IDX Zolar Z440 Installation instructions

1

Zolar

TM

System Z440

Installation & Operation Instructions

Rev 11/04

General Description

The Z440 ZOLAR System is the ultimate in antifreeze controls for the carwash industry. ZOLAR cycles the weep water

for your bays, controls blow down for your low pressure/foam products, and turns on a floor heat system, equipment

room heater, or even your air conditioner in the summer. Zolar includes an output to control the FB880 Foam Blower to

purge the Foam Brush lines. The Auto-Dialer option alerts you to power outage or freezing conditions.

Specifications

Power Supply: 115VAC @ 7VA (230VAC optional)

Relay Outputs: 3A continuous, 8A inrush @ 24VAC to 240VAC, each with NO & NC contacts.

Output Protection: Plug replaceable fuses and Varistor spike clamping for low interference and long contact life.

Temperature Probe: ±0.2°C accuracy, 0.2°C / 0.5°F display resolution, ¼" OD x 4.0" stainless steel sheath.

Light Probe: ± 5% accuracy 1% to 100% full sunlight (8,500 ft.cdl), 3/8"OD x 1.5" HDPE silicone sealed case.

Internal Time Clock: Battery backed clock chip with 10 year life and "low battery" warning message.

Enclosure: 9.75" x 6.88" x 2.88", polycarbonate, sealed cover, #8 mounting screws at 9.125" x 6.187"

Optional Configurations and Accessories

115VAC or 230VAC Power Configuration is specified at the time of your order. A checkbox on the enclosure

cover label near the input power terminals indicates the configuration of the unit.

Expanded Output Option. One each Weep and Auxiliary Outputs are included in the Standard Configuration. One

each additional Weep and Auxiliary outputs may be added to the Standard Configuration to provide sensing and control

for larger carwashes having additional functions or services. When the Expanded Output Option is installed there will

be a second connector installed for its sensor inputs and relay outputs.

FB880 Foam Blower. The FB880 Foam Blower performs the control function of blowing down the foam brush

hoses during freezing weather by activating up to eight separate air and or antifreeze solenoids with a timed series of

electrical pulses.

Z440TP Temperature Probe. One Z440TP Temperature Probe is included with the Standard Configuration and one

additional Z440TP is included in the Expanded Output Option. Both the Standard Configuration and the Expanded

Output Option can each have a second temperature probe to provide additional functionality, or to sense weep

temperature at in two separated locations. The probe comes with 50 feet of PVC cable standard, other lengths optional.

Z440LP Light Probe. The Standard Configuration and the Expanded Output Option each allow for two sensor

inputs, the second of which may be the Z440LP Light Probe for sensing the ambient light to control exterior building

lights or other security functions. The probe comes with 50 feet of PVC cable standard, other lengths optional.

