IBM 29 CARD PUNCH - User manual

IBY

/

FE

Supplement

Unit

29

Card Punch

Re:

Order

No.

S225-3357-3

This Supplement No.

SS23-4069

Date Novomber

23, 1970

Previous SupplementNos. None

\.

IBM FIELD ENGINEERING MAINTENANCE MANUAL

IBM

29

CARD PUNCH

.

@IBM

Corp.

1965, 1969

L

Pages to be inserted and/or removed are:

\-

Title Page, Preface

4-1

through

4-12

iii

through vi

4-17

through

4-22

1-9, 1-10 4-29, 4-30

1

2-3,

blank

4-35

through

4-41,

blank

3-1, 3-2 X-1

through

X-5,

blank

L,

3-5, 3-6

A change to the text

is

indicated by a vertical line to the left of the change; a changed or

added illustration

is

denoted by the symbol

to

the left of the caption.

C

Summary of Amendments

Maintenance Manual addition to list in Preface

L

Additional troubleshooting aids in Chapter

1

Lubrication changes in Chapter

3

Checkout procedure change in Chapter

2

L

Adjustment tolerance changes in Chapter

4

Figure

4-41

changed to improve figure-to-component association

C

Note: Please file this cover letter at the back of the manual to provide a record of

-

changes.

L

L

IBM Corporation,Product Publications, P.

0.

Box

390,

Poughkeepsie,

N.

Y.

I2602

\.

Field ~ngineerirbg

Maintenance Manual

2

Card Punch

S225-3357-3

FES: SS234069

Preface

This publicatibn provides information for the maintenance

of the IBM 29 Card Punch. The manual is written with

presupposition tfiifithe reader has a working knowledge of

the machine. As much applicable information as possible is

in each section of this manual. The sections are numbered

for easy reference. The sections are presented in a sequence

similar to the card path through the machine.

Timing adjustments for some units may vary among

machines due to features and engineering changes; refer to

the individual machine wiring diagram for accurate timing.

Special features are treated individually in a separate

manual, Field Engineering Theory

-

Maintenance,

IBM 29

Cad Punch Features, IBM 29 Interpreting Card Punch,

Model C,

S223-2926.

Other related manuals are:

Field Engineering Theory of Operation,

IBM 29 Card

Punch,

S225-3358

Illustrated Parts Catalog,

IBM 29 Card Punch,

S1244085

Reference Manual,

IBM 29 Card Punch,

GA24-3332

Field Engineering Maintenance Manual,

Motors, Genera-

tors, Relays, Circuit Breakers, Test Instruments, Miscella-

neous Components,

S225-3422

Fourth

Edition

(April 1969)

This a major revision of, and obsoletes, Form 225-3357-2, FE Supplement Form

S23-4035, and all earlier editions. Significant changes have been made throughout

this manual, including: new diagnostic flowcharts, Chapter 1; a new chapter,

Chapter 2; new lubricant specifications, Chapter 3;revised starwheel adjustments

and revised print suppress adjustments, Chapter

4.

This manual should be

reviewed in its entirety. Changes are periodically made to the specifications

herein; any such changes will be reported in subsequent revisions or FE

Supplements.

This manual has been prepared by the IBM Systems Development Division,

Product Publications, Dept B96, PO Box 390, Poughkeepsie,

N.Y.

12602.

A

form

for readers' comments is provided at the back of this publication. If the form has

been removed, comments may be sent to the above address.

@Copyright International BusinessMachines Corporation 1965, 1969

S225-3357-3

FES:

SS234069

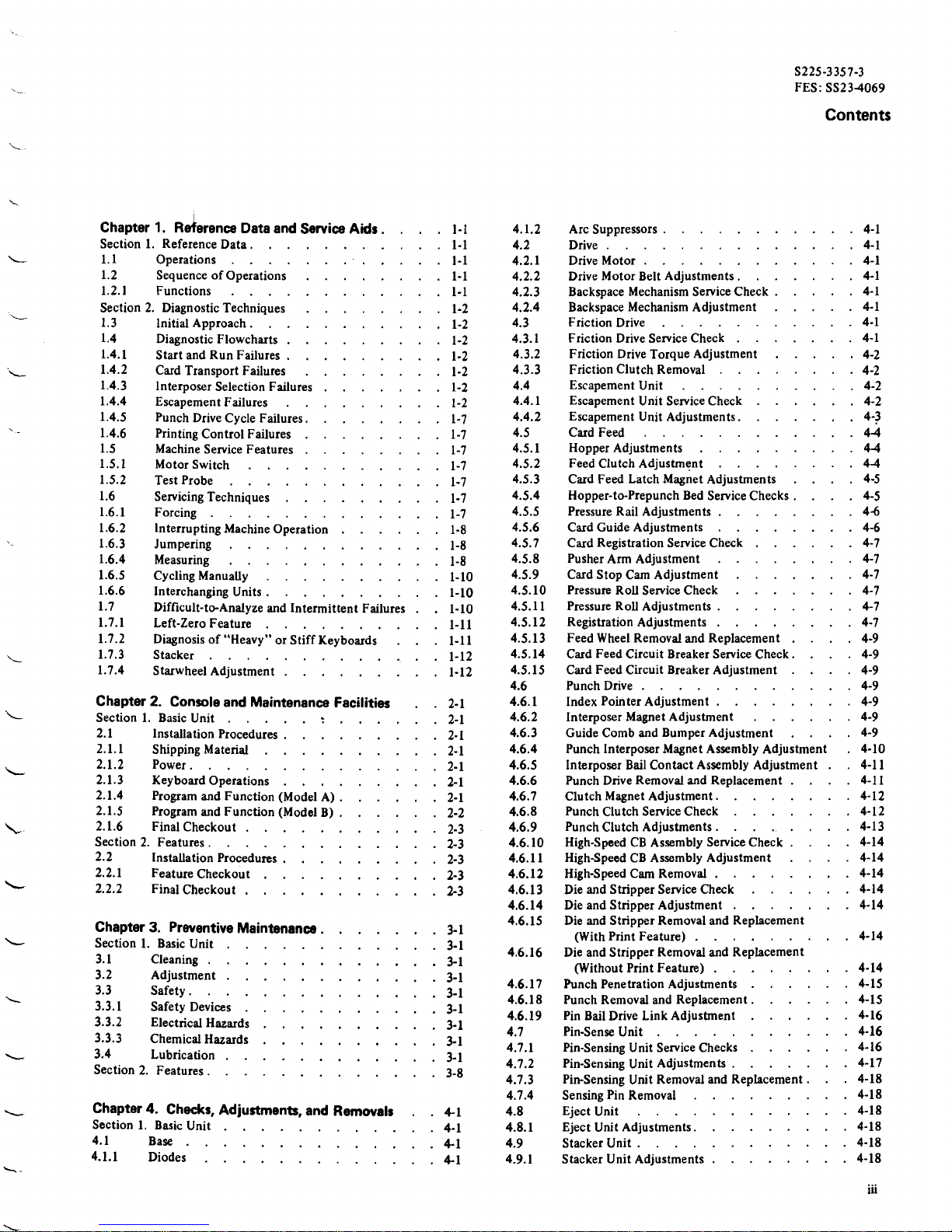

Contents

.

Chapter

1

~derenceDataand Service Aids

....

1-1

.

Section

1

Reference Data

...........

1-1

1.1

Operations

............

1-1

1.2

Sequence of Operations

........

1-1

1.2.1

Functions

............

1-1

.

Section

2

Diagnostic Techniques

........

1-2

1.3

Initial Approach

...........

1-2

1.4

Diagnostic Flowcharts

.........

1-2

1.4.1

Start and Run Failures

.........

1-2

1.4.2

Card Transport Failures

........

1-2

1.4.3

Interposer Selection Failures

.......

1-2

1.4.4

Escapement Failures

.........

1-2

1.4.5

Punch Drive Cycle Failures

........

1-7

1.4.6

Printing Control Failures

........

1-7

1.5

Machine Service Features

........

1-7

1.5.1

Motor Switch

...........

1-7

1.5.2

Test Probe

............

1-7

1.6

ServicingTechniques

.........

1-7

1.6.1

Forcing

.............

1-7

1.6.2

Interrupting Machine Operation

......

1-8

1.6.3

Jumpering

............

1-8

1.6.4

Measuring

............

1-8

1.6.5

Cycling Manually

..........

1-10

1.6.6

Interchanging Units

..........

1-10

1.7

Difficult-to-Analyze and Intermittent Failures

. .

1-10

1.7.1

Left-Zero Feature

..........

1-11

1.7.2

Diagnosis of "Heavy" or Stiff Keyboards

...

1-11

1.7.3

Stacker

.............

1-12

1.7.4

Starwheel Adjustment

.........

1-12

Chapter

2

.

Consoleand Maintenance Facilities

. .

2-1

.

Section

1

Basic Unit

.....

:

......

2-1

2.1

installation

Procedures

.........

2-1

2.1.1

ShippingMaterial

..........

2-1

2.1.2

Power

..............

2-1

2.1.3

Keyboard Operations

.........

2-1

2.1.4

Program and Function (Model A)

......

2-1

2.1.5

Program and Function (Model B)

......

2-2

2.1.6

Final Checkout

...........

2-3

.

Section

2

Features

.............

2-3

2.2

Installation Procedures

.........

2-3

2.2.1

Feature Checkout

..........

2-3

2.2.2

Final Checkout

...........

