A.1 Power Supply

Ensure that the voltage class of the inverter is consistent with that of the grid

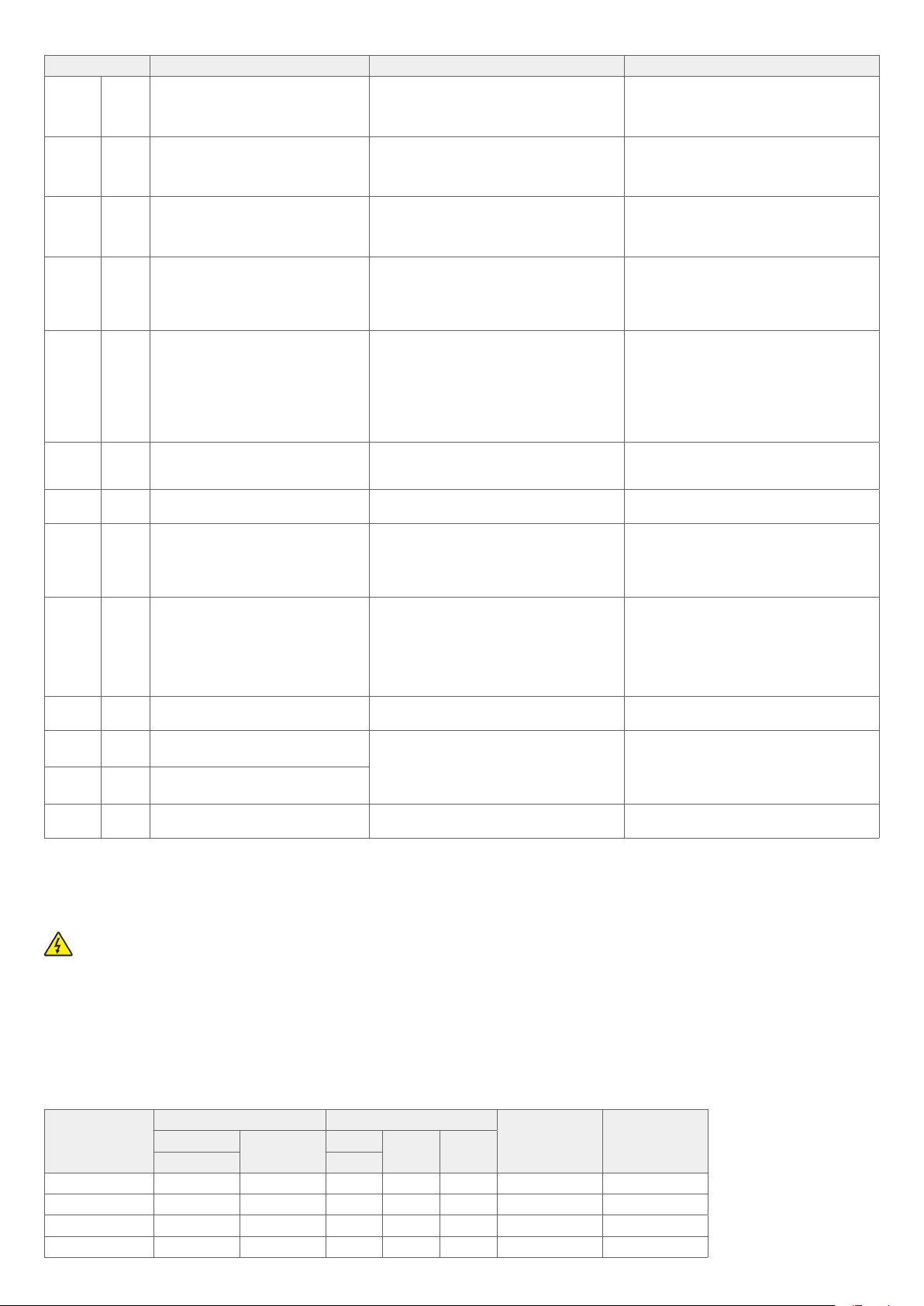

Fault Code Display Fault Type Possible Cause Solution

OL2 E12 Inverter overload

• R/S/T input phase loss or violent uctuation.

• Input-side screws loosened.

