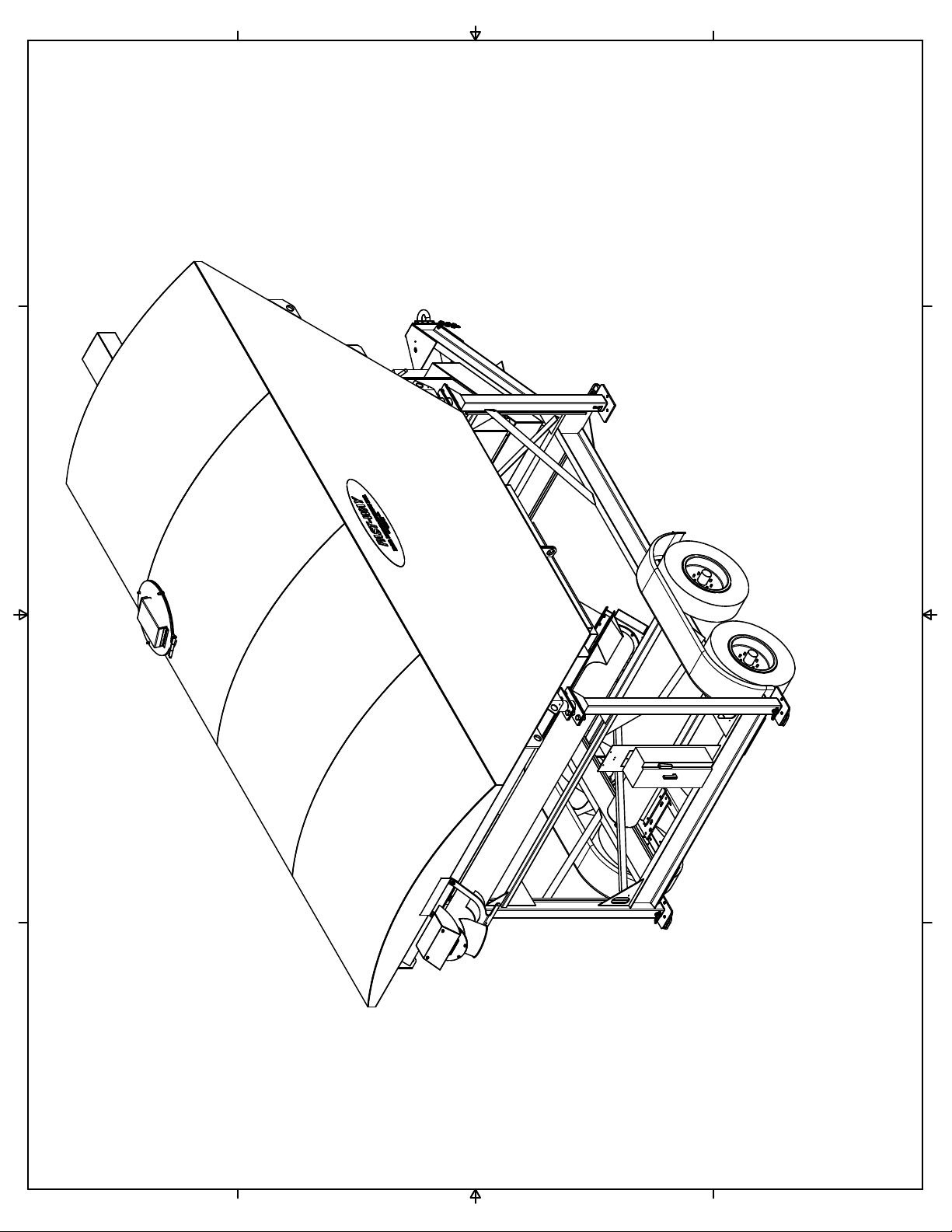

IDEAL FAST-WAY Si-Low 210 A1 User manual

Si-Low 210-A1

TABLE OF CONTENTS

DESCRIPTION PAGE #

Fast-Way Limited Warranty Policy

Si-Low 210 A1 Over View

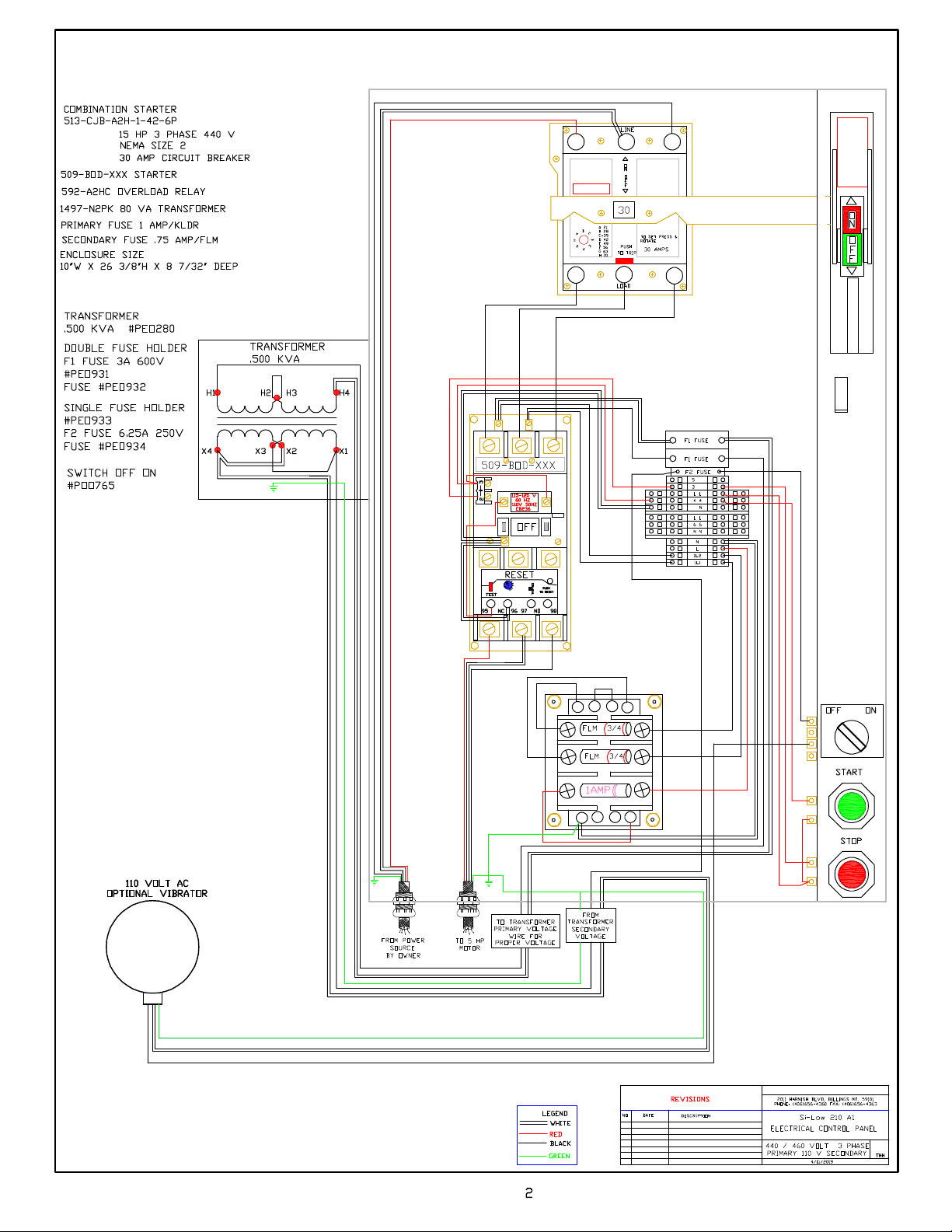

Electrical Control Panel 440/460 volt 3 phase 2

Electrical Control Panel 240 volt 3 phase 3

Main Component List 4

General Layout 5

Preparing Silo for Transport 6

Set Up Procedure 7

Safety Rules 8

Sumitomo Gear Box Lubrication 9

Operating Procedure 10, 11

Auger Speed Reducer & Electric Driven Motor 12, 13

Auger Drive Assembly with Guard 14, 15

Auger to Slide Gate to Silo 16, 17

Upper Bearing Assembly 18

Optional Control System 19

Bag-house Assembly 20,21

Maintenance of Bag-house 22

Adjustable Legs & Load Cells 23

Silo Trailer Wheel Components 24

Vibrator & Aeration System 25

Vibrator & Optional Pulse Aeration Wiring 26

Man Hole 27

Electrical Connector for Towing 28

12Volt DC Wiring 29

Slide Gate Assembly 30, 31

Electrical Control Panel 440/460 volt 3 phase with Remote 32

Electrical Control Panel 240 volt 3 phase with Remote 33

Load Cell J Box wiring diagram 34

Fuel Tank 35

Cardinal Scale Manual

Cyclo Gear Box Manual

FAST-WAY LIMITED WARRANTY POLICY

Ideal Manufacturing, Inc., hereinafter referred to as “Manufacturer” warrants FAST-WAY

equipment to be free from defect in material and workmanship, under normal use and service,

for a period of one (1) year from the date of original purchase. Manufacturer will, at its

option, replace or repair at factory in Billings, MT, any part or parts which shall appear, to

the satisfaction of the Manufacturer, upon inspection at its factory, to have been defective in

material or workmanship. This warranty does not obligate the Manufacturer to bear any

