2141 ICON Way, Vacaville, CA 95688 ‐Tel: 707.564.4000 –www.iconaircraft.com

SERVICE LETTER

SL-042820 REV A

ICA009717-E PAGE 3 of 9

Notes

1. Read repair instructions in their entirety before proceeding with this repair. Any questions

regarding interpretation of this disposition shall be forwarded to engineering immediately.

2. Unless otherwise specified, the following requirements apply when bonding features or

performing wet lay-up repairs:

2.1. No sprays, release agents, uncured silicone, or silicone-based lubricants shall be allowed

in the vicinity of the repair area.

2.2. Prior to application of adhesive, protect any areas that should not come in contact with

adhesive (fittings, hardware, exterior surfaces, etc.).

2.3. Unless otherwise specified, follow adhesive manufacturer's recommendations for material

handling, preparation, application, cleanup, and curing. Repair shall be completed (i.e.

bond closed, or wet lay-up repair placed under vacuum) within adhesive work life.

3. Composites are highly susceptible to impact and delamination damage. When breaking

bonds, be very careful not to damage the laminate of either substrate. Any damage will

require additional review by ICON Aircraft before proceeding with the repair.

4. During damage removal and tapered blend operations, be careful not to damage surrounding

structure, including adjacent parts, integral core, etc.

5. During any cutting or abrading process, ensure that the laminate is not over-heated; all

substrate materials must be protected from excessive temperatures (exceeding 200 °F).

6. When curing Hysol EA 9394 or EA 9396, use the following cure schedule:

6.1. Initial-cure the laminate or bond at 110-120 °F for 55-65 minutes.

6.2. Post-cure the laminate or bond at 190-200 °F for 55-65 minutes.

7. For bonded joints, Hysol EA 9394 paste adhesive shall be applied in a quantity sufficient to

meet bond gap requirements, such that the joint will be completely filled over the faying

surface with no areas void of adhesive. Excessive squeezout of adhesive shall be removed.

All edges of bond shall be filleted where possible.

8. For bonded joints, bondline thickness shall be 0.040 +/- 0.020 inch. Apply clamping pressure

as required to achieve the required bondline thickness. Clamping pressure shall not be

released until bond is at least initially cured. Do not apply, remove, and re-apply clamping

pressure, as this will cause air entrapment. If removal of a component is required, re-prepare

the joint in accordance with ICA010822.

