3

Design Guide

MANDATORY REQUIREMENTS

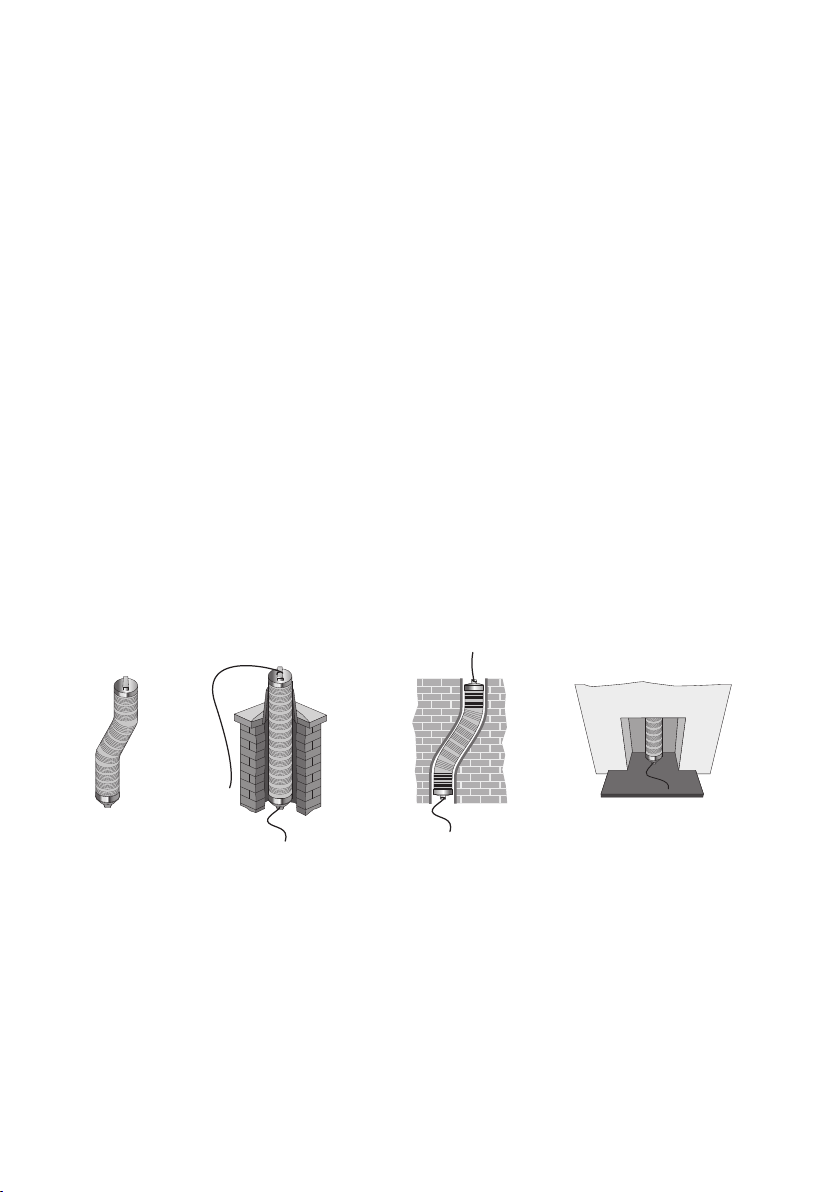

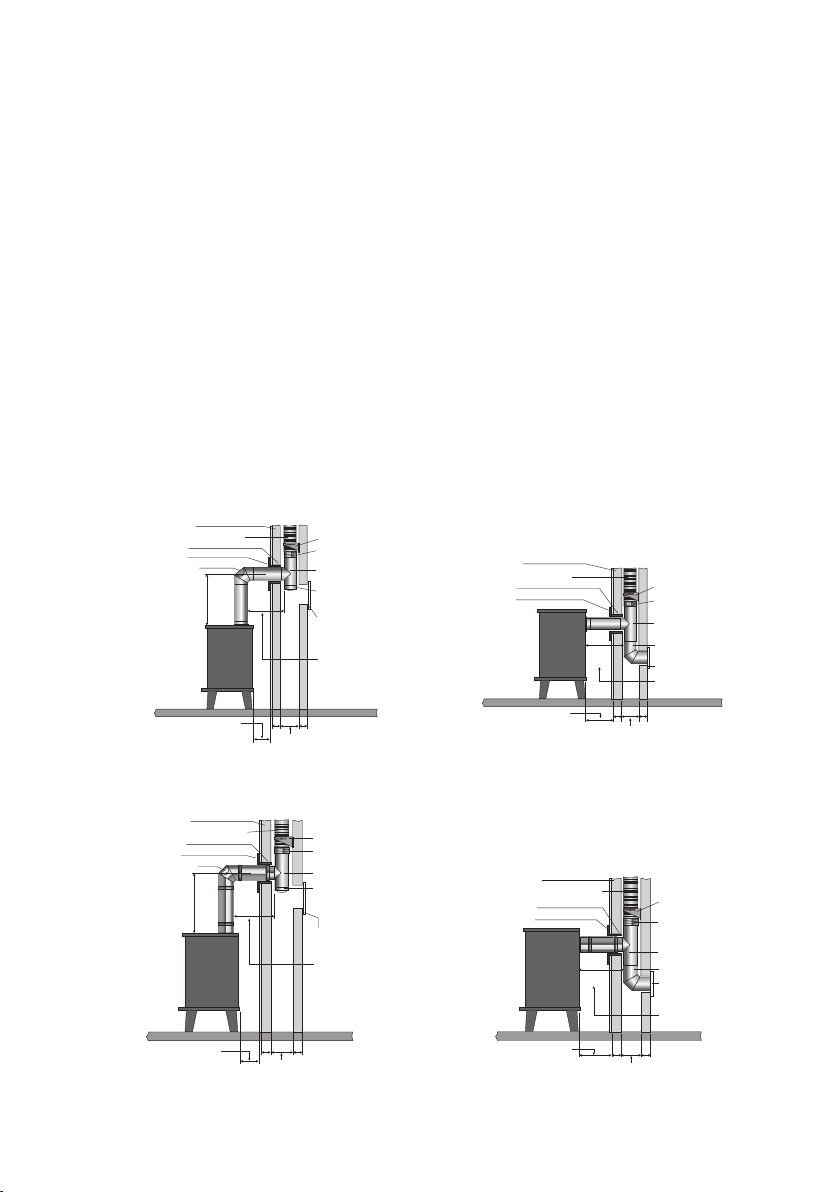

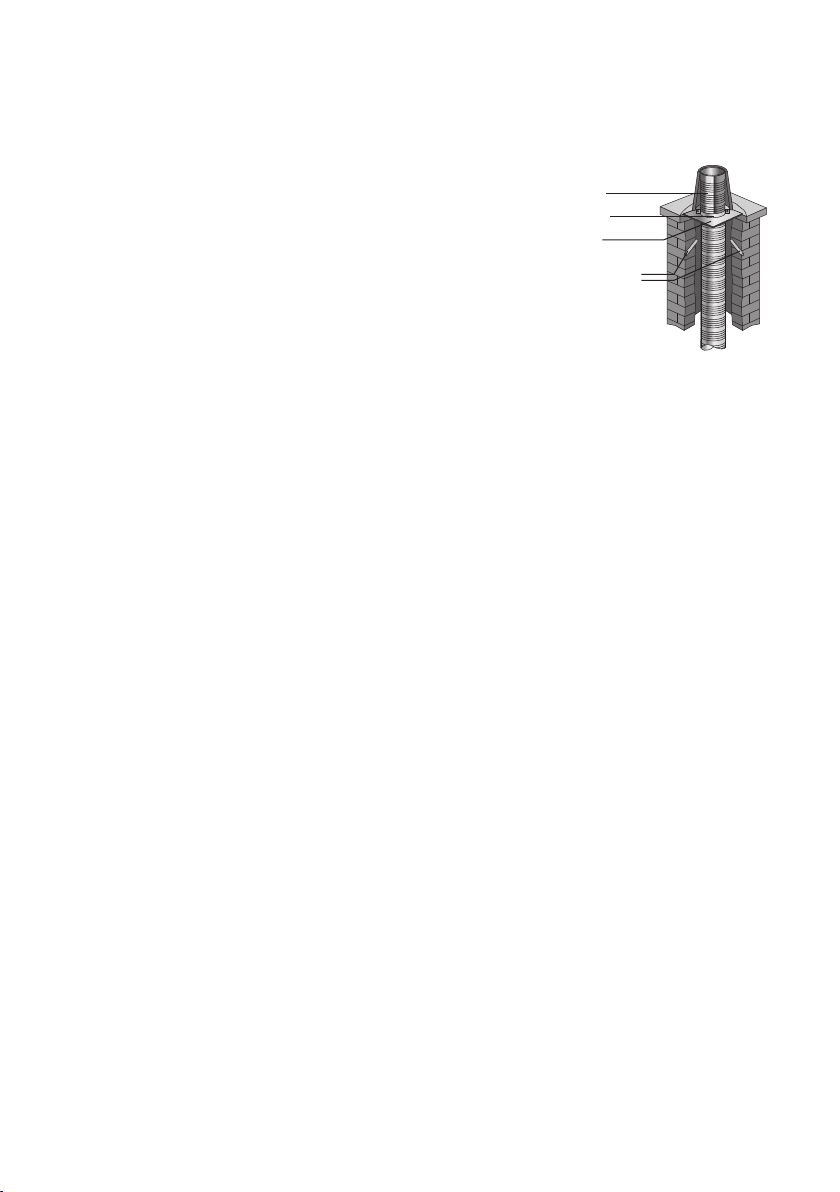

Building Regulations Document J requires that a flexible flue liner can only be installed

completely enclosed inside a masonry chimney. A non masonry enclosure such as timber or

plasterboard boxing in is not acceptable.

The type of flue liner permitted depends on the fuel to be used, the type of appliance and the

type and year of chimney construction in which it is to be fitted.

Building Regulations Document J, outlines different requirements for relining masonry chimneys

built before and after 1st February 1966. This is summarised in the table below.

Connection to an appliance which is not connected to the fuel supply, should be carried out

by a competent person. We recommend the use of HETAS approved installers for solid fuel

applications. If installation is carried out by a non HETAS registered installer, the installation

