opening manoeuvre includes the acceleration, constant speed

and deceleration phases and that the leaf limit switch is set a few centime-

tres from the opening mechanical stops.

02. Press the “Close” key and check that the closure manoeuvre includes the

acceleration, constant speed and deceleration phases. Check that the leaf

closure offset is correct. At the end of the manoeuvre, the leafs must be

perfectly closed on the mechanical closure stop.

These are the most important phases in the installation of the automation sys-

tem, in order to guarantee maximum system safety. Testing can also be used to

check the devices in the automation system regularly. The automation system

testing and commissioning phases must be carried out by qualified experts

who must be responsible for determining the tests necessary to check the

solutions adopted vis-à-vis the risks involved, and to check the observance of

all legal and regulatory obligations: in particular all the requirements of the EN

12445 standard which sets forth the test methods for checking automated

gates.

Additional devices must undergo specific testing, both in terms of functionality

as well as their correct interaction with HYKE; please refer to the relevant indi-

vidual instruction manuals.

5.1 - Testing

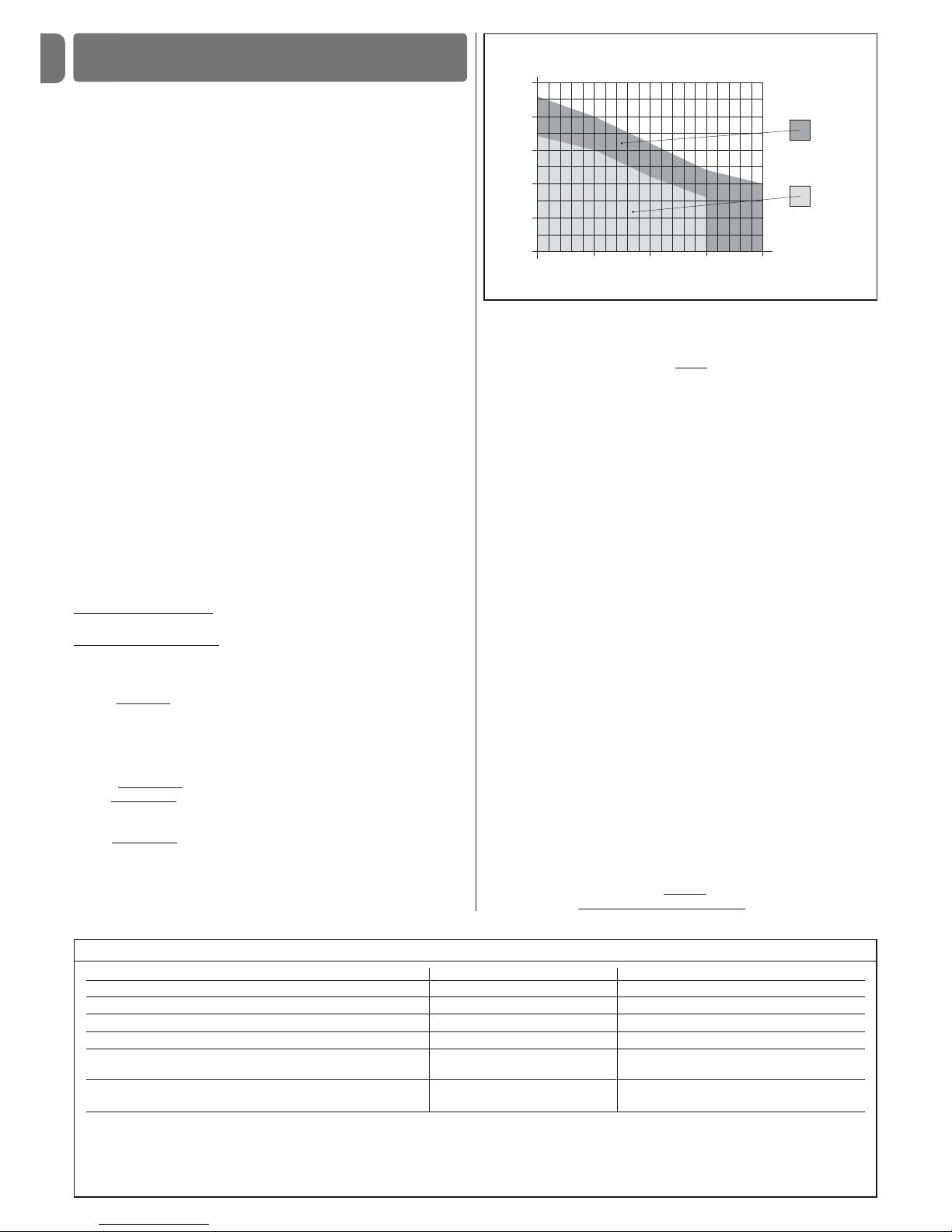

The sequence of steps to take to carry out testing refers to a typical system (fig. 3):

1Ensure that everything stated in the “Installation warnings” chapter has

been observed.

2Release the gearmotors manually and check that when you operate the

leaf, at the point designed especially for the manual manoeuvre, the leaves

can either be opened or closed with a force of less than 390 N.

3Secure the gearmotors (see chapter 3.6).

4Using the control devices (transmitter, command button, key selector, etc.),

perform some Gate Opening, Closing and Stop tests, making sure the

movement of the leaves corresponds with each test. It is a good idea to car-

ry out several tests in order to evaluate the movement of the leaves and pin-

point any assembly or adjustment defects as well as to check for any par-

ticular points of friction.

5Check one by one that all the safety devices in the system work properly

(photocells, sensitive edges, etc.). When a device is activated, the “BLUE-

BUS” LED on the control unit emits two quicker flashes to confirm that

recognition has taken place.

6If the hazardous situations caused by the movement of the leaves have

been safeguarded by limiting the force of impact, the force must be meas-

ured in accordance with the EN 12445 standard and, if necessary, if the

control of the “gearmotor force” is used as an aid to the system to reduce

the force of impact, try and then find the adjustment that achieves the best

results.

5.2 - Commissioning

Commissioning can only take place once all the testing phases have been

carried out successfully.

1Put together the automation system’s technical file, which should include

the following documents: an overall diagram of the automation system, the

diagram of the electrical connections made, the current risk analysis and

the related solutions adopted, the manufacturer’s declaration of conformity

for all the devices used and the declaration of conformity filled in by the in-

staller.

2Affix a data plate onto the gate which specifies the following information, at

least: the type of automation system, the name and address of the manu-

facturer (responsible for the commissioning), the serial number, the year of

manufacture and the EC mark.

3Fill in the declaration of conformity of the automation system and hand it

over to its owner.

4Fill in and hand over to the owner of the automation system the “User’s

guide” of the automation system.

5Fill in and hand over to the owner of the automation system the “Mainte-

nance schedule” which contains instructions on the maintenance of all the

devices in the automation system.

6Before commissioning the automation system, inform the owner of all the

hazards and residual risks entailed.

For all the documentation mentioned, the Nice technical support service

provides the following: instruction manuals, guides and precompiled forms.

Also visit: www.nice-service.com

TESTING AND COMMISSIONING

5

03. Make sure that the flashing light flashes at intervals of 0.5 sec on, 0.5 sec

off during manoeuvres.