GW-7553-CPM PROFIBUS/CANopen GATEWAY User Manual (Version 1.00, Apr/2016) PAGE: 3

Table of Contents

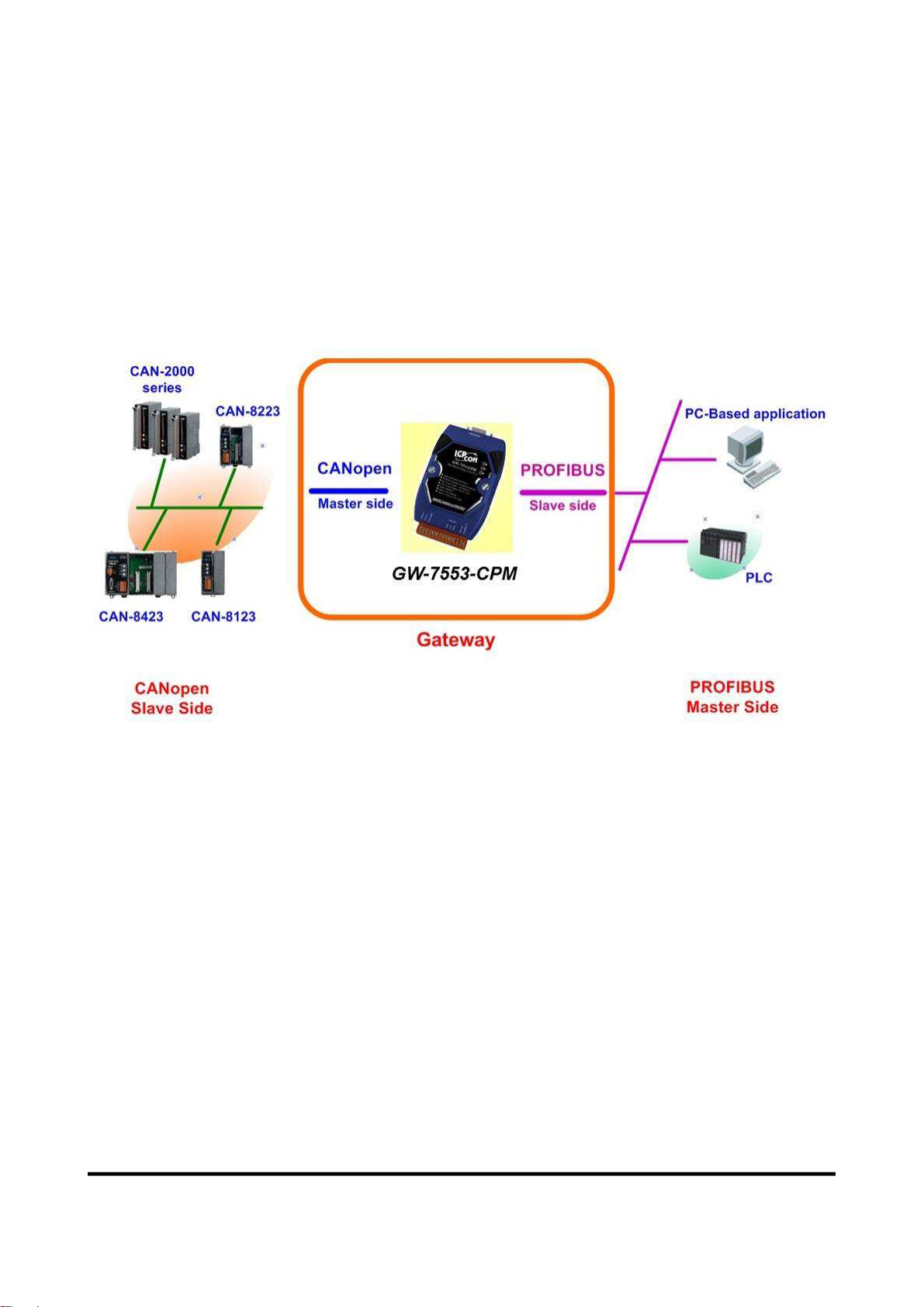

1. Introduction 4

1.1 Features ·······························································································4

1.2 Modules Support····················································································5

1.3 Specification··························································································5

2. Hardware 7

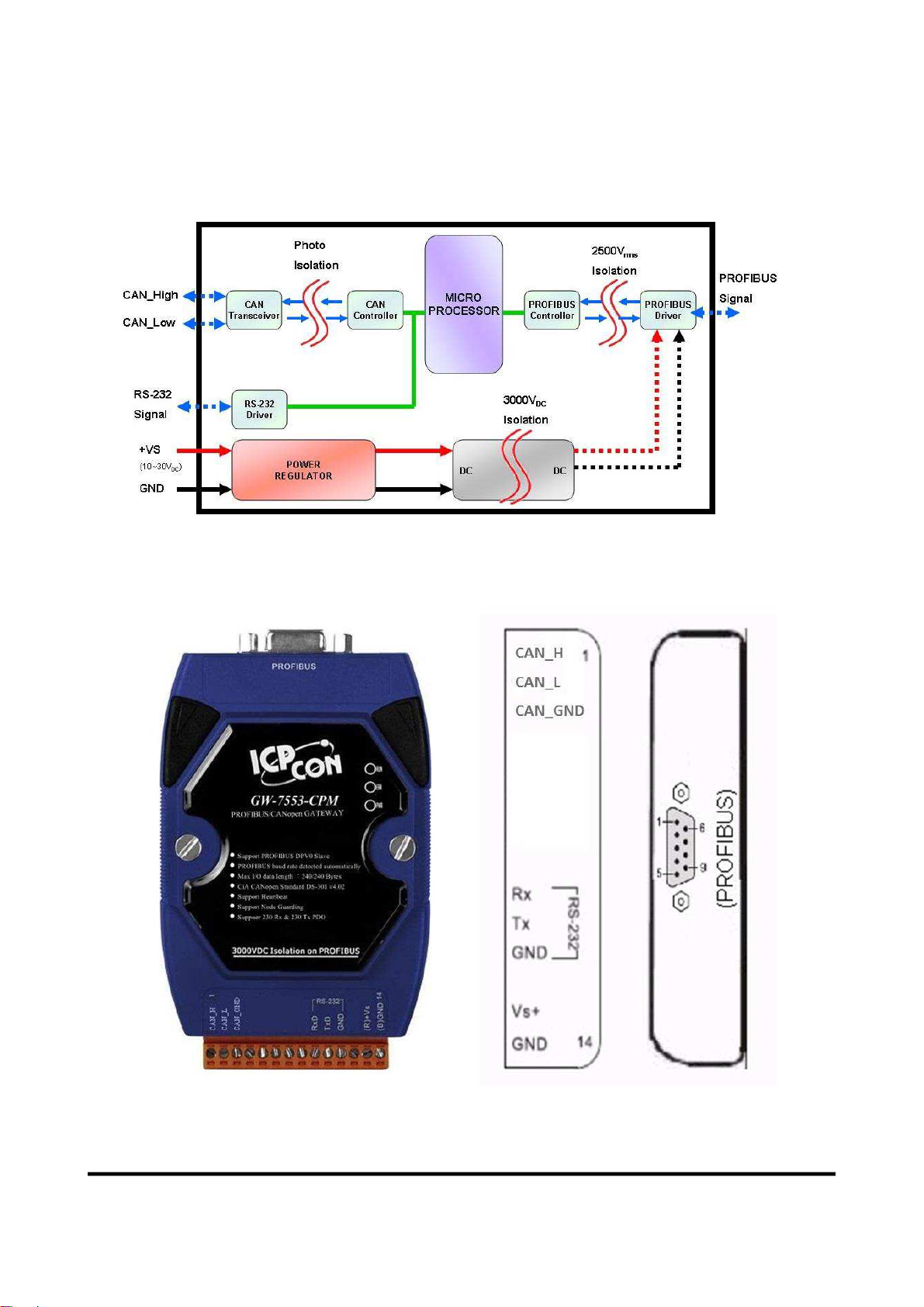

2.1 Block Diagram of GW-7553-CPM ······························································7

