Hypersen Technologies Co., Ltd. HPS-FT-USER V1.8

3/38

Table of Contents

1 Product introduction ........................................................................................................................................5

1.1 Sensor introduction ..................................................................................................................................5

1.1.1 Introduction ........................................................................................................................................5

1.1.2 Product features ................................................................................................................................5

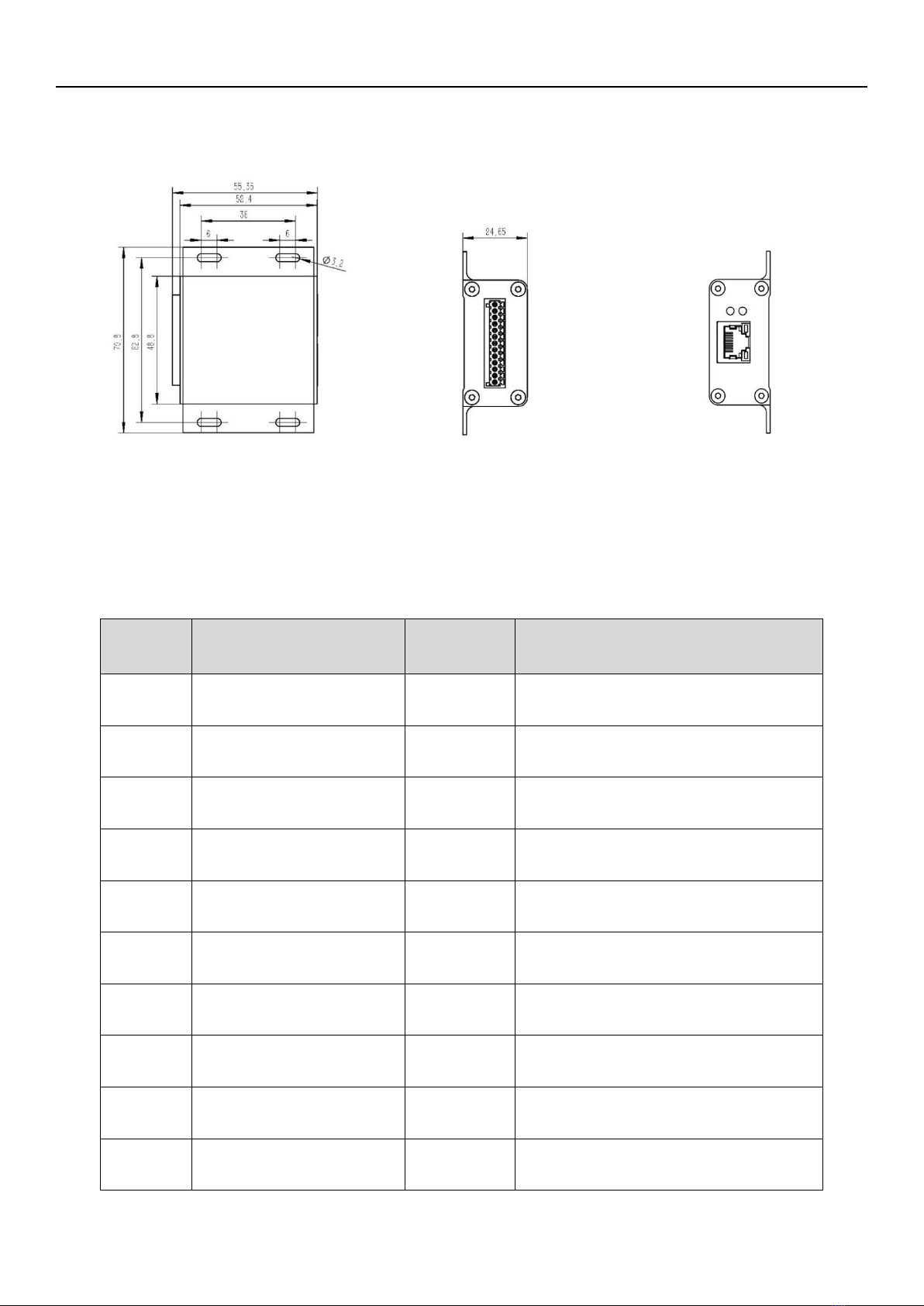

1.1.3 Physical dimensions ..........................................................................................................................6

1.1.4 Cable definition ................................................................................................................................. 8

1.1.5 Packaging information ...................................................................................................................... 8

1.2.1 Product description ........................................................................................................................... 8

1.2.2 Physical dimensions ..........................................................................................................................9

1.2.3 Wiring and indicator light definition ...................................................................................................9

1.2.4 IO protection alarm function ............................................................................................................10

1.2.5 Ethernet bus communication port ...................................................................................................10

2 Precautions for use .......................................................................................................................................11

2.1 Sensor overload protection ....................................................................................................................11

2.1.1 Calculation of the total torque during use .......................................................................................11

