5

•DON'T FORCE TOOL

•NEVER LEAVE TOOL RUNNING UNATTENDED

•DISCONNECT POWER

•PROTECT THE ENVIRONMENT

•MAINTAIN YOUR LOG SPLITTER WITH CARE

•MAKE THE WORKSHOP CHILDPROOF

•RECYCLING AND DISPOSAL

It will do a better and safer job at its design rate. Never try to split

logs larger than those indicated in the specifications table. This

could be dangerous and may damage the machine.

Don't use log splitter for a purpose for which it was not intended.

Don't leave tool until it has come to a complete stop.

Unplug when not in use, before making adjustments, changing

parts, cleaning, or working on the log splitter; Consult technical

manual before servicing.

Take used oil to an authorized collection point or follow the

stipulations in the country where the log splitter is used.

Do not discharge into drains, soil or water.

Keep the log splitter clean for best and safest performance.

Lock the shop. Disconnect master switches. Store the log splitter

This marking indicates that this product should not be disposed

with other household wastes. To prevent possible harm to the

environment or human health from uncontrolled waste disposal,

recycle it responsibly to promote the sustainable reuse of material

resources. To return your used device, please use the return

and collection systems or check with your local authority or local

stores for advice of environmental safe recycling.

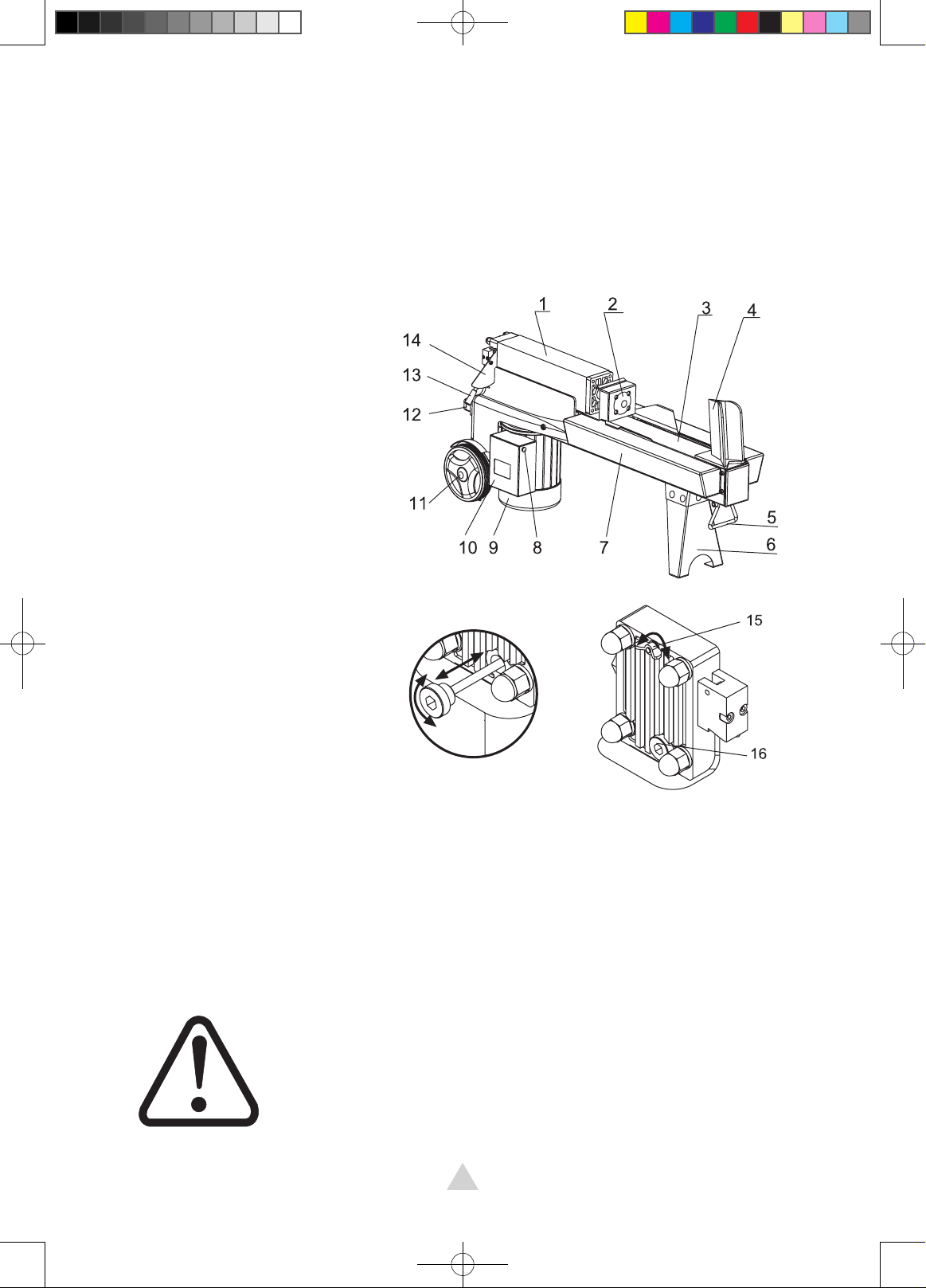

TABLE OF CONTENTS

Safety Warnings & Cautions...................................................................................................3

