Walkie Hydraulic Systems Table of Contents

TABLE OF CONTENTS

General ............................................................................................................................................................... 1

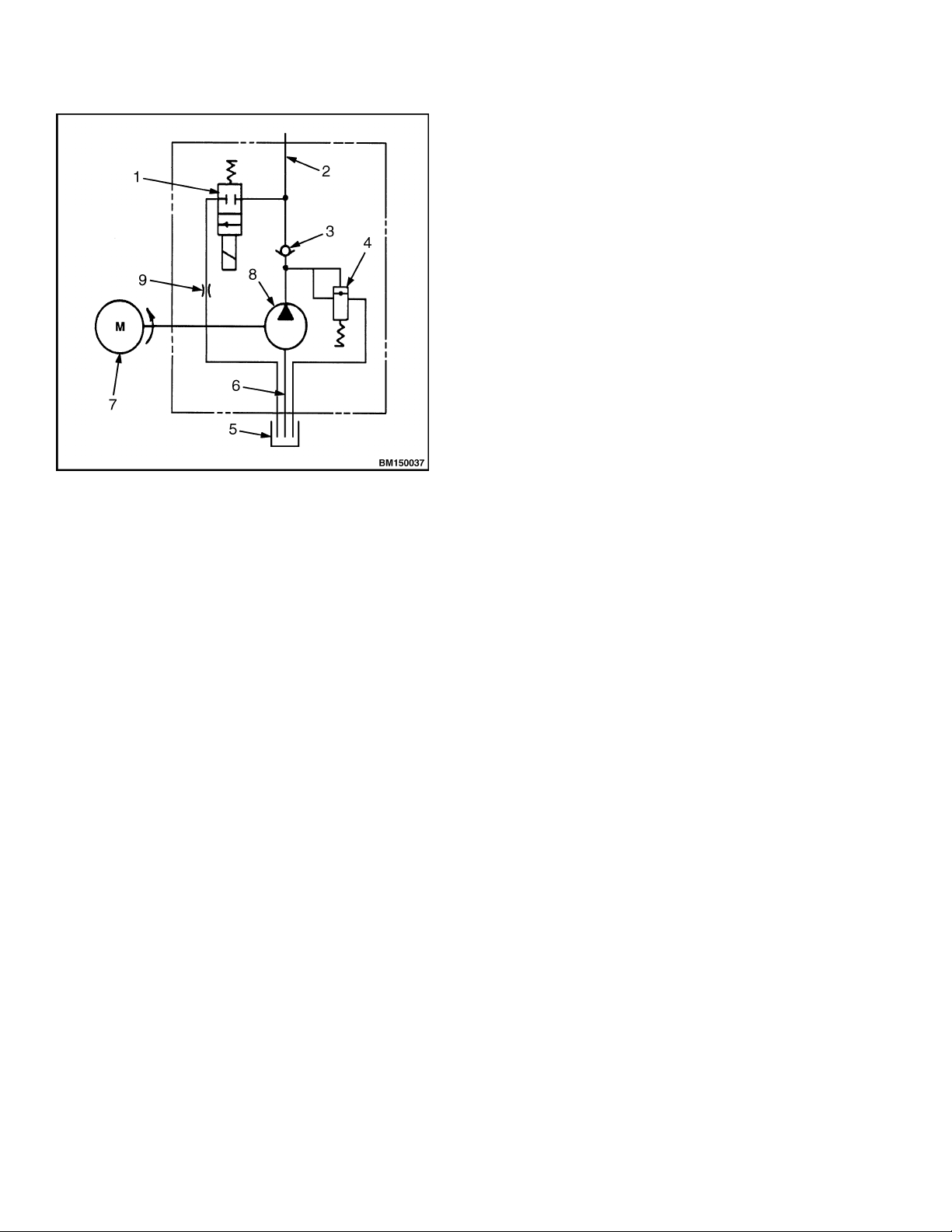

Description of Operation.................................................................................................................................... 1

Lifting a Load................................................................................................................................................. 2

Lowering a Load ............................................................................................................................................ 2

Hydraulic Lines ............................................................................................................................................. 2

Hydraulic Oil ................................................................................................................................................. 2

Clean .............................................................................................................................................................. 5

Sound Level.................................................................................................................................................... 5

Special Precautions............................................................................................................................................ 5

Hydraulic Reservoir........................................................................................................................................... 7

Description ..................................................................................................................................................... 7

Drive Unit Compartment Covers...................................................................................................................... 7

C60Z, C80Z, C60ZAC,andC80Z

AC ................................................................................................................ 7

Remove....................................................................................................................................................... 7

Install......................................................................................................................................................... 7

B60Z, B80Z, B60ZAC,B80Z

AC, W60Z, W65Z, and W80Z............................................................................. 8

Remove....................................................................................................................................................... 8

Install......................................................................................................................................................... 9

