IES 4416 User manual

Revision RB16

IES 4416

Onbord LED + CAM Controller

SYSTEM DESCRIPTION

Mobile ruggedized supply and control unit for up to 20 LED illumination heads

and 10 high speed video cameras.

Contents

1 OVERVIEW......................................................................................................................3

1.1 Mounting information.............................................................................................................4

2 CONNECTORS AND FRONT PANEL ELEMENTS........................................................5

2.1 MAIN connector.....................................................................................................................5

2.2 CTL/STS connector...............................................................................................................6

2.3 AUX connector......................................................................................................................6

2.4 LED head connector..............................................................................................................7

2.5 LED status markers...............................................................................................................7

2.6 Front panel button.................................................................................................................7

2.7 CAM1 to CAM10 port connector............................................................................................8

2.8 Trailing cable connector Lemo 5B.........................................................................................9

3 FUNCTIONAL DESCRIPTION.......................................................................................11

3.1 Unknown IP.........................................................................................................................11

3.2 Setup light...........................................................................................................................11

3.3 Starting the light...................................................................................................................11

3.4 SYNC and CONT modes.....................................................................................................12

3.5 External sync input..............................................................................................................12

3.6 Special Functions................................................................................................................12

3.7 Device shutdown timer........................................................................................................13

4 DIAG4400-SOFTWARE.................................................................................................14

4.1 Finding and connecting LED-Controllers.............................................................................14

4.2 CMD-Tab.............................................................................................................................16

4.3 Config-Tab...........................................................................................................................16

4.4 Battery-Tab..........................................................................................................................18

4.5 IP-Settings -Tab...................................................................................................................18

4.6 Status -Tab..........................................................................................................................19

5 CE CONFORMITY.........................................................................................................21

1 Overview

This onboard LED + CAM controller can supply energy and can control up to 20 LED illumination

heads and up to 10 high speed video cameras. It is made for installation on bord of a vehicle and

may be used in crash testing scenarios. It contains internal rechargeable batteries.

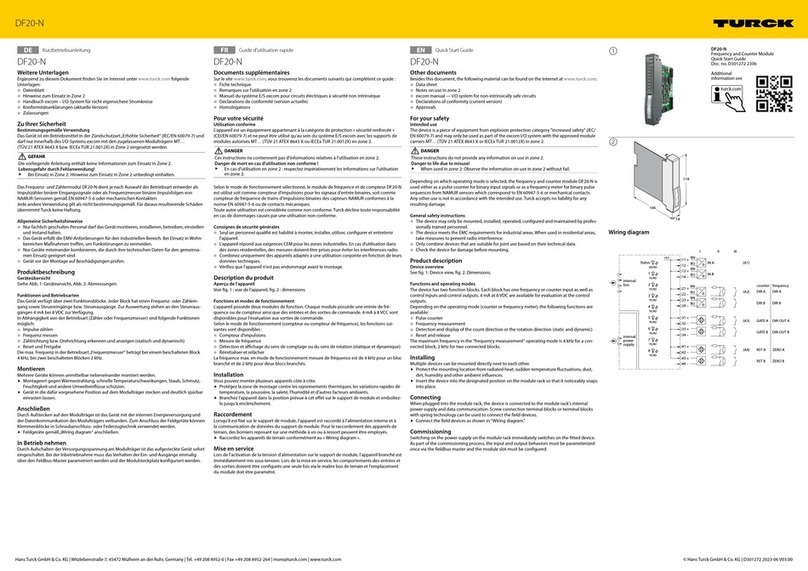

In its standard version it has a standard KT (Minidau) footprint. As an option, one or two "balconys"

(see photograph, shown is the 5B balcony) below are available, that allow connection of a small or

a full size trailing cable (Lemo 3B or Lemo 5B connectors).

1.1 Mounting information

The drawing below shows the main measures. From the bottom threads at least 6 should be used.

We also recommend the good practise of having a stopping edge on the users mounting plate,

which can take the acceleration force.

Bottom view

12 Gewinde M5, Einschraubtiefe max. 8 mm

12 threads M5, depth max. 8 mm

110

99

LED-Controller

4416

MF01

ON / OFF

RDY

SYN

ETH

TRG

90%

70%

50%

30%

LED 1 LED 2

CTL/STSMAIN

CAM 8CAM 7

CAM 5

CAM 2

CAM 4CAM 3

CAM 1

CAM 9

CAM 6

CAM 10

LED 7

LED 4 LED 5 LED 6

LED 3

LED 8 LED 9

LED 10

46 270

27016 30

Unverschobene KT-Befestigung

86,586,5

55,5

110

25,5

30

2 Connectors and Front Panel elements

All connectors and user interface elements are located on the front panel.

2.1 MAIN connector

The MAIN connector is used to connect this device to the user´s existing infrastructure.