transportation charges in connection with replacement or repair of defective parts. This

warranty excludes electrical components and damage due to Acts of God, unauthorized

modifications, misuse, abuse or negligence to this product.

In order to proceed with a warranty claim, Ideal Manufacturing must be notified of the

problem. A new part will be shipped out prepaid (Ground UPS). If the customer requests

that the part be expedited that shipping charge will be charged to the owner.

The part that is being warranted must be returned to Ideal Manufacturing postage prepaid.

When the new part is shipped out, it will go out with an invoice and a warranty part return

number. The defective part must be returned to Ideal Manufacturing, Inc freight prepaid, with

the warranty part return number. At that time the invoice will be considered paid in full.

This warranty is exclusive and in lieu of all other obligation, liabilities or warranties. In no

event shall Ideal Manufacturing be liable or responsible for incidental or consequential

damage or for any other direct or indirect damage loss, cost, expense or fee.

This warranty shall not apply to any products or parts that have been altered or repaired

without written consent of Ideal Manufacturing.

Labor to remove and reinstall defective product or parts will be paid from a labor rate and

schedule only. Consult Ideal Manufacturing for that rate and schedule.

For further information on returning your product or questions concerning Ideal

Manufacturing warranty, please contact Ideal Manufacturing.

Ideal Manufacturing Inc., 2011 Harnish Blvd., Billing’s, Montana 59101, 1-800-523-3888 toll free, 1-406-656-4360 phone, 1-406-656-4363 fax

