IDEM SAFETY SWITCHES SCR-2H Operation manual

User Information

Safety Relays from IDEM SCR-3 Safety Relays from IDEM SCR-2H

H02

Ver. A

E61-328-00

•

Up to PL e, SILCL 3, category 4

Correct Use

The SCR-2H 2-hand safety relay is an extremely com-

pact, universal safety two-hand control unit. It com-

plies with N574, Typ III C, and is intended for use in

safety circuits that are designed in accordance with N

60204-1, e.g. on presses, punches and bending tools.

Due to the internal error monitoring, the 2-hand safety

relay can be used, despite very compact dimensions,

for all applications up to the highest safety category 4

and PL e according to N ISO 13849-1, SILCL 3 accord-

ing to N 62061 or Typ III C according to N 574.

Features

•

2 safe, redundant relay outputs

•

Cyclical monitoring of the output contacts

•

Feedbac loop for monitoring downstream contactors or

expansion modules

•

Short circuit and earth fault monitoring

•

Extrem compact housing

Function

The IDEM 2-hand safety relay SCR-2H is suitable for set-

ting up and monitoring two-hand ir uits and is used to

prote t the operators. Dangerous work steps an only be

triggered when both two-hand buttons onne ted are ope-

rated simultaneously, i.e. within 0.5 s.

It is to be ensured a single fault or a malfun tion does not

result in the loss of the safety fun tion and every fault is

dete ted by the y li self-monitoring at the latest prior to

the next a tuation.

When the operating voltage is applied to A1-A2 and the

feedba k loop X1-X2 is losed, the SCR-2H is ready for

use. To be able to initiate a swit hing operation, the output

relays must be de-energized. The output relays only swit h

to the energized position when the two-hand buttons T1

and T2 are operated simultaneously, i.e. within 0.5 s.

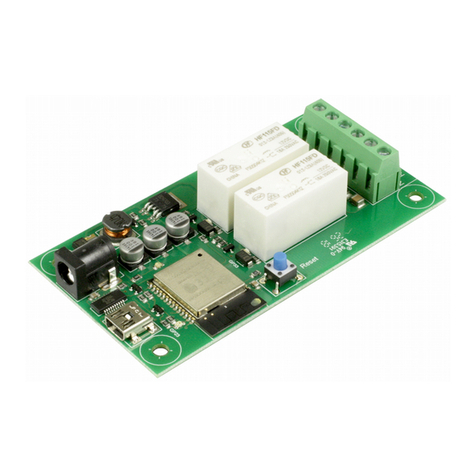

Fig. 1 Block diagram SCR-2H

•

All relevant sefety regulations and standards are to be

observed.

•

The overall on ept of the ontrol system in whi h the

devi e is in orporated must be validated by the user.

•

Failure to observe the safety regulations an result in

death, serious injury and serious damage.

•

Note down the version of the produ t (see label “Ver. X”)

and he k it prior to every ommissioning of a new de-

vi e. If the version has hanged, the overall on ept of

the ontrol system in whi h the devi e is in orporated

must be validated again by the user.

Installation

As per DIN EN 60204-1, the devi e is intended for installa-

tion in ontrol abinets with a minimum degree of prote tion

of IP54. It is mounted on a 35 mm DIN rail a ording to DIN

EN 60715 TH35.

Safety Precauti-

ons

•

Installation and ommissioning of the devi e must be

performed only by authorized personnel.

•

Observe the ountry-spe ifi regulations when installing

the devi e.

•

The ele tri al onne tion of the devi e is only allowed to

be made with the devi e isolated.

•

The wiring of the devi e must omply with the instru -

tions in this user information, otherwise there is a risk

that the safety fun tion will be lost.

•

It is not allowed to open the devi e, tamper with the

devi e or bypass the safety devi es.

