• e MicroMax750 is part of a range of control units adapted, with the necessary

additional functions, for optimum control of rotary heat exchangers.

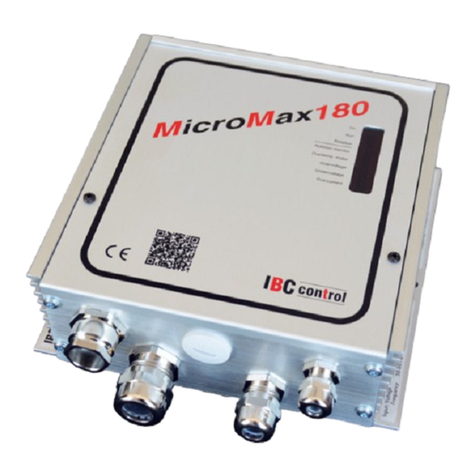

e series consists of ve sizes, MicroMax, MicroMax180, MicroMax370,

MicroMax750 and MicroMax1500.

All of the control units drive three-phase asynchronous motors with associated

gearing, the control unit designation denotes motor output. All control units

have an input signal of 0-10 V.

• MicroMax750 is designed for rotors up to 5000 mm with a rotor speed of

max 12 rpm.

If a faster rotor speed is necessary, rotor diameter should be reduced.

• Heat exchanger rpm and thus thermal eciency are governed by the control unit

so that rotor speed is proportional to the input signal from the control centre.

• MicroMax750 a adjustable threshold value of 0-2 V.

• MicroMax750 has adjustable boost function.

• MicroMax750 has a rotation monitor (magnet mounted on the rotor with

associated magnetic sensor) and built-in cleaning function.

e functions can be disconnected via DIP switches.

• MicroMax750 starts automatically following voltage

drop-out and resets all alarms on restart.

• e motor should not be disconnected from the control unit while under load.

DESCRIPTION OF FUNCTIONS

5