2-3

Chapter

3

.

Preventive Maintenance

.......

3-1

Section

1

.

Basic Unit

............

3-1

3.1

Cleaning

.............

3-1

3.2

Adjustment

............

3-1

3.3

Safety

..............

3-1

3.3.1

Safety Devices

...........

3-1

3.3.2

Electrical Hazards

..........

3-1

3.3.3

Chemical Hazards

..........

3-1

3.4

Lubrication

............

3-1

Section

2

.

Features

.............

3-8

Chapter

4

.

Checks. Adjustments. and Removals

.

.

4-1

.

Section

1

Basic Unit

............

4-1

4.1

Base

..............

4-1

4.1.1

Diodes

.............

4-1

Arc Suppressors

...........

4-1

Drive

..............

4-1

Drive Motor

............

4-1

.......

Drive Motor Belt Adjustments

4-1

.....

Backspace Mechanism ServiceCheck

4-1

.....

Backspace Mechanism Adjustment

4-1

...........

Friction Drive

4-1

.......

Friction Drive ServiceCheck

4-1

Friction Drive Torque Adjustment

.....

4-2

Friction Clutch Removal

........

4-2

Escapement Unit

..........

4-2

EscapementUnitServiceCheck

......

4-2

Escapement Unit Adjustments

.......

4-3

Card Feed

............

44

Hopper Adjustments

.........

44

Feed Clutch Adjustment

........

44

Card Feed Latch Magnet Adjustments

....

4-5

Hopper-to-Prepunch Bed ServiceChecks

....

4-5

Pressure Rail Adjustments

........

46

Card Guide Adjustments

........

4-6

......

Card Registration Service Check

4-7

........

Pusher Arm Adjustment

4-7

.......

Card Stop Cam Adjustment

4-7

Pressure Roll ServiceCheck

.......

4-7

Pressure Roll Adjustments

........

4-7

Registration Adjustments

........

4-7

Feed Wheel Removal and Replacement

....

4-9

Card Feed Circuit Breaker Service Check

....

4-9

Card Feed Circuit Breaker Adjustment

....

4-9

............

Punch Drive

4-9

........

Index Pointer Adjustment

4-9

......

Interposer Magnet Adjustment

4-9

Guide Comb and Bumper Adjustment

....

4-9

Punch Interposer Magnet Assembly Adjustment

.

4-10

Interposer Bail Contact Assembly Adjustment

.

.

4-11

Punch Drive Removal and Replacement

....

4-11

Clutch Magnet Adjustment

........

4-12

.......

Punch Clutch Service Check

4-12

........

Punch Clutch Adjustments

4-13

High-speed CB Assembly ServiceCheck

....

4-14

....

High-speed CB Assembly Adjustment

4-14

High-speed Cam Removal

........

4-14

......

Die and Stripper Service Check

4-14

Die and Stripper Adjustment

.......

4-14

Die and Stripper Removal and Replacement

.........

(With Print Feature)

4-14

Die and Stripper Removal and Replacement

........

(Without Print Feature)

4-14

......

Punch Penetration Adjustments

4-15

...

Punch Removal and Replacement

...

Pin Bail Drive Link Adjustment

Pin-Sense Unit

........

...

Pin-SensingUnit ServiceChecks

....

Pin-SensingUnit Adjustments

Pin-Sensing Unit Removal and Replacement

Sensing Pin Removal

......

Eject Unit

.........

EjectUnitAdjustrnents

......

.........

Stacker Unit

Stacker Unit Adjustments

.....

iii

........

Program Drum Unit

Sensing Assembly Service Check

....

....

SensingAssembly Adjustments

SensingAssembly Removal and Replacement

Program Cam ContactsService Check

.

.

...

Program Cam Contacts Adjustment

Program Drum

interlock

Arm (Split Hub)

.........

Adjustment

..........

Print Unit

Print Assembly Servicechecks

...

Print Assembly Adjustments

.....

Print Assembly Removal and Replacement

.

Ribbon Feed Pawl Adjustment

....

Print Drive Adjustment

.......

Print SuppressMagnet Adjustment

...

Keyboard

...........

Contact Adjustments

.......

Hook Support Bar Adjustment

....

Permutation Bar Adjustment

.....

Restoring Magnet Adjustment

.....

l

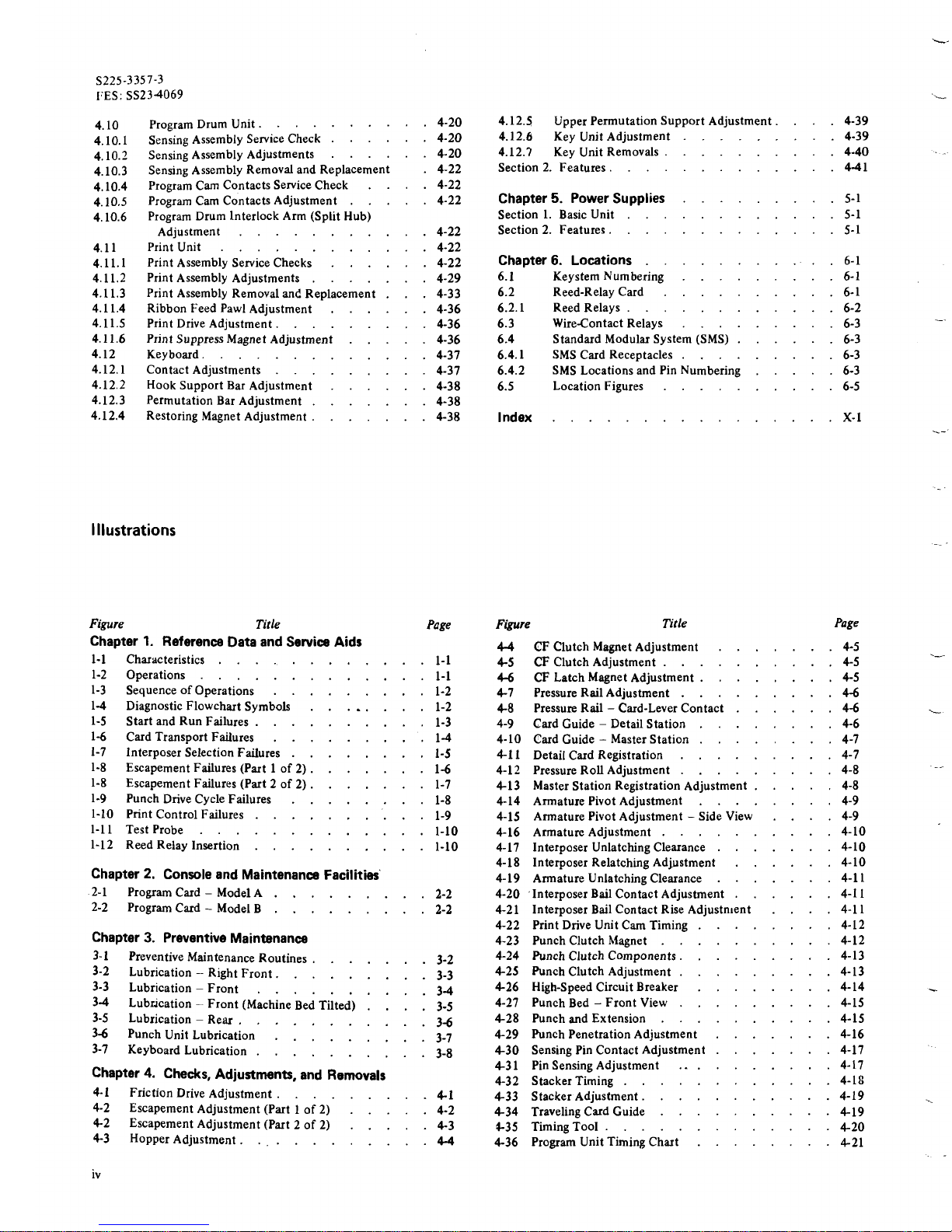

llustrations

Figure Title

Chapter

1

.

Reference Data and Service Aids

1-1 Characteristics

.........

1-2 Operations

..........

1-3 Sequence of Operations

......

.....

1-4 Diagnostic Flowchart Symbols

1-5 Start and Run Failures

.......

......

1-6 CardTransportFailures

1-7 lnterposer Selection Failures

.....

....

1-8 Escapement Failures (Part 1 of 2)

....

1-8 Escapement Failures (Part

2

of 2)

1-9 Punch Drive Cycle Failures

.....

1-10 Print Control Failures

.......

1-11 Test Probe

..........

1-12 Reed Relay

insertion

.......

Page

...

1-1

..

1-1

..

1-2

...

1-2

...

1-3

..

1-4

..

1-5

. .

1-6

..

1-7

..

1-8

...

1-9

..

1-10

..

1-10

Chapter

2

.

Consoleand Maintenance Facilit'm'

2-1 Program Card

.

Model A

.........

2-2

2-2 Program Card

.

Model B

.........

2-2

Chapter

3

.

PreventiveMaintenance

3-1 Preventive Maintenance Routines

.......

3-2

3-2 Lubrication

.

Right Front

.........

3-3

.

3-3 Lubrication Front

..........

3-4

3-4 Lubrication

.

Front (Machine Bed Tilted)

....

3-5

3-5 Lubrication

.

Rear 3-6

...........

3-6 Punch Unit Lubrication

.........

3-7

3-7 Keyboard Lubrication

..........

3-8

Chapter

4.