2

Operational Description Of Zolar

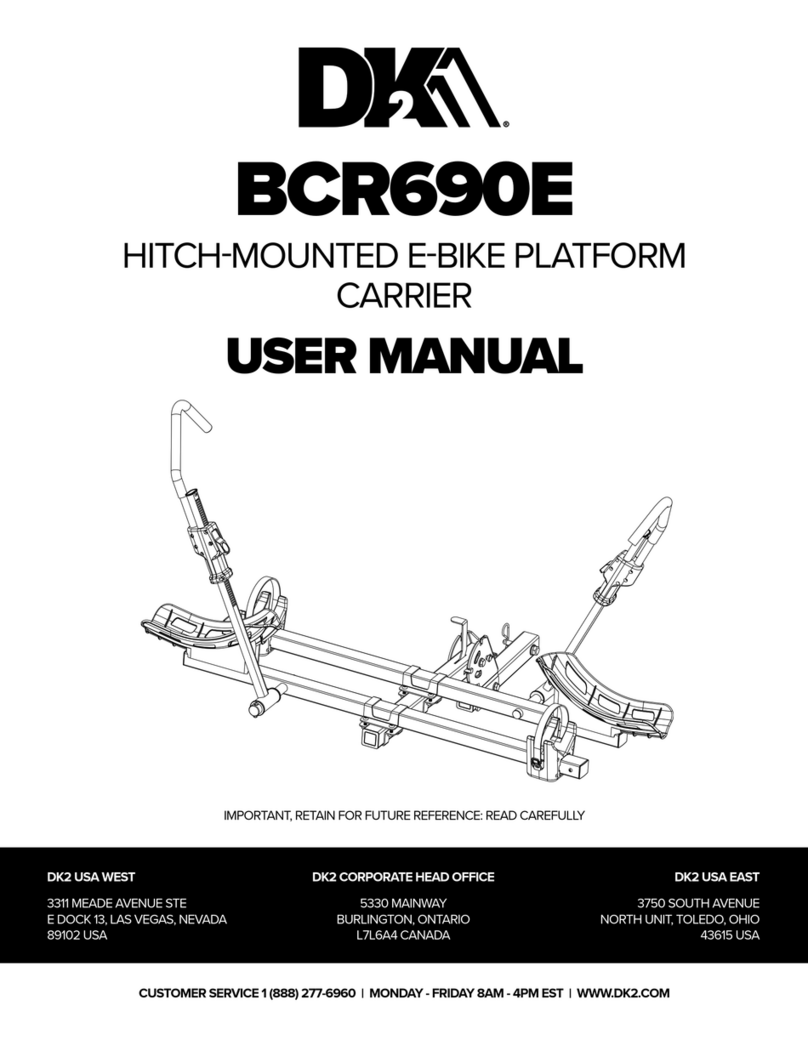

Weep #1 Output

The purpose of the Weep #1 Output is to control a weep solenoid

to provide a trickle flow of water through the high pressure wand

during freeze conditions. The Weep #1 relay output is controlled

by the lower reading of Temperature Sensor #1 and Temperature

Sensor #2, where Temperature Sensor #2 is optional and will be

ignored if not installed. The use of two temperature sensors can

be used to ensure at least one of them will always be on the

shaded side of the carwash were solar heating is not present.

With the front panel Configuration Menu, you select temperature

values for Weep-Start and for Full-Weep. As shown in the

diagram to the right, above the Weep-Start temperature the relay

output will always be on, below the Full-Weep temperature the

relay output will always be off, and at temperatures in-between

the relay will have a duty cycle (over a 1 minute period) prorated

according to the temperature. (See also the Application Notes.)

Aux #1 Output

The Aux #1 Output can be configured to control equipment based on time, temperature or ambient light intensity. The

front panel Configuration Menu allows you to configure this output according to your needs. For temperature or light

control, the respective Z440TP Temperature Probe or Z440LP Light Probe is connected to the Sensor #2 terminals. If

time is selected to control Aux #1 Output, then the internal battery backed clock controls the output.

Slab Heat Control: To prevent water from freezing on concrete slabs, the Aux #1 Output can be used to control a

contactor/pump system to circulate a warm antifreeze solution through pipes embedded in the slab. The front panel

Configuration Menu allows you to set a temperature threshold and gives you a choice of having the output relay turn

On-If-Hot or On-If-Cold. Most prefer to use On-If-Cold with the N.O. contacts for this application.

External Light Control: To turn on your external lighting at dusk, and turn it back off at dawn, connect the Z440LP

Light Probe to Sensor #2 terminals and use the front panel Configuration Menu to configure Aux #1 Output for control

by Light. The Light Probe will ensure that lights are turned on and off as needed no matter what time of year it is or

how thick the clouds are. See the Light Probe Application Note for useful information in using this function.

Time Of Day Control: Equipment, such as an office air conditioner or a bill changer, can be turned on and off at a

specific time of day. This may allow you to save electricity when nobody is in the office, or disable certain functions

late at night when they may be susceptible to vandalism. The front panel Configuration Menu panel allows you to select

the time for Turn-On and the time for Turn-Off.

Weep #2 Output - Optional

The Weep #2 Output operates exactly the same as Weep #1 Output, but is controlled by its respective Menu settings and

Sensor Input #3 and optionally Sensor Input #4.

Aux #2 Output - Optional

The Aux #2 Output operates exactly the same as Aux #1 Output, but is controlled by its respective Menu settings and

Sensor Input #4 if temperature or light is selected for its control.

Auto Dialer Output

The Auto Dialer Output is activated for 15 seconds after the temperature first exceeds the upper or lower bounds set via

the Configuration Menu for any of the four possible temperature sensors that may be installed. The Auto Dialer Output

will also activate following a power outage. To avoid repeated nuisance calls for the same problem, once activated, it

will not re-activate until all trigger sources have maintained a clear state for at least one continuous hour. Wiring

information will be provided with the Auto Dialer when purchased from IDX.

Foam Blower Output

The Foam Blower output is controlled by the lower reading of Temperature Sensor #1 and #3, where Temperature

Sensor #3 is optional and will be ignored if not installed. Its threshold is set via the Configuration Menu. The Foam

Blower Output connects to the Zolar Input on the FB880 Foam Blower. See the FB880 manual for more information.

Zolar Weep Duty Cycle

0

20

40

60

80

100

0 5 10 15 20 25 30 35 40 45 50 55 60

Degrees Fahrenheit

Percent Duty Cycle

Relay On

Relay Off

3

Status Display

Zolar uses a bright LED dot matrix display to continuously scroll easy to read status messages. These messages include

the time of day, the temperature of all connected temperature sensors, the current ambient light intensity (if installed),

and how many days have elapsed since the last cold event and since the last power outage.