1

1

2

2

3

3

4

4

A A

B B

C C

D D

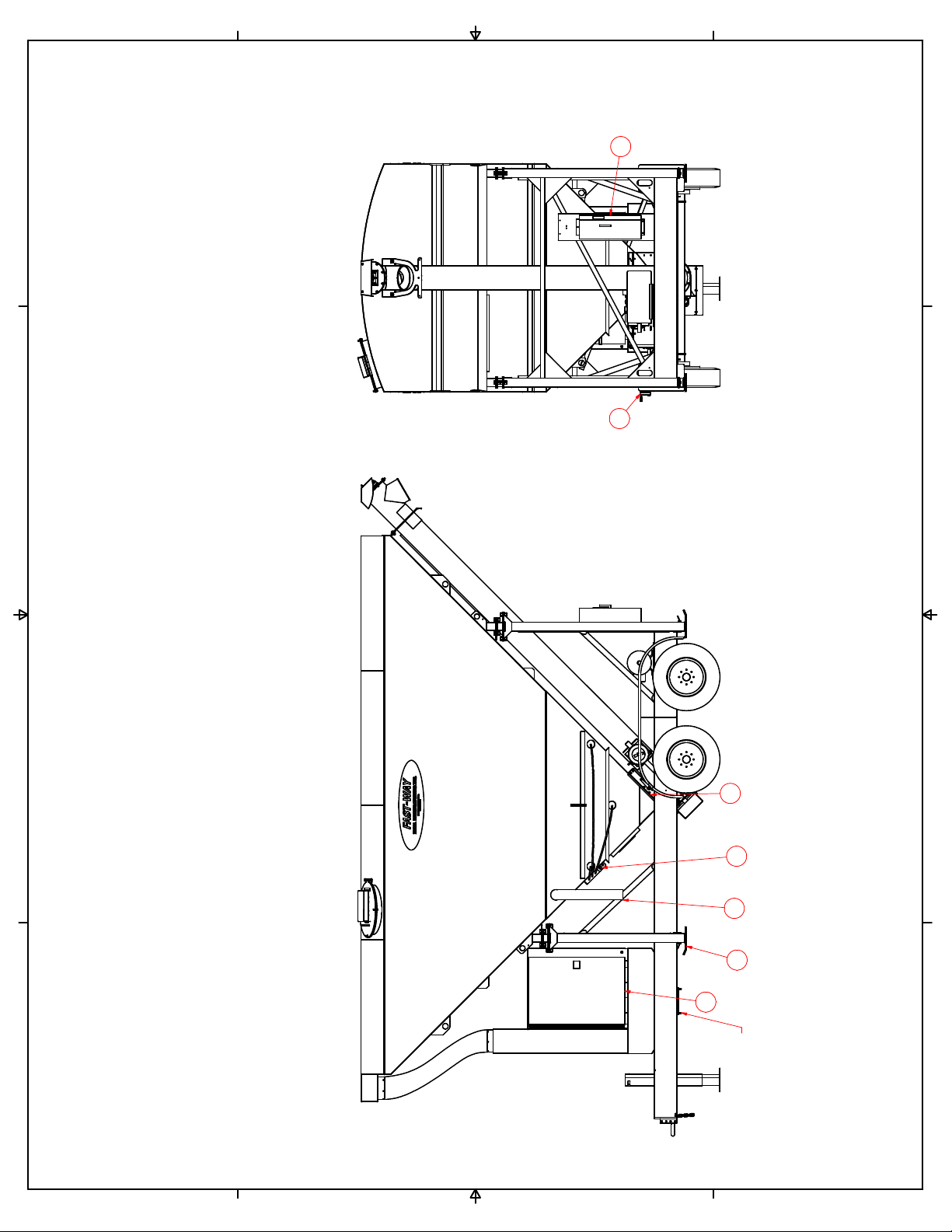

Si-Low 210 A1

1

IDEAL MANUFACTURING INC.

440 / 460 VOLT THREE PHASE

IDEAL MANUFACTURING INC.

240 VOLT THREE PHASE

4

Si-Low 210 A1

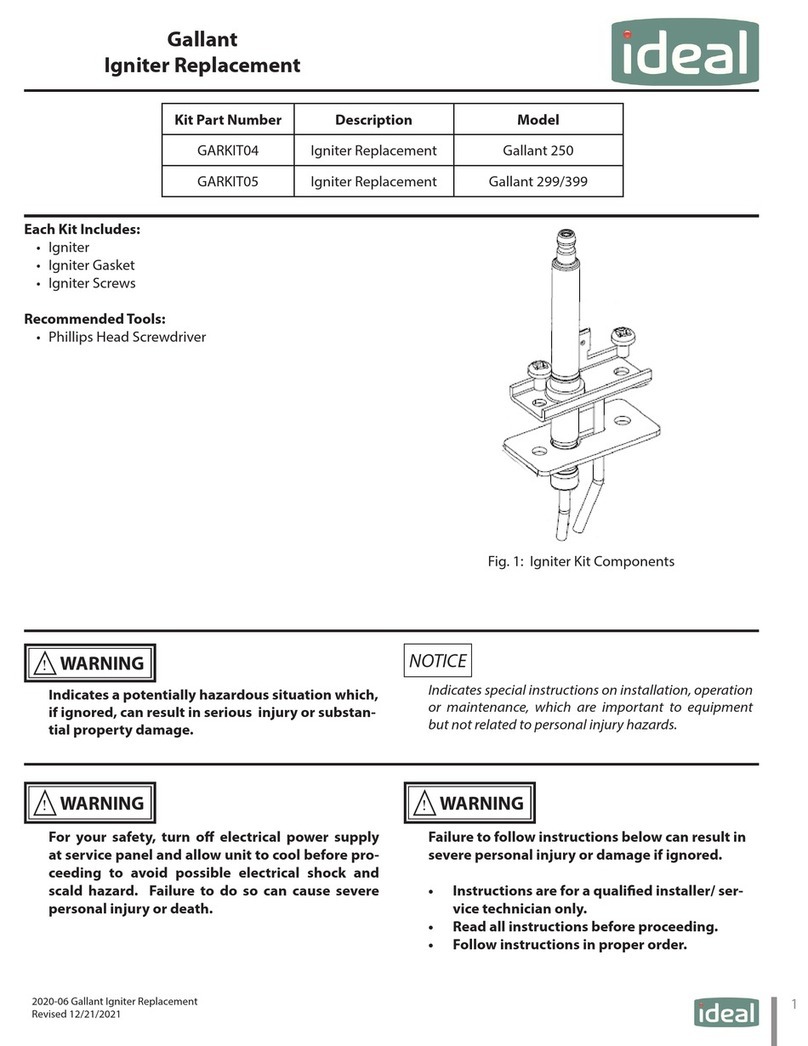

MAIN COMPONENT LIST

REF# DESCRIPTION

1 Auger to Silo Slide Gate

2 Speed Reducer and Electric Motor

3 Electrical Box

4 Aeration System

5 Fill Pipe

6 Bag Type Dust Collector and Clean Out Hopper

7 Side-Wind Tongue Jack

8 Adjustable Leg Assembly

9 Auger Drive Assembly

10 Man Hole

11 Upper Bearing Assembly

12 Vent Hose

13 Red Side Marker

14 Red Brake Light

15 Amber Side Marker

16 Tire and Axle Assembly

17 Cement Silo 200 Barrel capacity (30 tons)

18 Auger

19 Main Frame

20 Hand Crank for Slide Gate

1

1

2

2

3

3

4

4

A A

B B

C C

D D

Si-Low 210 A1

General Lay Out

Ideal Mfg., Inc. SL210 A1-213

5

7

6

15

10

54

8

18

17

3

129

14

14

20

16

19

13

11

12

9

8

10

6

Si-Low 210-A1

PREPARING SILO FOR TRANSPORT

1. Most important is to be positive that all cement has been removed from silo, auger

and bag-house.

2. Using a rubber mallet, hit the sidewalls of hopper section of silo; listening for a

hollow sound. Clean out remaining cement. A bag of floor dry will aid in cleaning

out the auger by opening the manhole on top of the silo, pour the floor dry inside of

the cement silo. Turn auger on, open discharge gate. Run auger until the floor dry

no longer comes out of discharge end of auger. Turn auger off and close discharge

gate.

3. Disconnect air supply.

4. Disconnect electrical supply. CAUTION! Only a qualified person should do this.

5. Using side-wind tongue jack, raise front of cement silo until all weight is off both

front legs...

6. Remove keepers from both front leg pins, slowly remover leg pins. CAUTION! Inner

leg will fall to ground. STAY CLEAR WHEN REMOVING LEG PINS.

