Hylio Agrodrone (AG-122) Maintenance Manual

©2020 Hylio Inc. All Rights Reserved 8

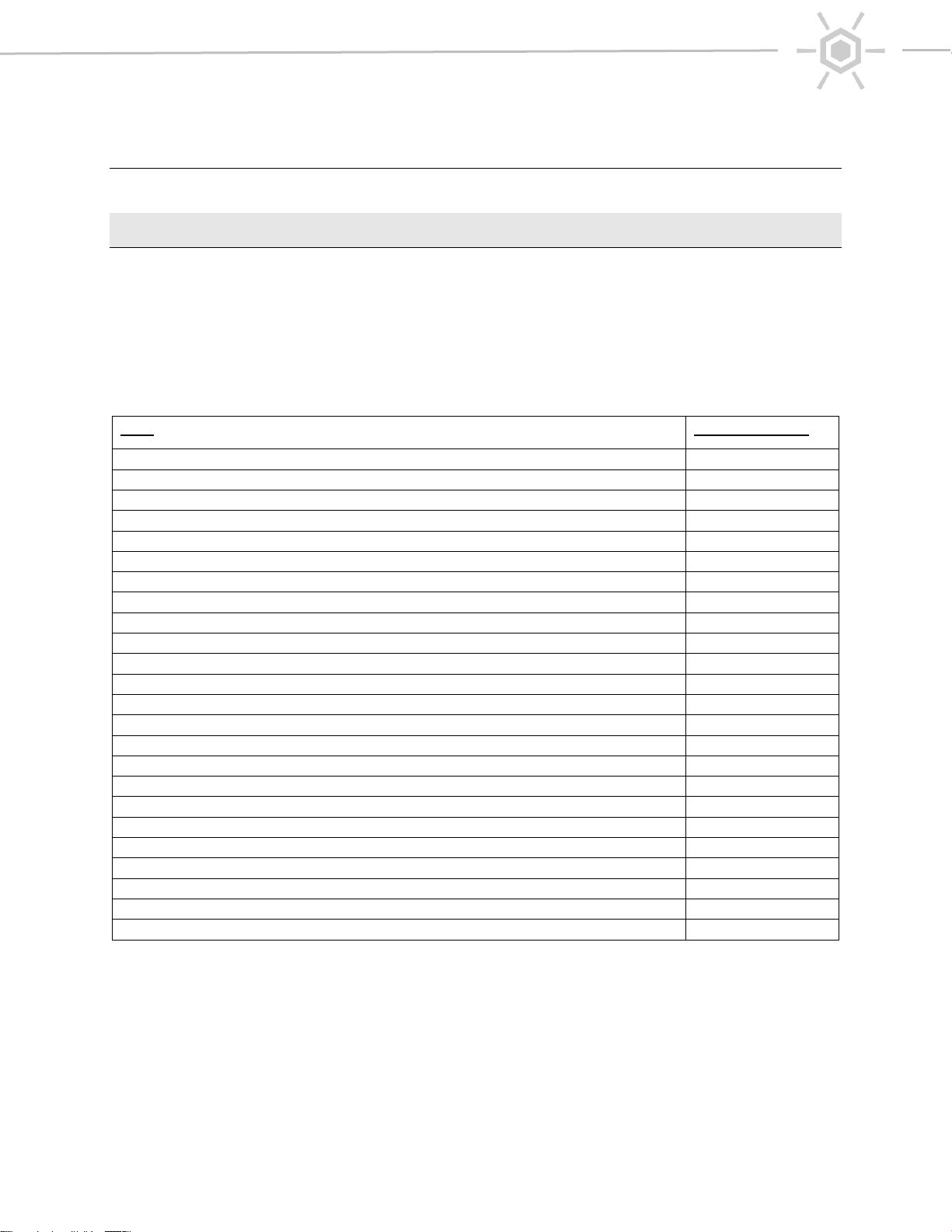

Inspection Criteria

If the part does NOT pass the listed criteria upon inspection, replace/repair part immediately. As

a part of the inspection for each part, check for tightness of all fasteners listed for that part in the

component identification description. Check for tightness to the listed torque.

- No cracks or chips larger than 0.1-inch radius

- Propeller blade level with arm

- M3x12 mount screws tight and rust free

- 10 mm lug bolts tight and rust free

- No rattling or scratching noise when spun by hand

- No large dents or cracks in rotor housing

- LED mount screws tight

- Rotor guard mount screws tight

Ground Station Link

Radio Antenna

- Antenna casing structurally intact

- Antenna screwed in tight to antenna mount

(comes loose often)

- Antenna mount screws tight and rust free

- Correct LED indicator colors when powered on

- GPS secured straight and tight to mast (Double sided tape OK)

- GPS housing and wire not damaged

(check closely at mount points and where wire enters frame)

- Acceptable GPS accuracy performance

- GPS does not frequently give errors in AgroSol

- No cracks in material

- All screws tight and rust free

- Radar housing intact

- Radar wire not damaged

(check closely at mount points and where wire enters frame)

- Unit does not heat up when powered on

- Acceptable altitude readouts in AgroSol

- Flowmeter housing intact

- Acceptable flowrate readouts in AgroSol

- Flowmeter wire not damaged

(check closely at mount points and where wire enters frame)

- Flowrate performance during flight (gal/ac output) should be

within 2%, or 5% in the worst case

- Set a constant test flowrate and measure output over 1 minute

using a graduated cylinder, actual flowrate should match desired

- If flowrate is not to desired accuracy, perform the flowmeter

calibration as described in the software manual

- Pump housing intact

- Acceptable maximum pump pressure performance

(maximum pressure output will decline over time)