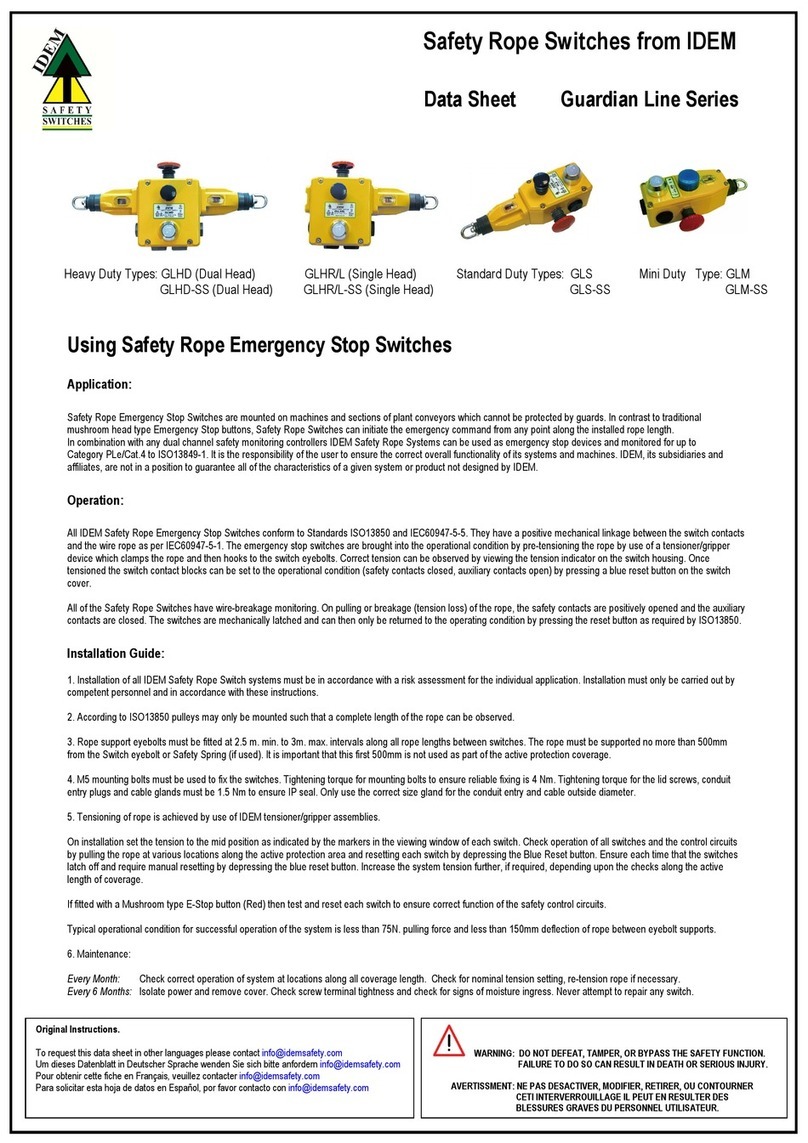

IDEM SAFETY SWITCHES MGL-P User manual

Non-Contact RFID Locking Safety Switches

MGL-SS

IMPORTANT NOTE

Read and understand these instructions before installing, operating, or maintaining this equipment.

The product is designed to be a component of a customised safety orientated control system. It is the responsibility of the user to ensure the correct overall functionality of its systems and

machines. IDEM, its subsidiaries and affiliates, are not in a position to guarantee all of the characteristics of a given system or product not designed by IDEM.

DESCRIPTION

The MGL range of Non Contact RFID Coded switches has been developed to provide and maintain a high level of functional safety whilst providing a reliable magnetic door interlock.

Coding is achieved by using magnetic and RFID techniques and both of these principles need to be satisfied for the switch to operate safely.

The MGL range will connect to the majority of popular standard safety relays to achieve door interlocking up to PLe/Category 4 to ISO13849 1.