Checks. Adjustments. and Removals

4-1

Friction Drive Adjustment

.........

4-1

4-2 Escapement Adjustment (Part 1 of 2)

.....

4-2

4-2 Escapement Adjustment (Part 2 of 2)

.....

4-3

4-3 Hopper Adjustment

............

4-4

4.12.5 Upper Permutation Support Adjustment

....

4-39

.........

4.12.6 Key Unit Adjustment 4-39

4.12.7 Key Unit Removals

..........

4-40

Section 2

.

Features

.............

4-41

.

........

Chapter

5

Power Supplies

5-1

Section 1

.

Basic Unit

............

5-1

Section 2

.

Features

.............

5-1

Chapter

6

.

Locations

...........

6-1

6.1 Keystem Numbering

.........

6-1

6.2 Reed-Relay Card

........

6-1

6.2.1 Reed Relays

.........

6-2

6.3 Wirecontact Relays

.........

6-3

6.4 Standard Modular System (SMS)

......

6-3

6.4.1 SMS Card Receptacles

.........

6-3

6.4.2 SMS Locations and Pin Numbering

....

6-3

6.5 Location Figures

..........

6-5

lndex

................

X-

1

Figure Title

CF Clutch Magnet Adjustment

...

CF Clutch Adjustment

......

CF Latch Magnet Adjustment

....

Pressure Rail Adjustment

.....

Pressure Rail

.

Card-Lever Contact

. .

Card Guide

.

Detail Station

....

Card Guide

.

Master Station

....

.....

Detail Card Registration

.....

Pressure Roll Adjustment

Master Station Registration Adjustment

.

....

Armature Pivot Adjustment

Armature Pivot Adjustment

.

Side View

......

ArmatureAdjustment

Interposer Unlatching Clearance

...

lnterposer Relatching Adjvstment

.

.

Armature Unlatching Clearance

...

lnterposer Bail Contact Adjustment

.

.

lnterposer Bail Contact Rise Adjustment

Print Drive Unit Cam Timing

....

PunchClutchhlagnet

......

Punch Clutch Components

.....

PunchClutchAdjustment

.....

....

High-SpeedCircuit Breaker

.

.....

Punch Bed Front View

PunchandExtension

......

Punch Penetration Adjustment

...

Sensing Pin Contact Adjustment

...

Pin Sensing Adjustment

......

........

Stacker Timing

.......

Stacker Adjustment

TravelingCardCuide

......

Timing Tool

.........

Program Unit Timing Chart

....

Page

.4-5

1

.4-5

.4-5

.4-6

4-6

-

.4-6

.4-7

.4-7

.4-8

..

.4-8

.4-9

.4-9

.

4-10

.

4-10

.

4-10

.

4-11

.

4-11

.

4-11

.

4-12

.

4-12

.

4-13

.

4-13

.

4-14

-

.

4-15

.

4-15

.

4-16

.

4-17

.

4-17

.

4-1C

.

4-19

..

.

4-19

.

4-20

.

4-21

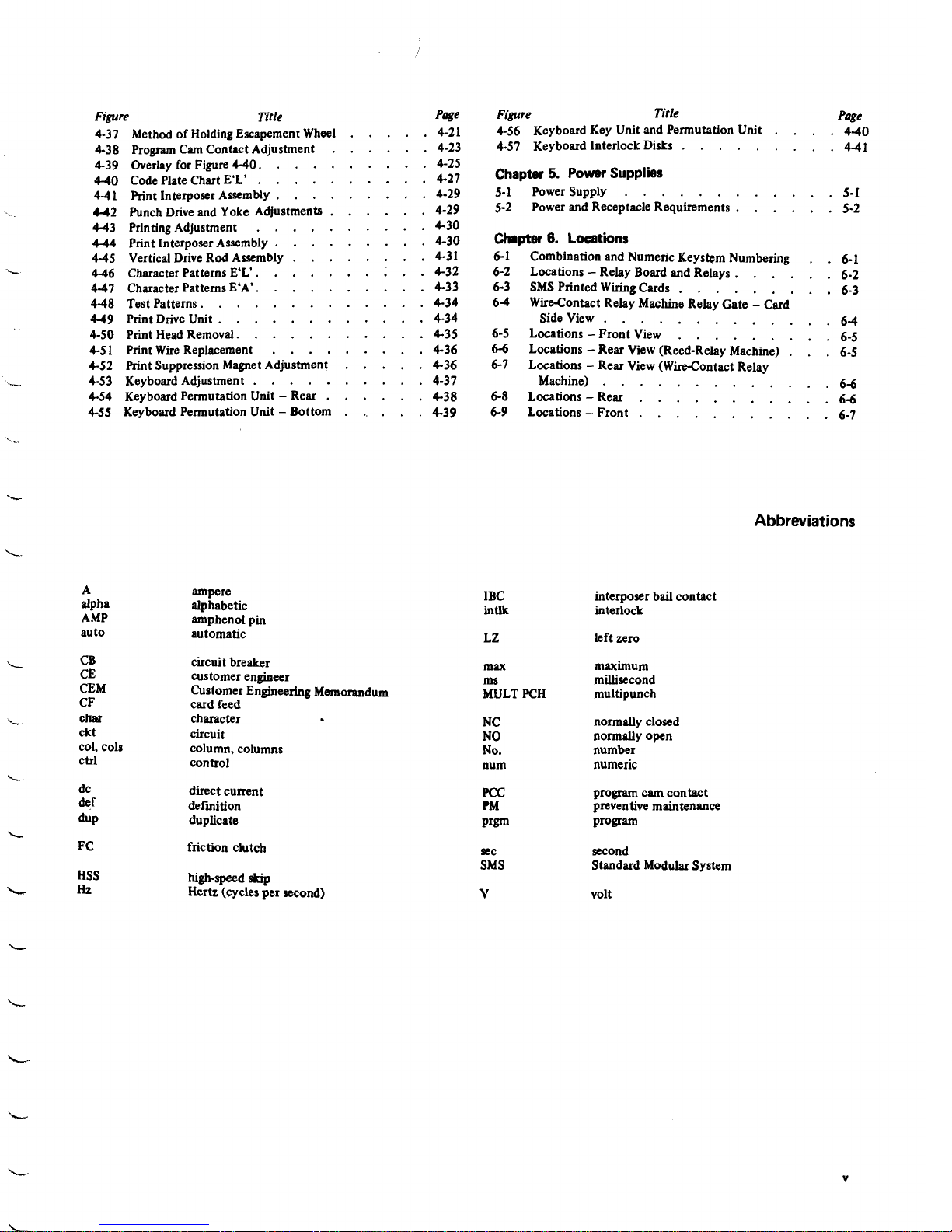

Figure Title

4-37 Method of HoldingEscapement Wheel

4-38 Program Cam Contact Adjustment

.

....

4-39 OverlayforFigure4-40.

.....

4-40 Code Plate Chart E'L'

....

441 Print Interposer Assembly

442 Punch Drive and Yoke Adjustments

.

4-43 Printing Adjustment

.....

4-44 Print Interposer Assembly

....

445 Vertical Drive Rod Assembly

...

....

4-46

CharacterPatternsE'L1.

....

447 CharacterPatternsE'A'.

448 Test Patterns.

.......

449 Print Drive Unit

.......

4-50 Print HeadRemoval.

.....

4-51 Print Wire Replacement

....

4-52 Print Suppression Magnet Adjustment

4-53 Keyboard Adjustment

.....

4-54 Keyboard Permutation Unit

-

Rear

.

4-55 Keyboard Permutation Unit

-

Bottom

A

alpha

AMP

auto

CB

CE

CEM

CF

chat

ckt

col, cols

ctrl

dc

def

dup

HSS

L

Hz

ampere

alphabetic

amphenolpin

automatic

Page

...

.4-21

.....

4-23

....

4-25

....

.4-27

.....

4-29

.....

4-29

....

.4-30

.....

4-30

.....

4-31

.

.

;

.

.4-32

.....

4-33

....

.4-34

....

.4-34

....

.4-35

....

.4-36

...

.4-36

.....

4-37

....

.4-38

.....

.439

circuit breaker

customer engineer

Customer Engineering Memorandum

card feed

character

circuit

column, columns

control

direct current

definition

duplicate

friction clutch

high-speed

skip

Hertz (cycles per second)

Figure Title

4-56 Keyboard Key Unit and Permutation Unit

. .

.......

4-57 Keyboard Interlock Disks

Chapter

5.

Power

Supplies

..........

5-1 Power Supply

5-2 Power and Receptacle Requirements

....

Chapter

6.

Locations

Combination and Numeric Keystem Numbering

Locations

-

Relay Board and Relays

....

.......

SMS Printed WiringCards

WireContact Relay Machine Relay Gate

-

Card

...........

Side View

Locations

-

Front View

.......

Locations

-

Rear View (Reed-Relay Machine)

.

Locations

-

Rear View (Wire-Contact Relay

...........

Machine)

.........

Locations

-

Rear

Locations

-

Front

.........

IBC

intlk

LZ

max

ms

MULT PCH

NC

NO

No.

num

FCC

PM

Prgm

sec

SMS

v

interposer bail contact

interlock

left zero

maximum

millisecond

multipunch

normally closed

normally open

number

numeric

program cam contact

preventive maintenance

ProkTm

second

Standard Modular System

volt

Page

. .

440

. .