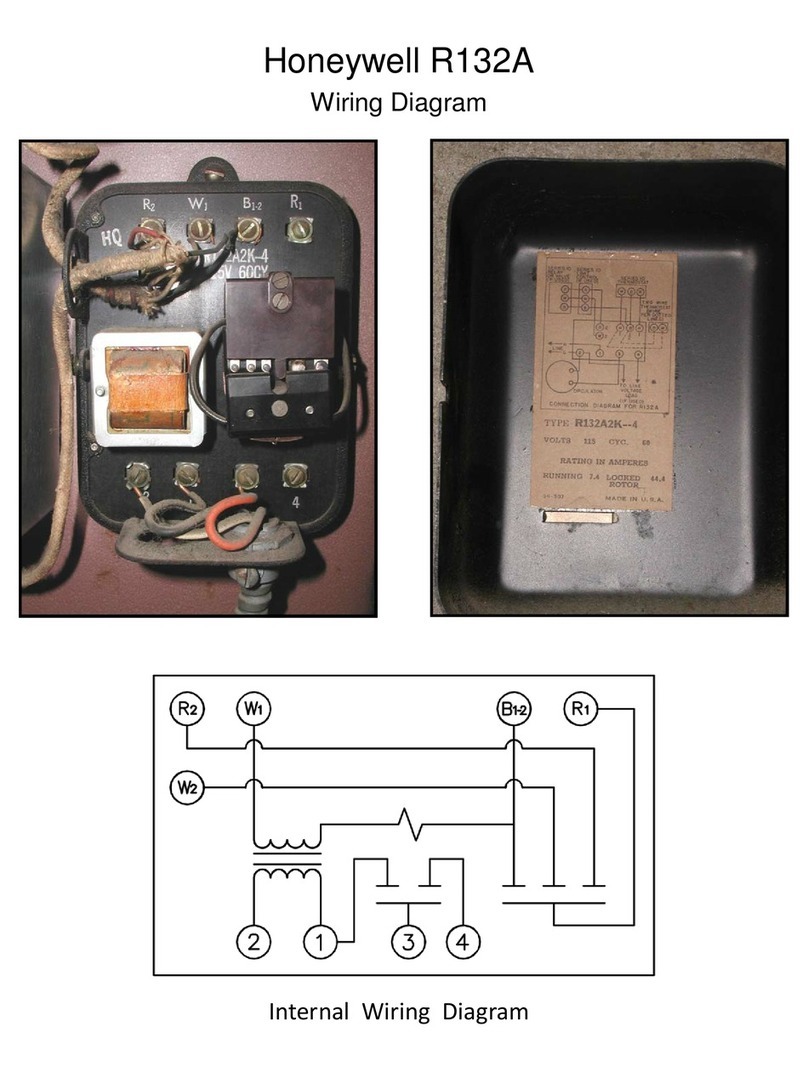

Fig. 2 In tallation/removal

Electrical Connec-

tion

•

When the 24 V version is used, a safety transformer

a ording to EN 61558-2-6 or a power supply unit with

ele tri al isolation from the mains must be onne ted.

•

External fusing of the safety onta ts (10 A gG) must be

provided.

•

A maximum length of the ontrol lines of 1000 meters

with a line ross se tion of 0.75 mm2 must not be ex ee-

ded.

•

The line ross se tion must not ex eed 2.5 mm2.

•

If the devi e does not fun tion after ommissioning, it

must be returned to the manufa turer unopened. Ope-

ning the devi e will void the warranty.

1

3

2

3

14 24

K

2

K

1

S

C

R

-

2

H

Fig. 3 Connection

A1: Power supply

A2. Power supply

S11: Control line T1

S12: Control line T1

S13: Control line T1

S21: Control line T2

S22: Control line T2

S23: Control line T2

X1; X2: Feedbac loop

13-14: Safety contact 1

23-24: Safety contact 2

The output relays are not swit hed if:

•

only one two-hand button is actuated or the time between the actuation of the 2 two-hand buttons is greater than 0.5 s,

•

the feedbac loop is open (fault in the external contactor),

•

another error (short circuit, cable brea , error in the switching device) has occurred.

When T1 and/or T2 are/is released, the output relays opens immediately. In order to trigger a new operation, both two-hand

buttons must first be released and the feedba k loop must be losed.

