4

4 - INSTALLATION INSTRUCTIONS

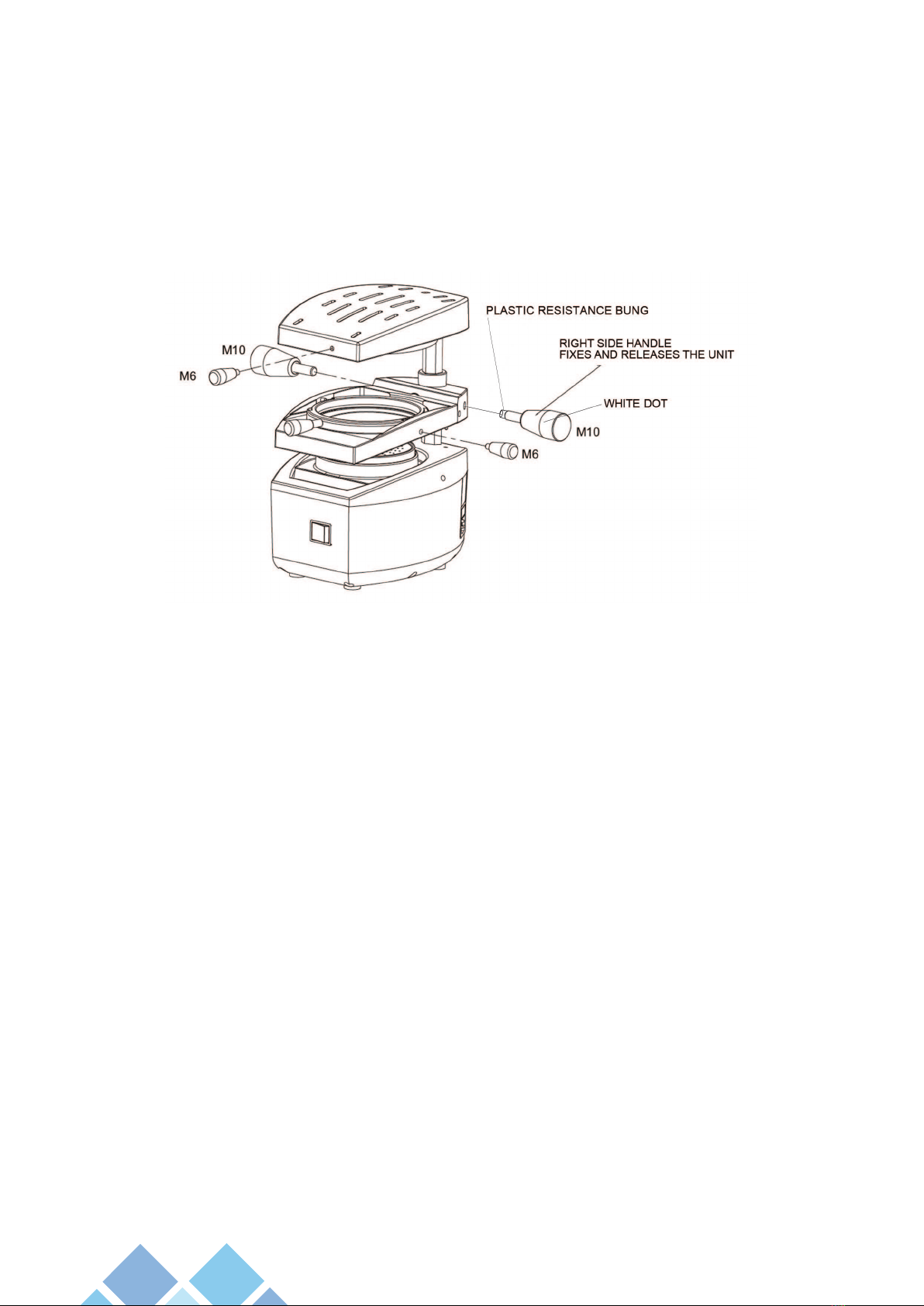

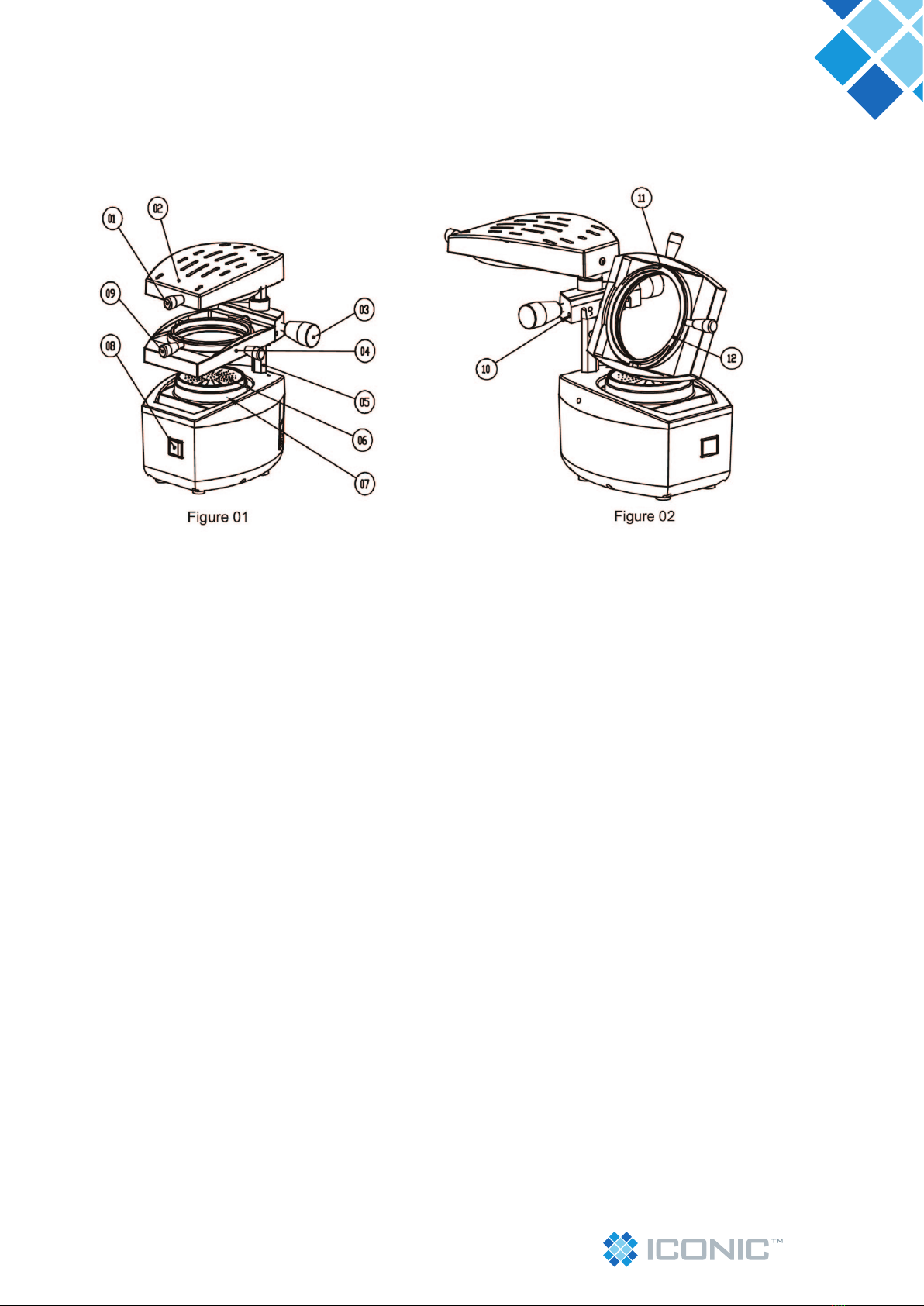

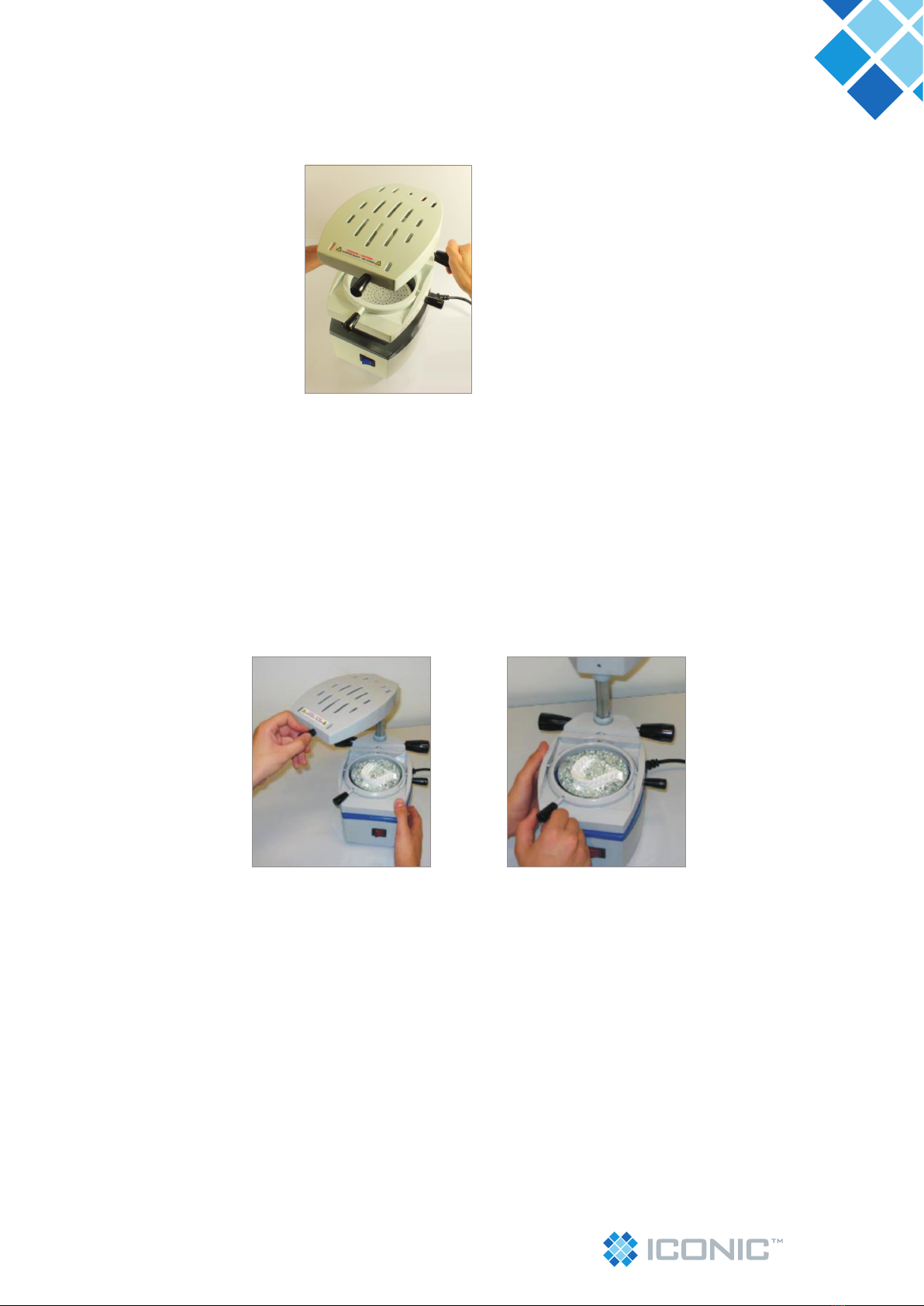

• Before the installation of the machine, mount the handles packed separately inside the packaging. These must be

mounted in the plasticizer before its installation, as shown in the illustrative drawing below;

• There are two (2) identical shorter M6 thread handles, one for the heating unit and one for the rotary ring and two

(2) longer vacuum driving M10 thread handles.