The time of day is presented in a 12-hour format, where an extra LED dot to the left of the time is illuminated to

indicate PM. If a Sensor is not physically connected, it will not be displayed. Temperatures are displayed to the nearest

0.5° Fahrenheit or nearest 0.2° Centigrade according to your Menu configuration selection. Light intensity (if used) is

expressed as a percentage of full sunlight. DAYS WARM indicates the number of days that have elapsed since the last

time a Foam Blower or Weep output was activated, while DAYS POWERED indicates the number of days since

Zolar’s power was last interrupted. Scrolling of each portion of the message is paused for 1 second while numeric

parameters are displayed to allow for easier viewing.

The following is an example status message for a configuration that includes one temperature sensor and one light

sensor. Scrolling of the display will pause for the underlined portions., parameters presented in italic are only displayed

if the option and/or sensor are present:

TIME: 03:27 TEMP #1: °F 33.5 LIGHT #2: 16.7% DAYS WARM: 164 DAYS POWERED: 973

In addition to the scrolling dot matrix display, 6 stationary LEDs to the right of the display indicate the status of all

Outputs: Weep #1, Aux #1, Weep #2, Aux #2, Auto Dialer and Foam Blower. The Weep LED is: a.) Off when it is

warm, b.) On solid when it gets cold and the relay is in the de-energized (weep water flows) portion of the weep cycle,

and c.) blinks when it gets cold and the relay is in the energized (weep water off) portion of the weep cycle. The other

LEDs are On when their corresponding outputs are On.

Configuration Menu

Just below the dot matrix LED display window is a set of four buttons (shown above) for navigating the Configuration

Menu. If the

Next

or

Back

keys are pressed, the status message is interrupted and the Configuration Menu is entered.

From the Configuration Menu, all time, temperature, or light threshold set points can be viewed by successive use of the

Next

and

Back

keys or changed by use of the

-/No

and

+/Yes

keys. If no key is pressed for 15 seconds while in the

Configuration Menu, the operator is prompted to either use the

Next

key to save the any changes made to the presently

displayed parameter and advance to the next parameter, or to use the

Back

key to cancel any changes made to this

parameter and return to the previous parameter.

PUSH NEXT TO SAVE OR BACK TO CANCEL

If, while in the Configuration Menu, no key is pressed for 30 seconds (an additional 15 seconds after the prompt to

either save or cancel), the display will revert to the status message leaving any “un-saved” parameters unchanged. Saved

parameters are stored in nonvolatile EEPROM memory where they are safe from power outages and battery failure and

will remain in effect until changed again through the Configuration Menu.

SET TIME Y/N?

After entering the Configuration Menu by pressing either the

Next

or

Back

key, the first prompt of the Configuration

Menu asks if you wish to set the time on Zolar’s Real Time Clock. If the

+/Yes

key is pressed in response to this

prompt, the current time in the Real Time Clock is displayed. If this time is not correct, the

+/Yes

and

-/No

keys can

be used to set the correct time. The time displayed will advance one minute for each press of the

+/Yes

key, or retreat

one minute for every press of the

-/No

key. If the key is held down for at least one second, the time will automatically

change at a rate of 5 minutes for every second the key his held down. Once the correct time has been reached, press the

Next

key to save this value into the Real Time Clock and proceed to the next item in Configuration Menu.

4

TEMP UNITS: °F

This prompt indicates that Zolar is currently configured to display all temperatures degrees Fahrenheit. Use the

+/Yes

or

-/No

keys to toggle between the °F and °C format. Once the desired units are displayed, press the

Next

key to save

the temperature format and proceed to the next item in Configuration Menu.

START WEEP #1: °F 34

This prompt indicates that the Weep #1 Output will start cycling at 34°F. This output is controlled by the lower of the

temperatures indicated by Sensor #1 and Sensor #2 (if configured for Dual-Temp Weep). Fail-Safe reasons the Weep

Output relays are normally energized when it is warm and de-energized when it is cold. Also, for Fail-Safe reasons, we

recommend using the N.O. relay contacts to drive a N.O. solenoid valve for the weep system. In this manner, if power

fails or a wire is broken, the weep water will flow and prevent freezing of the high pressure hoses and wands. The Start

Weep set point controls the temperature at which "weep cycling" of the output begins. The Start Weep set point can be

adjusted in one-degree steps by using the

+/Yes

and

-/No

keys. The

Next

key will save the new value and advance the

menu to the Full Weep message.

