Ier steamOvap User manual

ELECTRIC RESISTIVE STEAM HUMIDIFIER

Installation and Operation Manual

Please read and save this manual

steamOvap technologies inc, 1490 Mazuree, Montreal, Qc, H4N 1H2, Canada

Tel.: 1-844-357-4477 • www.steamOvap.com

Rev.: 210601

IER

Introduction

Foreword

Thank you for purchasing IER steamOvap electric steam Humidifier.

If you have quesons or comments please contact us:

www.steamOvap.com

1-844-357-4477

Intended use

IER electric steam humidifier is intended exclusively to produce steam from water at atmospheric

pressure for air humidificaon.

Operang condions are specified in this Installaon and Operaon Manual (IOM).

Operaon of this humidifier in the intended use scope requires that all direcons and

informaon contained in this IOM are observed.

Any other use or operaon outside the above design scope without wrien authorizaon from

steamOvap may lead to trouble and hazardous condions and will void warranty.

No alteraon or modificaon to the humidifier must be done without wrien authorizaon from

steamOvap.

Replacement of any defecve components must be done with original component and spare

parts from steamOvap representave.

Installation and Operation Manual Limitation

This IOM is intended for trained and qualified personnel and must be applied along with the

applicable local codes and regulaons.

Any work related to installaon or service for this humidifier must comply with local code and

regulaon regarding safety and prevenon of accidents.

End of life disposition

Ensure that IER electric steam humidifier is empty from water, if not proceed same way as for a

standard drain for service.

Disconnect IER electric steam humidifier from power supply, electrical control signal, water main

supply, Steam line, and drain. IER electric steam humidifier can then be removed from the wall or

stand.

IER electric steam humidifier is an electrical equipment and as such MUST not be disposed of in

domesc waste.

This humidifier should be returned to the closest steamOvap authorized representave for

proper dismantling, recycling and disposion of components according to local regulaons.

Table of content

Introduction.....................................................................................................3

Table of content..............................................................................................4

Safety warnings..............................................................................................5

Before to proceed to Installation.....................................................................6

IER Overview..................................................................................................7

Installation overview......................................................................................10

Installation – step 1 IER Positioning & Mounting...........................................12

Installation – step 2 Water supply installation................................................17

Installation – step 3 Drain installation............................................................19

Installation – step 4 Steam distribution installation........................................21

SR models for horizontal in duct humidification.......................................................21

SR models for Vertical duct - Option -V...................................................................22

SR models for round duct - Option -R.....................................................................22

SOS or SOE – steamOsorb, multi-ramp steam grid................................................24

Steam line installation..............................................................................................25

Installation – step 5 Power supply installation...............................................28

Installation – step 6 Control installation.........................................................30

Verification before start-up............................................................................32

Configuration & Operation.............................................................................33

Warranty.......................................................................................................47

Other Manuals and information that can

help you:

•Modbus tables for IER

•BACnet PICS for IER

•IER service manual

Please visit our website: steamOvap.com

for the latest revision of all manuals &

instructions

You can also visit our Youtube® channel:

youtube/steamovap and watch our 2

minutes IER service/cleaning video.

Figure 1, IER one module

Informaon contained in this manual is subject to change without noce.

To obtain the latest technical informaon visit our website at steamOvap.com

4

S A F E T Y

Safety warnings

General

Risk of electric shock.

Disconnect power supply before installaon or service.

For safety and warranty reasons, Installaon and service of this humidifier should be

carried out by trained and qualified personnel.

Any work related to installaon and service of this humidifier must comply with local code and

regulaon regarding safety and prevenon of accidents.

Electrical Warning

Risk of electric shock.

Disconnect power supply before installaon or service.

Power supply connecon must be done by a trained and qualified electrician.

Any work related to power supply installaon or service of this humidifier must comply with

local code and regulaon regarding safety and prevenon of accidents.

Water safety warning

Any work related to water supply, drain connecon as well as steam lines and condensate

returns lines installaon or service of such for this humidifier must comply with local code and

regulaon regarding safety and prevenon of accidents.

Water supply connecon must be done by a trained and qualified plumber.

Risk of malfuncon. Steam lines should not have any restricon or blockage that may

cause a burst of pressure in the steam line.

