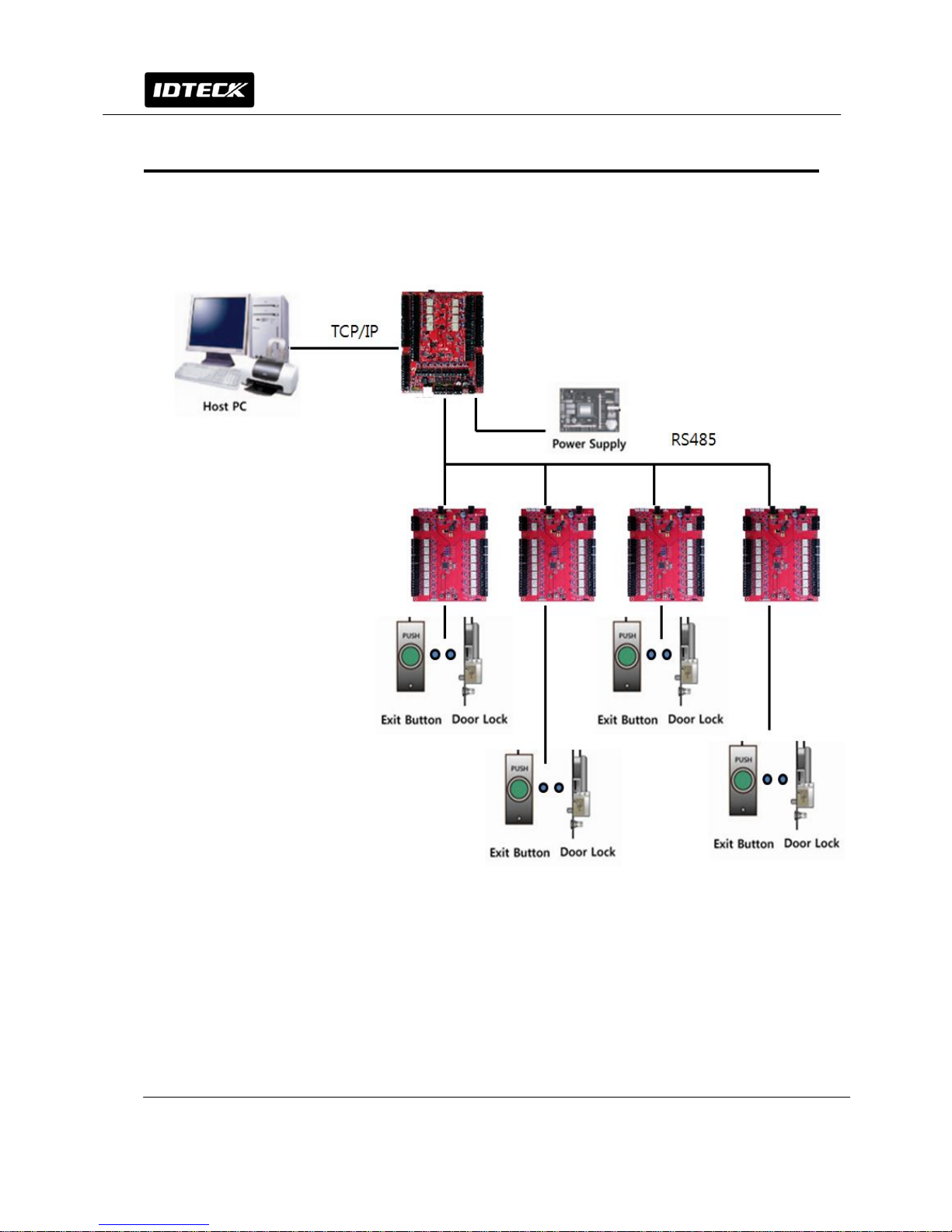

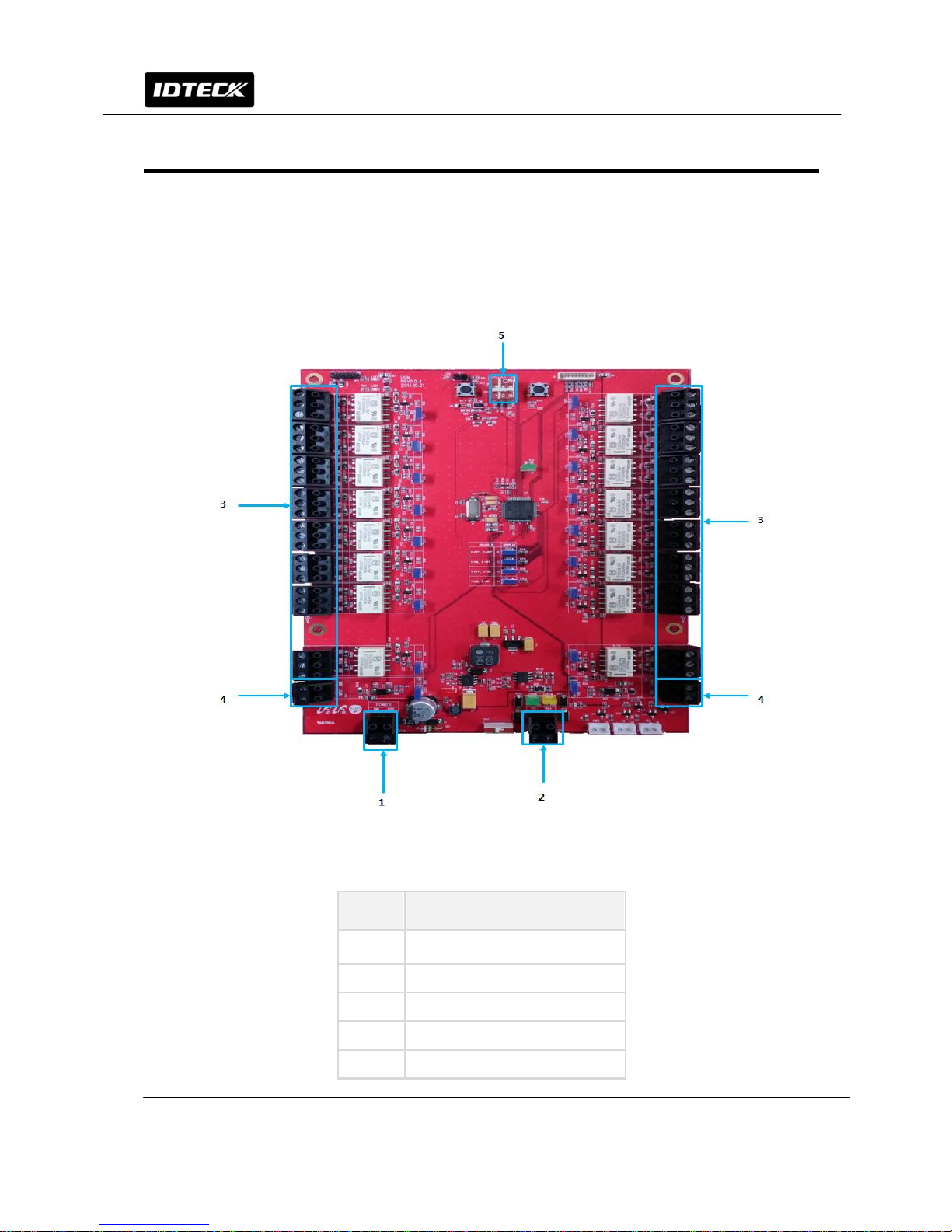

2 RS485 Communication port Used when connecting iFDC/iEDC board

3 relay #1 ~ #16 (Relay #1 ~

#16) output port

Provides sixteen FORM-C (COM, NO, NC) relay outputs.

(DC12~24V, Max 2A)

4

input #1 ~#2 (Input #1 ~#2)

port

Consists of 2 input ports.

5 LD #7 ~ #22

When an output occurs, the corresponding output

LED blinks for the output time

(LD #7 – Relay #1, LD #8 – Relay #2, LD #9 – Relay #3, LD

#10 – Relay #4, LD #11 – Relay #5, LD #12 – Relay #6, LD

#13 – Relay #7, LD #14 – Relay #8, LD #15 – Relay #9, LD

#16 – Relay #10, LD #17 – Relay #11, LD #18 – Relay #12,

LD #19 – Relay #13, LD #20 – Relay #14, LD #21 – Relay

#15, LD #22 – Relay #16)

6 LD #23 ~ #24

When a normal input is received, the corresponding input

LED

blinks for a moment (LD #23 – Input #1, LD #24 – Input #2)

7 Fixing hole Can be used when fixing board to NEMA case or to Earth

Ground.