must be certied by a local Building Control inspector. Connection to an appliance that is

connected to the fuel supply must be carried out by a Gas Safe (Gas) or OFTEC (Oil) registered

installer.

The design guide must be read in conjunction with the detailed component installation

instructions.

For full design and installation details the key referral documents are:

• BS EN 1856-2: Connecting Flue Pipes

• BS EN 1856-2: Flue Liners

• BS EN 1859: Metal Chimneys - Testing Methods

• BS EN 1443: Chimneys - General Requirements

• BS EN 15287-1: Chimneys. Design, installation and commissioning of chimneys. Chimneys for

non-room sealed heating appliances.

• Approved Document J: - Combustion appliances and fuel storage systems (England & Wales)

• DFP Technical Booklet L: - Combustion appliances and fuel storage systems (NI)

• Technical Handbook (Domestic & Non Domestic),Section 3 - Environment (Scotland)

• Appliance Installation Instructions and related standards. Other standards covering specific

applications will also be relevant and must be adhered to.

Ensure all chimney components are available and check them to ensure there has been no

damage. Do not use damaged components.

Appliance Chimneys built before 1.2.1966 Chimneys built after 1.2.1966

Gas Burning

Output up to 45kW

Triplelock can be used in unlined

chimney on dry applications.

Triplelock can be used in lined

chimney on dry applications.

Kerosene Burning

Output up to 45kW

Triplelock can be used in unlined

chimney on dry applications.

Triplelock can be used in lined

chimney on dry applications.

Gas/Oil Burning

Output up to 45kW

TecnoFlex Plus can be used in

unlined chimney on wet and dry

applications.

TecnoFlex Plus can be used in

lined chimney on wet and dry

applications.

Solid Fuel Burning

Output up to 45kW

TecnoFlex Plus can be used in

unlined chimney.

TecnoFlex Plus can be used in

lined chimney.