IBM 77 User manual

IBM

CUSTOMER ENGINEERING

REFERENCE

UAL

COLLATOR

TYPE

CONTENTS

Page

ADJUSTMENTS

FeedHoppers

. .

.

.

. .

.

.

.

. . . .

.

. . .

.

.

Feed Knives

.

.

.

.

.

.

.

............

FeedKnifeGuides

.

.

. .

.

.

. . . .

. .

Card Guides

. . . .

.

.

. .

.

. .

.

.

. .

FeedRolls.

.-.

.

rn

. . .

.

.

.

. .

.

Brushes

. .

.

.

.

. . .

.

rn

. . .

rn

. .

.

ChuteBlades

. .

.

.

.

.

. . . .

.

.

. . .

Pocket Selection Magnets

.

. . .

.

. .

.

. . .

I

Primary and Secondary Clutches

. . . . . .

.

Eject Clutch Assembly

.

. . .

.

.

. . . .

.

Selector and SequenceUnit

. .

rn

.

.

.

..

.

. . .

Circuit Breakers

.

.

.

.

. . . . .

. . .

. .

LUBRICATION

.

. .

. . .

.

.

.

. . .

.

.

Copyright

1947,

195

1

INTERNATIONAL

BUSINESS

MACHINES CORPORATION

New York, New York

Printed in U.S.A.

Form

22-3780-2

COLLATOR,

TYPE

77

ADJUSTMENTS

Feed Hoppers

Position the front and rear hopper side plates so the holes in the card are

aligned with the brushes and there is a

.005"

to .008" clearance over the length

of the cards.

Position the hopper posts

by

adding or removing shims to obtain a .005" to

.008" clearance over the width of the cards.

Feed Knives

The feed knife piv0.t screws should be adjusted so the feed knives travel

.020" to .040" beyofid the right or

"12"

edge of the card.

Be

sure the feed knives

are square with the first set of feed rolls.

Feed

Knife

Guides

Adjust the feed knife guides for rninimum sideplay without causing any

binds.

Card

Guides

Card guides are set for

.020"

clearance between the guides. The ends of

the guides should clear the contact rolls by not less than

.005".

r

Feed

Rolls

Adjust all floating feed rolls for even tension over the entire length. Primary

and secondary rolls are equipped with adjustable plungers; remaining rolls are

equipped with pull springs.

Brushes

The brush unit assemblies should be checked for a rninimum end-shake

between the side frames at the pivot rod.

Use brush setting jig 454090 to set the brushes for a

11/8

"

projection from

the brush block tothe toe of the brush; this should provide a

'/8

"

projection above

the card line. If necessary, holes for the brush holder locating block may be

elongated to secure a

'748

I'

projection. Use brush adjusting glass 450388 to position

the brushes using scribed line farthest from the 90" bend.

Position the brush separator rolls so the distance from the inside of the

front side frame to the front edge of the

#1

brush groove in the separator roll is

5/s

".

This may be obtained by driving the bronze bearings in the separator roll

bearing brackets in or out. Align the brushes to the middle of

the

brush separator

roll slots

by

adjusting the brush block lateral aligning screws.

For the earlier machines not equipped with aligning screws, the adjustment

is obtained by filing one end of the brush block and placing shims between the

other end of the brush block and the side frame. In either case, it will be neces-

sary to align individual brushes with the three-group brush bending tool.

Shift the hopper side plates so that one set of brushes tracks through the

center of the hole in card. If necessary to re-align other set of brushes, be sure

the brush separator roll is adjusted along with the brush block assembly.

Rotate the picker knife cam on its shaft to cause the primary brushes to

make through the hole in the card not laterthan

3"

before the corresponding line

of the index and break not earlier than

12

"

after the line of index. Repeat for

secondary brushes.

To

obtain the correct timing for primary sequence brushes,

adjust the brush block assembly. It is suggested that

a

dynamic timer be used

when timing the brushes to obtain the best possible condition. Check columns at

both ends

of

card using

1,

5

and

9

time.