Others

Risk of flooding. In order to avoid any risk of flooding steamOvap recommends a Hi limit

humidity switch installed in the air duct downstream of the steam distribuon ramp.

Risk of freezing. Plan an an-freeze system in case of installaon in a locaon that would

be exposed to outside condions and suscepble of freezing.

Risk of malfuncon. Do not block steam outlet(s).

5

I N T E N D E D U S E

Before to proceed to Installation

Please read this Installation and Operation manual before to proceed to the Installation

Receiving & Unpacking

1. Upon receipt verify that packaging is complete and not damaged.

In case of damage, and/or missing boxes advise immediately the carrier by wring a note

on the waybill.

2. Verify that model of the humidifier matches the purchase order and that all accessories are

included.

3. Any missing item should be reported as soon as possible to steamOvap or its

representave and within 5 business days aer receipt.

steamOvap will not assume any responsibility for missing item aer this delay.

4. Proceed carefully to unpacking, and check that the humidifier and its accessories are not

damaged. in case of damage please proceed as for point 3

Included in standard delivery of IER electric steam humidifier

1. IER electric steam humidifier

2. Water supply hose

3. Collar(s) to secure steam hose on steam outlet of IER

4. 3in [80mm] long drain connecon sleeve 1-1/4in [DN32] Diam.

5. This IOM

Depending on other accessories ordered

6. Steam ramp(s)

7. Steam hose

8. Condensate hose

9. RH% sensors for duct or room, or Humidistat

10. HI Limit RH% switch, model DHL

11. Air flow switch, model DAP

IER name plate

Figure 2, IER name plate

6

O V E R V I E W

IER Overview

Model designation and options codification

Nominal Voltage

Nb of Phase

Opons

MB Mounng Bracket

FS Floor Stand

Type & Model B BACnet RS485

IER 12 - 208 / 3 - MB RT Roof top enclosure

IER electrical rating

Model Steam

Capacity

Power (kW) / Current (A)

120Vac/1p 240Vac/1p - - -

IER-02 6.3lb/h

[2.8kg/h]

2.1kW

17.5A

2.1kW

8.75A - - -

Model Steam

Capacity 208Vac/1p 240Vac/1p 208Vac/3p 380Vac/3p 480Vac/3p 600Vac/3p

IER-04 10lb/h

[4.5kg/h]

3.3kW

16.0A

3.3kW

13.9A

3.3kW

9.3A

3.3kW

4.8A

3.3kW

4.0A

3.3kW

3.2A

IER-05 15lb/h

[6.8kg/h]

5.0kW

24.0A

5.0kW

20.8A

5.0kW

13.9A

5.0kW

7.2A

5.0kW

6.0A

5.0kW

4.8A

IER-09 24lb/h

[11.4kg/h]

8.3kW

39.9A

8.3kW

34.6A

8.3kW

23.0A

8.3kW

12.0A

8.3kW

10.0A

8.3kW

8.0A

IER-12 35lb/h

[15.9kg/h] -11.5kW

47.9A

11.7kW

32.4A

11.7kW

16.8A

11.7kW

14.0A

11.7kW

11.2A

IER-17 50lb/h

[22.7kg/h] - - 16.7kW

46.3A

16.7kW

24.1A

16.7kW

20.0A

16.7kW

16.0A

IER-22 65lb/h

[29.5kg/h] - - - 21.7kW

31.3A

21.7kW

26.1A

21.7kW

20.8A

IER-24 70lb/h

[31.8kg/h] - - 23.4kW

64.8A - - -

IER-31 93lb/h

[42.3kg/h] - - - 31.0kW

44.7A

31.0kW

37.3A

31.0kW

29.8A

IER-34 100lb/h

[45.4kg/h] - - 33.4kW

92.6A - - -

IER-44 130lb/h

[59.1kg/h] - - - 43.3kW

62.5A

43.3kW

52.1A

43.3kW

41.7A

IER-62 185lb/h

[84.1kg/h] - - - 61.7kW

89.1A

61.7kW

74.2A

61.7kW

59.3A

7

O V E R V I E W

IER Dimensions & weight

DW

H

Figure 3, IER Dimensions, single module

W

Steam outlets Condensate return

Drain outlets

H

D

Water inlet

Figure 4, IER Dimensions, two modules, model IER24, 34, 44 & 62

8

O V E R V I E W

Model Steam

Capacity

Nb Cyl

+ size

Nb Steam

Outlet + Ø Dimensions Net

weightW H D

IER02 6.3lb/h

[2.8kg/h]