441

Abbreviations

5225-3357-3

FES:SS234069

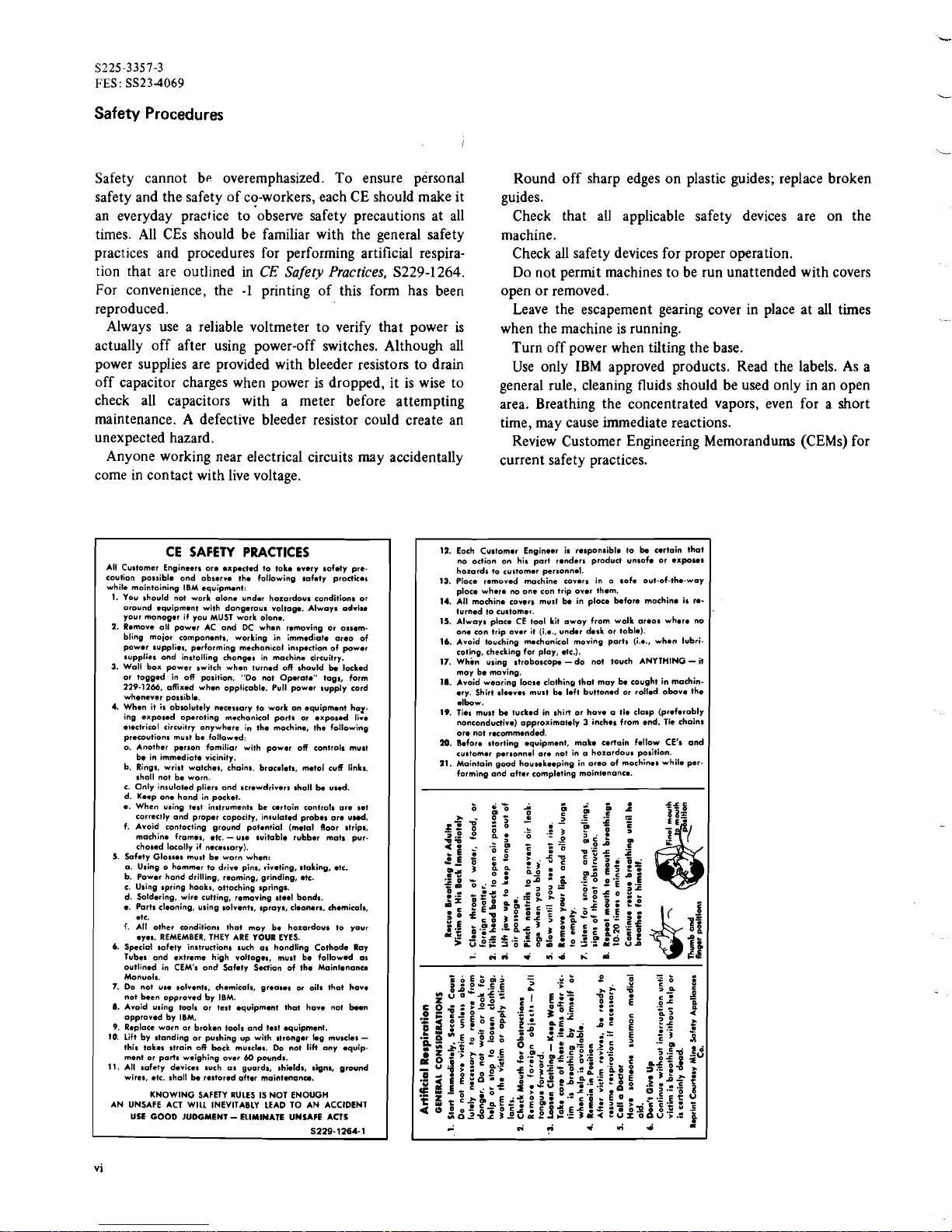

Safety Procedures

Safety cannot be overemphasized. To ensure personal

safety and the safety ofco-workers, each CE should make it

an everyday practice to'observe safety precautions at all

times. All CEs should be familiar with the general safety

practices and procedures for performing artificial respira-

tion that are outlined in

CE

Safety Practices,

S229-1264.

For convenience, the

-1

printing of this form has been

reproduced.

Always use a reliable voltmeter to verify that power is

actually off after using power-off switches. Although all

power supplies are provided with bleeder resistors to drain

off capacitor charges when power is dropped, it is wise to

check all capacitors with a meter before attempting

maintenance. A defective bleeder resistor could create an

unexpected hazard.

Anyone working near elect~icalcircuits may accidentally

come in contact with live voltage.

Round off sharp edges on plastic guides; replace broken

guides.

Check that all applicable safety devices are on the

machine.

Check all safety devices for proper operation.

Do not permit machines to be run unattended with covers

open or removed.

Leave the escapement gearing cover in place at all times

when the machine is running.

Turn off power when tilting the base.

Use only IBM approved products. Read the labels. As a

general rule, cleaning fluids should be used only in an open

area. Breathing the concentrated vapors, even for a short

time, may cause immediate reactions.

Review Customer Engineering Memorandums (CEMs) for

current safety practices.

CE SAFETY PRACTICES

All Cu~tomerEngineers ore .xp.cted to toke every sofety pre.

caution po~~ibleond observ. the following safety procticas

while mointoining IBM equipmant:

1.

You should not work alone undar

hazardous

conditions or

oround equipment with

dangerous

voltage. Always adrim

your monoger if you MUST work olon..

2.

Remove oll power AC ond DC when removing or ossem-

bling moior components, working in immediate areo of

power supplies, performing mechonicol inspectionof power

supplies ond instolling chonges in machine circuitry.

3.

Wall box power switch when turned off should be locked

or togged in off position. "Do not Operat." togs, form

229-1266,

ofixed when opplicoble. Pull power supply cord

whenever possible.

4.

When it is

absolutely

necessary to work on equipment har

ing exposed

operating

mcchonical ports or expo~dlire

electrical

circuitry anywhere in the mochine. the following

precautions

must be followed:

o. Another person fomiliar with power off controls must

be in

immediate

vicinity.

b. Rings, wrist watches, chains, bracelets, met01 cuff links,

sholl not be worn.

c. Only

insulated

pliers ond screwdrivers shall be used.

d. Keep one hond in pocket.

e.

When u~ingtest

instrument^

be artoin controls are set

correctly and proper copocity, in~ulatedprobes ore uud.

f. Avoid rontocting ground potential (metal floor strips,

machine frames, etc.

-

use suitable rubber mots pur-

chased

locolly if necessary).

5.

Safety Glos~esmuat be worn when:

a. Using o hommer to drive pins, riveting, stoking, etc.

b. Power hond drilling, reoming, grinding, etc.

c. Using apring hook,, ottoching springs.

d. Soldering, wire cutting, removing steel bond*.

e. Ports cleoning, using solvents, sprays,

cleaners.

chemicals,

.tC.

f.

All other wnditbns thot moy be ho~ordousto your

eyes. REMEMBER, THEY ARE YOUR EYES.

6.

Special softly instructions such as hondling Cothode Ray

Tubel ond extreme high voltogea, must be followed

01

outlined in CEM's ond Safety Section of the Maintenance

Monuols.

7.

Do not

use

solvents, chemicals, greases or oils that hove

not been opproved by IBM.

8.

Avoid wing tools or test equipment thot hove no1

b..n

approved by IBM.

9.

Replace worn

ar

broken tools and test equipment.

10.

Lift by standing or pushing up with stronger leg muscles

-

this tokes strain off bock muscles. Do not liH any equip-

ment or ports weighing over

60

pounds.

11.

All safety devices such as guards, shields, signs, ground

wires, ctc. shall be restoredofter maintenonu.

KNOWING SAFETY RULES IS NOT ENOUGH

AN UNSAFE ACT WILL INEVITABLY LEAD TO AN ACCIDENT

USE

GOOD

JUOGMENT

-

ELIMINATE UNSAFE ACTS

S229-1264-1

12.

Each Customor Enginoer in

responsible

lo be cortain that

no oction on his part renders product unsofo or exposel

hozards to customer personnel.

13.

Ploce removed machine covers in o sofe out-of-the-way

ploce where no one con trip over them.

14.

A11 mochin. covers mull be in ploce before mochino is re-

turned to customer.

15.

Always CE tool kit awoy from wolk oreos where no

one con trip

over

it (i.4.. under desk or loblo).

16.

Avoid touching m.chanicol moving ports (i.e., when lubri-

coting, checkingfor play, etc.).

17.

Whin using stroboscope-do not touch ANYTHING- it

moy be moving.

la.

Avoid wearing loose clothing thot may be cought in machin.

err. Shirt sleeves mu11 be left buttoned or rolled obove the

elbow.

19.

Ties must be tucked in shirt or hove a tie clasp (preferably

nonconductive) opproximotely

3

inches from end. Tie chain1

ore not recommended.

110.

Befor. storting equipment, make certain fellow CE's and

customer personnel ore not in a horardous position.

21.

Maintaingood housekeeping in oreo of mochines while per-

forming and after completing mointenonce.

L

.i.i

.

rid

h:

d

-

"r'd

Chapter

1.

Reference Data and

SerLice

Aids

Section

1.

ReferenceData

4.

Card Transport:

Mechanical control of the movement of

the card through the machine.