Chute Blades

Chute blades should be shaped to provide sufficient tensior. to cause the

blade to follow the select shoe. Form the blades so the tips of the secondary blades

are

1

'1

6" above the card line and the tip of the primary blade is

1

/

16" below

the card line when the select shoe is latched in normal positiori. When the select

shoe is unlatched, tips of the secondary blades should be

1

/

16"

below the card

line and the primary blade

1

46'' above the card line,

REFERENCE

MANUAL

77

COLLATOR

3

Pocket

Selection Magnets

.::.:..:;j;;,.::

ik

-;:.;::::::::.I'

...

.

..

.

...a.

...

.

;'<;<:,;':

.:

.:.:;.;.;:.;::

..

.

.

.

.

...

I......

..

........a3

..........

..

.

.

.

.

.

...

.

.

.

.

.

...

.

.....

.

.

.

.

:

..

..*

...&..:.

.""

L:

1.

Adjust this screw so

shoulder stops armature for

.0

15

I'

unlatching clearance.

This should provide

.003

'I

4

to

.0

12

If

clearance between

armature and core.

2.

Adjust

these backstop

screws

so

that select shoe

latch projects

.005

"

beyond

thickness

of

armature.

3.

Loosen mounting screws

and move magnet assembly

up

or down toprovide

.0

10

Y

to .020

I'

relatching

clear-

Primary and Secondary Clutches

1.

Set adjusting screw

.010" to

.015"

unlatching

clearance.

The

pawl

must

not trip later

than

220".

4

COLLATOR

77

CUSTOMER

ENGINEERING

I

\

9.

Position armature

horizontally for .005

'I

to

.008

"

armaturerelatch clear-

1-1

ance when in extreme

u

cammed position.

verti-

cally for .02OV to .02511

overlap with magnet de-

I

energized.

mounting screws and position magnet verti-

.008

I'

unlatching clearance and .003

clearance between armatureand core nearer pivot point.

This adjustment should result in .02511air

gap

between

the armature and core farther from thepivot point with

I4'

armature

in

de-energized position.

5.

Adjust knockoff screw

-for

.010"

to

,012"

clear-

ance with armature in

ex-

. .

H

\

0

1

treme cammed position.

i.

Peen

or

stone

".

003

I'

clearance.

-655ff

keeper for

REFERENCE

MANUAL

--

77

COLLATOR

5

Eject

Clutch

Assembly

The eject clutch one-tooth ratchet is timed to engage

the

pawl at

235'

+2'.

The

adjustments are as follows:

and

.call

y

ad-

for

3.

Loosen these screws and

hift magnet coil assembly

r

.030

clearance when de-

energized and

.003

I'

clear-

ance when energized.

This

should

pro-

vide an unlatching

clearance

of

.008"

to

.012".

w

w

DE-ENERGIZED

ENERGIZED

6

COLLATOR

77

CUSTOMER ENGINEERING

4.

Peen or stone keeper for

.002

to

.003

clearance.

.00311

to

.005"

clearance

Magnet Armature Knockoff-

Selector

and

Sequence

Unit

for

.

1

.

Form individual armatures for

.003

to

.00511

clearance between armature and

/

111

11

I

core nearer pivot point when armature

is

attracted.

2.

Locate magnet assembly mounting

brackets to provide

,004"

to

.OIO1'

un-

latching clearance.

clearance between knockoff and armature

on restoring magnet

when

knockoff

is

on,

high

dwell of knockoff cam.

REFERENCE MANUAL

77

COLLATOR

7

5.

Moveindividualmagnets

to front or rear to provide

.008

"

to

,012

I1

clearance be-

tween stop pawls and setup

ratchetteethwithstoppawls

latched on armature.

This should result in a

relatching clearance

of

.O1Oll

to

.01411

6.

To time the unit to the machine: Turn the restoring

bail adjusting screws so they project through the bail

approximately

&'I

at the point where the screw bears

against the cam follower. Set unit on support bars. In-

stall holding screws and turn them in just far enough to

hold unit without meshing gears. Set the machine at

8

(18")

on the index. Trip the restoring magnet armature

and turn the unit drive gear clockwise until the stop

pawls overlap the

9

tooth of the setup ratchets approxi-

mately

.030

I'

to

.040".