Offered in Stainless Steel 316, high specification robust Plastic or in Die Cast Metal housings the MGL switches can used in almost any environments including high pressure cleaning

following contact with foreign particles.

The Stainless Steel 316 version of the MGL incorporates a Stainless Steel magnet and has an IP69K ingress protection rating making it suitable for CIP and SIP processes.

APPLICATION

MGL RFID Coded Non Contact Safety Switches with integral holding magnet have been designed to interlock hinged or sliding guard doors. They are specifically advantageous when:

a) high level anti tamper is required

b) high hygiene requirements exist e.g. food industry hose down

c) long mechanical life is required (no moving parts)

d) there is a requirement to hold a guard closed

When used in combination with a Dual Channel Safety Relay or Controller they can be used to provide door interlock protection up to Category 4 and PLe to ISO13849 1.

OPERATION

All RFID Coded Non Contact Safety Switches are designed to conform to EN60947 5 3 and be used as directed by ISO14119, EN ISO12100 and EN60204 1. They have coded RFID

sensing which provides a wide (>10mm) sensing distance and provides a high tolerance to misalignment after sensing. They can operate in extreme environments of temperature and

moisture. The switches are provided factory coded either uniquely or by series master code.

IMPORTANT

The guard locking function is Power ON applied, Power OFF released as described in ISO14119. This locking function needs to be risk assessed against any hazard to an

operator in the case of machine overrun after release or loss of power.

The Risk Assessment for the particular application should include the risk of spare actuators. Spare actuators should not be readily available and must be securely controlled.

Record any RFID codes as required by factory rules or with reference to any risk assessment for the particular application and user location.

INSTALLATION

Installation of all RFID Coded Non Contact Safety Switches must be in accordance with a risk assessment for the individual application.

The use of a Safety Relay is required for monitoring RFID Coded switches. These relays monitor 2 redundant circuits as per ISO13849 1 for up to PLe/Category 4 protection.

RFID Coded Non Contact Safety Switches are designed to operate with most Dual Channel Safety Relays to satisfy EN60947 5 3.

M5 mounting bolts must be used to fix the switches. Tightening torque for mounting bolts to ensure reliable fixing is 1.0 Nm. Always mount on to Non Ferrous materials.

Do not mount adjacent switches or actuators closer than 100mm. To achieve nominal holding force ensure face to face alignment of magnetic parts.

After installation always check each switch function by opening and closing each guard individually in turn and ensuring that the Green LED on the switch and the LEDs on the Safety Relay

or Controller are illuminated when the switch is closed and are extinguished when the switch is open. Check that the machine stops and cannot be re started when each switch is open.

Note

The safety outputs will only close when the actuator is in place and the lock magnet is energised.

Forcing open of the lock will cause the safety outputs to open.

M

AINTENANCE

/ SAFETY CHECKS

Monthly: Check alignment of actuator and look for signs of mechanical damage to the switch, actuator or cable.

Replace any switch displaying damage.

These requirements form part of the product warranty

.

The safety

functions and mechanics must be tested regularly. For applications were infrequent guard access is foreseeable, the system mu

st have a manual function test to detect a

possible accumulation of faults. At least once per month for PLe Cat3/4 or once per year for PLd Cat3 (ISO13849 1). Where possible it is recommended that the control system of the

machine demands and monitors these tests, and stops or prevents the machine from starting if the test is not done, (ISO14119).

Check that the machine stops and cannot be re started when each switch is open.