Connections are:

Power supply to internal charger

Ethernet for communication

Trigger input

Sync input

The pinout is given in the table below.

Connector type in front panel: Lemo EGA.2B.318

Connector type for user cable: Lemo FGA.2B.318

Pin Signal Remark

1 Ethernet A-

2 Ethernet D-

3 Ethernet B-

4 Ethernet B+

5 Ethernet C+

6

7 +CHGSUP Charger-Input 40-48 V, 1 A

8 +CHGSUP as above

9 SYNC+

10 SYNC-

11 -CHGSUP Device-GND and Charger-GND

12 -CHGSUP as above

13 Ethernet A+

14 Ethernet D+

15 Ethernet C-

16

17 +T0

18 -T0

Case

The input signals SYNC and T0 are of type RS-485. They are pulled to their respective quiet

voltage levels by internal pullup resistors and therefore may be left open, if unused.

These inputs also accept TTL input signals. These must be referenced to GND. This table shows,

how to connect a TTL sync signal to the MAIN connector:

TTL sync out from user´s equipment MAIN Pin 9

TTL GND from user´s equipment MAIN Pin 11

It would be possible to signal T0 with a closing contact between pins 17 and pin 11 - however this

is not recommended, because it is an RS-485 input and not an explicit contact input. But it´s ok for

testing purposes.

2.2 CTL/STS connector

The CTL/STS connector has control and status signals for exchange with external equipment. The

signals are optoisolated and the couplers have internal current limiting circuity, so they can be

driven from sources between 5 V and 24 V without additional resistors. Functions provided:

START signal input to start the light

READY output to signal ready status

Remote front panel button control input

There is also an isolated 5 V voltage source provided on this connector. It makes it easy to use the

optoisolated inputs from closing contacts.

The pinout is given in the table below.

Connector type in front panel: Lemo EGG.1B.308

Connector type for user cable: Lemo FGG.1B.308

Pin Signal

1 Opto-Start K

2 ISO 0V

3 Opto RDY C

4 Opto RDY E

5 ISO +5 V

6 Opto Start A

7 Opto Setup light A

8 Opto Setup light K

2.3 AUX connector

The AUX connector is used for user specific extensions. There is no general description available

or possible. In case of devices with no trailing cable "balcony", this connector is typically used to

feed in the camera power.

2.4 LED head connector

The LED illumination heads are connected to the LED 1, LED 2 , ... output connectors. Each

output connector can supply two LED heads, or one double LED head. Each output connector has

one temperature supervising input channel.

If (downgraded) devices are not fully equipped with LED ports, then the lower connector numbers

ar functional (starting at LED1) and the higher numbers are not functional.

The pinout is given in the table below.

Connector type in front panel: Lemo EGG.1B.306

Connector type for user cable: Lemo FGG.1B.306

Pin Signal

1 LED A1

2 LED K1

3 LED A2

4 LED K2

5 NTC a

6 NTC b

Case Screen

2.5 LED status markers

The status markers indicate

Charge level of internal batteries

Ethernet communication activity

Sync input signal present

Controller ready status

During charge (when external power supply is attached to MAIN connector) the highest charge

level LED blinks. This indicates, charging takes place. The charging is complete, if all charge

indication LED´s are ON.

Ethernet indicator is normally ON, and is blanked for a moment, if a command is received and

processed.

Sync LED is ON, if a valid external sync signal is recognized.

Controller ready status is signalled, if battery is in good condition and no temperature is higher than

the "ready level". See operating instructions for more on ready signalling.

2.6 Front panel button

The front panel button provides these functions:

Switch ON the device (press short)

Switch ON or OFF the light (press 1/2 second)

Force device to use a default IP

Switch OFF the device

Switching ON is simple, just press shortly.

Switching the light is done by pressing the button a bit longer, then release. Light is switched on at

the lowest level on the first press (called setup light), then switched to full level on the second

press, then switched off on the third press.

If pressed for a long time (around 6 seconds), the LED´s give feedback: All turned off exept RDY

and ETH. Releasing the button at this moment will bring the device into DEFAULT IP mode. In this

mode, the device has the following IP:

Default IP 192.168.1.40

This mode is indicated by blinking the ETH LED every second. It is usefull to discover and set up a

device with unknow IP. The mode is ended by switching off the device.

Switching OFF the device is done by pressing the button long, approx 8 seconds (or more).The

LED´s give feedback: All turned off.

Please note, that after 6 seconds the default IP mode is offered (LED feedback), and switching

OFF requires to keep on pressing the button!