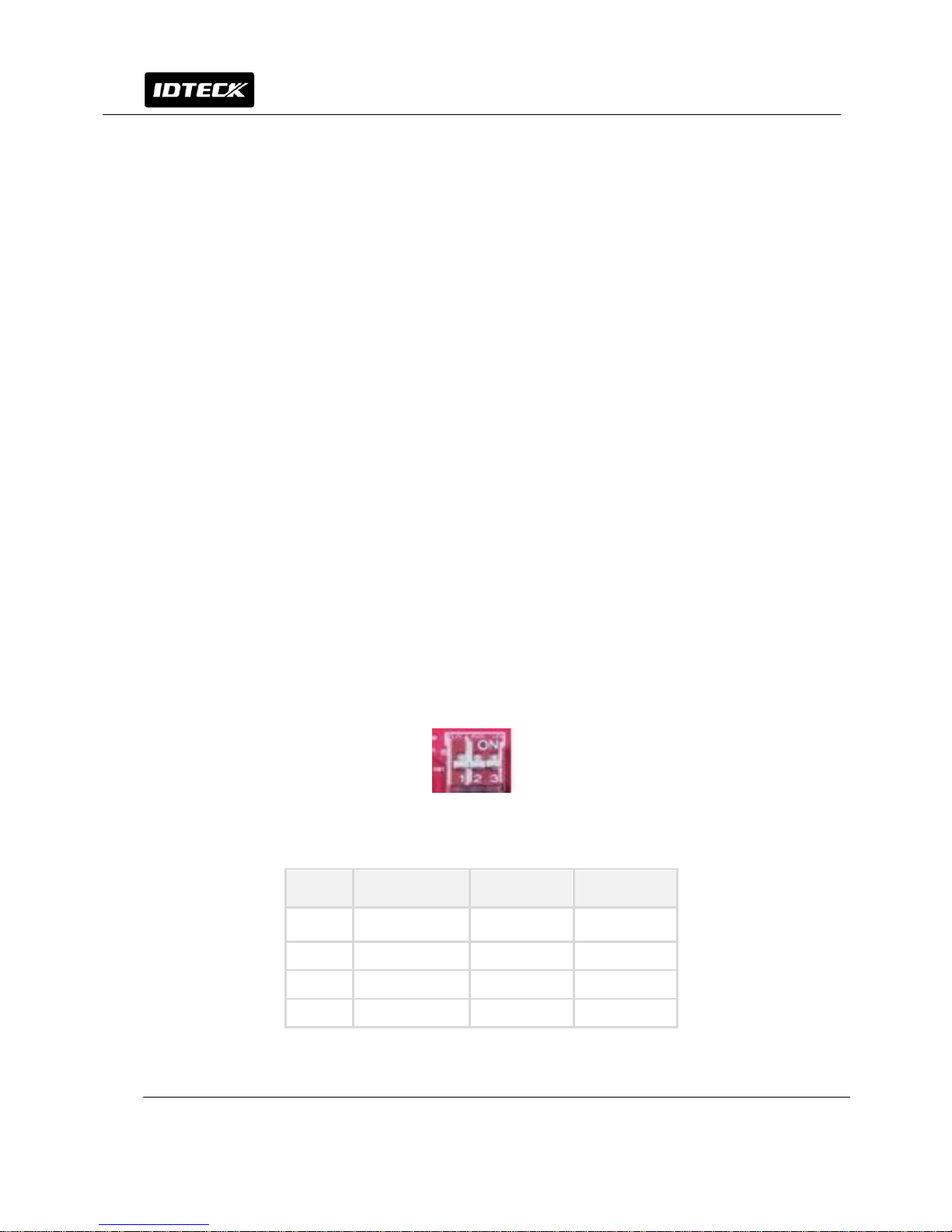

8 Dip switch for setting board

ID & ADC

Switch for setting board ID. Board ID indicates device’s own

address for communication. Switch1-2: shows applicable

board ID via LED. Switch 3: whether to use ADC.

9 Board ID LED Shows board ID

10 RESET S/W Reboot UOM. Setting values remains after the reboot.

11 Initialization Switch

Initializes all the values of UIM to factory default and resets

UIM. Press this switch for more than 3 seconds to initialize

the device.