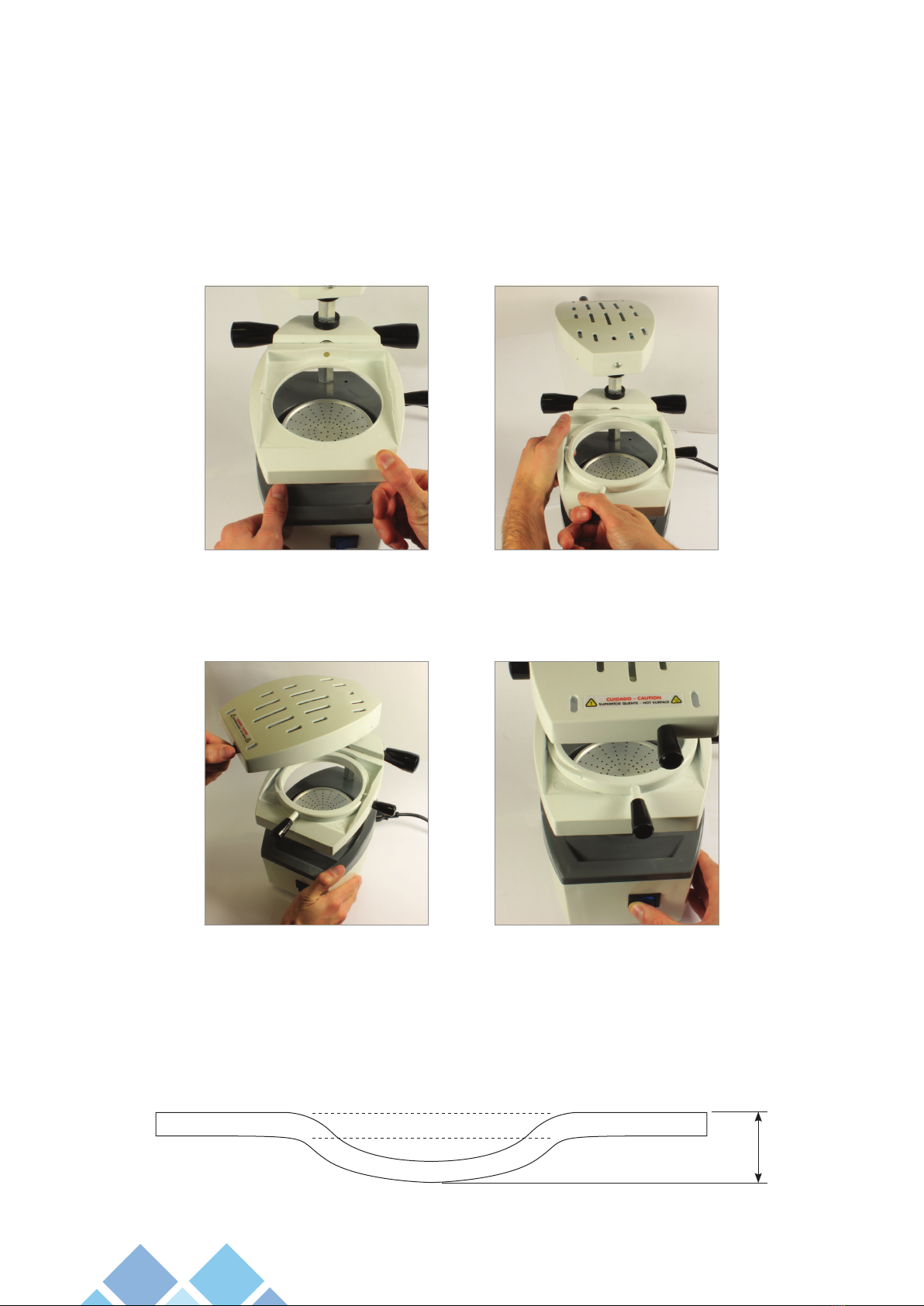

• Mount the handles according to drawing below, screwing them clockwise until you feel resistance of the thread end;

• Important: The right vacuum driving handle also has the function to x and release the plate setting unit, therefore

it must be threaded until a slight resistance of the thread end is felt and then release it half turn in the counter-

clockwise direction.

Note: Except for the right vacuum driving handle, the handles cannot be loose and must be tightened manually only,

do not use any type of tool to install them.

• The machine must be installed in a ventilated area, free from moisture and excessive heat and placed on a table or

at bench. Do not build in and do not leave any material between the supporting base and the machine bottom so

that this area can be free to allow air out and refrigerate the motor;

• Keep the machine away from heat sources or liquids (approximately 1 metre);

• It is advisable to install a bipolar protection device (bipolar circuit breaker) in the electric network where the

machine will be installed, for phase disconnection in case of possible failures;

• Do not use extension plugs or any other type of similar connection to run the machine in the same outlet where

other equipment is installed;

• Important conditions for the ideal operation of the machine:

• Use the machine in a sheltered area;

• Room temperature between 5°C and 40°C;

• Maximum relative humidity 80%;

• Maximum altitude 2000m;

• Voltage variations allowed for power supply: ±10% of the rated voltage.

Attention:

If the machine is not used in accordance with the specications described in this chapter, the safety and functionality of

the product may be put at risk.