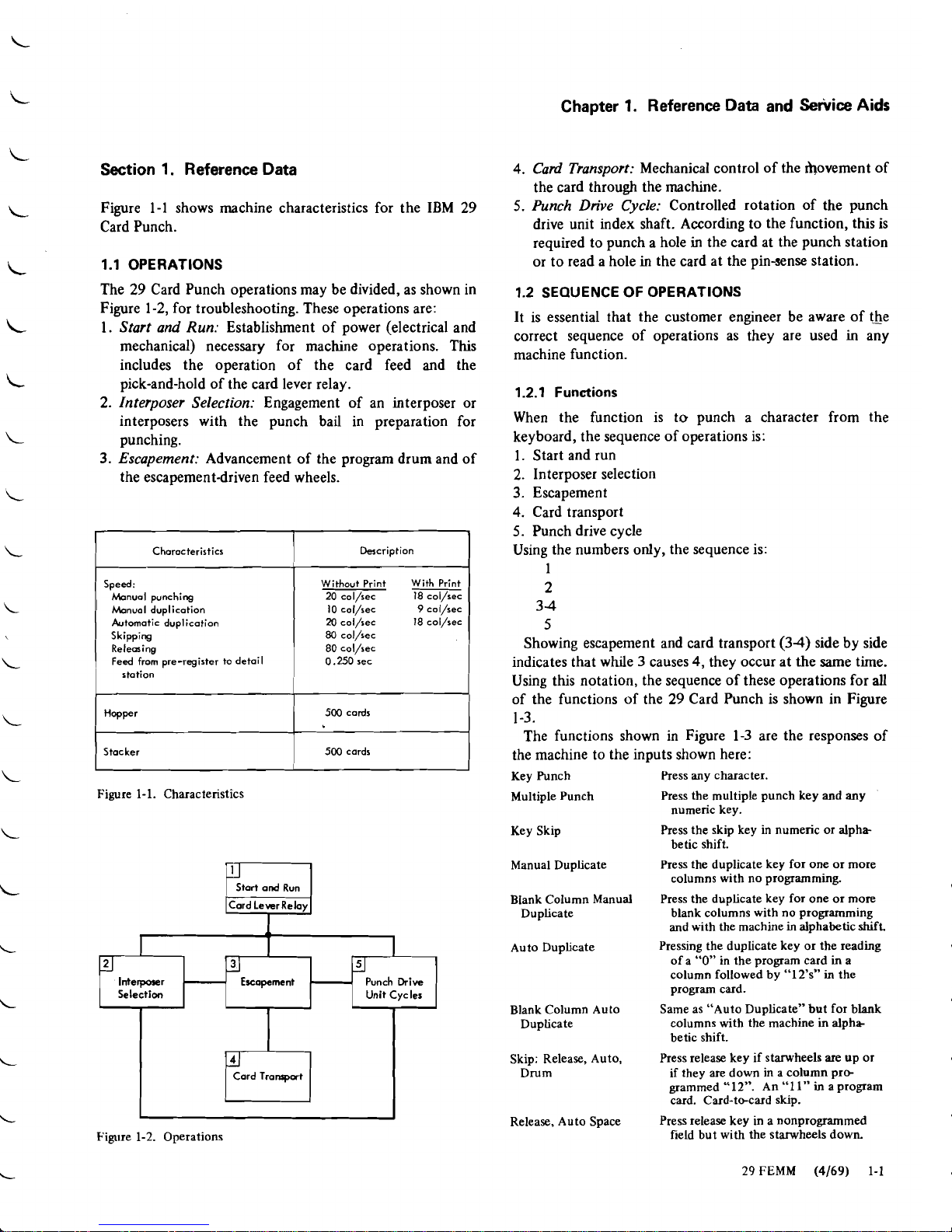

Figure 1-1 shows machine characteristics for the IBM 29

5.

Punch Drive Cycle:

Controlled rotation of the punch

Card Punch. drive unit index shaft. According to the function, this is

required to punch a hole

in

the card at the punch station

1.1 OPERATIONS

or to read a hole

in

the card at the pin-sense station.

The 29 Card Punch operations may be divided, as shown in

Figure 1-2,for troubleshooting. These operations are:

1.

Start and Run:

Establishment of power (electrical and

mechanical) necessary for machine operations. This

includes the operation of the card feed and the

pick-and-hold of the card lever relay.

2.

Interposer Selection:

Engagement of an interposer or

interposers with the punch bail in preparation for

punching.

3.

Escapement:

Advancement of the program drum and of

the escapement-driven feed wheels.

1

Chorocteristics

I

Description

I

Speed:

Manuol punching

Manual duplication

Automatic duplication

Skipping

Releasing

Feed from pre-register to detail

station

Without Print With Print

20 col/sec

18

col/sec

10 col/sec

9

col/sec

20

col/sec

18

col/sec

80

col/sec

80 col/sec

0.250 sec

/

500

cords

I

1

Stacker

1

500

cards

I

Figure

1-1.

Characteristics

I

Figure

1-2.

Operations

Interposer

Selectian

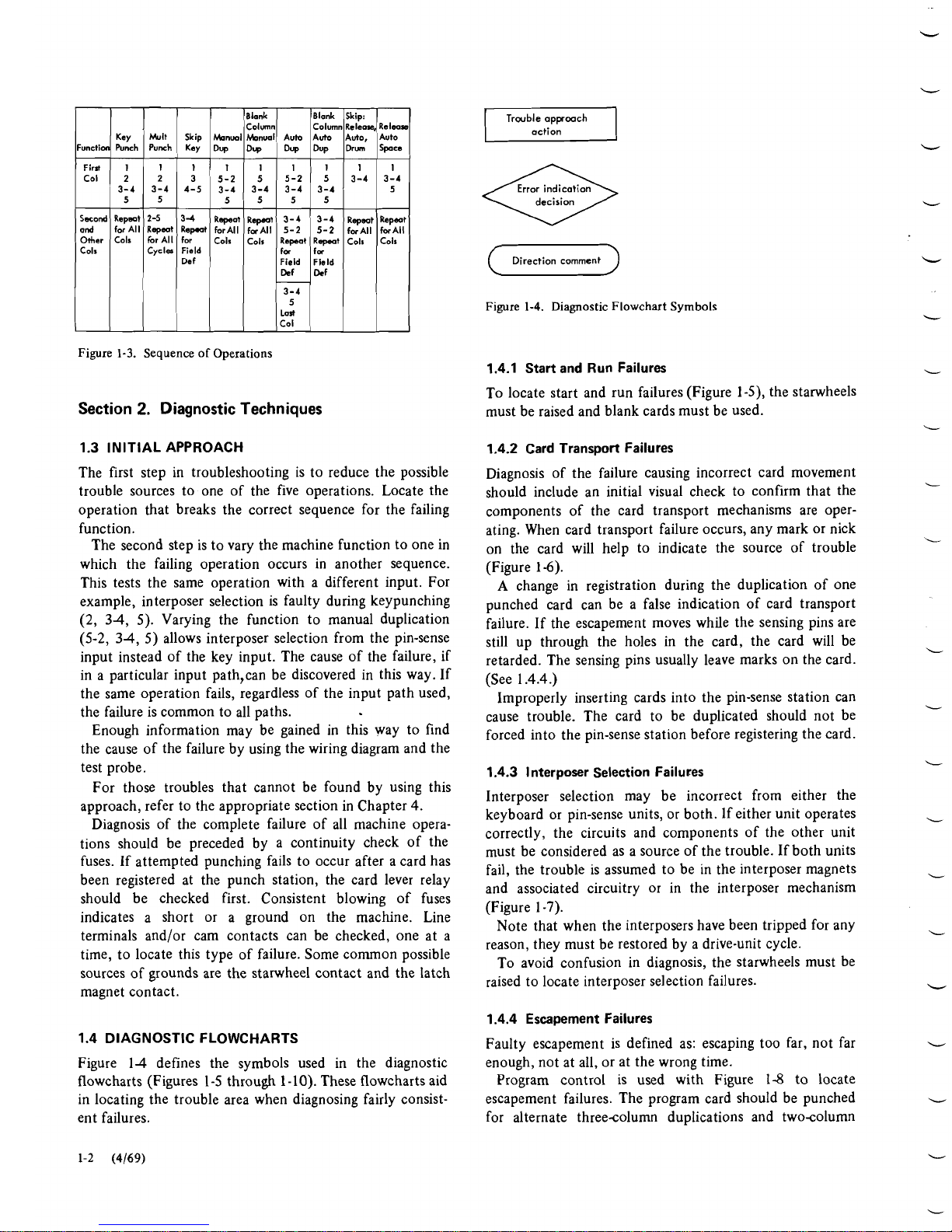

1.2 SEQUENCE OF OPERATIONS

It is essential that the customer engineer be aware of the

correct sequence of operations as they are used

in

any

machine function.

I I I

Escapement

1.2.1 Functions

Punch

Drive

Unit Cycles

When the function is to punch a character from the

keyboard, the sequence of operations is:

1. Start and run

2.

Interposer selection

3.

Escapement

4.

Card transport

5.

Punch drive cycle

Using the numbers only, the sequence is:

1

2

34

5

Showing escapement and card transport (34) side by side

indicates that 'hile 3 causes

4,

they occur at the same time.

Using this notation, the sequence of these operations for

all

of the functions of the

29

Card Punch is shown in Figure

1-3.

The functions shown in Figure 1-3 are the responses of

the machine to the inputs shown here:

Key Punch Press any character.

Multiple Punch Press the multiple punch key and any

numeric key.