(not for plug-in terminal )

SCR-2H

User Information

Safety Relays from IDEM SCR-3 Safety Relays from IDEM SCR-2H

H02

Ver. A

E61-328-00

The arrangement of the two-hand buttons must be designed in a ordan e with the standard EN 574 su h

that a idental a tuation or simple bypassing of the safety fun tion is ex luded.

The SCR-2H unit is provided for the onne tion of 2-hand push-buttons, with one normally open or one

normally olsed onta t.

Figur 1 shows the wiring of the SCR-2H with a 2-hand push-buttons:

Applications

Fig. 1:

Wiring of the SCR-2H with a 2-hand push-

buttons

Fig. 2: Feedback loop

Contactors connected to the SCR-2H or the basic devices are

monitored via the feedbac loop of the basic device. K

A

and

K

B

are the positively driven contacts of the connected contac-

tor or expansion module.

Feedback loop

Note: The items listed under “Electrical connection” must be observed during commissioning.

Commissioning

Procedure

1. Wiring SCR-2H:

Wire the SCR-2H with the IDEM basi devi e a ording to

your appli ation (see Fig. 1).

2. Wiring feedback loop:

Wire the feedba k loop as shown in Fig. 2.

3. Wiring power supply:

Conne t the power supply to terminals A1 and A2.

Warning: Wiring only in de-energized state.

4. Starting the device:

Swit h the operating voltage on.

5. Switch to working condition:

Press the two buttons T1 and T2 simultaneously, or within

0.5 se onds.

The positive-guided relay switches on.

6. Switch into hibernation:

Release the two buttons T1 and T2.

The positive-guided relay swiches off.

Jumper X1-X2:

See des ription

X1 X2

Installation

Avoiding unintentional actuation or bypassing of the safety device

The arrangement of the two-hand buttons must be designed in a ordan e with the standard EN 574 su h that a idental

a tuation or simple bypassing of the safety fun tion is ex luded.

The operation of both buttons using one hand must be prevented by an adequate distan e (at least 260 mm) or by a sepa-

rating wall. A tuation using forearm, elbow, knee, hip or other parts of the body an be effe tively prevented by a further

in rease in the distan e between the two buttons, adequate distan e from the floor and/or overs and/or separating walls.

Distance from the two-hand buttons to the danger area

It is ne essary to maintain a minimum distan e between the buttons for the two-hand ir uit and the danger area on the

ma hine or plant so that, after the release of one or both buttons, the ma hine or plant an only be rea hed on e the dange-

rous movement has been interrupted or ompleted. A ording to the standard DIN EN ISO 13855, the distan e is al ulated

with the following equation:

S = (K · T) + C

S: Minimum distan e from the nearest pushbutton (two-hand button) to the danger area.

K: Parameter in mm/s, derived from data on the approa h speeds of the body or parts of the body, for two-hand ir uits

1600 mm/s.

T: The overtravel of the overall system in se onds, that is the time from releasing the two-hand button to the end of the dan

gerous movement.

C: Additional distan e in mm that based on entry into the danger area prior to the triggering of the safety devi e. For twohand

ir uits this is 250 mm, this distan e an also be set to 0mm given an adequate over on the buttons, however then S

must be at least 100 mm.

Exa ple

The overtravel time for the entire system is 90 ms. Then the above equation gives for the minimum distan e:

S = (1600 mm/s · 0.09 s) + 250 mm

S = 144 mm + 250 mm = 394 mm

If a suitable over is used, S an be redu ed to 144 mm (see above).

SCR-2H

User Information

Safety Relays from IDEM SCR-3 Safety Relays from IDEM SCR-2H

H02

Ver. A

E61-328-00

Maintenance

What to Do in

Case of a Fault?

On e per month, the devi e must be he ked for proper

fun tion and for signs of tampering and bypassing of the

safety fun tion (to do this, he k the wiring of the devi e

and a tivate the emergen y stop fun tion. Che k the delay

time).

The devi e is otherwise maintenan e

free, provided that it was installed proper-

ly.

Note:

Additional data an be requested from the manufa turer for

appli ations that deviate from these onditions.

