5

Note : The welding duty cycle is the percentage of actual continuous welding time that can occur in a ten minute cycle. For

example: 15% at 200amps- this means the welder can weld continuously at 200 amps for 1.5 minutes and then the unit

will need to be rested for 8.5 minutes.

The duty cycle can be affected by the environment in which the welder is used. In areas with temperatures exceeding

40℃, the duty cycle will be less than stated. In areas less than 40 ℃, higher duty cycles have been obtained

All tests on duty cycles have been carried out at 40℃with a 50%. So in practical working conditions the duty cycles

will be much greater than those stated above.

4. Structure of welder

4.1. Environment to Which the Product Is Subject

* The surrounding temperature range: when welding: -10~﹢40℃,

During transport or in storage: -25~﹢55℃.

* Relative humidity: when at 40℃: ≤50%,

when at 20℃: ≤90%.

* The dust, acid and erodible materials in the air can not exceed the amount required by the norm (apart

from the emissions from the welding process). No violent vibration at the job site.

* Altitude no more than 1,000m.

* Keep from raining when it is used outdoor.

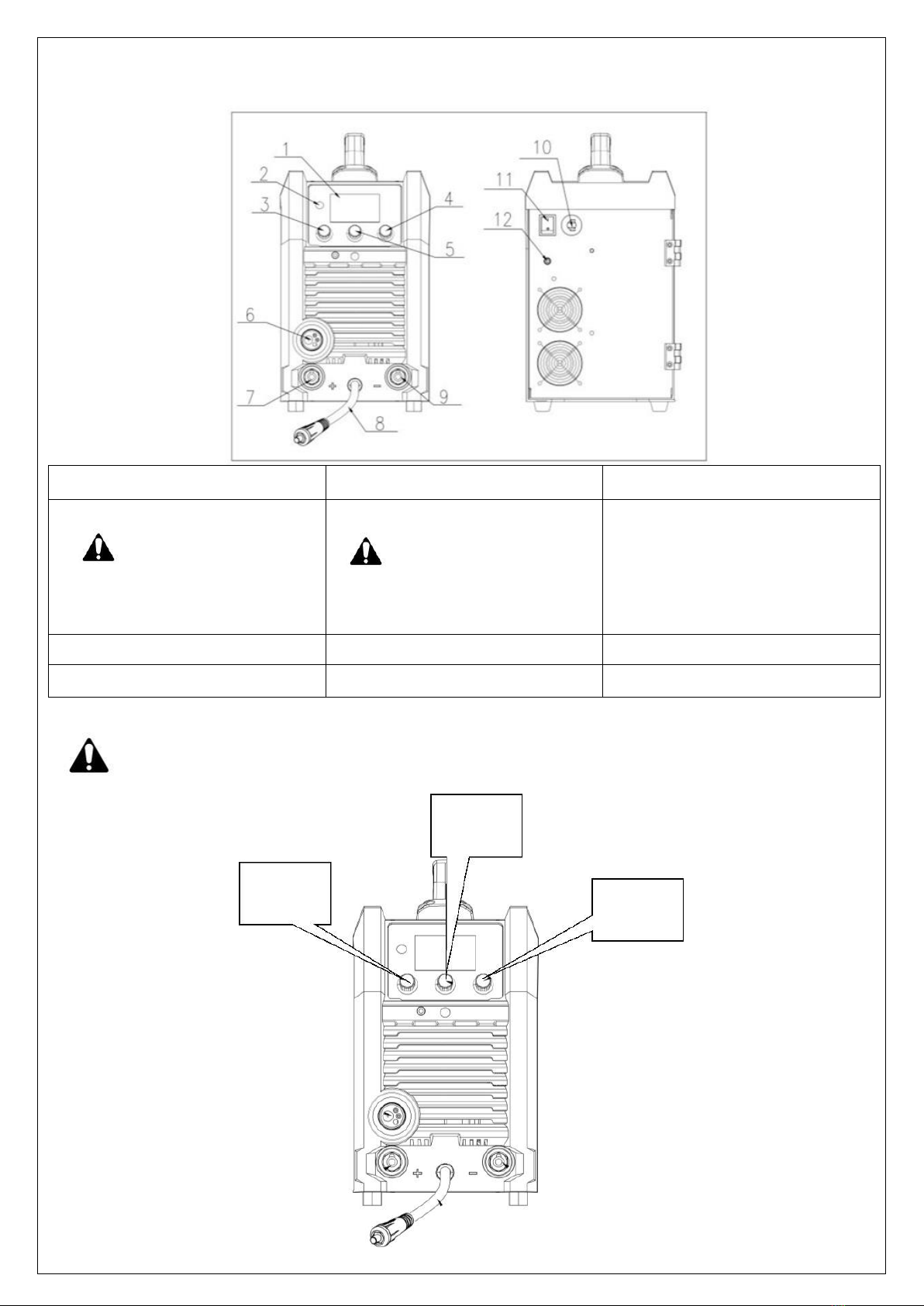

4.2. Welder’s Structures

HG200DP use the movable carton like structures: The upper part in the front is equipped with a welding current

regulation knob, power indicator light (green), abnormal indicator light (yellow), while the lower part is furnished with the

torch quick connector and “-” quick connector. The back side is installed with power switch, gas valve connection , cooling

fan, power source lead-in wire, breaker. On the top there is a handle for the convenient of easy transport.

4.3 Torch’s Construction

HG200DP, can weld alloy steel , aluminum silicon, aluminum magnesium alloy and carbon steel. For these welding wires

of different materials and different hardness, we consider more for the user when choosing the welding gun.

1. When welding for aluminum and aluminum alloy, include Al-Si, Al-Mg.

Please use the most original setting of the welding torch. The welding torch has a plastic wire feed tube.

Its advantage is smoother. It will not cause damage to aluminum welding wire and its alloy welding wire.

At the same time, you must ensure that the wire feeder roller is U-shaped!

2. When welding for stainless steel and carbon steel, include Fe, CrNi

Please replace the wire feeding hose of the welding torch with a metal spring tube. Since the stainless steel

and solid welding wire are too hard, it will cause damage to the plastic hose, it must be replaced. At the

same time, please note that replacing the wire feeder roller is V-shape.

Please note: It’s important for your welding