Be

surethe ratchets aretravelling

from the

9

toward the

0

position. Mesh the unit gear

with the continuously running shaft gear and install

the two holding screws.

.

-

7.

The outer restoring bail adjust-

ing screws are accessible with the

unit on the machine and should

now be adjusted for an even over-

lap of

.03011

to

.04011

of the stop

pawls tothe setup ratchet teeth ct

a line on the index. (Complete

adjustments

8

and

9,

then perform

adjustment

10

on the next page.)

8

COLLATOR

77

CUSTOMER ENGINEERING

8.

Position right-hand unit adjusting

.002

"

lash of the drive gears.

,/;

>-

=

>:

.

Tighten right-hand support screw.

Ad-

just left-hand screw until it just touches

support bar and tighten support screw.

This is to prevent warping the unit.

I"

$

'

,q'

";

/.

4

\'.

P

-

d

@*

'//

--

-

-b

-:<

- -

-

/A

9.

Remove theunit from themachine and

adjust the lower restoring bail adjusting

screws as in paragraph

6

above, using the

upper half of the unit as a guide. Check

by tripping stop pawls

1

and 16, upper

and lower, and noting that they drop

into the setup ratchet teeth at the same

time on the restoring part of the cycle.

Reinstall the unit on the machine.

10.

Adjust restoring latch bail pawl ec-

centric pivot for

.024

"

to

.032

"

clearance

to

restoring magnet pawl. (see large

illustration, page

7).

Check

for

at least

\

.010"

clearance

of

restoring bail to setup

ratchets

when

restoring

pawl

is

against

its

latch.

\

//

\

11.

When the restoring bails are resting

\

//-\

against the cam followerson thelow dwell

of the cam, adjust the armature knockoff

bail eccentric adjusting studs so that the

armatures will have

.002

If

to

.006

I'

move-

ment. Both sides of the unit should be

cleared to zero before starting to check

this adjustment. Check one side of the

unit at

a

time by turning theymachine by

hand and tripping all stop pawls. This

provides the greatest load on therestoring

bail spring.

U

12.

Oil groove in setup ratchet shaft .should be

45'

off center to

prevent loose

fit

of differential guide plate on shaft.

REFERENCE

MANUAL

..

.

--

-

.-

-

-

-

-

-.

-

-

-

-

-

77

COLLATOR

9

Contact

Assembly

1.

Set the adjustment bushings for

19,i64"

clearance between mounting pads on side

frames and outer surface of contact mount-

ing bar. Adjust any one bushing to remove

any rock.

2.

With ones in lower section of unit, and

upper section cleared to zero, adjust lower

N/C

contact support straps until center

straps come against cam lobes and

N/C

contacts open

.001"

to

.003".

3.

Clear lower reading and put ones in

upper side of unit. Adjust upper

N'C

con-

tact support straps until center straps come

against cam lobes and

N~!C

contacts open

.OO

1"

to

.003".

4.

With both sides of unit cleared to zero,

back out adjustment bushings evenly to

bring center straps as close as possible to

cain lobes without exerting pressure on the

cams.

5.

Remove contact unit and place hori-

OPEN

01"-.

zontal with

N,/'c

straps up. Adjust

N,'O

strap tension for

15

to

25

grams tension

against support. Use contact bending tool as

a weight tocheck adjustment. It should just

move

N/'O

strap away from its support.

6.

With contact unit horizontal and

N/C

straps up, adjust center strap tension so it

just pulls away from

N/C

contact with

weight of contact bending tool.

N/C

strap

NORMALLY

OPEN

1

#-

CONTACT

JUST

MOVED

FROM

SUPPORT

STRAP

should have just a perceptible rise from its

By

WEIGHT

OF

TOOL

RUBBER

BAND

.CONTACT

BENDING

TOOL

support under tension of center strap.

10

COLLATOR

77

_

-

-

.

_

_-

.-

-

P

--

CUSTOMER ENGINEERING

7.