FULL WEEP #1: °F 15

This prompt indicates the temperature at which "weep cycling" becomes 100%. At this temperature and below, the

associated Weep Output relay will always be turned off so that the N.O. solenoid valve will be open providing weep

water to prevent freezing of the high pressure hoses and wands. At temperatures between Start Weep and Full Weep,

the Weep Output relay will energize for only a percentage of each minute in proportion to the proximity of the sensed

temperature to the Start Weep and Full Weep set points as detailed in the diagram on page 2. In the example using Start

Weep = 34°F and Full Weep = 15°F, if the sensed temperature is 20°F then we would be 5° from Full Weep out of a

total of 19° between Start Weep and Full Weep. Since at Start Weep the relay is On 100% of the time, then at 20°F the

relay would be On 5/19 = 26.3% of the time during each minute, for a period of 16 seconds each minute. As with the

Start Weep set point, this set point can be adjusted in one-degree steps by using the

+/Yes

and

-/No

keys. The

Next

key will save the new value and advance to the next item in Configuration Menu.

AUX #1 TYPE: TEMP

The equipment connected to the Aux #1 output can be controlled based on time, temperature or ambient light intensity.

The above message indicates that Zolar is currently configured to control the Aux #1 Output based on having a

Temperature Probe connected to the Sensor #2 terminals. If this is not the desired configuration, use the

+/Yes

or

-/No

key to select either LIGHT or TIME.

¾If TEMP is selected, the next prompt displays a temperature set point:

TEMP TRIP: °F 34

You can change the temperature trip set point by using the

+/Yes

and

-/No

keys. The

Next

key will save the

new value and advance the menu to the next item.

AUX #1 ON IF COLD

This prompt indicates that the Aux #1 Output relay will be energized on temperatures below the Temp Trip

setting This example setting would be useful to control a pump circulate antifreeze solution in pipes embedded

in a concrete slab. When controlling Aux Outputs by temperature, Zolar uses 2°F of hysteresis to prevent

indecisive behavior near the set point. In this example Aux #1 Output will turn Off when the temperature rises

to 36°F. You can change the setting to On If Hot by using the

+/Yes

and

-/No

keys. The

Next

key will save

the new value and advance the menu to the next item.

5

¾If LIGHT is selected, the next prompt displays a light intensity set point:

LIGHT TRIP: 0.7%

The Light Probe is connected to the Sensor #2 input and is calibrated to produce a reading of 100% in direct

sunlight on a clear summer day at mid latitudes. There is generally sufficient light to wash cars down to about

0.5% of full sunlight intensity. See the application note later in this document for more lighting information.

When light levels fall below the Light Trip value, the Aux #1 Output relay will be energized. About 100%

hysteresis is provided on this Light Trip value to prevent the Aux #1 Output relay from being energized and

de-energized as moving clouds and other factors vary near sunrise and sunset. You can change the temperature

trip set point by using the

+/Yes

and

-/No

keys. The

Next

key will save the new value and advance the menu

to the next item.

¾If TIME is selected, the next two prompts display the time at which Zolar will energize the Aux #1 relay.

ON TIME: '08:00 (note the PM indicator just before the numerical digits)

OFF TIME: 06:00

Times can span midnight. For example, if you wish to have lights come on at 8:00 PM and go off at 6:00 AM,

set On Time and Off Times as shown in the example above. The

+/Yes

and

-/No

keys will modify this time

set point if desired and the

Next

key will save the values and advance to the menu to the next parameter.

After the Weep and Aux outputs are configured, Zolar presents information for the Foam Blower output set point.

FOAM BLOWER TEMP: °F 34

The Foam Blower output is controlled by the lower of temperature sensor #1 or temperature sensor #3 (if installed). At

temperatures above the set point, the Foam Blower output will be active low. At temperatures below the set point, the

Foam Blower output will be inactive. Once the Foam Blower becomes active, the temperature must rise 2°F above the

set point before the output will switch to inactive (2° hysteresis). The

+/Yes

and

-/No

keys will modify the set point

and the

Next

key will save the values and advance to the menu to the alarm parameters.

TEMP #1 ALARM LOW: °F 55

The last set of parameters presented in the Configuration Menu is for Zolar’s Auto Dialer Alarm capability, which may

be triggered by either a temperature extreme or a power outage. If the power fails for any reason, the Auto Dialer will

be triggered as soon as power is restored. Zolar will only prompt you for Alarm set points for those Sensor Inputs

having attached Temperature Probes. Since Sensors #1 and #3 are each associated with a Weep Output they will trigger

an Alarm for a low temperature only. Since Sensors #2 and #4 can be used to sense temperatures that are too low, or too

high, they can trigger an Alarm Output if the temperature gets either too cold or too hot. This output is designed to be

used with an Auto Dialer to provide a phone call to an off-site location but could also provide some local alarm

annunciation if desired. Each temperature set point can be individually adjusted using the

+/Yes

and

-/No

keys.

To avoid repeated “nuisance” calls for the same problem, once triggered, the alarm output will not re-trigger until all

trigger sources have maintained a clear state for at least one continuous hour. As there are no more parameters to

configure, the

Next

key will now return to the Status display.

