PAGE NUMBER

ABOUT THIS MANUAL ………………………………………………………………….....….

SAFETY PRECAUTIONS ……………………………………………………………………..

ENGINE BREAK-IN …………………………………………………………………………….

3

4

5

CHAPTER 1 ENGINE OVERVIEW ………………………………………………………………

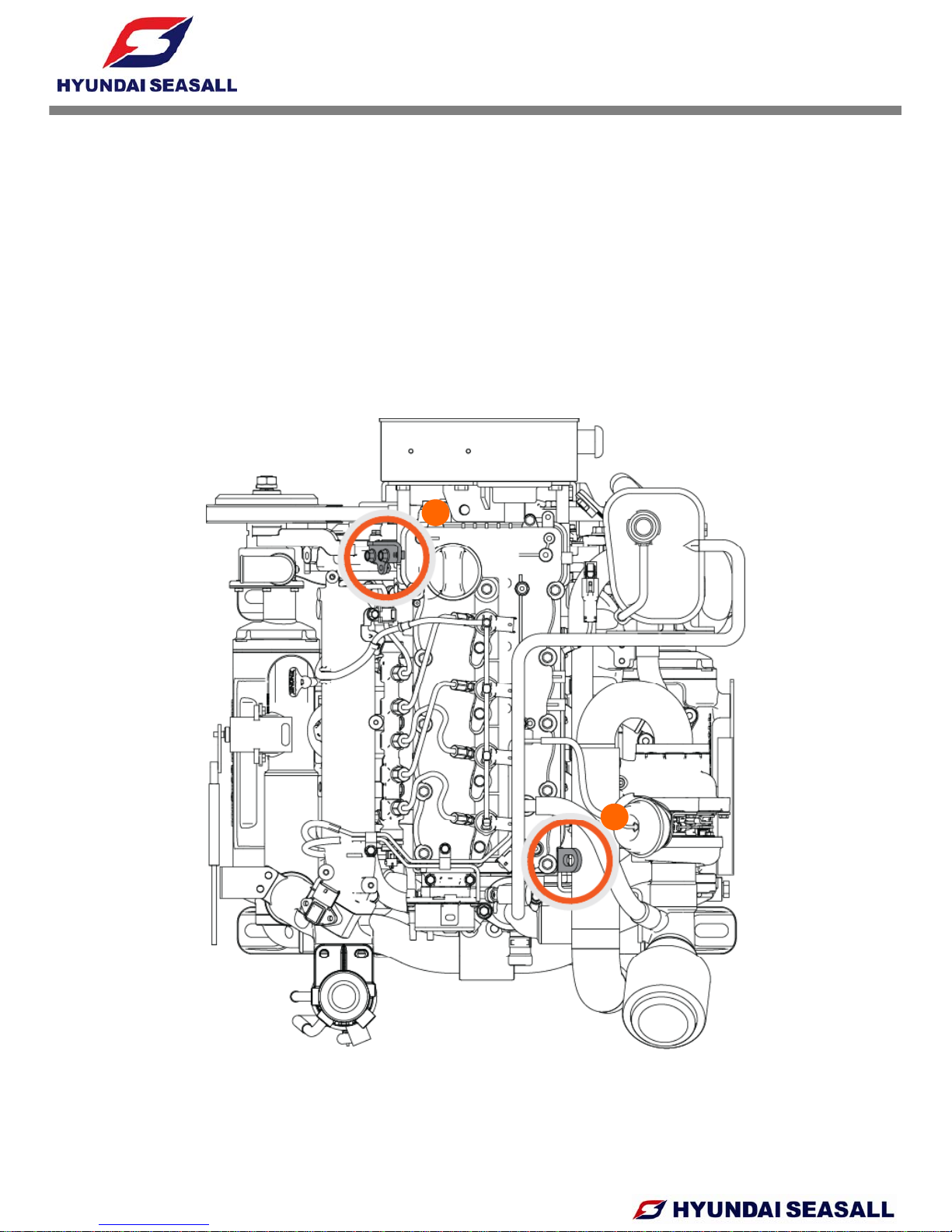

ENGINE COMPONENTS …………………………………………………….……

ENGINE SUSPENSION EYES …………………………………………………..

ENGINE IDENTIFICATION ……………………………………………………….

TECHNICAL DATA ……………………………………………...……………

PERFORMANCE CURVES …………………………………………………

6

6

7

8

9

10

ENGINE DIMENSIONS …………………………………………………...…

CHAPTER 2 ENGINE MOUNT SYSTEM .………………………………………………..

ENGINE MOUNTING REQUIREMENTS ………………………………….

MOUNT DIMENSIONS ………………………………………………………

ENGINE MOUNT TOOL FOR STERNDRIVE MODEL …………………..

12

15

15

15

16

CHAPTER 3 ENGINE OPERATION …………………………………………..…………….

STARTING ENGINE…………………………………………………..………

STOPPING ENGINE…………………………………………………..………

EMERGENCY STOP …………………..…………………………….……….

WINTER OPERATION AND STORAGE ……………………….…………..

17

17

17

18

18

CHAPTER 4 COOLING & EXHAUST SYSTEM ………………………………………….

SCHEMATIC DIAGRAM OF ENGINE COOLING CIRCUIT ……..….......

SEAWATER FLOW.…………………………………………………………...

ENGINE COOLANT FLOW…………………………………………..………

19

19

20

23

CHAPTER 5 FUEL SYSTEM ………………………………………………………………..

SCHEMATIC DIAGRAM OF COMMON RAIL DIESEL ENGINE………….

FUEL FLOW.….……..…………………………..……………………………..

LOW PRESSURE FUEL LINE …………………....………………………….

ACCELERATION SENSOR AND CONTROL LEVER …………………….

RECOMMENDED FUEL QUALITY ………………....………………………

26

27

28

28

29

30

DRAINING WATER FROM FUEL FILTER …………………………………

CHAPTER 6 AIR INTAKE SYSTEM ………………………………………………………..

ENGINE ROOM VENTILATION ……………………………………………...

CHECK AIR FILTER ……………………………………..……………….…..

CLEANING AIR FILTER ……………………………………..…………….…

30

31

31

32

32

-1-