Key Skip Press the skip key in numeric or alpha-

betic shift.

Manual Duplicate Press the duplicate key for one or more

columns with no programming.

Blank Column Manual Press the duplicate key for one or more

Duplicate blank columns with no programming

and with the machine

in

alphabetic

shift.

Auto Duplicate Pressing the duplicate key or the reading

of a

"0"

in the program card

in

a

column followed by "12's" in the

program card.

Blank Column Auto Same as "Auto Duplicate" but for blank

Duplicate columnswith the machine

in

alpha

betic shift.

Skip: Release, Auto, Press release key if starwheels

are

upor

Drum if they are down in a column pre

grammed

"1

2".

An

"1

1"

in a program

card. Card-tecard skip.

Release, Auto Space Press release key in a nonprogrammed

field but with the starwheels down.

29

FEMM (4169)

1-1

Blank

Column

(

Direction comment

)

iunctlon

Col

Second

ond

Other

Cols

Figure

1-4.

Diagnostic Flowchart Symbols

Blank

Column

Figure

1-3.

Sequence of Operations

Key

Punch

2

3-4

5

Repsot

forAll

Colr

Section

2.

DiagnosticTechniques

Skip:

Release,

1.3 INITIAL APPROACH

Release

The first step in troubleshooting is to reduce the possible

trouble sources to one of the five operations. Locate the

operation that breaks the correct sequence for the failing

function.

The second step is tovary the machine function toone in

which the failing operation occurs in another sequence.

This tests the same operation with a different input. For

example, interposer selection is faulty during keypunching

(2, 34, 5). Varying the function to manual duplication

(5-2, 34,5) allows interposer selection from the pin-sense

input instead of the key input. The cause of the failure, if

in a particular input path,can be discovered in this way. If

the same operation fails, regardless of the input path used,

the failure is common to all paths.

Enough information may be gained in this way to find

the cause of the failure by using the wiring diagram and the

test probe.

For those troubles that cannot be found by using this

approach, refer to the appropriate section in Chapter 4.

Diagnosis of the complete failure of all machine opera-

tions should be preceded by a continuity check of the

fuses. If attempted punching fails to occur after a card has

been registered at the punch station, the card lever relay

should be checked first. Consistent blowing of fuses

indicates a short or a ground on the machine. Line

terminals and/or cam contacts can be checked, one at a

time, to locate this type of failure. Some common possible

sources of grounds are the starwheel contact and the latch

magnet contact.

Mult Skip

Punch Key

1.4 DIAGNOSTIC FLOWCHARTS

Figure 14 defines the symbols used in the diagnostic

flowcharts (Figures 1-5through 1-1

0).

These flowcharts aid

in locating the trouble area when diagnosing fairly consist-

ent failures.

knml

Dy

First1111I111I

5-2

3-4

Raped

forAll

Cols

2

3-4

5

2-5

Rspmt

krAll

Cycla

1.4.1 Start and Run Failures

To locate start and run failures (Figure 1-5), the starwheels

must be raised and blank cards must be used.

3

4-5

3-4

Revt

for

Field

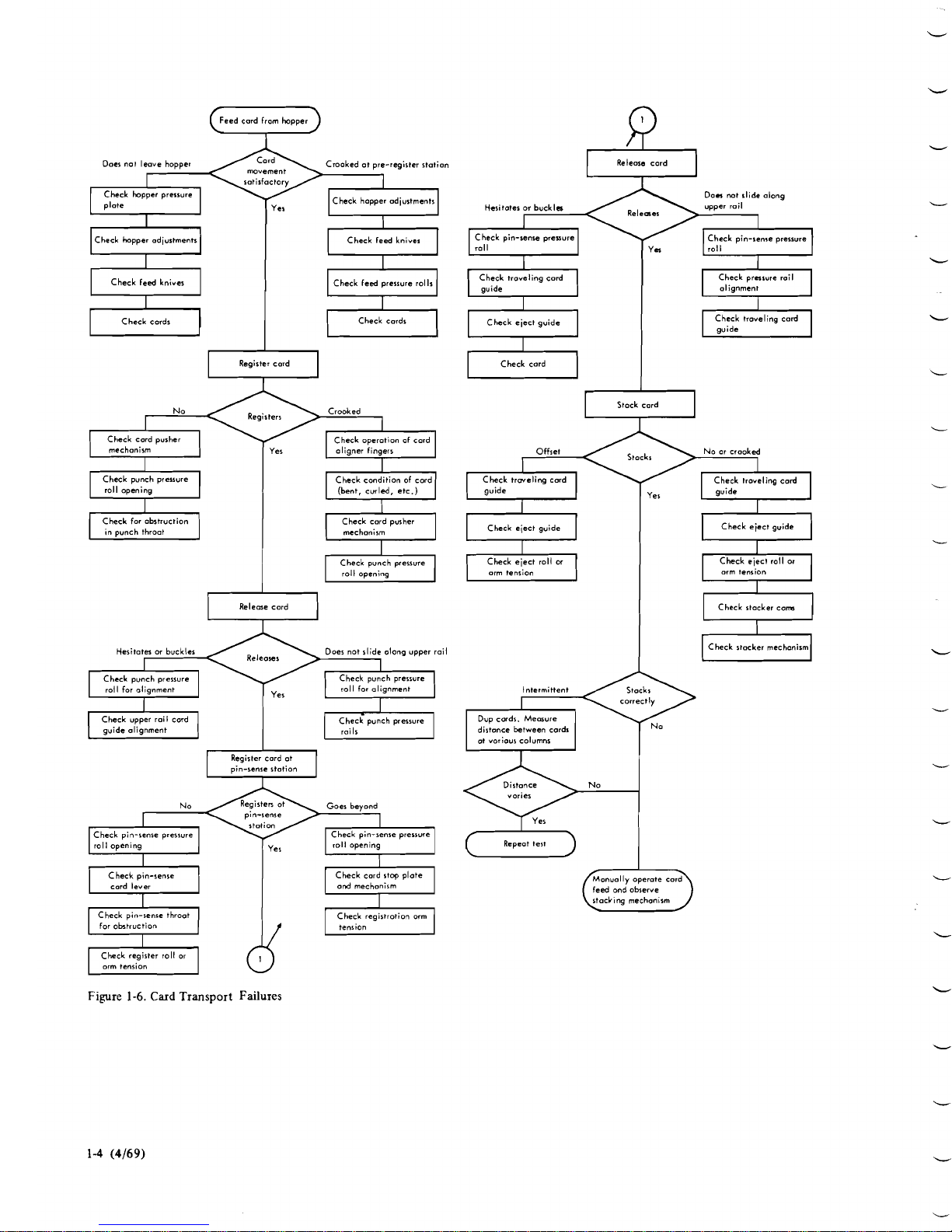

1.4.2 Card Transport Failures

Diagnosis of the failure causing incorrect card movement

should include an initial visual check to confirm that the

components of the card transport mechanisms are oper-

ating. When card transport failure occurs, any mark or nick

on the card will help to indicate the source of trouble

(Figure 1-6).

A

change in registration during the duplication of one

punched card can be a false indication of card transport

failure. If the escapement moves while the sensing pins are

still up through the holes in the card, the card will be

retarded. The sensing pins usually leave marks on the card.

(See 1.4.4.)

Improperly inserting cards into the pin-sense station can

cause trouble. The card to be duplicated should not be

forced into the pin-sense station before registering the card.

~onu.1) Auto

1.4.3

l

nterposer Selection Failures

Auto

Dup

5

3-4

3-4

5-2

R-t

for

Dy

5

3-4

Revt

forAll

Cols

Interposer selection may be incorrect from either the

keyboard or pin-sense units, or both. If either unit operates

correctly, the circuits and components of the other unit

must be considered as a source of the trouble. If both units

fail, the trouble is assumed to be in the interposer magnets

and associated circuitry or in the interposer mechanism

(Figure 1-7).

Note that when the interposers have been tripped for any

reason, they must be restored by a drive-unit cycle.

To avoid confusion in diagnosis, the starwheels must be

raised to locate interposer selection failures.

Dy

5-2

3-4

5555

3-4

5-2

Rspeot

fa

1.4.4 Escapement Failures

Auto,

Dru

3-4

Rspmt

forAll

Cols

Faulty escapement is defined as: escaping too far, not far

enough, not at all, or at the wrong time.

Program control is used with Figure 1-8 to locate

escapement failures. The program card should be punched

for alternate threecolumn duplications and twocolumn

Auto

SPu

3-4

5

Repmt

forAll

Colr

Slowly or overheah No

I

I

(

Check motor start relay

1

Check mainline voltage

Check motor

I

Release ond feed card

a

Check mainline

furer

a

Check motor stort relay

a

Check motor

I

I

I

Check wnchclutch

I

operation

1

Cord ir not fed to pre-register $totion Drum doer not go to column

1

Check cord feed clutch

mechanism

I

Check CF clutch magnet

a

Check cord feed mechanism

Check card lever operation

cord tronrport flowchart

I

Register the cord and

space out

Check skip relay

'-4

to ercopement flow-

chart (Figure 1-8)

Doer not register Nospacing

or

punch drive cycles

Check CF latch mechanism

L

t

I

(

Check CF latchmagnet

/

Check cord lever contact

rl

f

Notrouble found, go

to

ercopement flowchart

(Figure

1-8)

if

no

rpocing,

or

go to

~unchdrive cycler

flowchart (Figure

1-91

ifno punch drive cycles

Figure

1-5.