LOWEST TEMPERATURE: F 12.5 RESET? Y/N

Zolar will keep track of the lowest temperature recorded since last time the value was reset. A Yes response to the

prompt above would reset the lowest temperature to the current temperature.

6

Output Test Menu

Zolar has a built-in Output Test Menu to confirm operation of each Output circuit after installation or to

troubleshoot suspect systems. In order to enter the Output Test Menu, you must simultaneously press all

four buttons for one second continuously. Zolar will then respond with the following prompt:

OUTPUT TEST MODE: WEEP #1 OFF

You can change the state of the indicated Output by pressing the

+/Yes

key to turn the Output On or

by pressing the

-/No

key to turn the Output Off. Press the

Next

key to test the next Output. As you

move on to each next Output, the prior one will automatically turn Off.

During the time you use the Output Test Menu all other normal Sensing and Output functions are

temporarily halted. If there has been no further key press for at lest 60 seconds, any Output currently

turned On will be turned Off and the normal functions of Zolar will restart.

Serial Data Port

Zolar is optionally equipped with an RS-232 serial data port for use with remote configuration and data acquisition

computer applications. IDX intends to offer such applications in the future. The protocol for communication is

proprietary and will be shared with other OEM equipment manufacturers on request.

Autodialer Interface

The Zolar Autodialer Enable output is an open-collector NPN transistor that sinks current to Common when activated in

an alarm situation. Most all autodialers on the market will work with this type of output as it is compatible with a N.O.

relay or switch contact. IDX recommends one of the two autodialers below… or their successor models. The manuals

for these products can be downloaded from the IDX Web site from the Autodialer page.

Visonic DL-125C

Connect the Visonic DL-124C autodialer as

shown in their manual in Figure 5 of

section 3.2 on page 2 as shown to the right.

Connect the “-” terminal on the DL-125c to

Zolar’s “Autodialer Com” terminal and

their "Z-1" terminal to Zolar’s “Autodialer

Enable” terminal. The dialer channel 1

must be configured as N.O. (normally open

- factory default) as indicated in the manual

on page 5, location 22. Please refer to the

Visonic manual for other programming and

operation information. A link to a PDF

copy of the manual can be found on the

Zolar Web page.

United Security Products AD-2001

Connect the AD-2001 “1” terminal to the Zolar “Autodialer Enable” and the AD-2001 “C” terminal to the Zolar

“Autodialer Com” terminal. One must additionally configure Channel 1 as N.O. and Momentary. See the AD-2001

manual pages 5 and pages 10 to 11 for more details. A link to a PDF copy of the manual can be found on the Zolar Web

page.