2.1.2 Robot emergency stop IO control ...................................................................................................12

2.1.3 Setting of the overload protection threshold ...................................................................................12

2.2 Sensor and robotic arm connection .......................................................................................................13

3 Warranty ....................................................................................................................................................... 13

3.1 Product warranty ....................................................................................................................................13

3.2 Disclaimer .............................................................................................................................................. 14

4 Installation .....................................................................................................................................................14

4.1 Tools and accessories ...........................................................................................................................14

4.2 Mechanical structure installation ........................................................................................................... 15

4.3 Electrical cable installation .................................................................................................................... 17

4.4 IO protection wiring ................................................................................................................................18

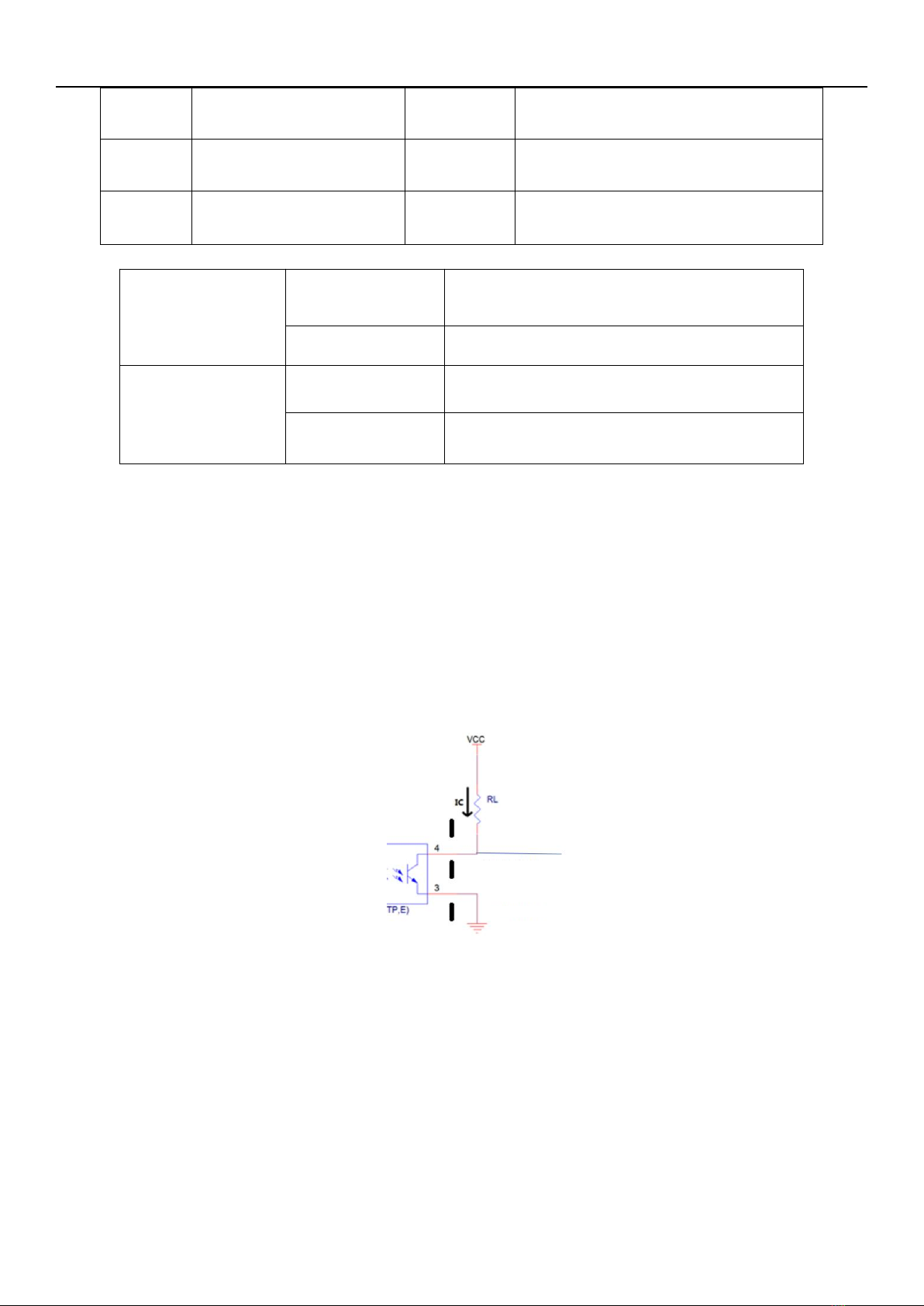

4.4.1 Robot emergency stop IO wiring (NPN, no-load IO)......................................................................19

4.4.2 Robot protective stop wiring (NPN, no-load IO) ............................................................................. 19

4.4.3 Setting and enabling of the protection mode of the robot .............................................................. 20

5 Host demonstration software ....................................................................................................................... 21

5.1 Ethernet-based host demonstration software ....................................................................................... 21