Wire test light as shown using a neon bulb. Adjust each contact position by

bending

N

o

support strap until light just blinks out when center strap goes from

N

'c

to

N

'o

strap. Obtain smallest possible center strap motion with light out.

8.

Remove jumpers and test light leads and recheck for no strap pressure on

cam lobes with unit at zero reading. To check for this condition have machine idle

under power and trip one side of each unit at

a

time. If there is an appreciable

movement of the center strap on the side of the unit where the contacts are not

transferring, it is a sign of strap pressure on cam lobes at zero reading. When this

check indicates an incorrect adjustment, the contacts for that position should be

adjusted individually on the machine

by

bending the

N

'C

support strap until

contact pressure is relieved with zero reading in both sides.

REFERENCE

MANUAL

-P~---

77

COLLATOR

11

9.

Check visually for a minimum of

.020"

air gap between

N/C

points with

zeroes in one side of the unit and ones in the other. Reverse zero, one readings

and check other side.

If

this adjustment cannot be obtained, it is an indication

of lost motion due to wear of the linkage.

A

check should be made of the parts

affected in any position where this adjustment cannot be obtained and the worn

parts replaced.

Circuit

Breakers

1.

Clean points.

2.

Loosen screws A and align contact points so that full contact area is used.

3.

Loosen locknut C and adjust screw

B

for correct air gap. There are 40

threads per inch on contact screw, giving

.025"

movement for each turn. Air gap of

CB's 1,

2,

3

and

4

is

.025

".

On all others the air gap may vary from .012

"

to .040

"

to

obtain the correct contact duration.

4.

Form at

E

so that contact surfaces meet squarely.

5.

Loosen screws

D

and turn cam toobtain proper timing as given on electrical

timing chart supplied with each machine.

LUBRICATION

The following list indicates the lubricants to be used at various points on the

machine.

IBM

6

Feed knife slides

Select magnet armature pivot

Relay armature pivot

Contact roll oil wells

Clutch latch lever pivots

CB

cam lever pivots

Selector unit Pawl pivots

Setup ratchet pivot shaft oil well clutch knockoff lever pivots

and felt wick

Stop pawl pivots High speed contact rolls

Studs on differential link and guide

plate (follow with No.

i7)

Restoring magnet knockoff cam fol-

lower rollers (follow with No.

17)

12

COLLATOR

77

CUSTOMER ENGINEERING

IBM

9

Motor and generator bearings

Control panel frame pivot points

All oilite bearings

Feed roll bearings

IBM

77

All feed roll drive gears and idlers

Variable speed cam

Drive pulley bearing

Feed knife cam follower guide and

roller

CB

cam rollers

Selector unit cams

Selector unit restoring bail spring stud

Thrust bearings on endsof primary and

secondary feed shafts

Feed roll pressure shoes

Feed roll bearing pivots in brush as-

sembly side plates

Remove screw in 1st lower CR

(hollow) feed roll and lubricate eject

clutch drive shaft

Clutch knockoff cam follower rollers

Restoring magnet knockoff cam fol-

lowers

Sentinel switch points

Differential link studs

Thin film on: all linen dilecto cams and

gears; all primary and secondary

commutators;linen dilecto card levers

at the point where they operate

against the contact strap

Clutch magnet armature at latching

point

Repacking matched bearings on feed

rolls

i..

.

.