7

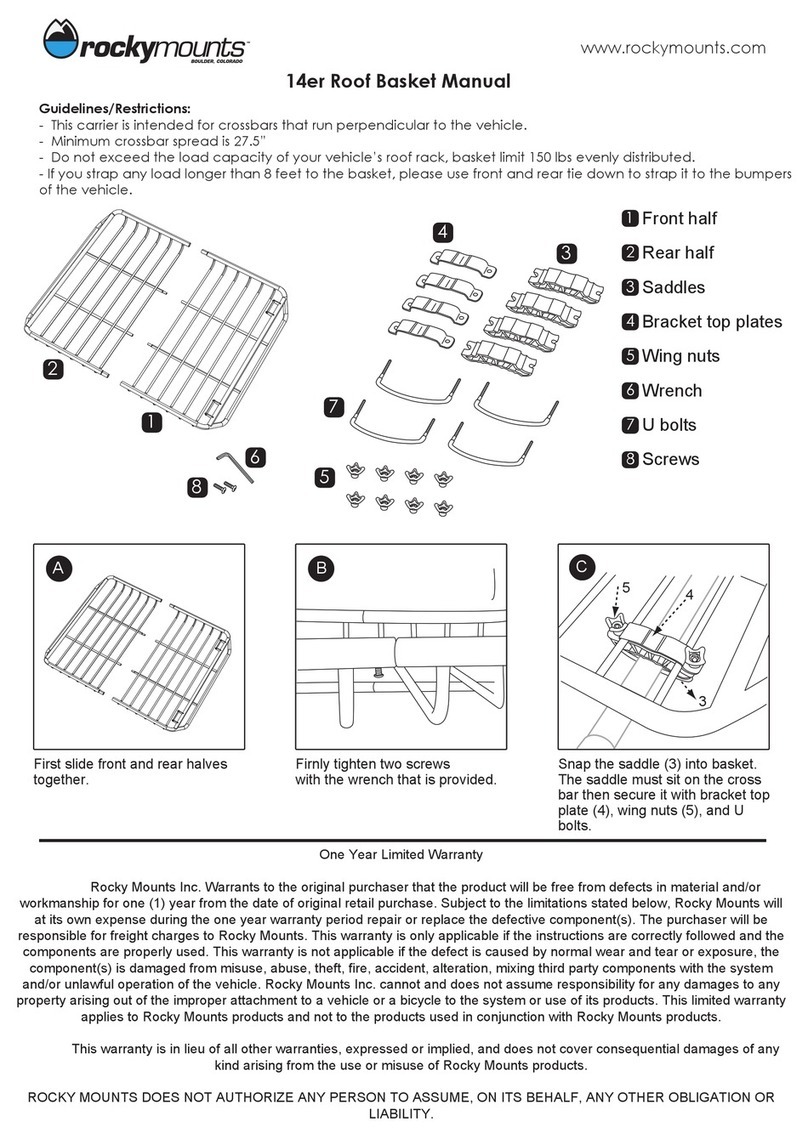

Field Wiring Example

See Foam Blower Manual for more wiring information.

RB S

Probe Wiring:

RED to Sensor

BLK to Reference

SHLD To Shield

Z440LP For Bay Lighting

Z440TP For Weep -Tunnel

Z440TP For Slab Heater

Z440TP For Weep - Bays

Contactor

To Bay

Lights

Solenoid

To N.O.

Tunnel

Weep

Valve

Solenoid

To N.O.

Bay

Weep

Valve

Contactor

To Slab

Heater

Pump

120VAC

Com

Hot

24 VAC Common

Co

m

8

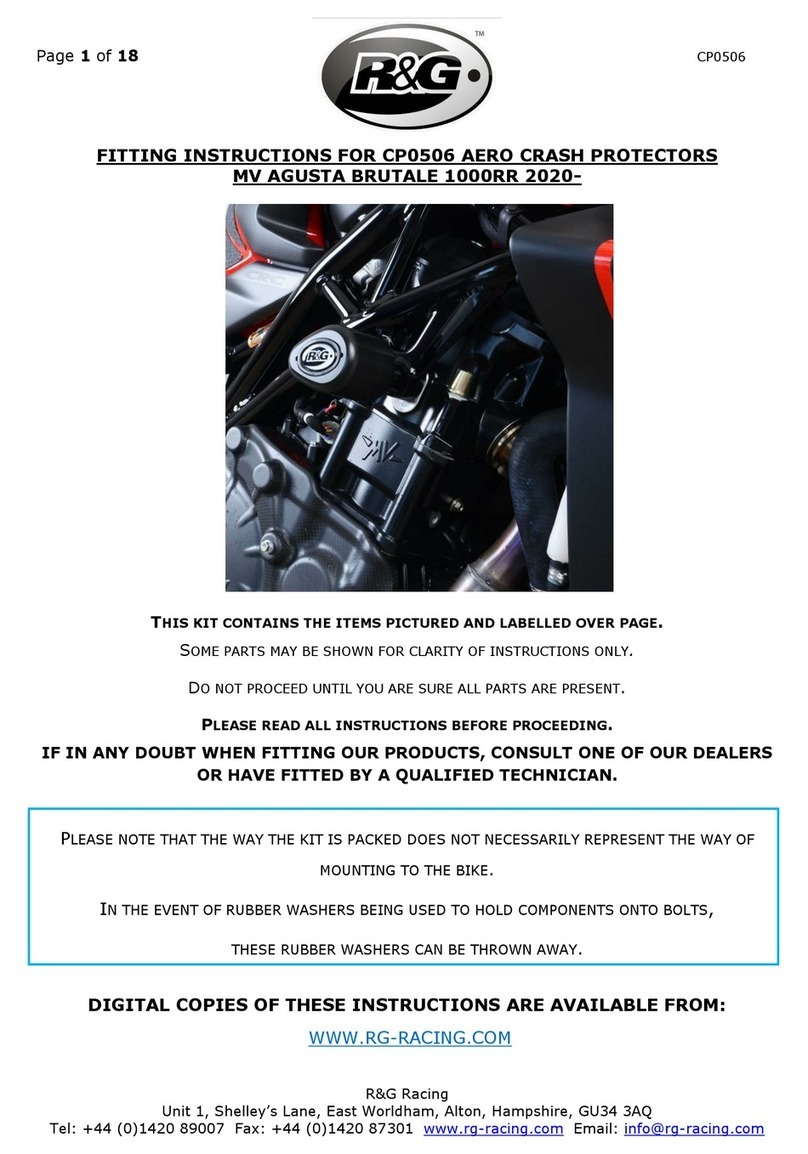

Zolar Configuration Examples

Ex. Weep #1 Output Aux. #1 Output Sensor #1 Sensor #2 Notes:

1 Single-Temp Weep ---- Temperature ---- Configure Aux #1 for control by Temperature.

2 Single-Temp Weep Slab Heat Temperature Temperature Configure Aux #1 for control by Temperature.

3 Single-Temp Weep Exterior Lights Temperature Light Configure Aux #1 for control by Light.

4 Single-Temp Weep Equipment-Timed Temperature ----- ( Time ) Configure Aux #1 for control by Time.

5 Dual-Temp Weep ---- Temperature Temperature Configure Aux #1 for control by Time. (2)

6 Dual-Temp Weep Equipment-Timed Temperature Temp (Time) Configure Aux #1 for control by Time. (2)

8 ----- Slab Heat ----- Temperature Configure Aux #1 for control by Temperature.