7. Using handle on leg pad, raise leg until pin can be installed in first hole. Install leg

pin through hole, install keeper. Repeat on second leg at front of cement silo.

8. Using side-wind tongue jack, lower front of cement silo until all weight is on both

rear legs.

9. Remove keepers from both leg pins; slowly remove leg pins. CAUTION! Inner leg

will fall to ground. STAY CLEAR WHEN REMOVING LEG PINS!

10. Using handle on leg pad, raise leg until leg pin can be installed in first hole. Install

leg pin through hole and install keeper. Repeat on second leg at rear of cement silo.

11. Using side-wind tongue jack, raise front of cement silo until tow vehicle can back

under pintle hitch.

12. Back tow vehicle under pintle hitch, using top-wind tongue jack, lower front of

cement silo onto tow vehicle hitch, secure latch. Hook safety chains and break-away

cable to tow vehicle. Plug in lights, check lights for proper operation.

13. Raise top-wind jack to full up position. See drawing (Adjustable Legs) on page 23.

14. Clean all debris of silo before towing.

7

Si-Low 210-A1

SET UP PROCEDURE

1. Select a level site with solid footing for setting up and operating cement silo.

2. Block tires, to keep cement silo from moving, before unhooking tow vehicle..

3. Unhook tow vehicle, move vehicle away from cement silo.

4. Remove keepers from both leg pins at rear of cement silo. Slowly remove leg

pins. CAUTION! Inner leg will fall to ground; STAY CLEAR WHEN

REMOVING LEG PINS! See page 23.

5. Using side-wind tongue jack, lower front end of silo until leg pins can be

installed in second hole in rear legs.

6. Install leg pins through holes in both rear legs; install keepers.

7. Remove keepers from both leg pins, at front of silo. Slowly remove leg pins

CAUTION! Inner leg will fall to ground. STAY CLEAR WHEN

REMOVING LEG PINS!

8. Using sdie-wind tongue jack, raise front of cement silo until leg pins can be

installed in second hole in front legs

9. Install leg pins through holes in both front legs; install keepers.

10. Using sdie-wind jack, lower front of cement silo until all weight is off jack.

11. Check cement silo for level and stability. Correct as needed..

12. Connect electric power to disconnect box at rear of cement silo, using

qualified person See page 2 and 3 for diagram. Check for proper rotation of

Auger. Correct as needed.

13. Connect air supply to valve. Silo fluidizer aerators require 10.2 CFM @ 90

PSI with a 60 gallon tank. See drawing #110 on page 25.

8

SAFETY RULES

Follow instructions. Don’t take chances. If you don’t know, ask. When setting up

lowering or putting equipment into traveling position, follow all instructions in operator’s

manual.

Correct or report unsafe conditions. If you are not sure of how to correct a hazard, report

it and get help.

Help keep everything clean and orderly. Trips or falls can cause serious injuries.

Use the right tools and equipment for the job. Use them safely. Replace all machine

guards after repairs.

Report all injuries and get first aid or medical treatment promptly.

Use, adjust and repair equipment only when authorized.

Use prescribed protective equipment. Keep it in good condition. Wear your hard hat,

safety climbing devices or belt. Wear safe clothing to protect you from material being

handled, cold or hot. Wear dust mask when conditions require them. Gloves, safety

glasses or eye protection, and ear plugs for noise.

Don’t horseplay; avoid distracting others.

When lifting, bend your knees and get help for heavy loads.

Don’t repair or adjust equipment while in motion. Shut off power at source, gasoline

engines or electric motors.

Gasoline, L.P. gases fumes are highly explosive.

CYCLO BEVEL BUDDYBOX LUBRICATION

NOTES: Total amount of oil needed is 0.4 gallons. Output section use 0.44 gallons.

Input section use 0.22 gallons. Omala Oil 100, 150 installed at factory.

1. Cyclo input section on small units is greased packed from the factory and is

maintenance free for 20,000 operating hours

2. Cyclo vertical section of units is grease packed and requires periodic

replenishment.

3. Consult factory if greased lubrication of gear output section is required.

4. Before reinstalling plugs, reapply Teflon tape to threads to prevent leakage.

5. “G” denotes grease lubricated as standard.

Standard Oils

Ambient Temperature (ºF)

ChevronTexaco Exxon Oil Mobil Oil Shell Oil BP Oil

14 to 41º

EP Gear Spartan EP Mobilgear 626 Omala Oil Energol

Compound 68 68 (ISO) VG 68) 68 GR-XP 68

32 to 95º

EP Gear Spartan Mobilgear Omala Oil GR-XP 100

Compound EP 100 627, 629 100, 150 GR-XP 150

100, 150 EP 150 (ISO) VG 100, 150)

86 to 122º

EP Gear Spartan Mobilgear Omala Oil Energol

Compound EP 220 630, 632 220, 320 GR-XP 220

220, 320, 460 EP 320 633, 634 460 GR-XP 320

EP 460 (ISO VG 220-460) GR-XP 460

Oil Fill Quantities Unit U.S. Gallons *G = Grease

Frame Size Y1

Output Input

Y2

Output Input

Y3

Output Input

Y4

Output Input

Y5

Output Input

Y6

Output Input

2A100, 2A105

2A110, 2A115

2A120, 2A125

2A140, 2A145

2B120, 2B125

2B140, 2B145

2B160, 2B165

2C140, 2C145

2C160, 2C165

2C170, 2C175

2D160, 2D165

2D170, 2D175

2E170, 2E175

G

G

0.29

G

0.08

G

0.48 0.12

0.20

0.12

0.87 0.20

0.28

0.18

1.16

0.24

1.95 0.24

G

G

0.26

G

G

G

0.37 G

G

G

0.92 G

G

G

1.32

G

1.93 G

G

G

0.29

G

0.08

G

0.48 0.12

0.20

0.12

0.87 0.20

0.28

0.18

1.16

0.24

1.95 0.24

G

G

0.26

G

G

G

0.48 G

G

G

1.16 G

G

G

1.11

G

1.59 G

G

G

0.45

G

0.08

G

0.61 0.12

0.20

0.12

0.95 0.20

0.28

0.18

1.48

0.24

1.90 0.24

G

G

0.42

G

0.08

G

0.66 0.12

0.20

0.12

1.4 0.20

0.28

0.18

1.59

0.24

2.80 0.24

9

10

Si-Low 210-A1

OPERATING PROCEDURE

A. CHARGING SILO

1. Close silo discharge gate, (REF# 1)

2. Air pump cement through filler pipe, (REF# 5))

3. You must open ball valve on side of bag-house to operate vibrator to clean

filter bags each time after filling silo. (REF #6). Vibrator requires 4.5

CFM @ 60 PSI or 5.5 CFM @ 80 PSI. Or open side doors and manualy

shake bags.