Application Conditions............................................................................................................6

Electrical Requirements..........................................................................................................7

Contents of Shipping Container..............................................................................................7

Set up and Preparation for Operation.....................................................................................8

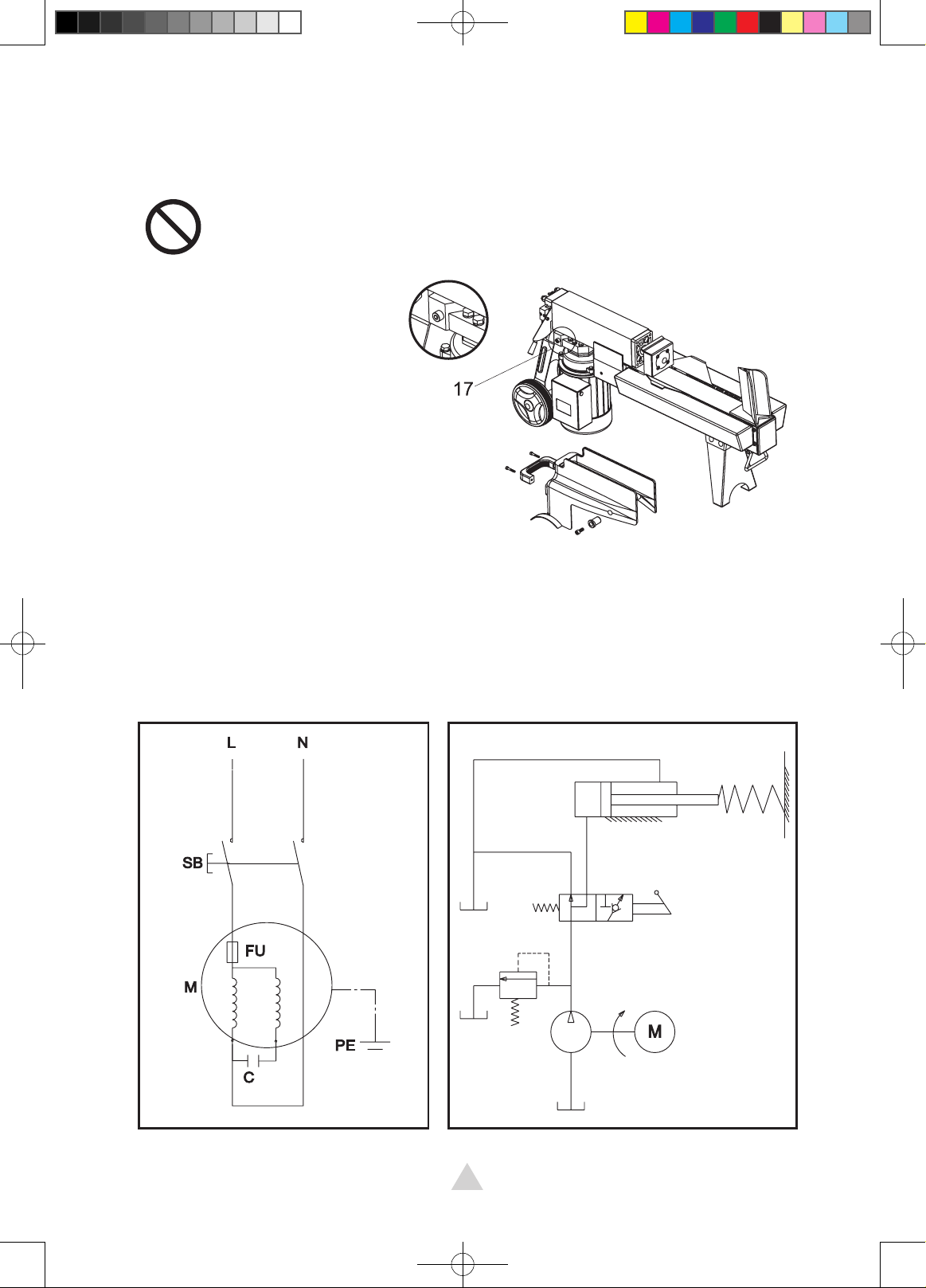

Wiring Diagram.......................................................................................................................9

Plumbing Diagram..................................................................................................................9

Log Splitter Operation...........................................................................................................10

Freeing a Jammed Log........................................................................................................11

Replacing Hydraulic Oil........................................................................................................12

Sharpening Wedge...............................................................................................................12

Trouble Shooting...................................................................................................................13

Parts Schematic....................................................................................................................14

65563UK00M100.indd 5 2019/8/30 11:38:43