1x

small

1x 1-1/2in

[DN40]

20in

[510mm]

23in

[585mm]

13in

[330mm]

45lb

[21kg]

IER04 10lb/h

[4.5kg/h]

1x

small

1x 1-1/2in

[DN40]

20in

[510mm]

23in

[585mm]

13in

[330mm]

45lb

[21kg]

IER05 15lb/h

[6.8kg/h]

1x

small

1x 1-1/2in

[DN40]

20in

[510mm]

23in

[585mm]

13in

[330mm]

45lb

[21kg]

IER09 24lb/h

[11.4kg/h]

1x

small

1x 1-1/2in

[DN40]

20in

[510mm]

23in

[585mm]

13in

[330mm]

45lb

[21kg]

IER12 35lb/h

[15.9kg/h]

1x

medium

1x 2in

[DN50]

23in

[585mm]

27in

[686mm]

17in

[432mm]

68lb

[31kg]

IER17 50lb/h

[22.7kg/h]

1x

medium

1x 2in

[DN50]

23in

[585mm]

27in

[686mm]

17in

[432mm]

68lb

[31kg]

IER22 65lb/h

[29.5kg/h]

1x

medium

1x 2in

[DN50]

23in

[585mm]

27in

[686mm]

17in

[432mm]

68lb

[31kg]

IER24 70lb/h

[31.8kg/h]

2x

medium

2x 2in

[DN50]

42in

[1067mm]

27in

[686mm]

17in

[432mm]

136lb

[62kg]

IER31 93lb/h

[42.3kg/h]

1x

medium

1x 21/2in

[DN65]

23in

[585mm]

27in

[686mm]

17in

[432mm]

68lb

[31kg]

IER34 100lb/h

[45.4kg/h]

2x

medium

2x 2in

[DN50]

42in

[1067mm]

27in

[686mm]

17in

[432mm]

136lb

[62kg]

IER44 130lb/h

[59.1kg/h]

2x

medium

2x 2in

[DN50]

42in

[1067mm]

27in

[686mm]

17in

[432mm]

136lb

[62kg]

IER62 185lb/h

[84.1kg/h]

2x

medium

2x 2-1/2in

[DN65]

42in

[1067mm]

27in

[686mm]

17in

[432mm]

136lb

[62kg]

9

I N S T A L L A T I O N

Installation overview

General

1. Installaon of this humidifier should be carried out by trained and qualified personnel.

2. Any work related to installaon of this humidifier must comply with local code and

regulaon regarding safety and prevenon of accidents.

WARNING. Risk of electric shock.

Power supply must be disconnected during installaon.

Main power should be connected only aer all installaon steps have been completed

and properly verified.