MGL

-

P, MGL

-

M, MGL

-

SS

Operating Instructions

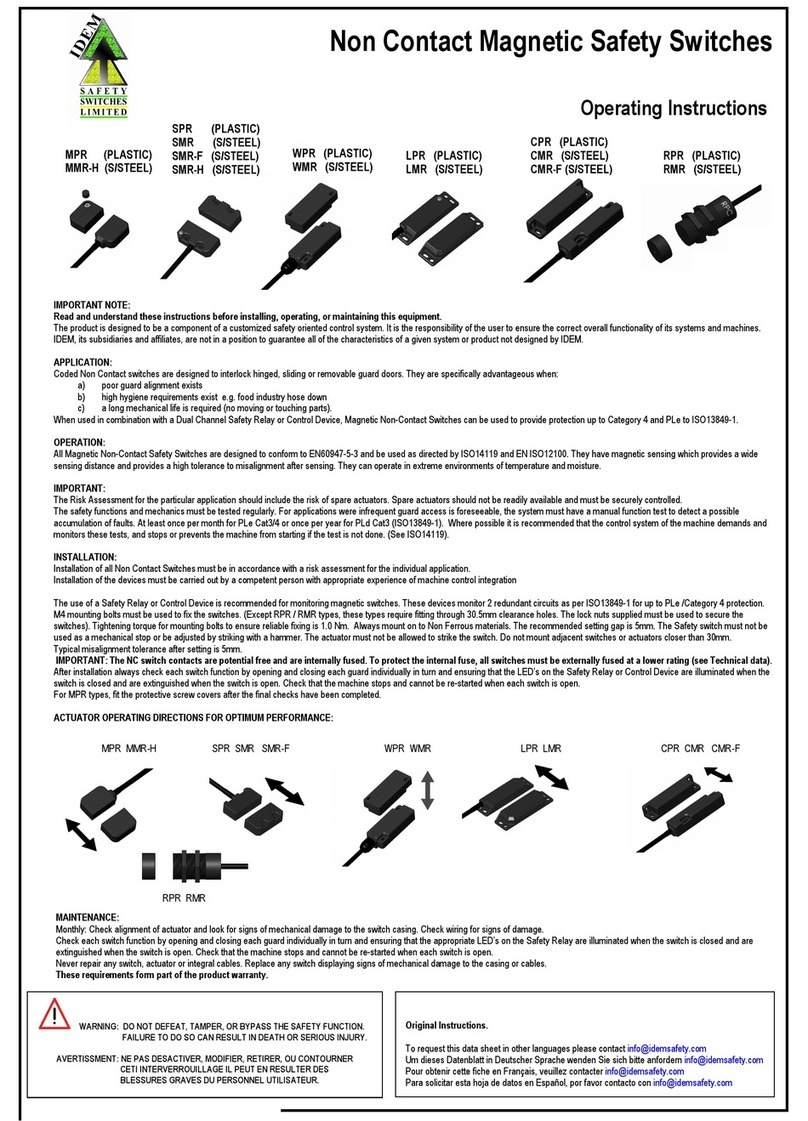

MGL-M

MGL-P

FEATURES

HEAVY DUTY: (F1 max.) 1100N S/Steel, 1500N Plastic and Die Cast Metal

MEDIUM DUTY: (F1 max.) 600N S/Steel, 1000N Plastic and Die Cast Metal

2NC Safety Outputs (Door closed – Lock energised)

1NO Auxiliary Output for indication of door open

No moving parts – high switch life and provides resistance to

shock and vibration.

Remanence magnetization holding technique acts as a light

magnetic latch before and after unlocking.