4. Open cleanout gate, at bottom of bag-house hopper, remove over flow

cement from hopper; close gate. (REF #6)

B. AUGER OPERATION

1. Raise disconnect handle on electrical panel to ON position. (REF #3).

2. Open discharge gate. (REF#1)

3. Turn air supply on. (Supplied by customer)

4. Open ball valve on aerator system for one minute.(REF# 4) Close ball

valve. If optional pulse system is purchased turn air valve control to ON

position. (REF# 3). (Optional)

5. Push start button, (REF # 3). Auger will start. Turn vibrator on. Optional

aerators will pulse on for three seconds, off for seven seconds, until stop

button is pushed.

NOTE: If slower delivery of cement is needed; close discharge gate to

get desired amount.

6. Fill unit with cement.

7. When unit is filled push stop button, and turn vibrator off. (REF #3)

8. Close discharge gate. (REF # 1).

9. Lower disconnect handle on electrical panel to OFF position. (REF #3).

10. NOTE: The auger should be emptied on last load of the shift. Discharge

boot should be rolled up and secured to keep moisture out of auger tube to

prevent build up on auger screw.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

Si-Low 210 A1

Operating Procedure

Ideal Mfg., Inc. SL210 A1-213-1

11

6

54

3

1

1

8

BAGHOUSE CLEAN

OUT GATE

12

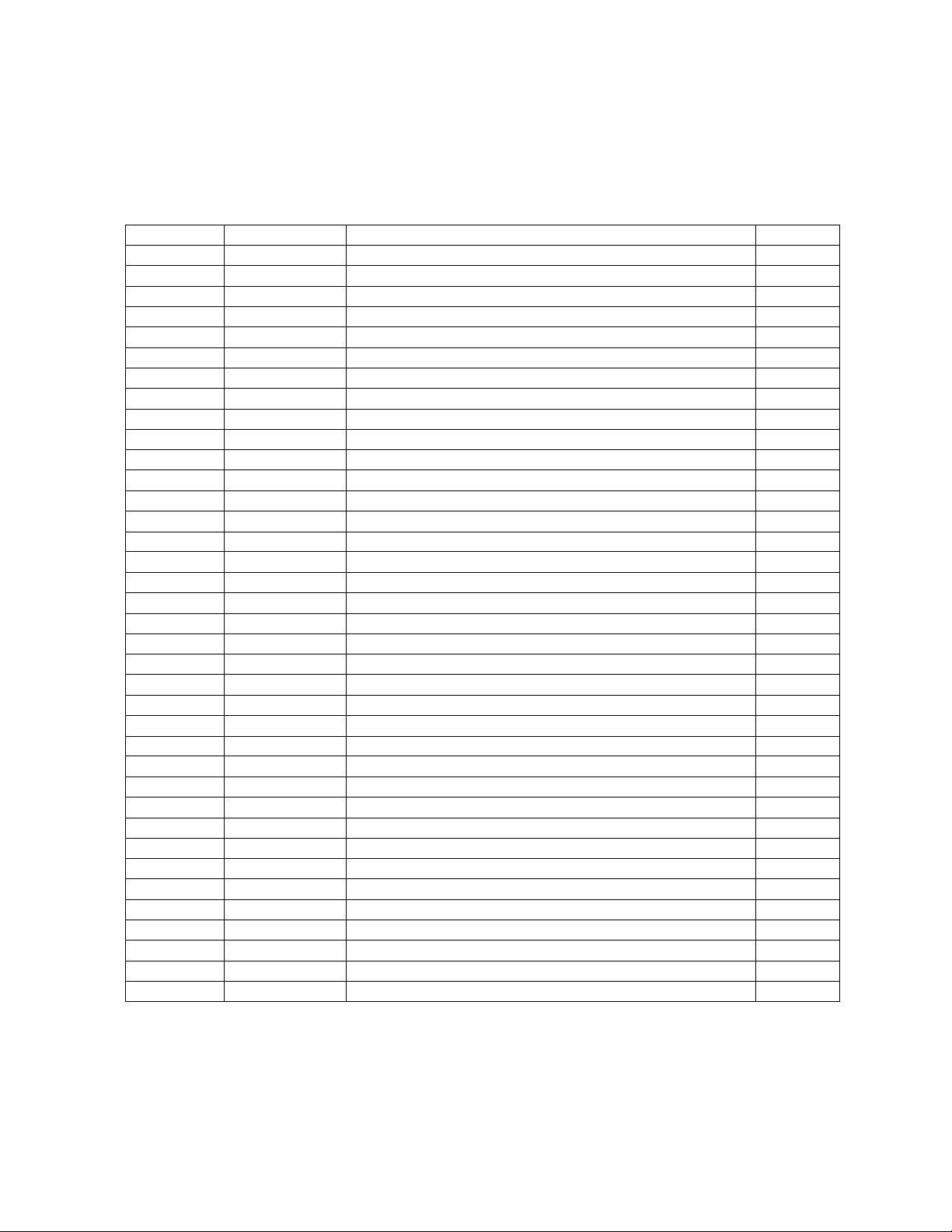

Si-Low 210-A 1

AUGER DRIVE COMPONENTS

SL210 A1-201

REF NO.

PART NO.

DESCRIPTION

REQ’D

1

SLO301

Auger Assembly

N/A

2

POO677

Electric Motor

1

2

-

A

POO637

Diesel Engine

1

2

-

B

POO638

Gas Engine

1

3

POO676

Speed Reducer

1

4

POO679

2TB66 Sheave

1

4

-

A

POO63

6

Pulley Clutch (Diesel & Gas Engine)

1

5

POO681

P 1 5/8 Bushing

1

6

POO138

2BK47H Sheave (Electric Motor)

1

6

-

A

POO649

2BK60H Sheave (Diesel Engine)

1

6

-

B

POO233

2BK70H Sheave (Gas Engine)

