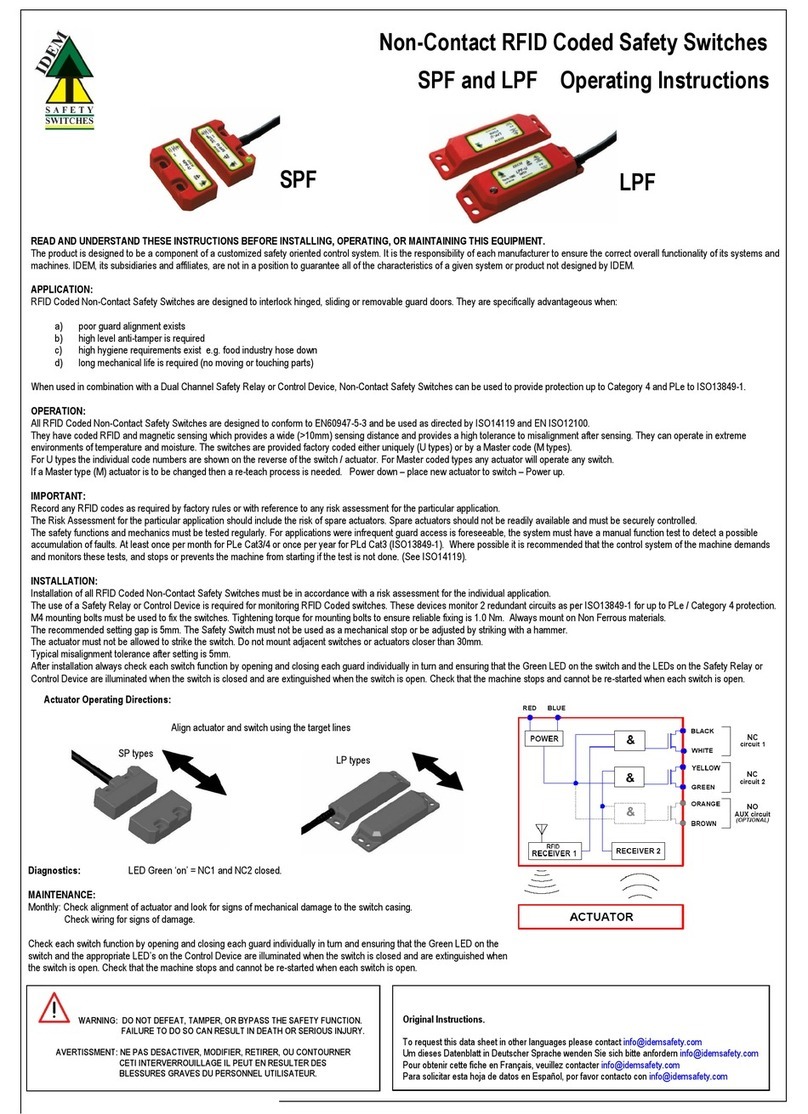

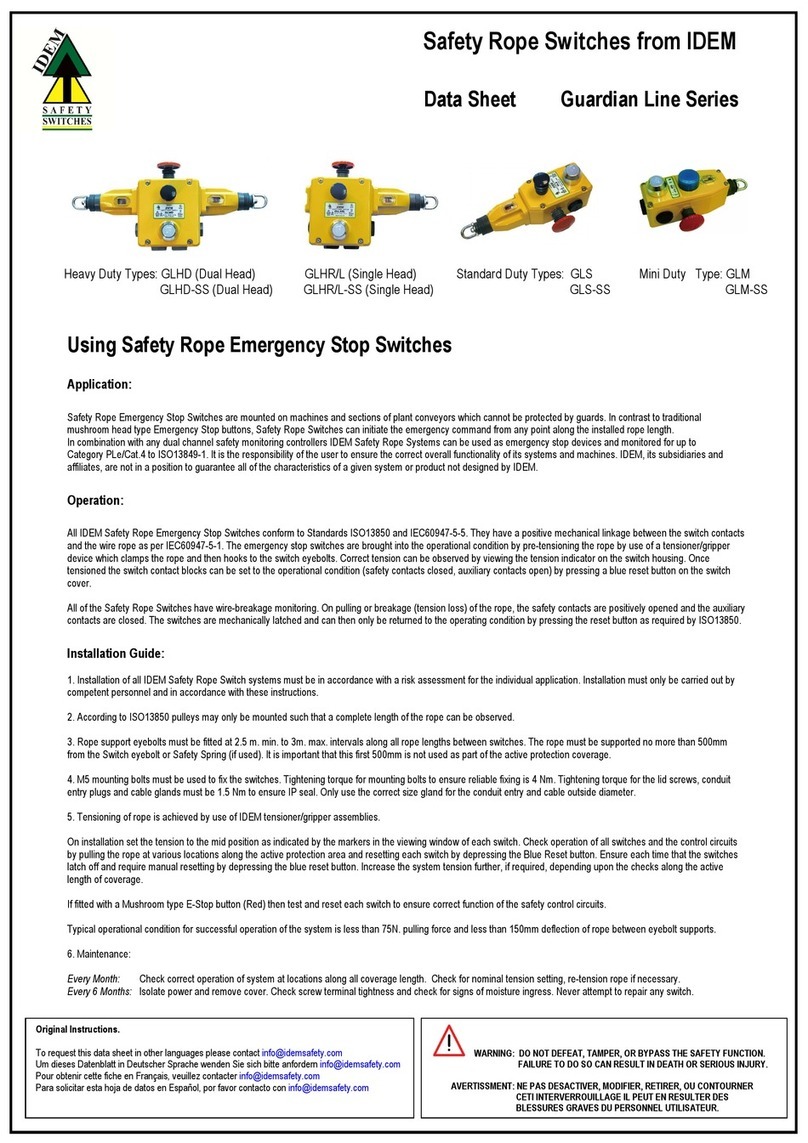

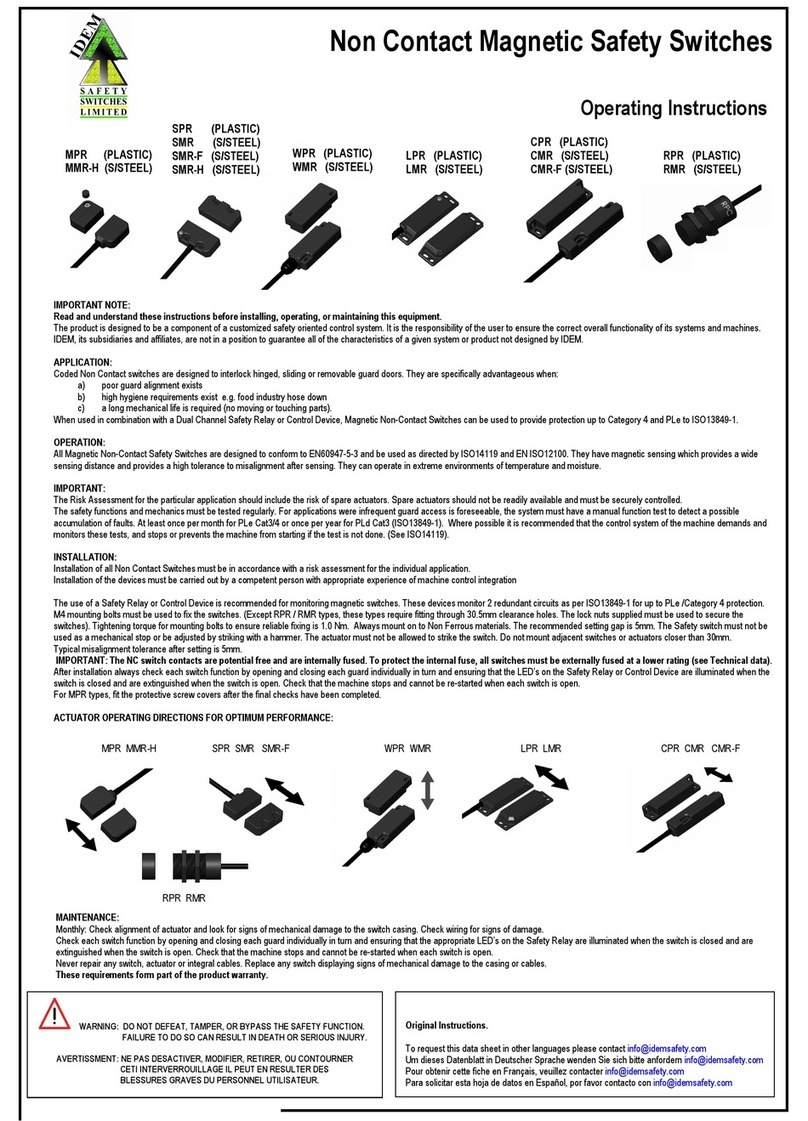

IDEM SAFETY SWITCHES KLM-P2L User manual

Safety Interlock Switch with Guard Locking

Insta

llation:

1. Installation of all interlock switches must be in accordance with a risk assessment for the individual application.

Installation must only be carried out by competent personnel and in accordance with these instructions.