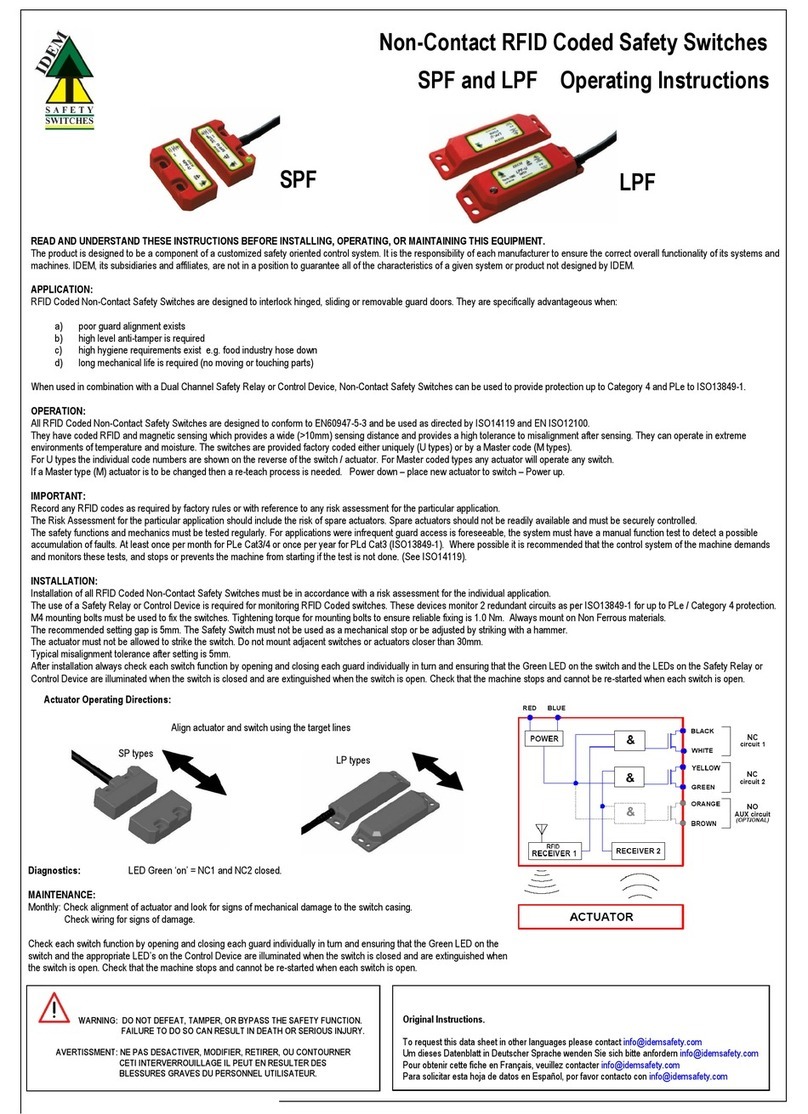

CONNECTION EXAMPLE

Dual circuit to a SCR

-

31

-

I Safe

ty Relay

PLASTIC

DIE CAST METAL

STAINLESS STEEL

Non-Contact RFID Locking Safety Switches

Switch Status

Guard

Green LED

Yellow LED

Locked

Closed

Steady

Off

Solenoid Power OFF (unlocked)

Closed

Flashing

Off

Guard Open

Open

Off

Steady

Door Forced Open

Open

Off

Flashing

Q

uick Connect (QC)

250mm (10”)

M12 8 Way

Male Plug

Conductor

Colours

Function

Power

Ratings

3

Blue

Supply 0Vdc

50mA max.

2

Red

Supply 24Vdc

8

Orange

Lock Applied (24Vdc)

500mA max.

7

Black

Safety Output 1

200mA (max. switching)

1

White

Safet

y Output 1

4

Yellow

Safety Output 2

200mA (max. switching)

6

Green

Safety Output 2

5

Brown

Auxiliary Signal

+24Vdc

MGL

-

1

Switch Dimensions (mm)

(Heavy Duty)

Connection Colours

IDEM SAFETY SWITCHES Ltd., 2 Ormside Close, Hindley Industrial Estate, Hindley Green, Wigan, WN2 4HR UK. Tel +44 (0)1942 257070 Fax. +44 (0)1942 257076

IDEM (USA), 4416 Technology Drive, Fremont, CA 94538 Tel 510-445-0751 Fax 1866-431-7064 email [email protected] Web www.idemsafety.com

D

oc: 102557

Aug 17

Standards

ISO14119 EN60947 5 3 EN60204 1

ISO13849 1 UL508

Dielectric Withstand: 250V.ac

Insulation Resistance: 100 Mohms

Switching Distance: Sao 1mm Close

Sar 10mm Open

Tolerance to Misalignment: 5mm in any direction from a gap of 5mm

Switching frequency: 1.0 Hz maximum

)