Start and Run Failures

L

29

FEMM

(4169)

1-3

Feed card from hopper

+

Doer

no1

leave hopper movement Crooked ot pre-register station

$atisfactory

Check hopper pressure

plate Check hopper adjustments

1

Release cord

1

Donnot slide along

Hesitater

or

buckln upper rail

Releeer

Check pin-senre preuure Check pin-$eweprerrvre

Check hopper adjustments

-

Check troveling card Check prnsure roil

Check feed knives

I

I

Check feed pressure rolls

I

Check eject guide Check troveling card

Register card

a

Check card

CI

Regirterr Crooked

Check cord pusher Check operotion

of

cord

mechanism oligner fingers

Stock cord

u

Offset Stocks

No

or

crooked

Check trwcling card Check troveling cord

guide guide

roll opening (bent, curled, etc.)

Check for obstruction Check card pusher

in

punch throot

I

Chcck eject guide

I

I

Check eject gvide

I

Check eject roll or Check

eject

roll

or

roll opening

Releme card

I

Check stocker cons

u

Heritat-

or

buckles

I.

-oes not slide

along

upper rail

-7

Check stacker mechonirm

D

Check punch pressure

roll for nlignment

Dup cards.

Measure

\

at

various

columns

No

Goes beyond

I

I

Check pin-senre prerwre

I

I

Check pin-sense pressure] Repeot test

m

I

roll o~enina

I

roll opening

I

feed

ond

observe

stacking mechanism

Check regirtrotion orm

I/

Figure

1-6.

Card

Transport Failures

and olphobatic

character

keys

Check interposer relotch

a

Check keyboardrestore No

selected

Check interposer relotch Check interpan magnet

Check pin-sere contoch

v

Check cornmar bar

=?

Check throot plates and

Check inkrpoler

Check keybodshift ckt

w

Check

for

mopat impulse.

If

no

~ulre,proceed

to

Check kybordcontoch

1

Check mtorecircuit

a

Check pin-tare contoch

+

Check rmingpin

=7

Check codregirtrotion

Figure

1-7.

Interposer Selection Failures

29

FEMM

(4169)

1-5

A. Alphabetic Duplicate switch off. kev duo

.,,

(

olphobetic and blank

)

Extra column

or

ot wrong time

Check 12 program contact and circuit

Check dup reloy retup

Check PI cam contact Check escape circuit

to interposer selection

flowchart (Figure 1-7)

0. Numeric

Duplicate

and Skip

Yer

auto dup 011 I2digits,

Perform Bond C

Check dup relays

a

Check dup circuits

-

No

trouble found, go

(-1

to interposer selection

flowchart (Figure 1-7)

Too far No Yer (nicked

or

torn holer)

Check retup of IBC

-

Yes

I

Check ercope circuit

I

No

to interpmer selection

flowchort (Figure 1-7)

Perform A and C

C

Check escapement

interlock relay

Check PI cam contact

Check that punch

interposer is

engaging bail

I

Figure

1-8.

Escapement Failures (Part

1

of

2)

Check

0

pragrom cantoct

Check auto rkip/dup

switch

Check dup reloy

I

I

Check PI timing and

duration Check 12 program contoct

Check punch clutch

Check escape interlock

relay

Check dup relor

Check dup circuit

C.

Ksv

Punch

Perform

A

and

B

Check escape

mechanism

Tm

far

No

I

Check drive

gsa

train

+

Check FC torque

Check

PI

cam contact

Check

FC

torque

or

escape

mognet

onolyre original

foiling condition

I

I

Figure

1-8.

Escapement

(Part

2

of

2)

skips through column 38. This is followed by a 25column

skip (ending

in

column 63), an llcolumn alphabetic

duplication, a Scolumn skip, and duplication of column

80.

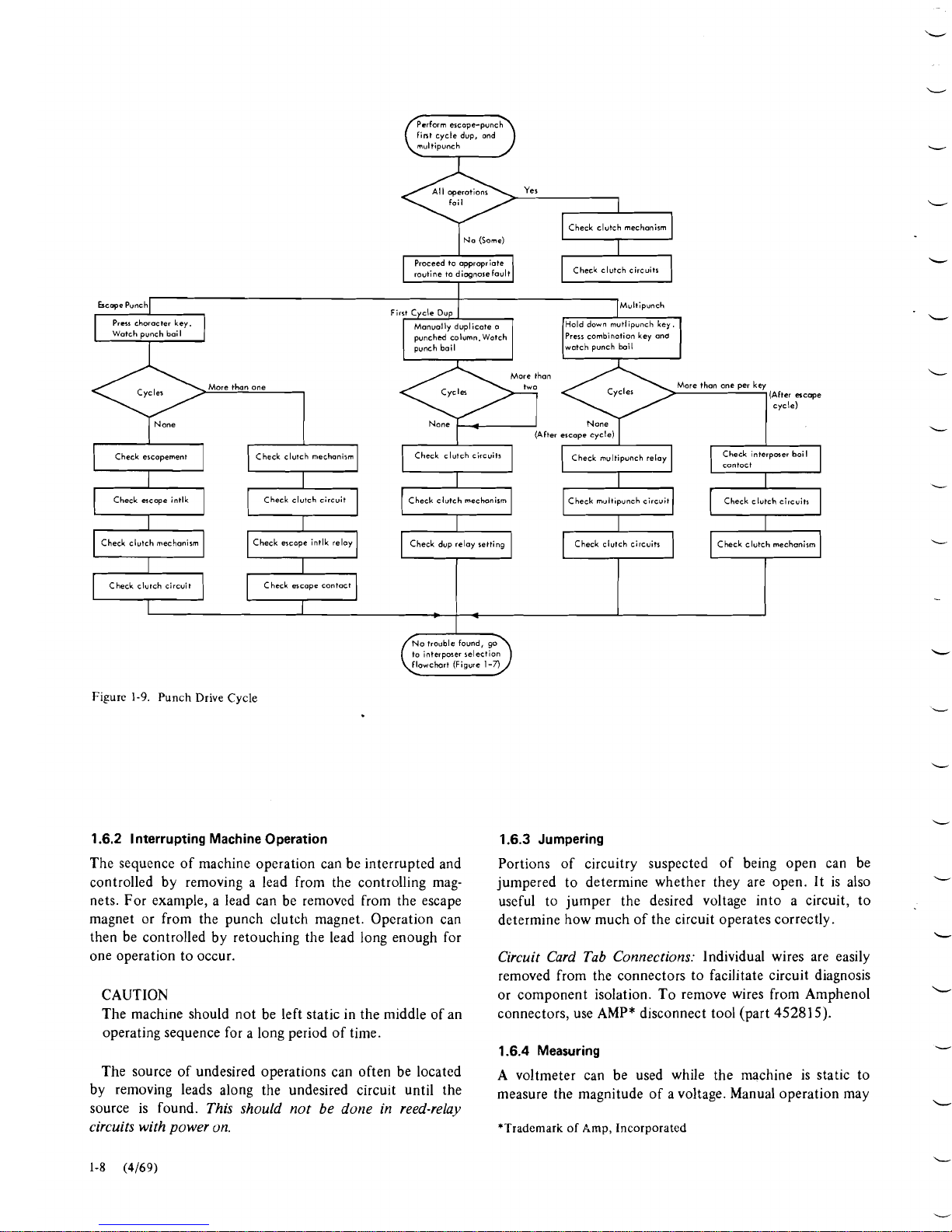

1.4.5 Punch Drive Cycle Failures

Locate punch drive cycle failures with the starwheels raised

(Figure 1-9). Diagnosis of clutch failures should include an

initial manual cycle of the punch drive unit. Incorrect

clutch overthrow or a defective detent can be found while

performing this operation

1.4.6 Printing Control Failures

The program card used for locating escapement failures can

be used for locating programmed printing failures. Diagnos-

tic flowchart is Figure 1-10.

1.5 MACHINE SERVICE FEATURES

The 29 Card Punch has two diagnostic features that have

been incorporated to aid the customer engineer. These are:

Motor switch

Test probe

1.5.1 Motor Switch

The motor switch turns the motor off and allows other

areas of the machine to remain energized. It is useful when

manually cycling the machine. Some adjustments are made

with the motor stopped.

1.5.2 Test Probe

The test probe (Figure 1-1

1)

contains a neon indicator in

series with

a

resistor. One lead of the indicator is connected

to the power supply. The other lead is used to trace circuits

leading tocoils or magnets. A jack is provided on the power

supply chassis.

CAUTION

Care must be used when probing relay points because the

point of the probe might spread the pin connectors and

cause the reed switch to make poor contact or break the

pin. Be careful in the use of the test probe; an accidental

short could tack several relay points. The probe should

not be used to estimate circuit voltages. Use the meter for

voltage measurements.

Reed relays should be probed through the top of the

bobbin because the vertical rows of holes on the land

pattern for a particular relay position do not, in all cases,

connect to the relay connector.

Note: When probing P3, a false indication may occur; P3

appears not to make. This is due to the timing relationship

between the short duration of P3

(7

ms) and the 60-Hz

negative line pulse used to bias the probe.

1.6 SERVICING TECHNIQUES

1.6.1 Forcing

Extra pressure can be applied to various components to

simulate malfunction. For example, the friction drive can

be forced or retarded manually at the top of the program

drum, or finger pressure can be applied to the escape

magnet armature tohelp or hinder its operation. Magnetism

of the escape magnet can be detected, and its strength

estimated with any lightweight steel blade (screwdriver or

burnishing tool).

