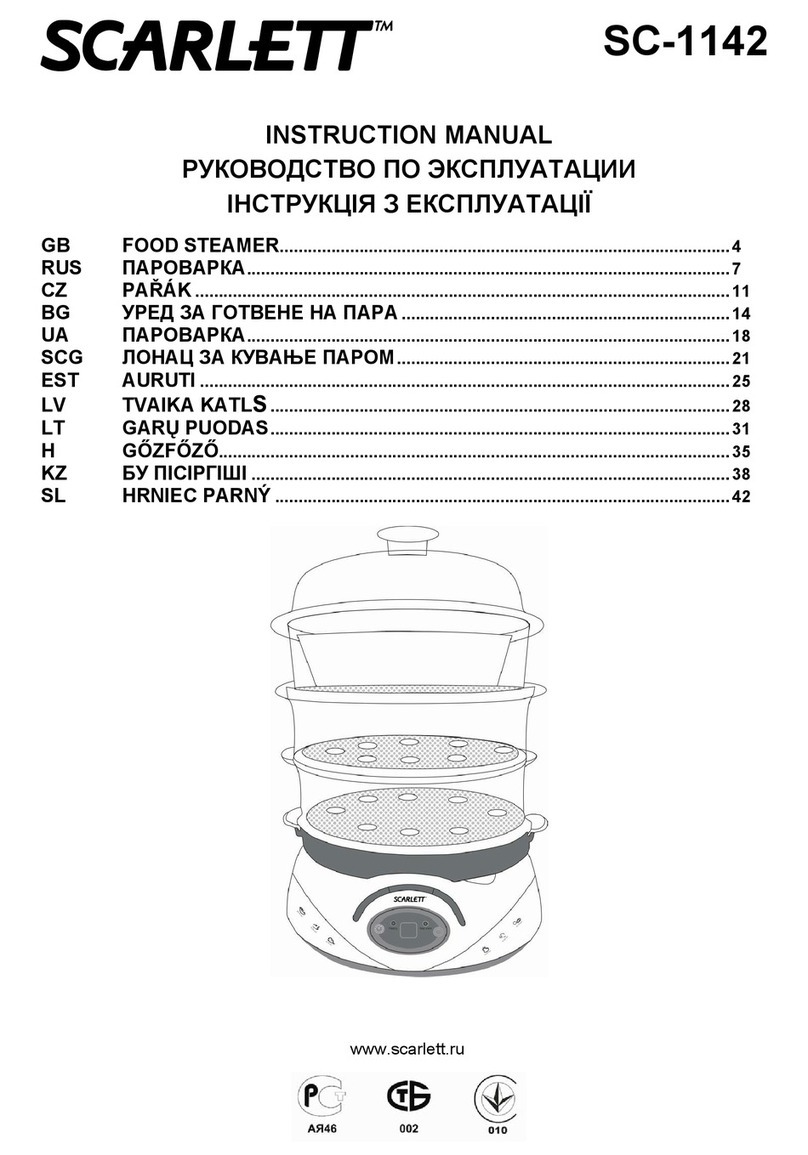

English

1

ENGLISH

WARNING!

Before usage read this manual carefully and follow the instructions so as to avoid improper and dangerous (to people,

animals and objects) operations while using the steamer.

The manufacturer is not responsible for and reserves the right to not apply the warranty to:

Damage caused by normal wear and tear, abnormal use or conditions, misuse, neglect, abuse, accident, improper

handling or storage, exposure to moisture, unauthorized modifications, alterations, or repairs, improper installation,

improper use of any electrical source, undue physical or electrical stress, operator error, non-compliance with

instructions or other acts which are not the fault of manufacturer, including damage or loss during shipment.

Certified Product

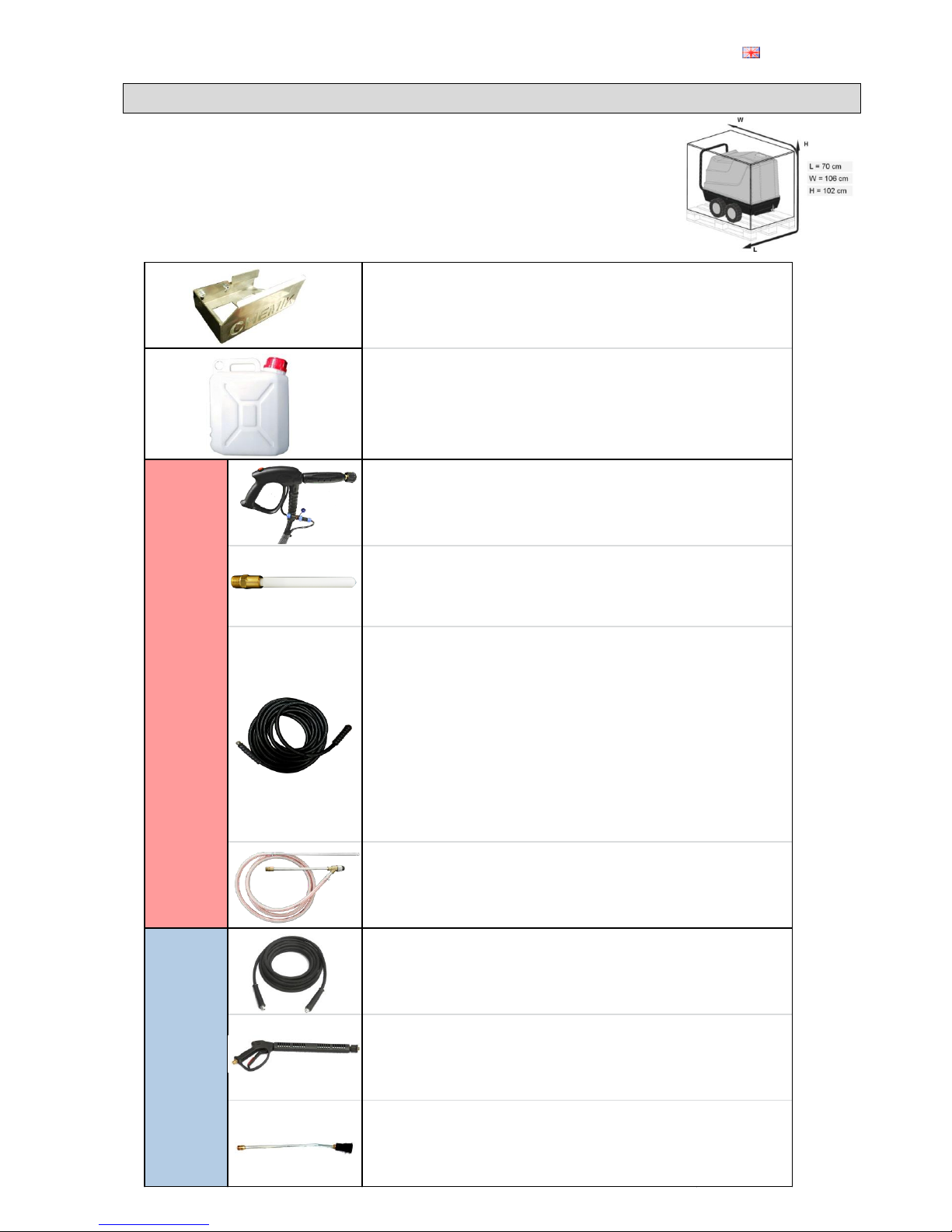

Idromatic s.r.l.

via Petrarca n°127

46030 Borgoforte (MN) - Italy

p.iva e cod. fiscale –VAT: 02096330200

website: www.idromatic.it

tel. +39 0376 648756

fax. +39 0376 649140