Approach speed: 200mm/m to 1000mm/s

Body material: MGL *P = Plastic

MGL *M = Die Cast Metal

MGL *SS = Stainless Steel 316

Temperature Range: 25C to +40C

Enclosure Protection: IP67/IP69K (Stainless Steel)

Cable Type: PVC 8 core 6mm OD

Mounting Bolts: 2 x M5 Tightening torque 1.0 Nm

Mounting Position: Any

Power Supply: +24Vdc ± 10% (SELV / PELV)

Maximum Switched Current (outputs): 200mA (Minimum internal resistance 8.5 Ohms)

Characteristic Data according to EN ISO13849-1

Performance Level e If both channels are used in combination with a

SIL3/PLe control device

Category Cat4

MTTFd 1100a

Diagnostic Coverage DC 99% (high)

Number of operating days per year: dop = 365d

Number of operating hours per day: hop = 24h

B10d: Not mechanical parts implemented

When the product is used deviant from these assumptions (different load, operating frequency,

etc.) the values have to be adjusted accordingly.

MGL

-

2 Switch Dimensions (mm)

(Medium Duty)

Pin View from Switch

LED Operation and Switch Status Indication

The MGL switch uses 2 LEDs to indicate all the different possible switch states.

The LEDs are in a clearly visible location at either side of the cable exit point.

Actuator Operating Di

rection

MGL shown in OPEN position.

Steady Yellow LED indication.

MGL shown in CLOSED position

, lock energised

.

Steady Green LED indication.

INFORMATION WITH REGARD TO UL508

Type 1 Enclosures.

Maximum temperature 40ºC. Maximum output 24V.dc 200mA.

Powered by Class 2 or equivalent.

WARNING Hot surface – risk of burn if used at ambient temperature of +40C degrees.

(Affix a warning label to the switch).

Original Instructions.

To request this data sheet in other languages please contact info@idemsafety.com

Um dieses Datenblatt in Deutscher Sprache wenden Sie sich bitte anfordern info@idemsafety.com

Pour obtenir cette fiche en Français, veuillez contacter info@idemsafety.com

Para solicitar esta hoja de datos en Español, por favor contacto con info@idemsafety.com

WARNING DO NOT DEFEAT, TAMPER, OR BYPASS THE SAFETY FUNCTION.

FAILURE TO DO SO CAN RESULT IN DEATH OR SERIOUS INJURY.

AVERTISSMENT NE PAS DESACTIVER, MODIFIER, RETIRER, OU CONTOURNER

CETI INTERVERROUILLAGE IL PEUT EN RESULTER DES

BLESSURES GRAVES DU PERSONNEL UTILISATEUR.