2.7 CAM1 to CAM10 port connector

Connector type in front panel: Lemo EGG.2B.318

Connector type for user cable: Lemo FGG.2B.318

Pin Signal Remark

1 Ethernet A-

2 Ethernet D-

3 Ethernet B-

4 Ethernet B+

5 Ethernet C+

6 GPIOP general purpose input

7 +SUP CAM supply 20-32 V, fused 5 A

8 +SUP as above

9 SYNC+

10 SYNC-

11 -SUP RTN from CAM supply

12 -SUP as above

13 Ethernet A+

14 Ethernet D+

15 Ethernet C-

16 GPIOM general purpose input

17 +TRG

18 -TRG

Case

Same Pinout as in all IES camera control products.

2.8 Trailing cable connector Lemo 5B

Pin Signal Remark

1

2 Ethernet-Screen (optional)

3 Ethernet D-

4 Ethernet D+

5

6 Ethernet A-

7 Ethernet B-

8 Ethernet C+

9 Ethernet C-

10 Ethernet B+

11 Ethernet A+

12 RTN 48V

13 RTN 48V

14 Data C 485 + T0+, quiet level: 0 V

15 SUP 48V

16 SUP 48V

17 SUP 48V

18 Data C 485 - T0-, quiet level 5 V

19 RTN 48V

20 -

21 Data C Shield

22 -

23 -

24 Data A 485+ +START light opto input

25 Data D 485 + +SYNC RS-485

26 Data B 485+ +RDY opto output

27 -

28 Data B 485- -RDY opto output

29 Data D 485 - -SYNC RS-485

30 Data A 485- -START light opto input

31 Data A Shield

32 Data D Shield

33 Data B Shield

34 CAM P

35 CAM P

36 Data E 485 + +SETUP LIGHT opto input

37 CAM M

38 CAM M

39 CAM M

40 Data E 485 - -SETUP LIGHT opto input

41 CAM P

42 CAM P

43 Data E Shield

44 CAM M

Power pins Signal

1 CAM M

2 CAM M

3 CAM P

4 CAM P

Remark: This is a big connector and during handling big forces and moments could be applied, but

should be avoided. If the connector sits tight in its socket, please do not try turning, it is better to try

loosen it by applying moderate forces to left and right alternating.

3 Functional Description

3.1 Unknown IP

If the devices IP is unknown, these are the possibilities:

use DEFAULT IP mode, see 2.6

use SRCH cmd from Diag4400 with ethernet broadcast in a small network

use SRCH cmd from Diag4400 with device address "0000", e.g. together with broadcast

If still lost, device must be sent in to factory.

3.2 Setup light

High speed filming typically goes in parallel with a short term lighting demand. But for the set up of

cameras and lenses more time is required. To prevent excessive heating up of LED heads,

drawing energy out of batteries and heating up test objects it is wise to use a lower light light level,

called setup light. This can be switched ON by command or by pressing the front panel button, and

the percent level of light can be set using Diag4400 software.

A better concept for setting up cameras and lenses is to use the full light level, but a reduced frame

rate like 100 fps. It means only a tenth of energy and heating, and also very convenient light level

for the human eye. And, as the pictures are illuminated with the final parameters (shutter time, light

level) you see what you get during the set up. No post-adjustment of lenses is to be done then.

The low frequency setup can be done by feeding in an external sync signal (e.g. from a camera),

or by setting the internal frequency generator to 100 fps.

3.3 Starting the light

The light can be started by

pressing the front panel button (once or twice)

software command

electrical signal or closing contact at CTL/STS connector (OPTO Start function)

electrical signal or closing contact at same connector (RMT function)

The OPTO start function switches ON full light immediately. The RMT (remote) function is

internally wired in parallel with the front panel button and thus all functions of this button can be

done with an external signal. For example it would be possible to use a small user built operator

panel with 6 meters cable as a remote control.

The duration of light ON can be selected between two possibilities. If "Start is signal controlled" is

checked in Diag4400 software, then the light is ON as long as the external signal is active. The

external signal directly controls on/off of the light. If this is unchecked, then the external signal acts

as a start timer trigger and light is switched ON for a duration set by the timer value.

3.4 SYNC and CONT modes

The LED controllers may operate in SYNC mode or in CONT mode. The actual mode can be read

with the command GMOD ("get mode"), which is answered with a string like "0000". These are two

hex numbers 00 and 00 which reflect the settings für mode and sync edge.

To change the operating mode use command "SMODxxxx" (set mode"), where xxxx is the number

from this table:

Mode xxxx

Sync 0000

Cont 0101

For example send SMOD0000 to set sync mode.

3.5 External sync input

The devices have an internal frequency generator and feed the signal to cameras and light. They

also have inputs for external sync signals. These can be fed in at connectors MAIN, 5B or CAM1,

with MAIN/5B beeing connected in parallel and beeing the default. If CAM1 is to be used, see 3.6

to set the sync input multiplexer correctly.