9 ----- Exterior Lights ----- Light Configure Aux #1 for control by Light.

10 ----- Equipment-Timed ----- ----- ( Time ) Configure Aux #1 for control by Time.

Notes:

1. When the Expanded Output Option is installed, its respective outputs and sensors (Weep #2, Aux #2, Sensor #3, and Sensor #4 ) are configured

and behave identically as the corresponding outputs and sensors in the table above.

2. Zolar detects the Dual-Temp Weep configuration automatically when you install two Temperature Probes, but configure Aux #1 for control by Time

rather than by the attached sensor. Zolar then automatically assigns the purpose of the second Temperature Probe to that of Dual-Temp Weep.

3. Zolar automatically detects the presence or absence of a Temperature Probe. When a Temperature Probe is not installed for Sensor #1 or for

Sensor #2 (when configured for temperature) Zolar will disable the function of the corresponding Output so that it remains in the Off state.

Zolar Factory Default Configuration

The following table specifies the Menu Configuration values when Zolar is shipped from the factory unless other choices are specifically requested. Additionally,

should there be a replacement of, or failure of, the EEPROM chip that holds these values, Zolar will automatically re-initialize the EEPROM to these values.

Temperature Format °F Auxiliary Temperature 34°F On Lo Weep Alarm Low 0°F

Weep Start Temperature 34°F Auxiliary Light Level 0.7% Auxiliary Alarm Low 30°F

Weep Full On Temperature 15°F Auxiliary Time On 6:00 AM Auxiliary Alarm High 120°F

Foam Blower Temperature 34°F Auxiliary Time Off 6:00 PM Days Warm, Days Powered 0

9

Application Notes

Weep Control Fail Safe Wiring.

When it is winter and your carwash looses power from a storm, you want the system to behave in a manner that

assumes temperatures are below freezing. Failure to do so could result in serious damage. For this reason, normally

open solenoid valves are used so that if power is lost, by default your equipment will be protected from freezing

damage. This means that in warm weather this solenoid must be activated to prevent weeping. For similar fail safe

reasons, if you loose power only to Zolar, or if the overload protection fuse in Zolar is blown, or if for some reason

Zolar should fail, then you want the failed state of the unit to default to the same electrical state as if temperatures

were currently freezing. This means that the N.O. relay contacts should be used to drive the N.O. solenoid valve, and

it is also the reason the duty cycle graph shows that the relay is Off when it is cold and On when it is warm.

Weep Control Multiple Probe Sensing.

The temperature at opposite ends of your carwash may receive sunlight at different parts of the day, causing one side

to be warmer in the morning and the other to be warmer in the afternoon. It is often difficult to find a single location

for mounting the Z440TP Temperature Probe that can provide satisfactory safety from freezing under varying

sunlight conditions. Zolar provides you with the option of using two Z440TP Temperature Probes to solve this

problem. When configured for using two Temperature Probes for the Weep function, Zolar will use the lower of the

two temperatures to control the Weep Output duty factor. Zolar will automatically know if the second Temperature

Probe is to be used with the Weep Output or the Auxiliary Output by how you have configured the Auxiliary Output

through the front panel Configuration Menu. If the Auxiliary Output is configured to be controlled by either

temperature or ambient light, then the second Sensor Input will be associated with the Auxiliary Output control.

However, if you configure the Auxiliary output for control by time of day, then Zolar will use the second Sensor

Input in the dual Temperature Probe configuration for the Weep Output. (Note: If the Auxiliary Output is configured

for control by time of day and a 2

nd

Temperature Probe is not connected, Zolar will ignore the 2

nd

Sensor Input.)

Ambient Light Probe Notes.

The Z440LP Light Probe consists of a light sensor encapsulated in a light diffusing high density polyethylene tube

encapsulated with silicone sealant. It has fairly omnidirectional sensing characteristics to average light intensity over

its entire field of view. The light sensor has a filter for blocking visible light but passing infrared light. This allows

the sensor to easily detect sunlight, which contains a significant amount of infrared light, and ignore light from most

high powered outdoor lights, such as metal halide, mercury vapor, low pressure sodium and fluorescent lamps, all of

which emit virtually no infrared light. However, incandescent and tun

g

sten halo

g

en lamps do contain a

g

reat

deal of infrared light and should not be used near the Z440LP Light Probe. This is important in applications

where the light sensor is being used to control exterior lighting and we do not want these light sources to interfere

with proper detection of the sunlight intensity.