1

7

POO680

H 7/8 Bushing

1

8

SLO310

Drive Mounting Frame

1

9

SLO311

Silo Frame

N/A

10

N/A

1/2

-

13 x 18 All Thread

2

11

N/A

1/2

-

13 Hex Nut

16

12

NA

1/2 Lock washer

12

13

NA

1/2 USS Flat washer

1

6

14

NA

1/2

-

13 x 2” Hex Bolt

4

15

NA

1/2

-

13 x 2 1/2

” Hex Bolt

4

16

NA

3/8

-

16 x 1” Hex Bolt

8

17

NA

3/8 Lock Was

her

8

18

NA

3/8

-

16 Hex Nut

8

19

NA

3/8 USS Flat Washer

8

20

NA

M 12 Flat Washer (speed reducer not shown)

4

21

NA

M 12 Lock Washer (speed reducer not shown)

4

22

NA

M 12

-

1.75 X 25 MM Bolt (speed reducer not shown)

4

23

NA

¼

-

20 x ¾ Hex Bolt

8

24

NA

¼

Lock Washer

8

25

NA

¼

-

20 Hex Nut

8

26

SLO312

Belt Guard Back

1

27

SLO313

Belt Guard Cover

1

28

N/A

3/16 x 3/16 x 1 3/8 Key Stock

1

29

N/A

3/8 x 3/8 x 2 3/4 Key Stock

1

30

POO767

B

-

96 V Belt

2

31

SLO314

Guard Mount Front

1

32

SLO315

Guard Mount Rea

r

1

1

1

2

2

3

3

4

4

A A

B B

C C

D D

SHEET 1 OF 1

DRAWN

CHECKED

QA

MFG

APPROVED

T Henry 4/9/2019

DWG NO

SL210 A1-201

TITLE

Si-Low 210 A1

SIZE

C

SCALE

Ideal Mfg., Inc.