Instructions

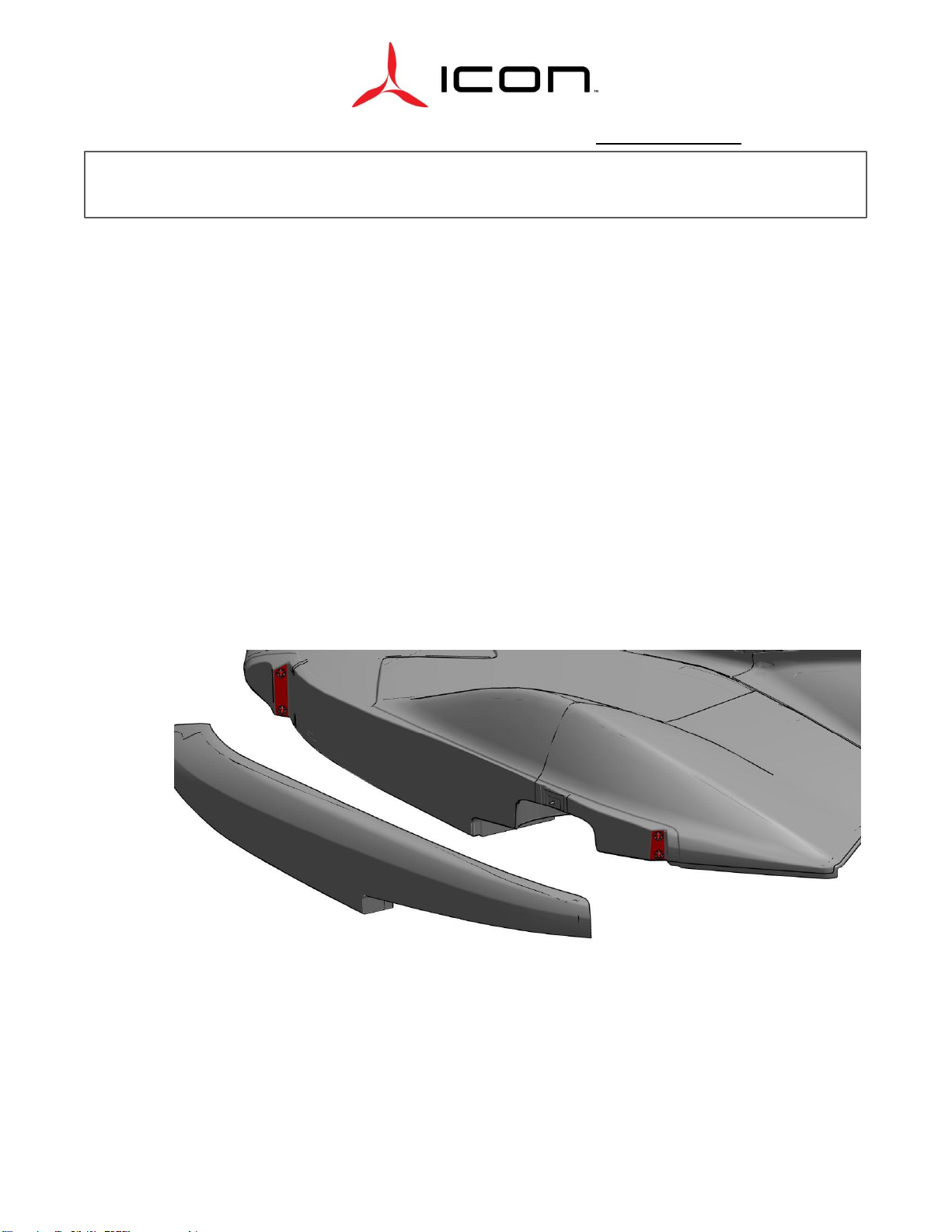

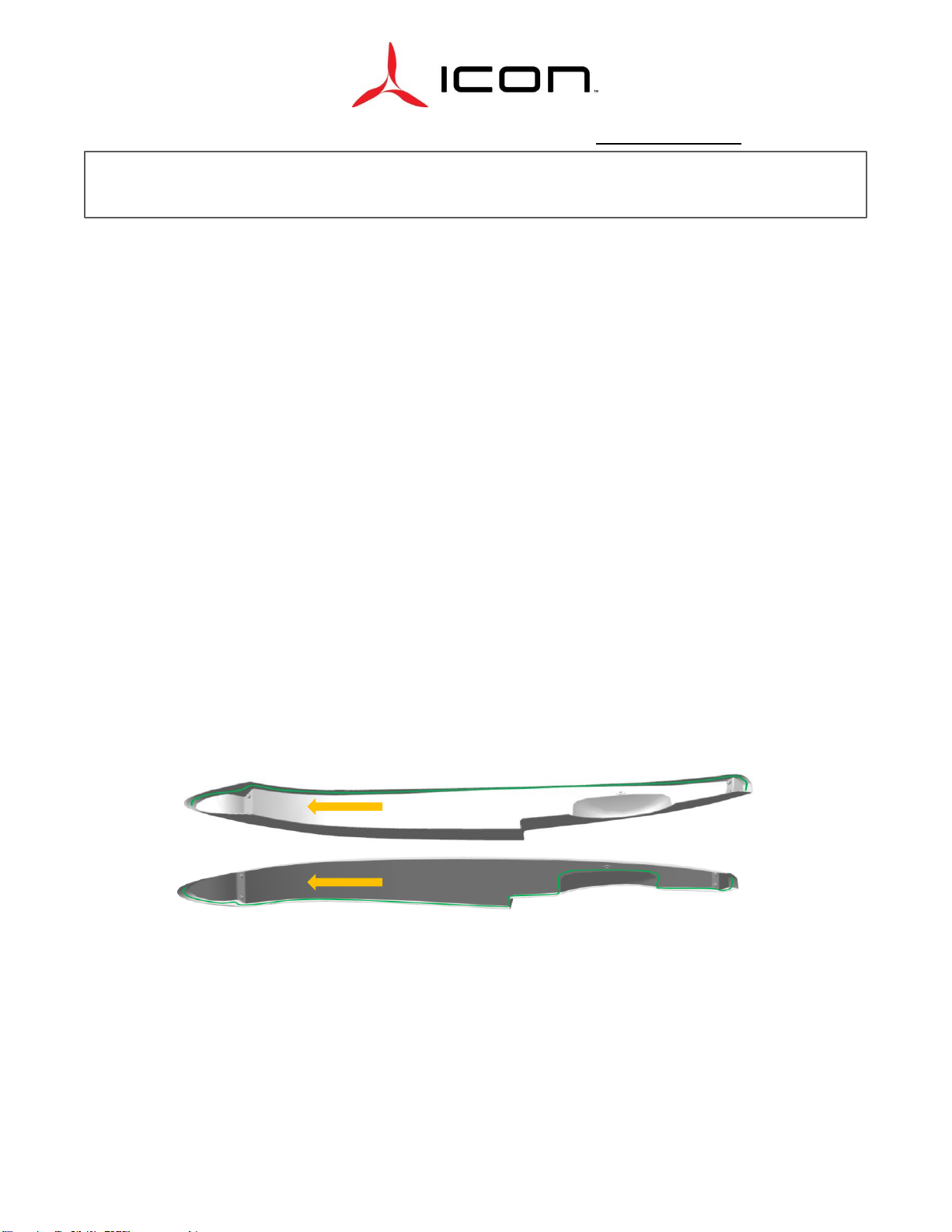

1. Carefully cut away the seawing studs and bushings as required. Studs may also be removed

by gently heating using a heat gun.

a. All substrate materials must be protected from excessive temperatures (exceeding 200

°F) during the application of heat to soften adhesive materials when breaking bonds.

Excessive temperatures can cause disbond, delamination, and blistering of composite