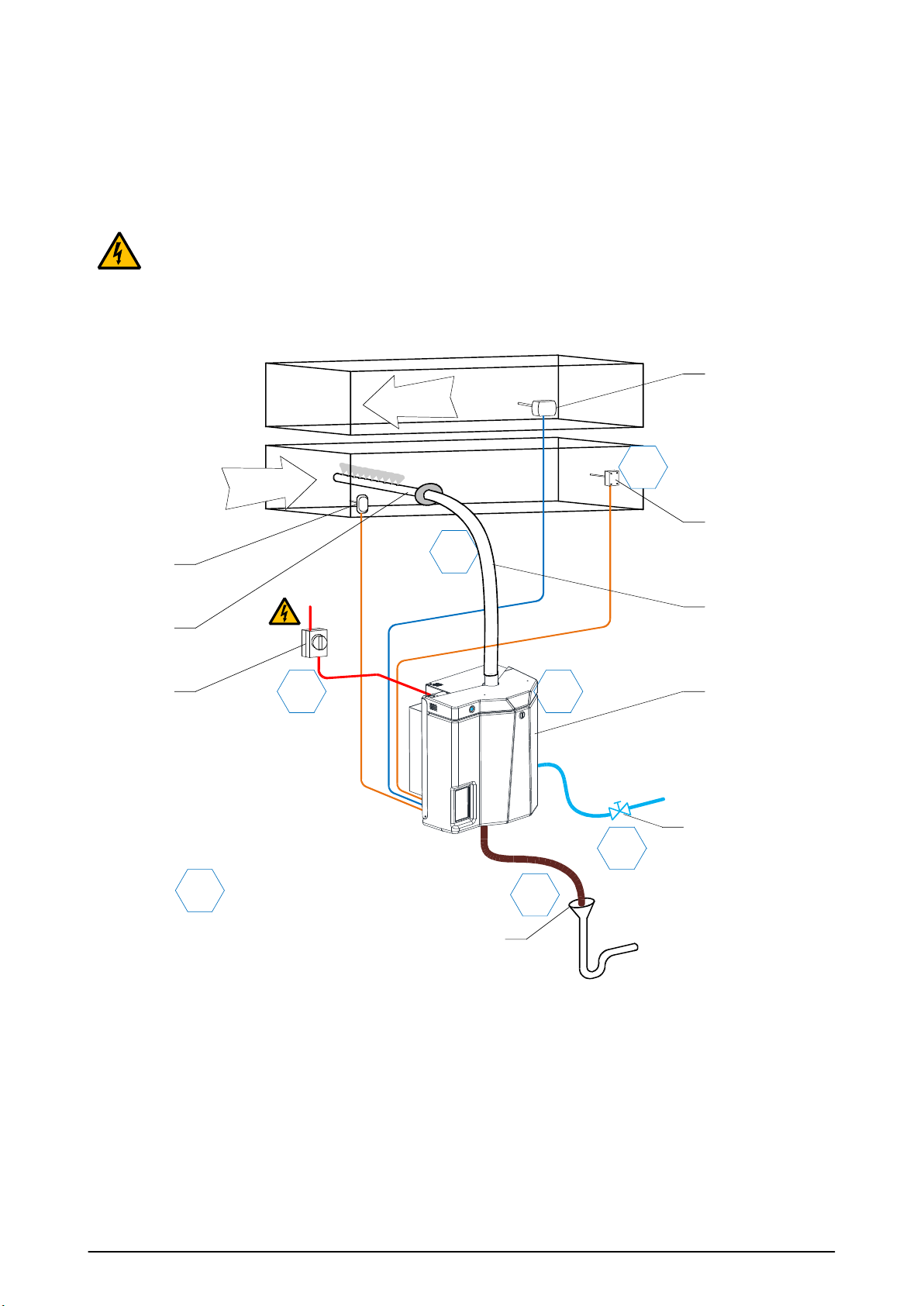

Typical installation with steam ramp

Figure 5, installaon overview with steam distribuon in duct

10

Air

Air

SUPPLY

RETURN

RH% Sensor

HI-Limit RH%

Safety switch

IER

Electric Steam

Humidifier

Open & deported Drain

with P Trap

Air flow

Safety switch

Line Voltage

Disconnect

switch

Shut-off valve on water

supply line

Steam ramp

Steam line

(hose)

1

2

3

4

5

6

0

Installaon steps

I N S T A L L A T I O N

Installation steps:

1. Posioning & mounng of IER electric steam humidifier

2. Water supply installaon

3. Drain installaon

4. Steam line installaon for duct humidificaon

or Direct humidificaon in room

5. Power supply installaon

6. Safety & RH% control installaon

Typical installation with SB- space blower

IER

Electric Steam

Humidifier

SB

Space blower

Condensate

return hose

Shut-off valve on

water supply line

Open & deported

Drain with P Trap

Room RH% sensor

Line voltage

disconnect switch

Steam hose

1

2

3

4

5

6

Figure 6, IER with remote Space blower typical installaon

Typical installation steps:

1. Posioning & mounng of IER electric steam humidifier

Space blower installaon (only if remote)

2. Steam & condensate return hose or piping

3. Water supply installaon

4. Drain installaon

5. Power supply installaon

6. RH% control installaon

11

I N S T A L L A T I O N

Installation – step 1

IER Positioning & Mounting

General guidelines for positioning

IER electric steam humidifier should be posioned so that:

Length of the steam line (or hose) is as short as possible,

In case steam hose is used, the bend radius of 12in (300mm) is ensured

Humidifier is easily accessible for service

CAUTION. Risk of malfuncon due to vibraon. Do Not mount IER electric steam

humidifier directly on venlaon duct.