2. M5 mounting bolts must be used to fix the switch and actuator, the tightening tor ue to ensure reliable fixing is 4.0 Nm.

To prevent loosening of the switch after installation, always fix the M5 ounting bolts with a thread-locking

co pound or secure using self locking nuts.

Tightening tor ue for the lid screws, conduit entry plugs and cable glands must be 1.5 Nm to ensure IP seal.

Only use the correct size gland for the conduit entry and cable outside diameter.

Tightening tor ue for the connection terminal screws is 0.7 Nm, max conductor size is 1.0 s .mm.

The switch head position can be selected by removing the actuator, loosening the 4 head bolts and then rota

ting

the head to the position re uired. Re-tighten the head bolts and then check actuator insertion and withdrawal.

Tightening tor ue for the head bolts is 1.5Nm.

3. Always fit a mechanical stop to the guard to prevent damage to the front of the switch.

Set the actuator gap to 3mm when the guard is closed and against the stop. (See Fig. A.)

Use alignment guides to ensure that the actuator enters the switch without interfering with the sides of the switch aperture.

Always fit the aperture plug to the unused entry aperture to prevent debris entering the switch mechanism.

4. After installation check operation of all control circuits and the locking function.

For applications with a run down time after removing power, ensure that the correct timing allowance has elapsed before energising the solenoid.

LED 1 GREEN will illuminate when power is applied to A1 and A2 (solenoid feed).

Hinged Guard Sliding Guard

Application and Operation:

The switch is rigidly mounted to the frame of the guard or machine. The actuator is fitted to the moving part (frame) of the guard and is aligned to the switch entry aperture. The actuator profile is

designed to match a cam mechanism within the switch head and provides a positively operated not easily defeatable interlock switch. When the actuator is inserted into the switch the safety

contacts will close only when power is applied to the solenoid. This will then allow the machine start circuit to be enabled. When the solenoid power is removed the safety contacts are opened

and the machine circuit is broken.

IMPORTANT: Any hazardous motion has to be controlled and a safe condition initiated in the event of power failure.

P2L versions (power to lock) may not be suitable for machines with a running down ti e.

KL

M

-

P2L

Operating Instructions

Fig. A

Plastic Body

IMPORTANT NOTE:

Read and understand these instructions before installing, operating, or aintaining this equip ent.

The product is designed to be a component of a customised safety orientated control system. It is the responsibility of the user to ensure the correct overall functionality of its systems and

machines. IDEM, its subsidiaries and affiliates, are not in a position to guarantee all of the characteristics of a given system or product not designed by IDEM.

8 actuator entry positions

rotatable head

Internal Ter inal Connections:

A1 0V dc

A2 24V.dc

11-12 Safety Circuit 1 – ( ust always be used)

21-22 Safety Circuit 2

33-34 Signal Circuit Guard - (Closed when Guard is closed)

43-44 Signal Circuit Guard - (Closed when Guard is open)

LED Function:

Green Solenoid Energised

Safety Interlock Switch with Guard Locking

IDEM SAFETY SWITCHES Ltd., 2 Or side Close, Hindley Industrial Estate, Hindley Green, Wigan, WN2 4HR UK. Tel: +44 (0)1942 257070 Fax.: +44 (0)1942 257076

IDEM (USA)

4416 Technology Drive

, Fre ont, CA 94538 Tel:510

-

445

-

0751 Fax:1866

-

431

-

7064 e ail:

sales@ide safety.co

Web:

www.ide safety.co

Quick Connect (QC)

M23 12 way Male Plug

(Pin view from switch)

Switch Circuit

1 3

A1 A2

4 6

11 / 12

7 8

21 / 22

2 5

43 / 44

9

33

10

34

Earth

12

Confor ing to S

tandard:

ISO14119, IEC 60947

-

5

-

1, UL508, ISO13849

-

1

Safety Classification and Reliability Data:

Mechanical Reliability B10d

ISO 13849-1

EN 62061

Safety Data - Annual Usage

2.5 x 10

6

operations at 100mA load

up to PLe / Cat.4 depending upon system architecture

up to SIL3 depending upon system architecture

8 cycles per hour / 24 hours per day / 365 days

MTTFd 356 years

Solenoid Voltage (by part number)

24V ac/dc (12W.

)

Safety Contacts 11/12 21/22

33/34

Overload protection fuse (fuse externally)

Utilization Category

AC15 A300

3A.

Thermal Current (Ith) 5A

10A. (FF).

Auxiliary Contact 43/44

230V.ac

/dc 0.5A.