Typically, ambient light levels are measured in foot-candles (ft.cdl.) or alternatively in Lux. The sun produces about

8,500 ft.cdl. or 90,000 Lux of light intensity at noon on a clear summer day. Rather than try to remember these

confusing terms and numbers, Zolar expresses light intensity as a percent of full sunlight brightness. So, a reading of

33.3% indicates the Light Probe is sensing 1/3 of full sunlight intensity.

Experimental data shows that on a sunny day, the light intensity under the eves on the sunny side of a building is

about 10% brightness, under the eves on the shady side of a building is about 5% brightness, and inside a self-serve

carwash bay is also about 5% brightness. There is satisfactory light for washing a car down to light levels in the

range of 0.5% to 1.0%. The default value set at the factory is 0.7%, but you may adjust this threshold using the

Menu on the front panel.

Table of contents

Popular Automobile Accessories manuals by other brands

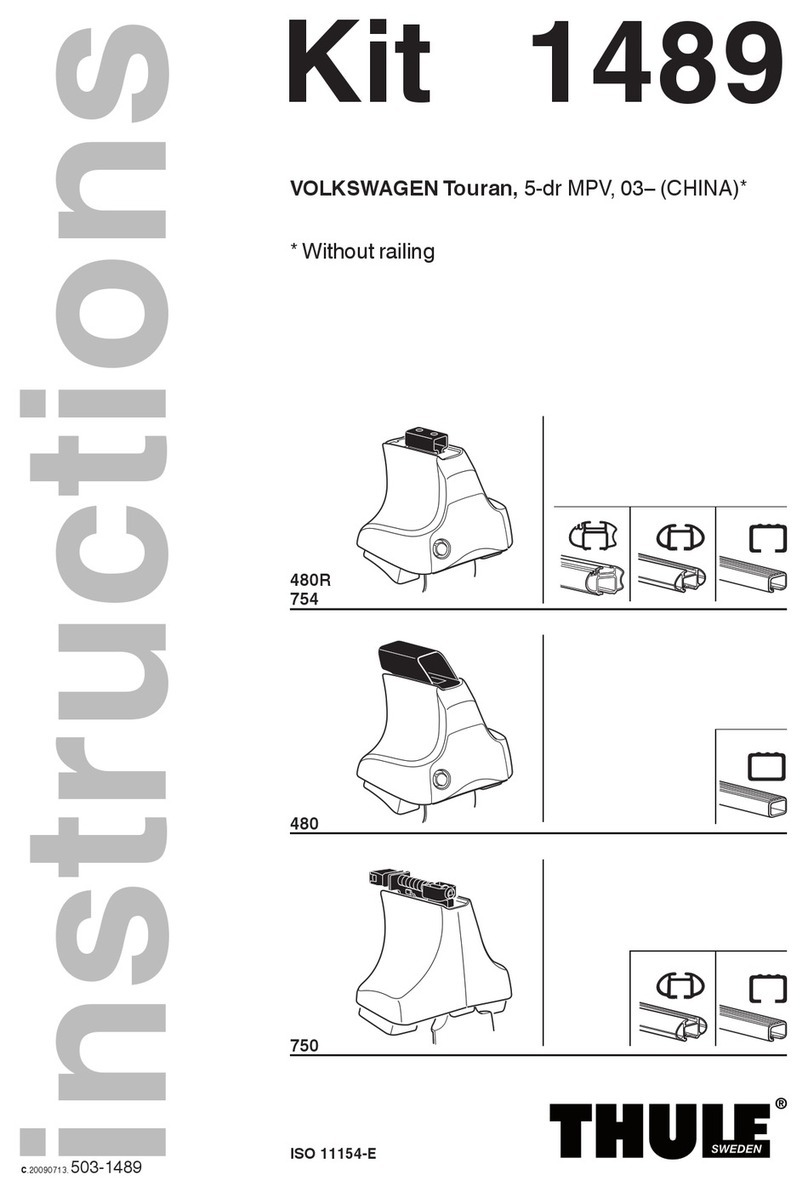

Thule

Thule 1489 instructions

Whispbar

Whispbar K618 Fitting Instructions for Basic Carrier

ULTIMATE SPEED

ULTIMATE SPEED 100113 operating instructions

Whelen Engineering Company

Whelen Engineering Company LINZ6 installation guide

ULTIMATE SPEED

ULTIMATE SPEED 1188 1525 Instructions for use and safety guidelines

NORAUTO

NORAUTO 90 Assembly instructions