CAUTION. Risk of flooding. Ensure that the local where IER electric steam humidifier will

be installed is equipped with floor drain.

In case of no floor drain is available; installaon of a water leak detector is required in

order to prevent any flooding in case of abnormal operaon or service.

IER steam humidifier should be installed in a well-venlated and dry environment.

If local is subject to below freezing point temperature, acvaon of ant freezing funcon of the

IER steam humidifier is required.

For outdoor installaon please contact your steamOvap representave to order and install special

RT outdoor enclosure for IER.

IER maximum ambient condions:

Temperature: 41°F to 113°F [+5 to +45°C]

Relave Humidity: 90%RH max (non condensing)

Ingress Protecon for IER standard enclosure: IP30

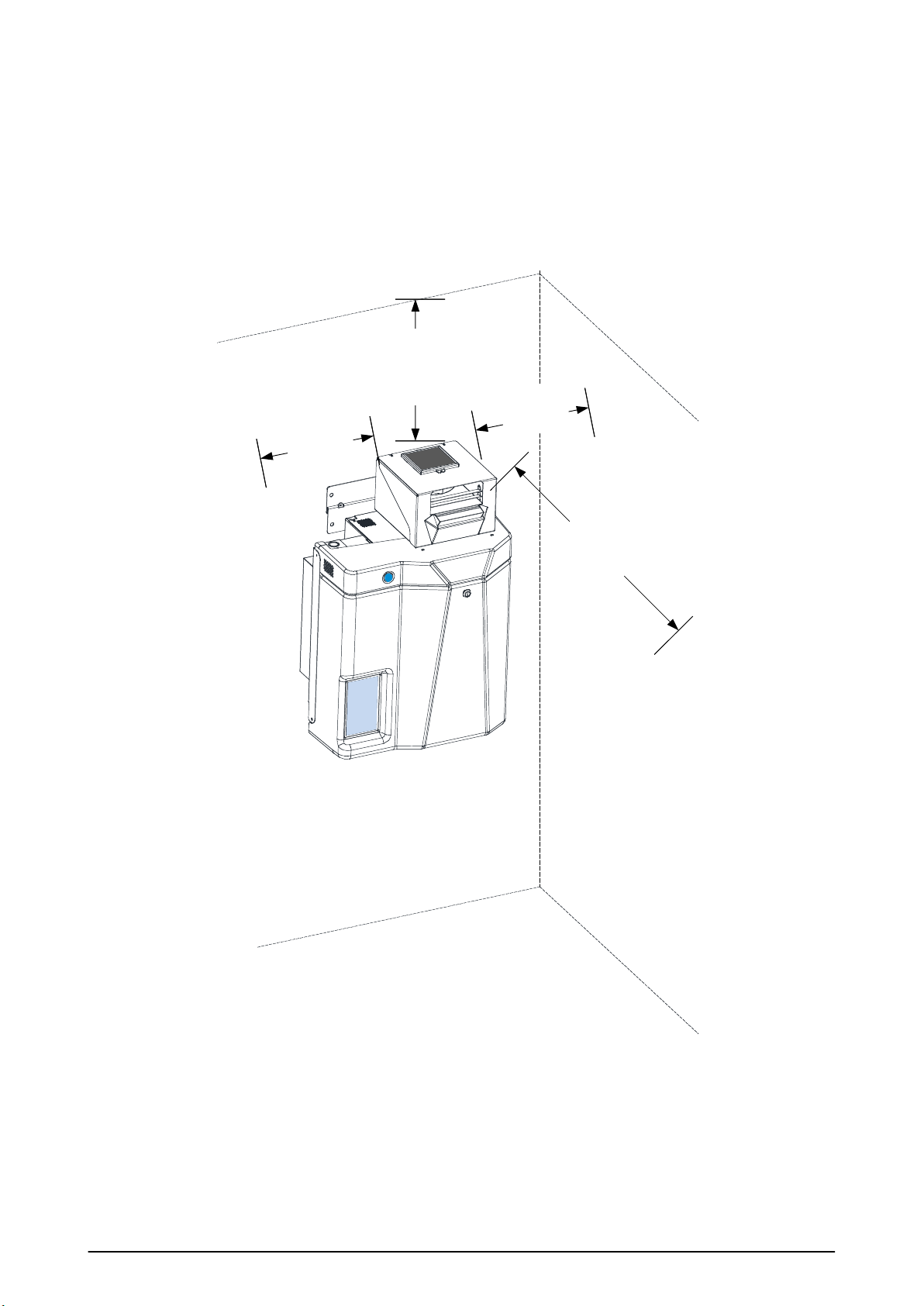

Clearances

5in min.