• Check for abnormal input power and loose

input cables.

• Set parameters to screen out the fault.

SPI E13 Input phase loss

• Output cables broken or short connected to

the ground.

• U/V/W output phase loss or seriously

asymmetrical 3PH loads.

• Check for loose or broken output cables.

• Check for sharp load uctuation and motor

3PH resistance imbalance.

SPO E14 Output phase loss

• Air duct blocked or fan damaged.

• Ambient temperature too high.

• Long-time overload running.

• Ventilate the air duct or replace the fan.

• Keep good ventilation to lower ambient

temperature.

• Select an inverter with larger power.

OH2 E16 Inverter module overheat

• Improper baud rate.

• Communication line fault.

• Incorrect communication address.

• Communication suffers from strong

interference.

• Set a proper baud rate.

• Check the communication port wiring.

• Set the communication address correctly.

• Replace or change wiring to enhance anti-

interference.

CE E18 RS485 communication fault

• Motor capacity and inverter capacity

mismatched.

• Improper motor parameter setting.

• Autotuned parameter settings deviate

sharply from the standard ones.

• Autotuning timeout.

• Change the inverter model.

• Set the motor type and nameplate

parameters correctly.

• Empty the motor load and re-perform

autotuning.

• Check motor wiring and parameter settings.

• Check whether the upper limit frequency is

greater than 2/3 of the rated frequency.

tE E20 Motor autotuning fault • R/S/T input phase loss or violent uctuation.

• Input-side screws loosened.

• Check for abnormal input power and loose

input cables.

• Set parameters to screen out the fault.

PIDE E22 PID feedback ofine fault • PID feedback ofine.

• PID feedback source disappears.

• Check PID feedback signal wires.

• Check PID feedback source.

dEu E34 Speed deviation fault • Load too heavy or stalled.

• Check for overload, increase speed deviation

detection time, or prolong ACC/DEC time.

• Check motor parameter settings and re-

perform motor parameter autotuning.

• Check speed loop control parameter settings.

STo E35 Mal-adjustment fault

• Load exception.

• Incorrect SM parameter settings.

• Autotuned motor parameters inaccurate.

• Inverter disconnected from the motor.

• Flux weakening application.

• Check for overload or stalling.

• Check motor parameter and counter EMF

settings.

• Re-perform motor parameter autotuning.

• Increase maladjustment detection time.

• Adjust ux weakening coefcient and current

loop parameters.

STO E40 Safe torque off • Safe torque off function is enabled by

external forces. • /

STL1 E41 Exception occurred to safe circuit of

channel H1 • The wiring of STO is improper.

• Fault occurred to external switch of STO.

• Hardware fault occurred to safety circuit of

channel H1/H2.

• Check whether terminal wiring of STO is

proper and rm enough.

• Check whether external switch of STO can

work properly.

• Replace the control board.

STL2 E42 Exception occurred to channel H2 safe

circuit

STL3 E43 Exception occurred to channel H1 and

channel H2 • Hardware fault occurred to STO circuit. • Replace the control board.

Appendix A - Optional Peripheral Accessories

A.2 Cables

The sizes of the input power cable, and motor cables must meet the local regulation.

• The input power cables, and motor cables must be able to carry the corresponding load currents.

• The maximum temperature margin of the motor cables in continuous operation cannot be lower than 70°C.

• The conductivity of the PE grounding conductor is the same as that of the phase conductor, that is, the cross-sectional areas are the same.

Check the insulation conditions of the input power cable of an inverter according to the local regulations before connecting it.

Table A 1 Cable Specications (SD1 Models only)

Model Recommended Cable Size (mm2)Size of Connectable Cable (mm2)Terminal Screw Terminal Torque

(Nm)

RST

PE

RST

PE, (+) PE

UVW UVW

SD1-2.5A-21 1.5 1.5 1~4 1~4 1~4 M3 0.8

SD1-4.2A-21 1.5 1.5 1~4 1~4 1~4 M3 0.8

SD1-7.5A-21 2.5 2.5 1~4 1~4 1~4 M3 0.8

SD1-10A-21 2.5 2.5 1~4 1~4 1~4 M3 0.8

www.imopc.com6