I

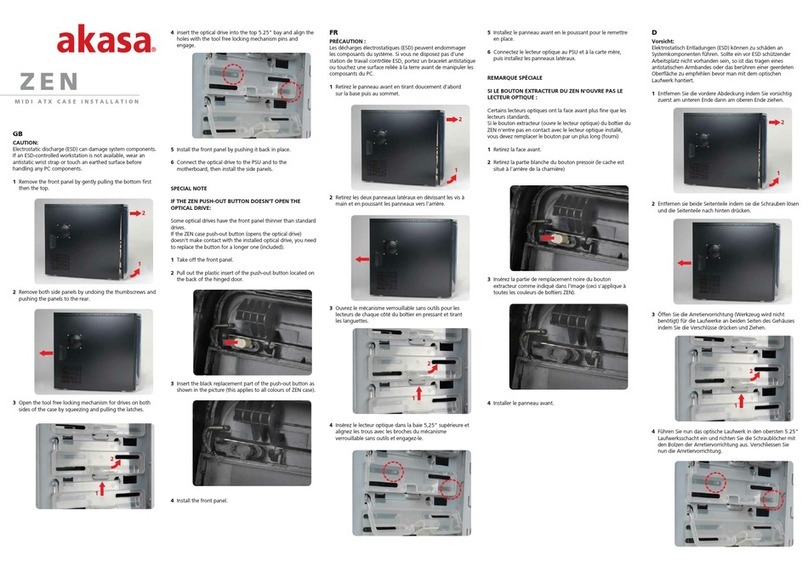

Other IBM Computer Accessories manuals

IBM

IBM 29 CARD PUNCH - User manual

IBM

IBM 29 CARD PUNCH - User manual

IBM

IBM THINKPAD 92P1836 User manual

IBM

IBM THINKPAD A30 Installation and operation manual

IBM

IBM IBM ThinkPad Multi-Burner PlusUltrabay Enhanced... User manual

IBM

IBM WAVV 2004 User manual

IBM

IBM ThinkPad Dock I User manual

IBM

IBM Wireless Keyboard and Mouse User manual

IBM

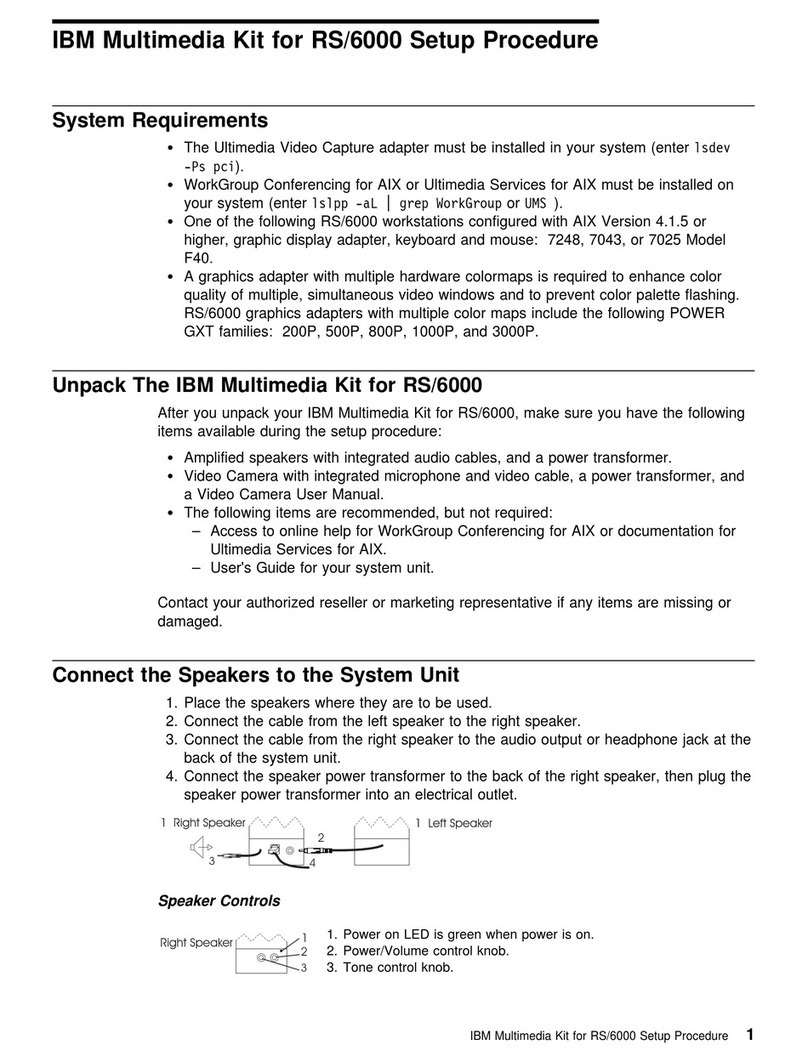

IBM Multimedia Kit for RS/6000 Manual