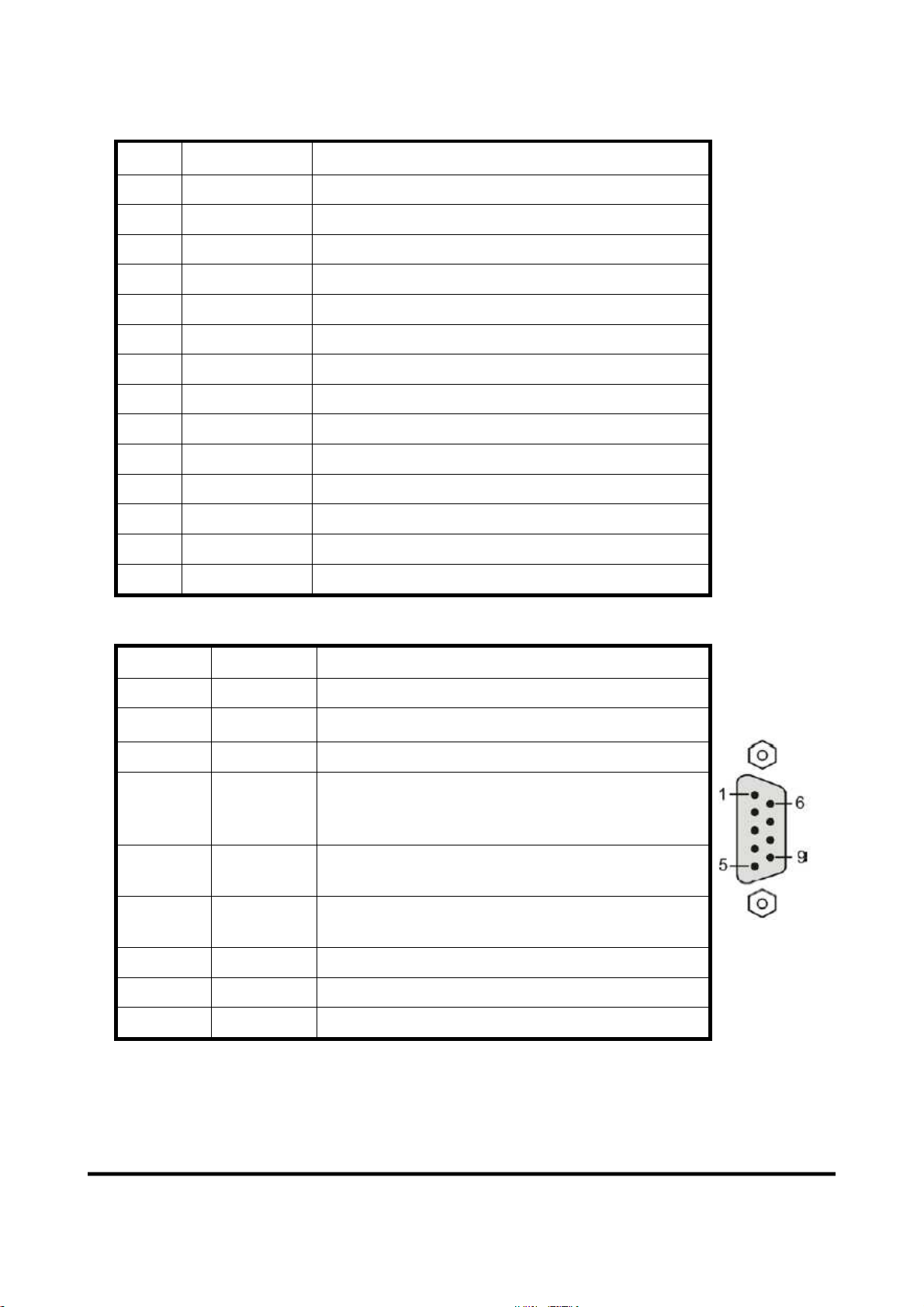

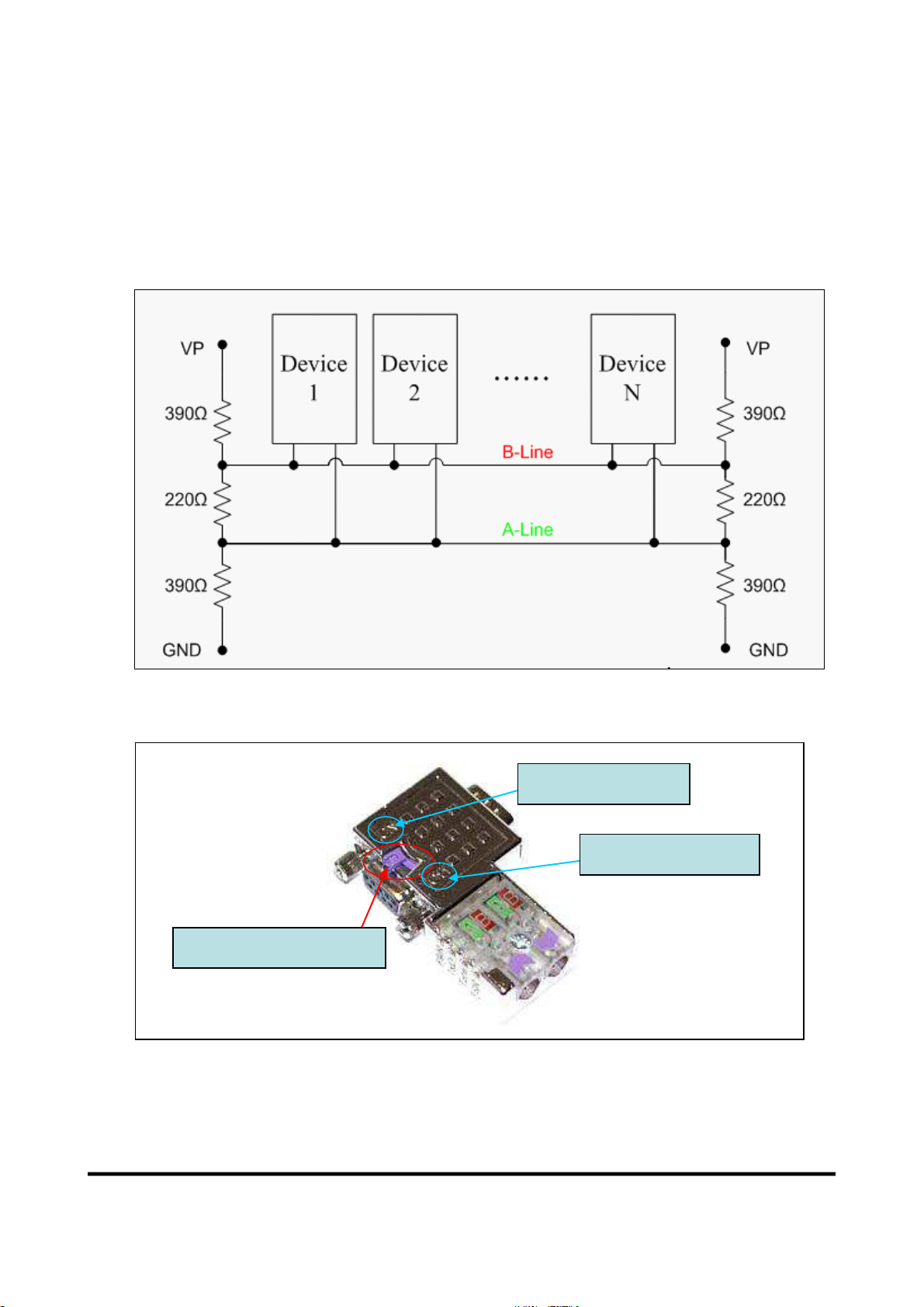

2.2 Pin Assignment······················································································7

2.3 Wiring································································································· 8

2.4 Setting the PROFIBUS Address······························································· 12

2.5 LED status indicator ············································································· 13

2.6 Normal/Setting Dip Switch ····································································· 14

3. Communication protocol transfer theorem 16

3.1 PROFIBUS data exchange······································································ 16

3.2 CANopen data exchange ········································································ 17

3.3 Communication protocol transfer····························································· 18

4. Communication 19

4.1 Field of application ··············································································· 19

4.2 GSD file ····························································································· 21

4.3 The Configuration of the modules····························································· 23

4.4 Diagnostic messages ·············································································· 23

4.5 I/O data exchange················································································· 24

5. Application of Utility 26

5.1 Install Utility······················································································· 26

5.2 Utility introduction ··············································································· 26

6. Troubleshooting 33

7. Dimensions 34

ГК Атлант Инжиниринг – официальный представитель вРФ иСНГ