This manual suits for next models

2

Other IDEM SAFETY SWITCHES Switch manuals

Popular Switch manuals by other brands

Ross

Ross ULTRIX-FR1 Upgrade guide

CYBEX

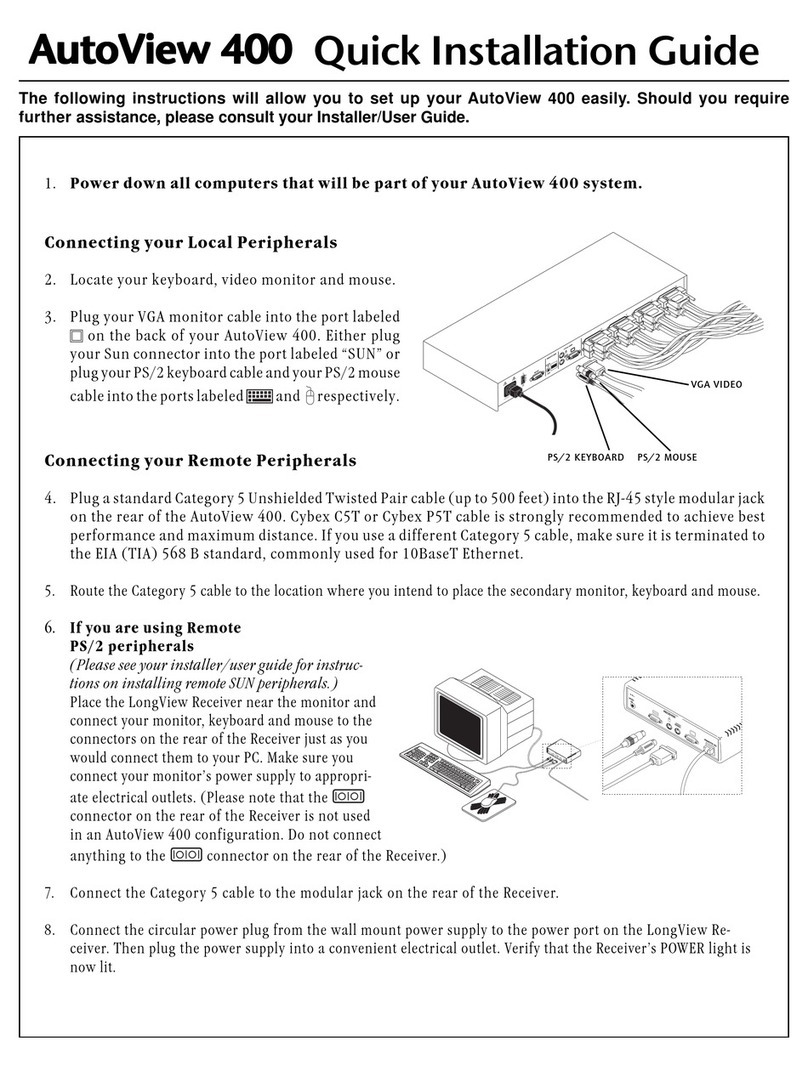

CYBEX AutoView 400 Quick installation guide

Timing

Timing TSC 4092A IRIG-B Operation and maintenance manual

Cisco

Cisco Catalyst 3850 series Configuration guide

Dataprobe

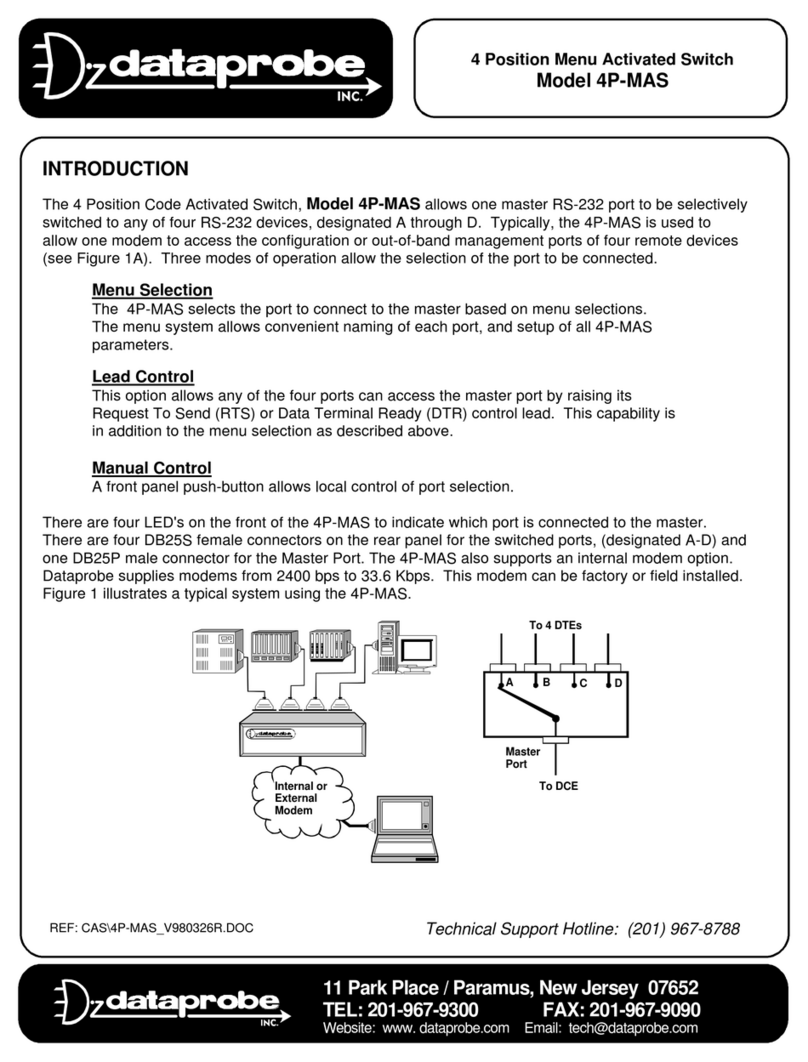

Dataprobe 4P-MAS quick start guide