29

FEMM

(4169)

1-7

fint cycle dvp, ond

multipunch

I

Na

(Some)

v

routine to dimnose fault Check clutch circuits

Multipunch

punched column.Watch

Prerr

combination key

and

punch bail watch punch boil

Prcsr

character

key.

Cycler

More

than

one

per key

cycle)

I

(After ercape cycle)

I

I

Check ercopement Check clutch rnechanirm

1

Check clutch circuits

I

(

Check multipunch relay Check interpaer bail

I

Ic~"toCt

Check escope intlk Check clutchmechanism Check multipunch circuit Check clutch circuits

Check clutch mechanism

a

Check dup relay setting Check clutch circuits Check clutch mechonirm

Check clutch circuit Check escape contact

to interposer relection

flowchart

(Fioure

1-n

Figure

1-9.

Punch Drive Cycle

1.6.2 InterruptingMachine Operation 1.6.3 Jumpering

The sequence of machine operation can be interrupted and

controlled by removing a lead from the controlling mag-

nets. For example, a lead can be removed from the escape

magnet or from the punch clutch magnet. Operation can

then be controlled by retouching the lead long enough for

one operation to occur.

Portions of circuitry suspected of being open can be

jumpered to determine whether they are open. It is also

useful to jumper the desired voltage into a circuit, to

determine how much of the circuit operates correctly.

Circuit Card Tab Connections:

Individual wires are easily

removed from the connectors to facilitate circuit diagnosis

or component isolation. To remove wires from Amphenol

connectors, use AMP* disconnect tool (part

452815).

CAUTION

The machine should not be left static in the middle of an

operating sequence for a long period of time.

1.6.4 Measuring

The source of undesired operations can often be located

by removing leads along the undesired circuit until the

source is found.

This should not be done in reed-relay

circuits with power on.

A voltmeter can be used while the machine is static to

measure the magnitude of a voltage. Manual operation may

*Trademark of Amp, Incorporated

kypunch

and

dup

all chamctan

Prink

Chock print wppms

mechanism

With print switch

on

md

stamheals up, ke+unch

I

adprint al; ~horiton

1

Check platen

Q

Wrong, smudgy, or

toa

light No

I

for

obstruction

Check ribbon

chomcterr under progrom

control

Check print suppras

circuit

Check print switch

Q

I

I

I

Chock print switch

I

Check pintdrive

No

Check print relay

contach

I

Check print wpposs

magnet circuih

f-l

Ym

Ym

No

Notroubles

found, see

4.11

Extranwm

xua

No lmt chaacter

Invufficient zem

Chock print relay pick

circuit

Check print relay

-

Check print suppress

I

Cbck print suppress

I

circuit

I

Check

I2

stowh..l

Check print suppress

mochmim

Chock print supprau

I

Ckk

LZ

switch

I

No

Chak card

Iwu

relay

a

mechanism

Check ac-o interlock

a

I

Check

12

programcontac

(pint relay hold circuit)

Chak

U

print switch

m

CWpintrelay

m

Figure

1-

10.

Print Control

Failures

29

FEMM

(4169) 1-9

S225-3357-3

FES:

SS234069

Figure

1-1

1.

Test Probe

1.6.6.3

Reed

Relays

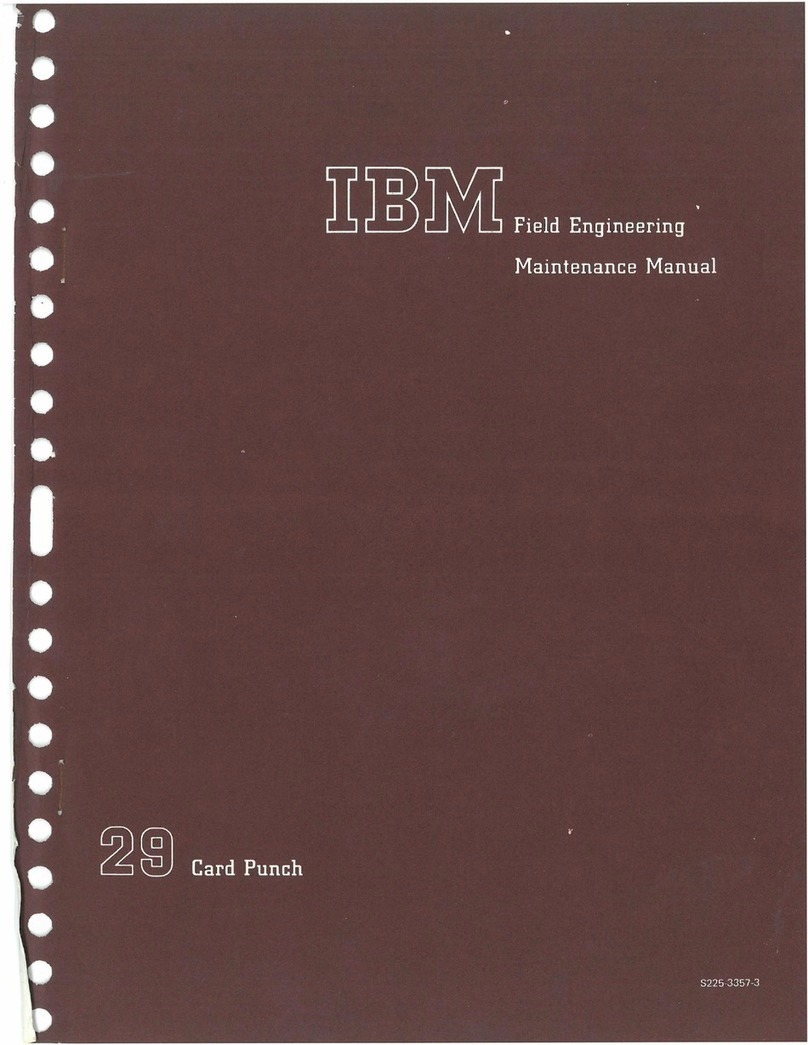

When inserting reed relays on the circuit board, care must

be exercised not toexert pressure on the coil portion of the

relay. Pressure exerted on the coil can cause the relay to

flex, and breakage of the glass reed switch may occur. To

prevent this breakage, the relay must be positioned and

pressed on the card with -equal pressure exerted on each of

the plastic ends of the relay (Figure 1-12).

A short caused by a defective part or a slip of the hand

while troubleshooting could damage several relays. All

relays in the circuit between the short and the line should

be checked because the sudden surge of current could cause

the interceding relay points to weld or develop a tacking

condition.

Do nor remove or replace relays during a

machine cycle.

If tacking is suspected, do not jar the machine because

the tacking problem may disappear temporarily.

Do not

interchanfe relnys or relay

types.

If the relay used does not

-

.

.-

have a hold coil, do not put one that has a hold coil in its

be performed to determine the timing of circuit breakers. place.

DO

not interchange relay reeds

The individual relay

The voltmeter can also be used while the machine is

reeds

are

matched

and

should

not

be

interchanged

by

operating, to detect the presence and relative magnitude of disassembly or use of ones from other relays.

Ihe "Itage'

Remember.

when

measuring power Repeated relay insertions and removals

can

caur

the glass

with no secondary fuse, a short in the secondary indicates envelope to break; Berg connectors may lose tension and

little or no voltage.

A

secondary short may not blow the cause intermittent failures. Check connector alignment with

primary fuse. a 0.010-inch feeler gage, aligning it with adjacent con-

1.6.5 CyclingManually

nector.

Turn the motor switch off. Observe machine functions

while manually operating the escapement gear train and the

punch clutch. This allows voltages to be checked at any

time during the machine cycle.

1.6.6 InterchangingUnits

Keyboards, relay boards, or relay gates may be inter-

changed with other machines of the same type and feature

configuration. This can help isolate suspected units when

diagnosing intermittent troubles.

1.6.6.1

Relay Gate

The relay gate in either type of machine is easily remove-

)

able. In the reed-relay machine, slide the relay gate out of

the guide tracks through the slots provided. In the

wire-contact relay machine, first slide one tab out of the

slot, then slide the other tab out.

1.6.6.2

Arc

Suppression

Figure

1-1

2. Reed Relay

Insertion

Arc suppression is necessary for the proper operation and

longevity of the reed-relay switches. If trouble is suspected

in an arc suppression network, it

must

be substituted with

1.7 DIFFICULT-TO-ANALYZE AND INTERMITTENT

another.

FAILURES

There are some sources of trouble

in

the

29

Card Punch

CAUTION that cause varying results and are difficult to diagnose.

Removal of arc suppression for diagnosis can cause Among these are:

considerable damage as well as faulty operation.

I

1.

Friction drive totque (too much, too little, or erratic)

Other manuals for 29 CARD PUNCH -

1

Table of contents

Other IBM Computer Accessories manuals

IBM

IBM 77 User manual

IBM

IBM Multimedia Kit for RS/6000 Manual

IBM

IBM 29 CARD PUNCH - User manual

IBM

IBM ThinkPad Dock I User manual

IBM

IBM IBM ThinkPad Multi-Burner PlusUltrabay Enhanced... User manual

IBM

IBM WAVV 2004 User manual

IBM

IBM THINKPAD A30 Installation and operation manual

IBM

IBM THINKPAD 92P1836 User manual

IBM

IBM Wireless Keyboard and Mouse User manual