REV

2011 Harnish Blvd. Billings MT 59101 Tel. (406) 656-4360

WEIGHT

PROJECTION

REMOVE ALL BURRS

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

.XX ± .01

.XXX ± .005

FRACTIONS ± 132

ANGLES ± 1°

DRILLED HOLE ± 164

13

11

13

11

12

13

11

10

15

8

14

2

29

2-A / 2-B

4-A

27

23

26

24

25

31

7

30

6 / 6-A / 6-B

4

5

16

18

17

19

32

16

18

17

11

12

13

13

12

11

11

12

13

16

19

17 18

23

24

25

11

12

13

AUGER DRIVE COMPONENTS

13

14

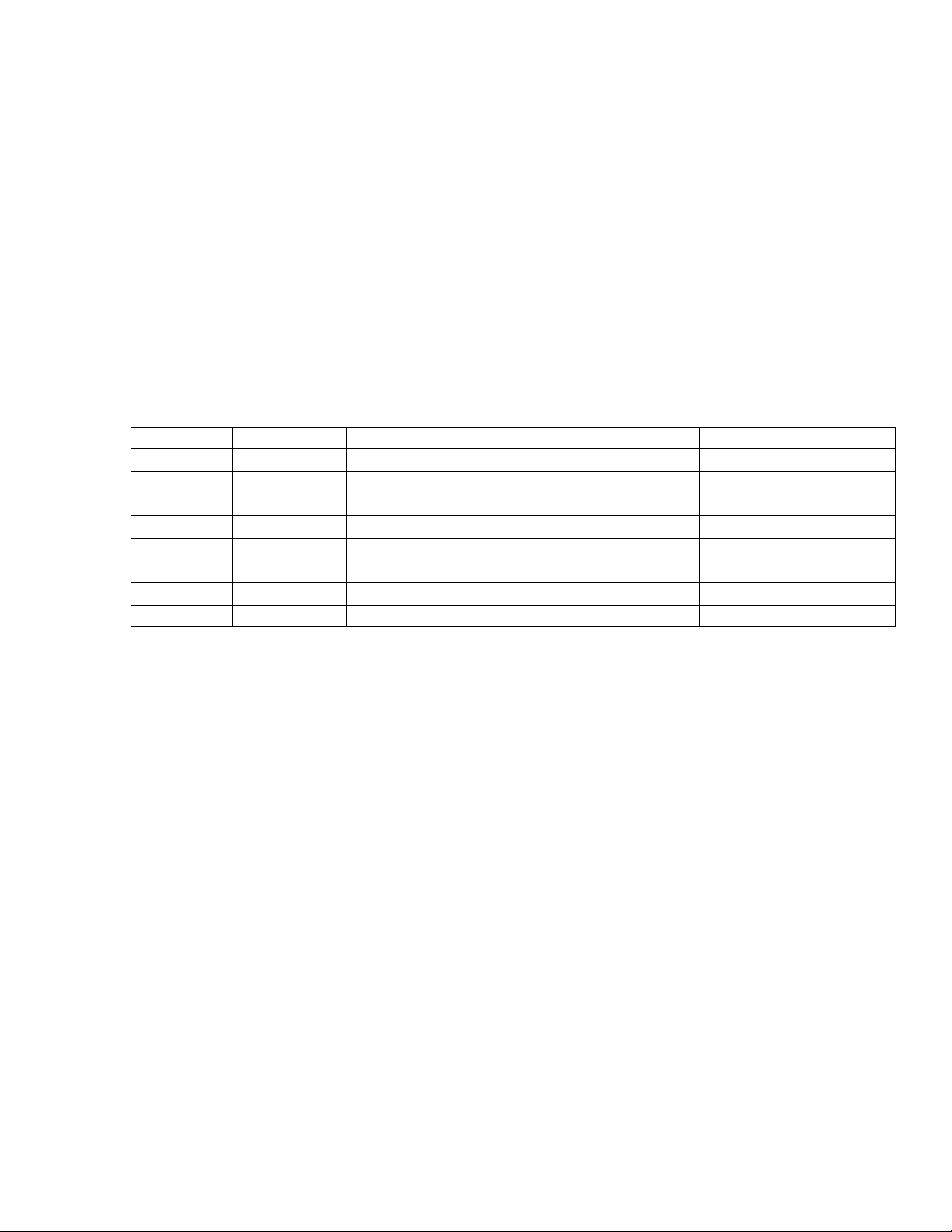

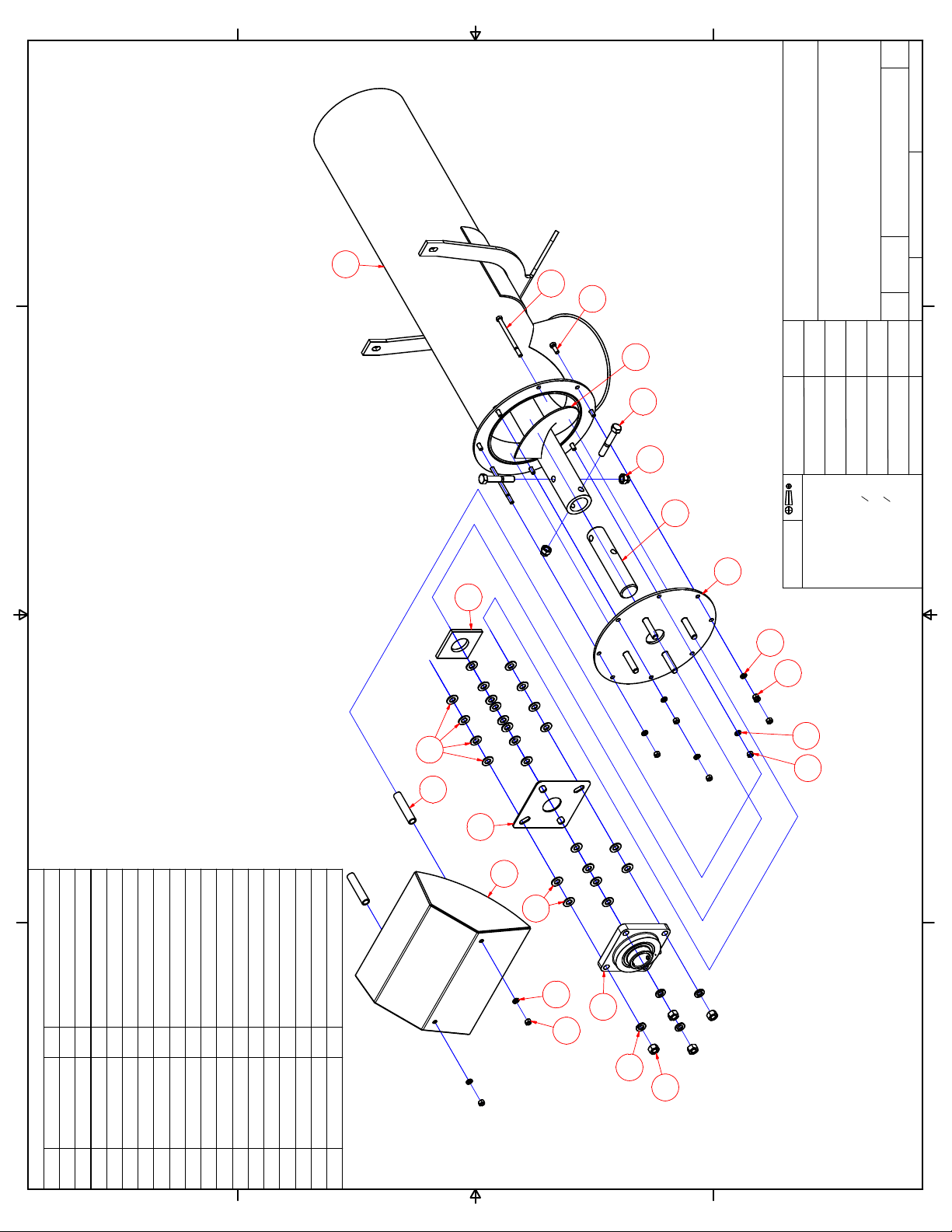

Si-Low 210-A1

LOWER AUGER ASSEMBLY

SL210 A1-212

REF NO.

PART NO. DESCRIPTION REQ’D

1 SLO301 Auger Assembly N/A

2 SLO343 Lower Auger Shaft 1

3 POO676 Speed Reducer 1

3A POO795 Bushing 1

4 N/A 5/8-11 x 4 Hex Bolt (not shown) 2

5 N/A 5/8-11 Lock Nut (not shown) 2

6 SLO344 Auger Drive Shaft 1

7 SLO342 Auger Flighting 1

8 POO791 Pillow Block Bearing 1

9 SLO345 Auger Flange Drive End 1

10 POO689 Felt Seal 6 x 6 1

11 SLO346 Felt Seal Plate 1

12 POO790 Flange Block Bearing 1

13 SLO306 Chain Guard Back 1

14 SLO307 Chain Guard Cover 1

15 POO793 Drive Sprocket 2

16 POO688A Off Set Link (not shown) 1 (if needed)

17 POO688 Roller Chain (not shown) 1

18 POO688B Master Link (not shown) 1

19 SLO308 1/2 x 1/2 x 2 1/4” Key Stock 2

20 N/A 3/8-16 x 1” Hex Bolt 6

21 N/A 3/8” Lock Washer 6

22 N/A 3/8” Hex Nut 6

23 N/A 1/2 USS Flat Washer 32

24 N/A 1/2 Lock Washer 4

25 N/A 1/2-13 Hex Nut 4

26 N/A 1/4-20 x 1” Hex Bolt 6

27 N/A 1/4” Lock Washer 6

28 N/A 1/4-20 Hex Nut 6

29 N/A 1/2-13 x 3” Hex Bolt 2

30 N/A 1/2 SAE Flat Washer 2

31 N/A 1/2 Lock Washer 2

32 N/A 1/2-13 Hex Nut 2

33 N/A M 12-1.75 X 25 MM 4

34 N/A M 12 Lock Washer 4

35 N/A M 12 Flat Washer 4

1

1

2

2

3

3

4

4

A A

B B

C C

D D

SHEET 1 OF 1

DRAWN

CHECKED

QA

MFG

APPROVED

T Henry 4/9/2019

DWG NO

SL210 A1-212

TITLE

Si-Low 210 A1

SIZE

C

SCALE

Ideal Mfg., Inc.

