Hyundai

06 tig-160/200

The machine is equipped with power voltage compensation equipment. When power voltage moves between ±

15% of rated voltage, it still can work normally.

When using long cable, in order to prevent voltage from going down, bigger section cable is suggested. If cable

is too long, it may affect the performance of the power system. So we suggest you to use configured length.

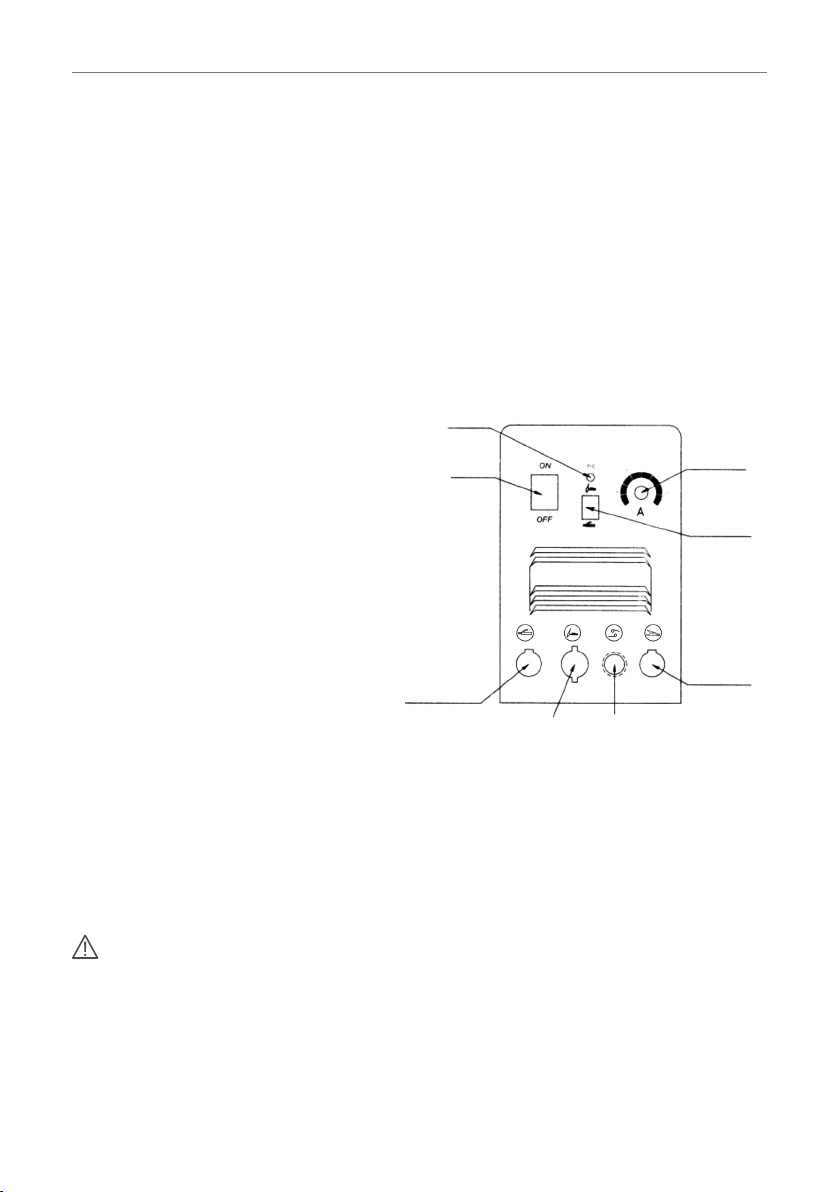

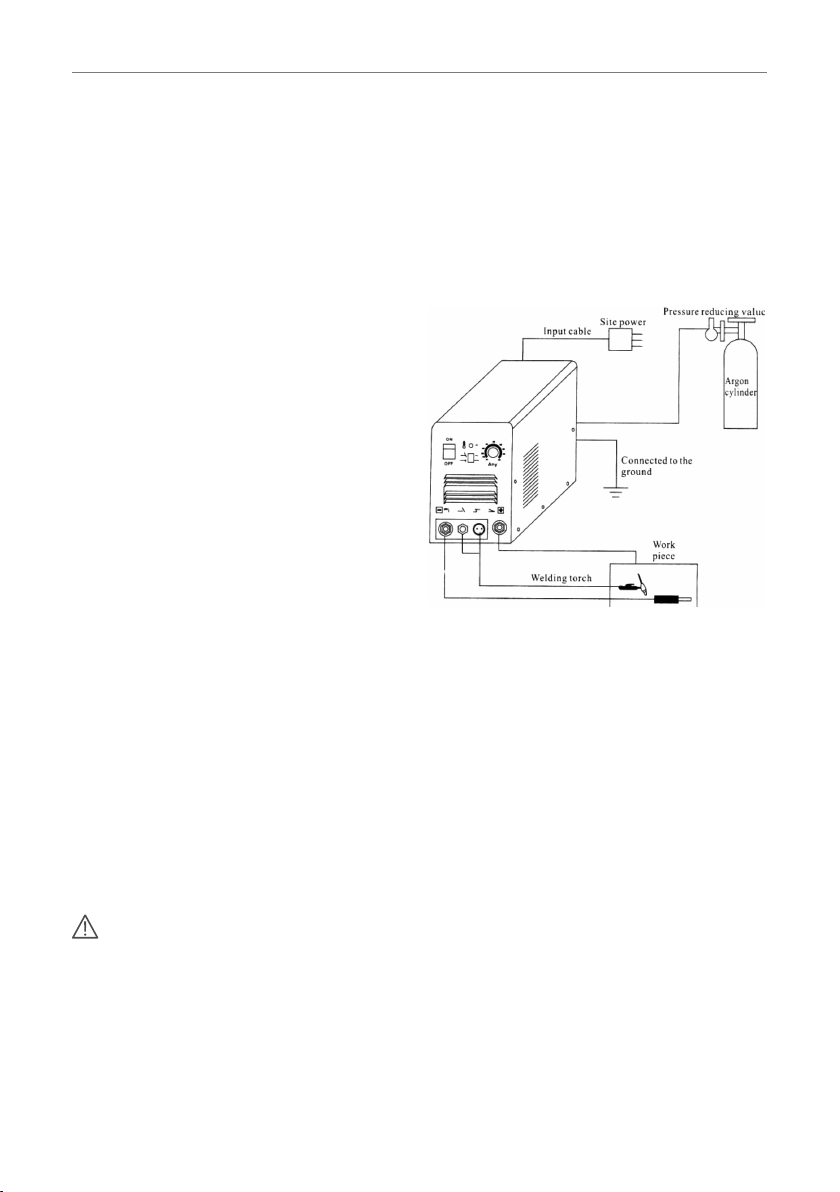

1) Make sure intake of the machine not blocked or

covered, lest cooling system could not work.

2) Make good connection of shielded gas source. Gas

supply passage includes cylinder, argon decompress

flow meter and pipe. Connecting part of pipe should

use hoop or other things to fasten, lest argon leaks

out and air gets in.

3) Use inducting cable whose section is not less than 6

mm2 to connect the housing to the ground. The way

is from the ground-connecting screw at the back to

the earth device.

4) Correctly connect the arc torch or holder according

to the picture. When using MMA welding: Make

sure the cable, holder and fastening plug have been

connected with the ground. Put the fastening plug into the fastening socket at the “-” polarity and fasten it

clockwise. When using pulse arc welding: Put the gas-electricity plug of the welding gun to the joint at the

front panel, and fasten clockwise. Put the air switch on the gun to the relevant joint at the front panel, and

fasten the screw.

5) Put the fastening plug of the cable to fastening socket of “+” polarity at the front panel, fasten it clockwise,

and the earth clamp at the other terminal clamps the work piece.

6) According to input voltage grade, connect power cable with power supply box of relevant voltage grade.

Make sure no mistake and make sure the voltage difference among permission range. After the above job,

installment is finished and welding is available.

Warning

Before connecting operation, please make sure all the power is turned off. The right order is

to connect the welding and ground cable to the machine first, and make sure they are firmly connected and

then put the power plug to the power source.

5. Installation Debugging and Operation