WARRANTY

IBI SCIENTIFIC warrants this apparatus against defects in materials and work-

manship, under normal service; for one year from the date of receipt by the

purchaser. This warranty excluded damages resulting from shipping, misuse,

carelessness, or neglect.

IBI SCIENTIFIC liability under the warranty is limited to the repair of such

defects or the replacement of the product, at its option, and is subject to

receipt of reasonable proof by the customer that the defect is within the terms

of the warranty. All claims made under this warranty must be presented

to IBI SCIENTIFIC within one year following the date of delivery of the product

to the customer.

This warranty is in lieu of any other warranties or guarantees, expressed or

implied, arising by law or otherwise.

Under no circomstances shall IBI SCIENTIFIC be able for damages either

consequential,, compensatory, incidental or special, negligence, strict liability,

breach of warranty or any other theory, arising out of the use

of the product listed herein.

IBI SCIENTIFIC makes no other warranty, expressed or implied, including

warranties of merchantability of fitness for a particular purpose.

IBI SCIENTIFIC reserves the right to make improvements in design, construction,

and appearance without notice.

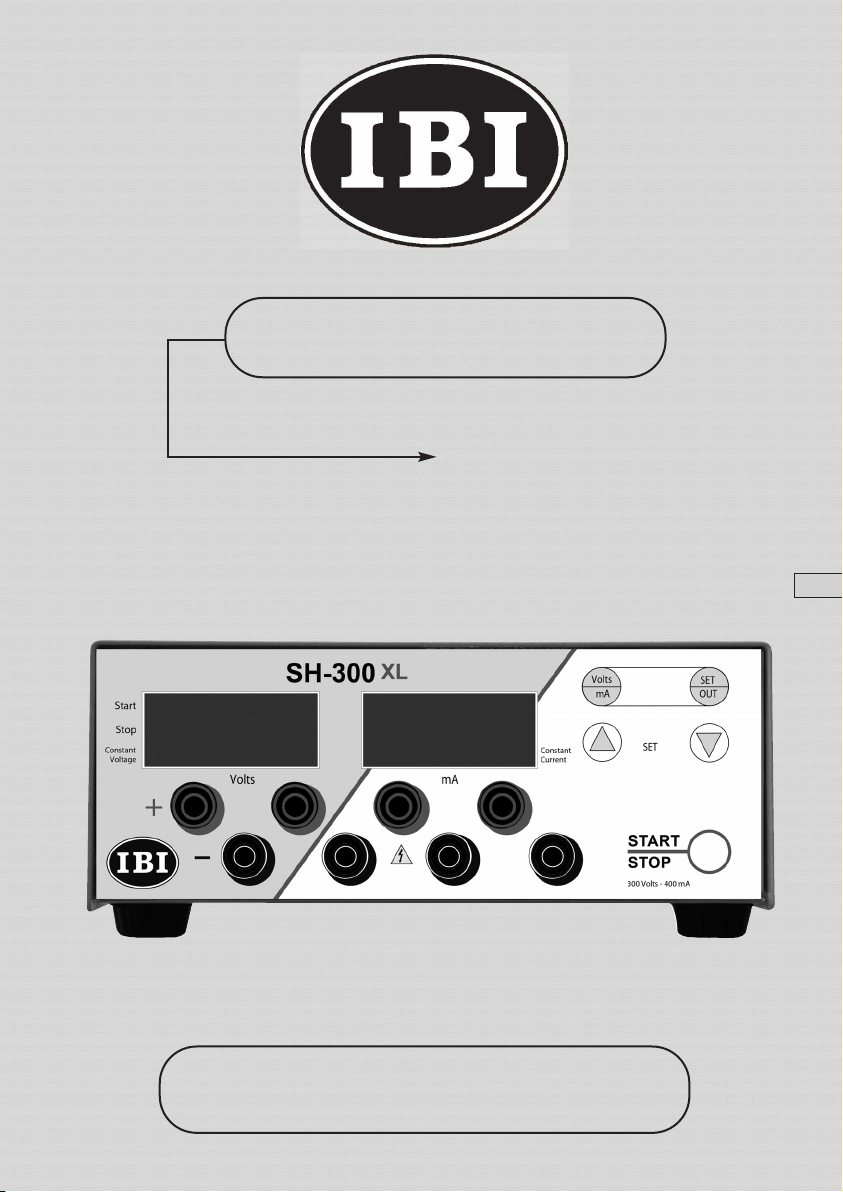

Declaration of conformity and CE mark

The information outlined in this section applies only to customers located in

the European Union (EU).

This laboratory apparatus is identified with the CE mark. This mark indicates

that the product complies to the following EU Directives and Standards:

72/23/EEC Low voltage directive

89/336/EEC Electromagnetic Compatibility

EN 61010-1: 1993 Product safety

EN 50081-1: 1992 Emissions

EN 50082-1: 1992 Immunity

A copy of the declaration of conformity certificate is available upon request.

3