REV

2011 Harnish Blvd. Billings MT 59101 Tel. (406) 656-4360

WEIGHT

PROJECTION

REMOVE ALL BURRS

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

.XX ± .01

.XXX ± .005

FRACTIONS ± 132

ANGLES ± 1°

DRILLED HOLE ± 164

27

28

14

19

15

26

13

25

24

12

23

11

10

23

22

21

9

25

4

20

1

6

30

31 32

8

29

35

34

33

3

3-A

7

LOWER AUGER ASSEMBLY

15

16

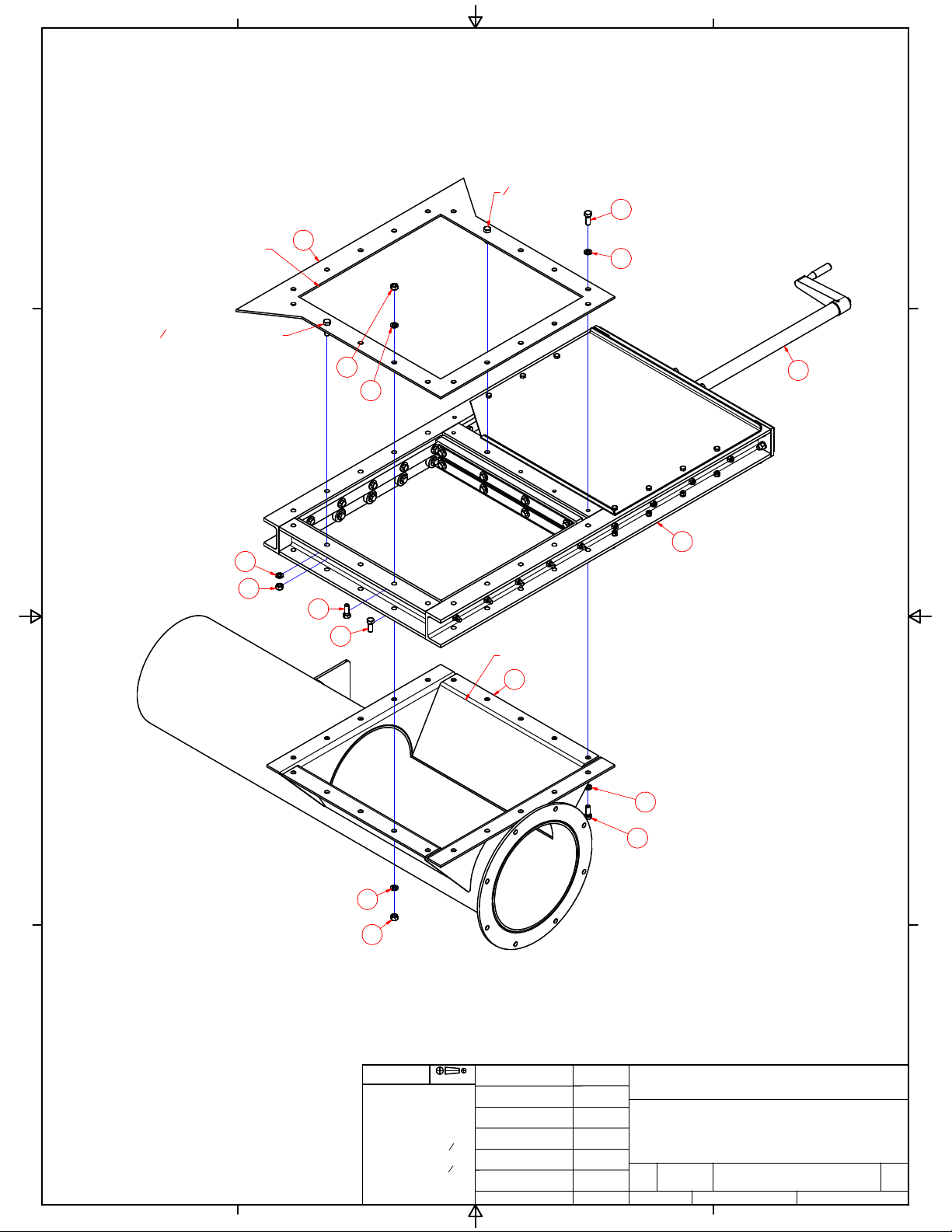

Si-Low 210-A1

AUGER TO SLIDE GATE TO SILO

SL210 A1-202

REF NO. PART NO. DESCRIPTION REQ’D

1 SLO318 Silo (flange) 1

2 POO783 I Slide Gate 1

3 SLO301 Auger Assembly 1

4 F00173A Gate Handle Extension 1

5 N/A 3/8-16 x 1 1/4 Hex Bolt 29

6 N/A 3/8 Lock Washer 40

7 N/A 3/8-16 Hex Nut 31

8 N/A 3/8-16 X 1 Hex Bolt 9

1

1

2

2

3

3

4

4

A A

B B

C C

D D

SHEET 1 OF 1

DRAWN

CHECKED

QA

MFG

APPROVED

T Henry 4/9/2019

DWG NO

SL210 A1-202

TITLE

Si-Low 210 A1

SIZE

C

SCALE

Ideal Mfg., Inc.

REV

2011 Harnish Blvd. Billings MT 59101 Tel. (406) 656-4360

241.8 lbmass

WEIGHT

PROJECTION

REMOVE ALL BURRS

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

.XX ± .01

.XXX ± .005

FRACTIONS ± 132

ANGLES ± 1°

DRILLED HOLE ± 164

AUGER INLET

HOPPER OUTLET

38BOLT WELDED TO FLANGE

38BOLT WELDED TO FLANGE

8

6

4

2

7

6

6

7

5

5

7

6

AUGER TO SLIDE GATE TO SILO

17

6

8

1

3

1

1

2

2

3

3

4

4

A A

B B

C C

D D

SHEET 1 OF 1

DRAWN

CHECKED

QA

MFG

APPROVED

T Henry 4/9/2019

DWG NO

SL210 A1-207

TITLE

Si-Low 210 A1

SIZE

C

SCALE

Ideal Mfg., Inc.

REV

2011 Harnish Blvd. Billings MT 59101 Tel. (406) 656-4360

N/A

WEIGHT

PROJECTION

REMOVE ALL BURRS

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

.XX ± .01

.XXX ± .005

FRACTIONS ± 132

ANGLES ± 1°

DRILLED HOLE ± 164

PARTS LIST

DESCRIPTIONQTYPART NUMBERITEM

3/8-16 X 1 HEX BOLT6N/A1

3/8-16 HEX NUT8N/A2

3/8 LOCK WASHER8N/A3

3/8-16 X 5 1/2 HEX BOLT

2

N/A

4

5/8 USS FLAT WASHER24N/A

5

5/8-11 HEX NUT4N/A6

5/8 LOCK WASHER4N/A7

5/8-11 X 4 HEX BOLT2N/A8

5/8-11 NYLOCK HEX NUT2N/A9

UPPER AUGER SHAFT1F0017410

FELT SEAL

1

POO689

11

FLANGE BLOCK BEARING1POO79212

AUGER ASSEMBLY1SLO30113

AUGER FLIGHT ASSEMBLY1SLO34214

FELT SEAL PLATE1SLO34615

UPPER AUGER FLANGE

1

SLO34716

RAIN CAP

1

SLO350-1

17

SPACER2SLO351-118 13

4

1

8

9

10

16

3

23

6

7

12

5

15

5

11

23

17

18

14

UPPER AUGER ASSEMBLY

18

2

Table of contents

Other IDEAL Industrial Equipment manuals