0in min.

12in standard

6in min.

24in standard

12in min.

30in min.

Figure 7, minimum clearances

12

I N S T A L L A T I O N

Clearance guidelines

There is no minimum clearance on both side of the IER humidifier, however it is a good pracce to

allow a clearance of 4 to 8 in [100 to 200mm] for ease of installaon and service

Allow a minimum clearance of 24in [610mm] with floor to allow for proper drain slope and drain

pipe column.

Front clearance of 30in [762mm] is required for access to the IER humidifier.

Top clearance is required of 12in [304mm] for access and ease of steam line connecon.

Clearances for IER with space blower

Min. 24in

[60cm]

Min. 80in

[200cm]

Min. 0in

[0cm]Min. 0in

[0cm]

Figure 8, minimum clearances for SB

Clearance guidelines

There is no minimum clearance on both side of the SB- space blower, but it is a good pracce to

have a clearance of 4 to 8 in [100 to 200mm] for ease of installaon and service.

Front clearance of 80in [2000mm] is required for steam absorpon.

A 24in [600mm] top clearance above SB – space blower is required for access and for steam

absorpon to avoid any condensing on the ceiling.

13

I N S T A L L A T I O N

Mounting holes positions & weights

M1

M2

M3

M4

Mounng holes paern

Electrical panel

M5

Figure 9, mounng holes single module

(IER 04 to 31)

M1

M2

Mounng holes paern

M3

M4

Electrical panel

M6

M5

Figure 10, mounng holes double module

(IER24, 34, 44 & 62)

Model Mounng holes posions (in) [mm]

M1 M2 M3 M4 M5 M6

IER02 to 09 2

[51]

8

[203]

½

[13]

19.25

[489]

6

[152] -

IER12 to 31 2

[51]

11.25

[286]

½

[13]

23.5

[597]

7.8

[197] -

IER24, 34,

44 & 62

2

[51]

34.3

[871]

½

[13]

23.5

[597]

7.8

[197]

30.7

[782]

Weight

Model Nb Cyl + size Net Weight Oper. Weight

IER02 1x small

45lb

[21kg]

74lb

[34kg]

IER04 1x small

IER05 1x small

IER09 1x small

IER12 1x medium

68lb

[31kg]

118lb

[54kg]

IER17 1x medium

IER22 1x medium

IER31 1x medium

IER24 2x medium

136lb

[62kg]

236lb

[107kg]

IER34 2x medium

IER44 2x medium

IER62 2x medium

14

I N S T A L L A T I O N

General guidelines for Mounting

CAUTION. Risk of malfuncon. IER electric steam humidifier must be levelled

in X & Z axis.

Installaon on wall (without mounng bracket)

1. Verify that wall structure and strength is appropriate to support the operang weight of

the IER electric steam humidifier.

In case, the wall is not solid enough to support operang weight of IER electric steam

humidifier, install humidifier on the floor stand (FS opon is available to your steamOvap

representave).

2. Mark the wall or support according to the above holes locaon, and drill 4 holes to the wall

or support as per the size of anchors and/or screws.

3. Use anchors of sufficient size (at least 1/4in [6mm]). Insert those anchors and the 2 top

screws, ensure that the screw heads extends 1/4in [6mm] from the wall, so that the IER

electric steam humidifier will be able to be hung on those 2 screws.

4. With front cover removed, hung the IER electric steam humidifier onto the 2 top screws.

Insert the boom screw through the back plate of the humidifier and into the anchors in

the wall.

Ensure that the humidifier is properly levelled.

Tighten the 3 screws. Re verify the level in the 2 direcon X and Z axis.

5. Re-install the front cover to the humidifier.

6. Oponal Mounng bracket (opon MB) is available to your steamOvap representave in

order to ease up wall mounng process.