Acuity Brands

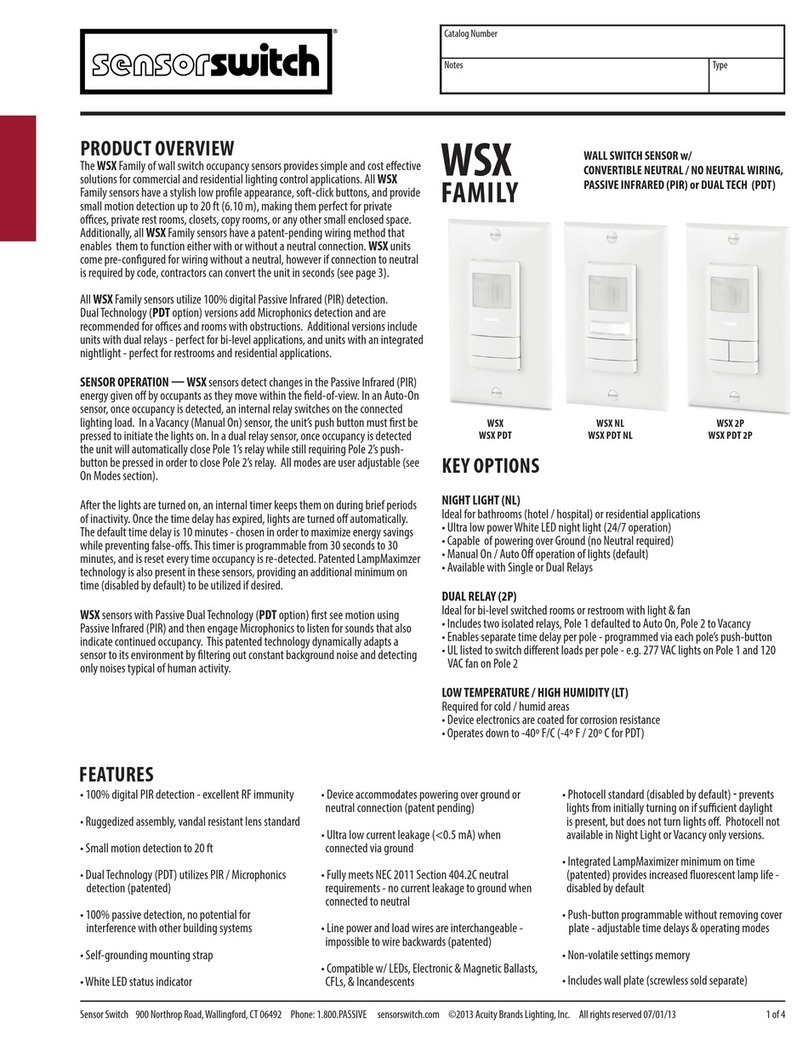

Acuity Brands Sensor Switch WSX Series quick start guide

NETGEAR

NETGEAR FSM726E - ProSafe Switch Hardware installation guide

Rose electronics

Rose electronics x series quick start guide

TP-Link

TP-Link TL-SG2424P reference guide

TRENDnet

TRENDnet TE100-S55Eplus - Switch user guide

Analog way

Analog way Pulse quick start guide

call4tel

call4tel NXGW-XET1 user manual