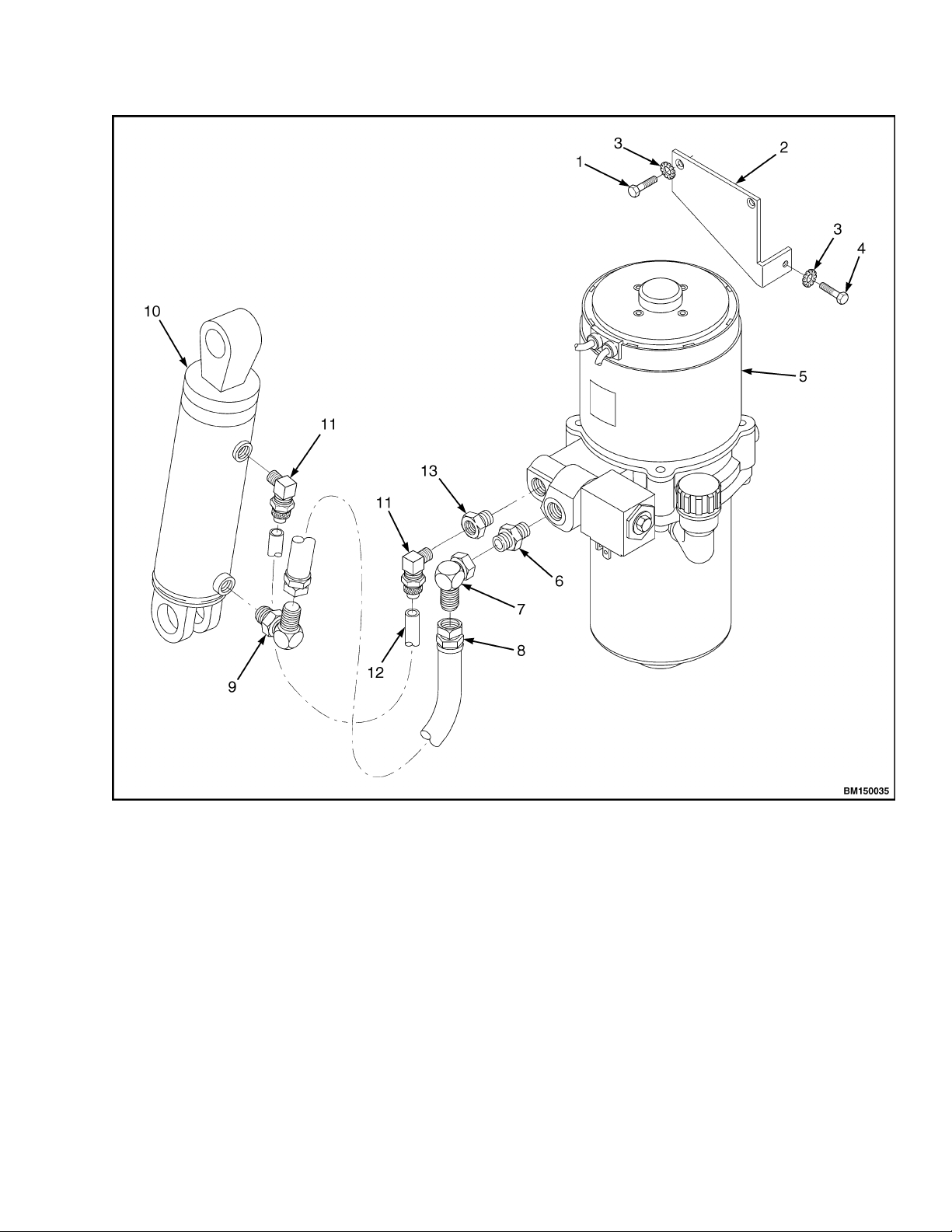

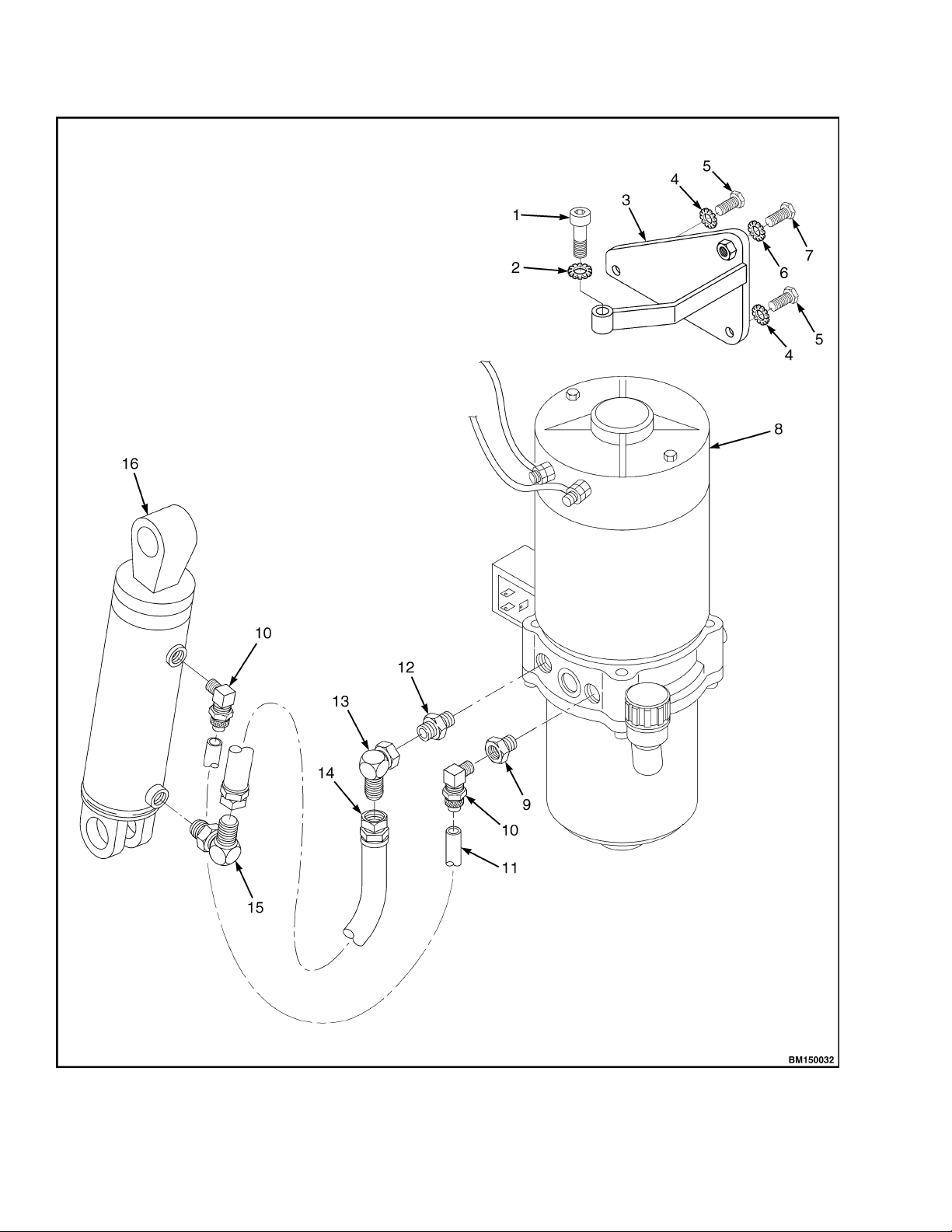

Lift Pump and Motor ......................................................................................................................................... 10

General........................................................................................................................................................... 10

Remove ........................................................................................................................................................... 10

Lift Pump and Motor Assembly................................................................................................................ 10

Disassemble ................................................................................................................................................... 11

Remove Reservoir...................................................................................................................................... 11

Remove Pump Motor................................................................................................................................. 13

B60Z, B60ZAC,C60Z,C60Z

AC, and W60Z............................................................................................ 13

B80Z, B80ZAC,C80Z,C80Z

AC, W65Z, and W80Z................................................................................ 13

Disassemble Pump .................................................................................................................................... 13

B60Z, B60ZAC,C60Z,C60Z

AC, and W60Z............................................................................................ 13

B80Z, B80ZAC,C80Z,C80Z

AC, W65Z, and W80Z................................................................................ 13

Assemble ........................................................................................................................................................ 15

Assemble Pump ......................................................................................................................................... 15

B60Z, B60ZAC,C60Z,C60Z

AC, and W60Z............................................................................................ 15

B80Z, B80ZAC,C80Z,C80Z

AC, W65Z, and W80Z................................................................................ 15

Install Pump Motor................................................................................................................................... 15

Install Reservoir to Pump......................................................................................................................... 16

Install ............................................................................................................................................................. 16

Lift Pump and Motor Assembly................................................................................................................ 16

Valve Repair ....................................................................................................................................................... 17

Lowering Valve .............................................................................................................................................. 17

Remove....................................................................................................................................................... 17

Install......................................................................................................................................................... 17

Relief Valve .................................................................................................................................................... 18

B60Z, B60ZAC,C60Z,C60Z

AC, and W60Z ................................................................................................ 18

Remove .................................................................................................................................................. 18

Install..................................................................................................................................................... 18

B80Z, B80ZAC,C80Z,C80Z

AC, W65Z, and W80Z .................................................................................... 19

Remove .................................................................................................................................................. 19

Install..................................................................................................................................................... 19

Check Valve.................................................................................................................................................... 19

B80Z, B80ZAC,C80Z,C80Z

AC, W65Z, and W80Z .................................................................................... 19

©2008 HYSTER COMPANY i