15

I N S T A L L A T I O N

Installaon on wall (with mounng bracket – opon MB)

1. Oponal Mounng bracket (opon MB) is available to your steamOvap representave in

order to ease up wall mounng process.

2. Verify that wall structure and strength is appropriate to support the operang weight of

the IER electric steam humidifier.

In case, the wall is not solid enough to support operang weight of IER electric steam

humidifier, install it on a floor stand (FS opon is available to your steamOvap

representave).

3. Mark the wall or support according to the mounng bracket holes locaon, Drill holes to

the wall or support to aach the bracket to the wall as per the size of anchors and/or

screws.

Distance between the 2 holes in mounng bracket is 15in [381mm]

15in

[381mm]

Figure 11, Installaon with Mounng bracket

4. Use anchors of sufficient size (at least 1/4in [6mm]). Install the mounng bracket to the

wall or support.

Ensure that the mounng bracket is properly levelled.

5. With front cover removed, hung the IER electric steam humidifier onto the mounng

bracket.

6. Install the 2 supplied screws to avoid the IER humidifier to move up from the mounng

bracket.

7. Re-install the front cover to the humidifier.

Installaon on Floor Stand (opon FS)

1. Ensure that the floor structure and strength is appropriate to support the operang weight

of the IER electric steam humidifier.

2. Aach the floor stand to the floor or structure to avoid any movement of the IER electric

steam humidifier.

You can use bolt or screws to aach this one to surrounding structure or to the floor.

3. Install Humidifier (with front cover removed) on the floor stand and secure it with supplied

bolts.

4. Re-install the front cover to the humidifier.

16

I N S T A L L A T I O N

Installation – step 2

Water supply installation

Water supply specification & quality:

Water supply pressure: 15 to 80PSI [1 to 5bar]

Water supply temperature: 37 to 105°F [3 to 40°C]

IER electric steam humidifier can accept a wide range of water quality.

Untreated water will lead to scale deposits that will need to be regularly removed from steam

chamber.

Use of addives such as scale inhibitor or corrosion inhibitors, disinfectants or other can impair

the normal operaon of the humidifier and are not allowed.

Water supply conducvity: 1 to 1500µS/cm

Water supply hardness: 0 to 16grains/gallon [0 to 15°gH][268mg CaCO3/l]

Water supply PH: 6.5 to 7.5

Water supply chloride content: 0 to 50ppm

Flexible braided hose supplied

Connecon G3/4’’

Drain

Water supply

Filter (10 µ) – recommanded [by others]

( if connected to tap water main)

Manual shut off valve

[by others]

Connecon 3/8’’

10.2in [259mm]

1-1/8in

[28.5mm]

Figure 12, water supply connecon

17

I N S T A L L A T I O N

Figure 13, water supply connecon, model IER24, 34, 44 & 62

Water supply connection:

1. Install a manual shut off valve (supplied by others) on the water main line.

2. If IER humidifier is supplied with tap water it is recommended to install a 10µ sediment

filter (supplied by others) on the line.

Alternavely steamOvap can provide a 2 stages pre-filter 5 + 1μ PP filter as extra

protecon and filtraon (model WF-51).

3. A flexible braided hose is supplied for an easy and secure connecon to the humidifier

water supply inlet.

This flexible braided hose will ease of the installaon and act as shock absorber and

protecon for the internal water fill valve.

18

Flexible hose (by others)

NPT ½ in female

Water supply

Filter (10 µ) – recommanded [by others]

( if connected to tap water main)

Manual shut off valve

[by others]

Connecon 3/8’’

10.2in [259mm]

1-1/8in

[28.5mm]

Drain

Drain

I N S T A L L A T I O N

Installation – step 3

Drain installation

Water drained specification:

Drained water maximum temperature: 140°F [60°C] (when supplied with cold water supply)

Drained water flow rate: 6.6 GPM [25 l/min]

Drain outlet dimension: IER04 to IER31: (1x)1-1/4in [32mm]

IER24. IER34, IER44 & IER62: (2x)1-1/4in [32mm]

Drain volume for full cylinder drain: IER04 to 09: 5.5Gal [21L]

IER12, IER17, IER22, IER31: 12Gal [46L]

IER24, 34, 44 & 62: 24Gal [86.5L]