Maximum

.

Rated Insulation Voltage

600VAC

Rated Impulse Withstand Volt

2500VAC

Travel for Positive Opening

Approach Speed

10mm

200mm/m. to 1000mm/s.

Man. Actuation Fre uency

2 cycle/sec

Actuator entry minimum radius

175mm Standard

100mm Flexible

Case Material

Head Material

Die Cast painted red

Stainless Steel 316

Actuator Material

Stainless steel

316

Enclosure Protection

IP67

Operating Temperature

-

25

°C to 4

0°C

Holding Force

F1Max: 3000N. Fzh: 2307

N.

Vibration

IE

C 68

-

2

-

6, 10

-

55Hz+1Hz,

Excursion: 0.35mm, 1 octave/min

Conduit Entry

Various (See Sales Part Numbers)

Fixing

4 x M5

Doc: 1025

28

Aug 17

Dimensions (mm)

Contact 33/34 is

positively operated at

withdrawal of actuator

6.0 5

Actuator insertion (mm)

Inf

ormation with regard to UL 508: Type 1 enclosure.

Maximum temperature 40°C.

Use 16-28AWG stranded copper conductors (rated 90°C).

Terminal Tor ue 6 lb ins. (0.7Nm).

Intended for same polarity use. A300 Pilot Duty. 240V. 3A.

PF 0.38 or greater, tested for 6,000 cycles endurance

Use one polymeric conduit connection.

Not suitable for connection to rigid metal conduit.

Original Instructions.

To re uest this data sheet in other languages please contact [email protected]m

Um dieses Datenblatt in Deutscher Sprache wenden Sie sich bitte anfordern info@idemsafety.com

Pour obtenir cette fiche en Français, veuillez contacter i[email protected]om

Para solicitar esta hoja de datos en Español, por favor contacto con [email protected]m

WARNING: DO NOT DEFEAT, TAMPER, OR BYPASS THE SAFETY FUNCTION.

FAILURE TO DO SO CAN RESULT IN DEATH OR SERIOUS INJURY.

AVERTISSMENT: NE PAS DESACTIVER, MODIFIER, RETIRER, OU CONTOURNER

CETI INTERVERROUILLAGE IL PEUT EN RESULTER DES

BLESSURES GRAVES DU PERSONNEL UTILISATEUR.

IMPORTANT

The Risk Assessment for the particular application should include the risk of spare actuators. Spare actuators should not be readily available and must be securely controlled.

Application consideration must be given to the fixing of the actuator which has to be in a way that prevents disassembly by easy means.

Ensure that the switch holding force (Fzh) is sufficient to withstand the static forces applied during normal use and dynamic effects caused by bouncing of the guard shall not create an impact reaction

force which exceeds the holding force. If the expected impact reaction forces are higher than the specified holding force for the switch, then design measures must be applied to avoid the force.

The safety functions and mechanics must be tested regularly. For applications were infre uent guard access is foreseeable, the system must have a manual function test to detect a possible

accumulation of faults. At least once per month for PLe Cat3/4 or once per year for PLd Cat3 (ISO13849-1). Where possible it is recommended that the control system of the machine demands and

monitors these tests, and stops or prevents the machine from starting if the test is not done. (See ISO14119).

Maintenance:

Every Month: Check the switch actuator and body for signs of mechanical damage and wear. Replace any switch showing damage.

Every 6 Months: Check for mechanical damage to switch body or actuator. Isolate power and remove cover.

Check screw terminal tightness and check for signs of moisture ingress.

Never attempt to repair any switch. Replace any switch displaying damage.

These require ents for part of the product warranty.

Other IDEM SAFETY SWITCHES Switch manuals

Popular Switch manuals by other brands

Triax

Triax TMS 17XX SE A-EU Series user guide

THOMSON

THOMSON GRASS VALLEY Triton TTN-BAS-1602CP installation manual

Philips

Philips Sonicare 300 SerieS datasheet

Brocade Communications Systems

Brocade Communications Systems Converged Enhanced Ethernet 8000 Hardware reference manual

LevelOne

LevelOne FSW-2208TX user manual

Siemens

Siemens S3VA41TDHD installation instructions

LOVATO ELECTRIC

LOVATO ELECTRIC GEX10 Series Assembly instructions

Ruijie

Ruijie Reyee RG-NBS5200-48GT4XS-UP Hardware installation and reference guide

Juniper

Juniper QFX5120 Series Hardware guide

LaCie

LaCie Hub Quick install guide

SDMO

SDMO VERSO S Operating and instruction manual

HP

HP ProCurve 2520-24-PoE Specifications