Safety

Characteristics

According to

EN ISO 13849-1

The devi e is ertified a ording to EN ISO 13849-1 up to a

Performan e Level of PL e.

Techn. Data

Corresponds to the standards EN574, EN60204-1, EN ISO 13849-1, EN 62061

Operating voltage AC 230 V, AC 115 V, AC/DC 24 V

Rated supply frequen y AC: 50-60 Hz

Permissible deviation +/- 10 %

Power onsumption DC 24 V AC 230 V

approx. 1.5 W approx. 3.7 VA

Control voltage at S12-S12 and at S22-S23 DC 24 V

Control urrent (both swit hes) approx. 2 x 40 mA

Release time for the safety relays after release of a button < 20 ms

Response delay after a tuation of the buttons < 20 ms

Syn ronization time < 0.5 s

Safety onta t onfiguration 2 NO onta ts

Max. swit hing voltage AC 250 V

Safety onta t breaking apa ity AC: 250 V, 2000 VA, 8 A for ohmi load

(6 swit hing y les/ min)

250 V, 3 A for AC-15

DC: 24 V, 192 W, 8 A for ohmi load

(6 swit hing y les/ min)

24 V, 3 A for DC-13

Max. total urrent through all onta ts: 12 A

Minimum onta t load 24 V, 20 mA

Min. Conta t fuses 10 A gG

Max. line ross se tion 0.14 - 2.5 mm2

Max. length of ontrol line 1000 m with 0.75 mm2

Conta t material AgSNO

2

Conta t servi e life me h. approx. 1 x 107

Test voltage 2.5 kV ( ontrol voltage/ onta ts)

Rated impulse withstand voltage, leakage path/air gap 4 kV (DIN VDE 0110-1)

Rated insulation voltage 250 V

Degree of prote tion IP20

Temperature range DC 24 V: -15 °C to +60 °C

AC 230/115 V: -15 °C to +40 °C

Weight a. 230 g

Mounting DIN rail a ording to EN 60715 TH35

Safety characteristics according to EN ISO 13849-1 for all variants of SCR-2H

Load (DC-13; 24 V) <= 0.1 A <= 1 A <= 3 A

T10d [years] 20 20 20

Category 4 4 4

PL e e e

PFHd [1/h] 1.2 -08 1.2 -08 1.2 -08

nop [ y le / year] <= 400,000 <= 100,000 <= 22,500

What to Do in

Case of a Fault?

If the fault still exists, perform the steps listed under

“Commissioning Pro edure”.

If these steps do not remedy the fault either, return the

devi e to the manufa turer for examination.

Opening the device is impermissible and will void the

warranty.

Device does not switch on:

•

Chec whether the 2-hand button of correct function.

•

Chec whether the wiring.

•

Chec the supply voltage on A1 and A2

•

Is the feedbac loop closed?

User Information

Safety Relays from IDEM SCR-3 Safety Relays from IDEM SCR-2H

H02

Ver. A

E61-328-00

Dimension

Drawing

Variants

SCR-2H-230 V AC 230 V (50-60 Hz), fixed s rew terminals

SCR-2H-115 V AC 115 V (50-60 Hz), fixed s rew terminals

SCR-2H-24 V AC/DC 24 V (50-60 Hz), fixed s rew terminals

SCR-2H-230 V AC 230 V (50-60 Hz), plug-in terminals

SCR-2H-115 V AC 115 V (50-60 Hz), plug-in terminals

SCR-2H-24 V AC/DC 24 V (50-60 Hz), plug-in terminals

IDEM SAFETY SWITCHES Ltd, 2 Ormside Close, Hindley Industrial Estate ,Hindley Green, Wi an, WN2 4HR UK, Tel: +44 (0)1942 261000 Fax.: +44 (0)1942 676293

IDEM ( U.S.A.) - 3909 Washin ton Blvd. 204, Fremont, CA 94538 email: [email protected] web: www.idemsafety.com

Feb 16

Fixed

Terminals

Plug-In

Terminals

Other IDEM SAFETY SWITCHES Relay manuals