IER humidifier

Drain

Connecon sleeve 1-1/4in [32mm]

(by others)

Slope minimum 5°

P trap

Open drain offset from IER

1-1/2in [40mm] minimum

2 collars

(by others)

18in [45cm]

minimum

18in [45cm]

minimum

Figure 14, water drain connecon (single module)

Connecon sleeve 1-1/4in [32mm]

(supplied)

2 collars

(by others)

IER module 2

Drain

Slope minimum 5°

P trap

Open drain offset from IER

1-1/2in [40mm] minimum

18in [45cm]

minimum

18in [45cm]

minimum

IER module 1

Figure 15, water drain connecon, 2 modules, model IER24, 34, 44 & 62

19

I N S T A L L A T I O N

Risk of overflow.

✔A minimum slope angle of 5 degree of the drain hose or pipe and a minimum length of

24in [60cm] must be provided between IER’s module drain outlet and building’s open

drain inlet.

✔Do not reduce diameter of the drain line. Drain line between IER’s module drain outlet and

building’s open drain inlet must be 1-1/4in [DN32] diameter minimum

✔18in [45cm] minimum vercal run before P trap or obstrucon must be provided.

✔Do not install P-trap directly (or any other obstrucon) at the IER’s drain outlet.

Installation steps:

Important note: There is one drain outlet per IER module.

So there are 2 drain outlets for models IER24, IER34, IER44 and IER62.

1. Ensure that an Open drain with a P-trap is installed offset from the IER humidifier.

Main building drain diameter should be

◦1-1/2in [DN40] for single module IER

◦2in [DN50] for two modules IER (model IER24, IER34, IER44 or IER62)

in case such drain diameter is not available (i.e. in old building), increase the diameter or

height of vercal run before to enter the main building drain.

Refer to informaon of full cylinder volume above for volume calculaon.

2. Drain line can be made either with flexible hose or hard pipe.

Supplied connecon sleeve 1-1/4 [32mm] allow for ease of connecon to IER’s module

drain outlet to the drain pipe, and secure it with the supplied 2 collars.

✔Drain line must be slopped - 5° minimum slope from IER module to building’s open

drain inlet.

✔Do not reduce 1-1/4in [DN32] diameter at any point of the drain line

✔Avoid short 90° elbow

✔a minimum 18in [45cm] vercal run pipe must be provided upstream any P-trap or any

other obstrucon.

20

Table of contents

Popular Humidifier manuals by other brands

Vicks

Vicks VH5000E User instructions

Aprilaire

Aprilaire 400 Series Instructions and installation instructions

Brune

Brune B 125 Instructions for use

Hamilton Beach

Hamilton Beach 840074800 user guide

Helios

Helios HygroBox KWL HB 250 EH L Installation and operating instructions

CLAIRION

CLAIRION SA-1015 instruction manual

DriSteem

DriSteem HUMIDI-TECH Installation, operation and maintenance manual

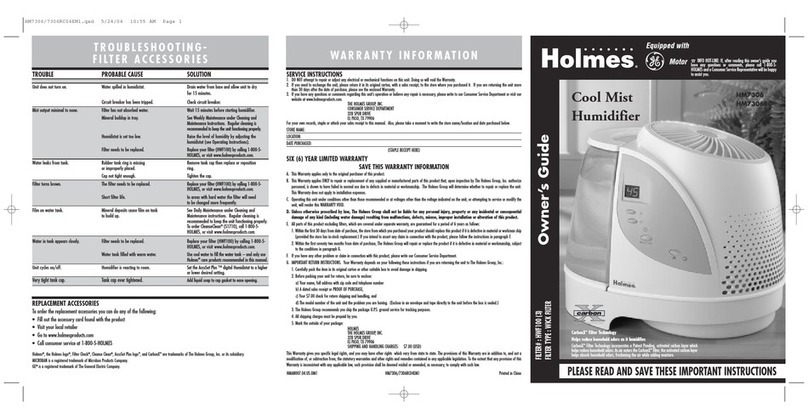

Holmes

Holmes HM7306 owner's manual

MoistAir

MoistAir MA0600 Use and care guide

Stadler Form

Stadler Form Jack operating instructions

DriSteem

DriSteem GTS SERIES Installation, operation and maintenance manual

Bort

Bort BLF-210 user manual