LED controllers detect the external signal automatically. If detected, the yellow LED is switched on

and the rising edge of the external signal is used to trigger an output pulse to cameras and lights. It

means, that for every rising edge one sync pulse with the configured width (see Diag4400) is

output. For example, if setting up 250 µs pulse width and applying an external signal of 1000 Hz,

then the cameras and lights will see one pulse 250 µs every 1 ms. If lowering the external

frequency to 100 Hz, the pulse width remains unchanged, so cameras and devices will see a pulse

with 250 µs every 10 ms.

3.6 Special Functions

Some special functions are implemented into the LED controllers. These functions can be switched

on or off using the Diag4400 software, see below. The bits are combined to form a number value.

An example: If TLH function and ET0 function are wanted, this gives a value 1+4 = 5 to be stored

into the device.

bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

- - - - - ET0 SYM TLH

TLH Set Temperature limit high

Setting may be used for climate chamber operation. LED heads will NOT be switched off at

elevated temperatures, when set. It is then a responsibility of user to ensure switching off before

damages to LED head or illuminated objects can occur.

SYM Sync multiplexer

If set, the external sync signal is taken from CAM1 connector. If not set, the external sync signal is

taken from MAIN (or 5B) connectors.

ET0 Emergency T0

When set, controller switches ON the light if a T0 signal is received. This provides some additional

"feel well" in scenarios where long delays between start light and T0 may occur and thus a timer

could unhappily may be timed out. A disadvantage of ET0 is, that light is switched ON repeatedly

during T0 test in preparation phase of a vehicle. This can potentially be harmfull for working

personell, if they are close to the LED heads. Administrive rules should be set up for working

people, if using this function.

3.7 Device shutdown timer

The LED controllers have an internal shutdown timer with a user settable value (see Diag4400).

Devices will be ON as long as external power is applied. If no external power is present, timer

counts down and finally switches off the device. This prevents (forgotten) devices from drawing the

battery empty. A special value 255 can be used for the timer: In this case the shutdown is

disabled and it is in users responsibility to switch off device before the battery is empty!

4 Diag4400-Software

IES provides a free PC software named "Diag4400", which is primary intended for diagnostic

purposes related to the LED controllers. It can also be used as a lightweight front end for

controlling the light function (switch on/off). To obtain the latest revision, or report bugs and wishes,

please contact office(at)ies-elektronikentwicklung.de.

The description is based on LED controller model IES 4416 with firmware QL16 or later and

Diag4400 revision RB11 or later.

The software has one EXE file (Diag4400.exe) and one INI file (IES4400.ini). These both should be

placed in a free to choose directory on a Windows PC. Microsofts DotNet 2.0 framework must be

installed on that PC.

4.1 Finding and connecting LED-Controllers

At first, a proper INI file should be prepared (text editor). See an example below. The port setting

(UDP) tells the software with what type of interface it should communicate with the controller. UDP

is the default setting for ethernet communications.

The [IPSEARCHLIST] provides a set of IP numbers and controller serial numbers. It should contain

at least one entry.

After program start, devices are searched according to this list. If no controller is found in the

network, this error message is displayed:

In this case, after clicking OK, the software shows a CMD tab, where a manual connection can be

established. Enter the IP address of an LED controller and the controllers serial number (like

PK09) into the text field "Controller address"), then press "open".

[REMOTEPORT]

PORT=UDP

[IPSEARCHLIST]

DEVICE1=172.22.102.81 PK03

DEVICE2=192.168.1.40 PK40

DEVICE3=192.168.40.37 PK08

To check, if the device responds to commands, send a remote command like IDFY (identify), using

the button "send remote cmd". The answers from the controller are displayed in the textfield at the

bottom.

If the controllers serial number is not known, the special address "0000" can be used. Then, only

one command, "SRCH", will give an answer, if a controller hears it. It sends its serial number, and

from then on communication can be made with the proper address.

If the IP is not known, a broadcast into the network can be done (255.255.255.255). This may be

rejected from your network. In smaller networks, or peer to peer cabling, you may use the

broadcast plus the "0000" to find a device with absolutely no preliminary information of it. Only, the

PC must be in the same network as the controller (a general requirement of ethernet networking).

If connection to an LED controller is finally established, press the button named "..." in the lower

right edge of the form. This brings you to the normal start screen.

In the normal case (finding controller from INI list) after program start, the screen looks like this:

It is an operator panel for switching on/off the light.

Access to the diagnostic functions is reached by pressing the "..." button in the lower right edge of

the form.

4.2 CMD-Tab

The CMD tab was already mentioned. Experienced users may send commands to the controller

from here and see the answers. Also, all buttons from all tabs of the software do the same,

sending commands and processing the answers. The commands are always four big letters, like

"IDFY", which is a mnemonic for the word "identify". The answers are shown in the big text box for

manual evaluation. Text here can be marked and deleted ("delete all" from the mouse context

menu), to clean up the area from time to time.

4.3 Config-Tab

This tab enables a lot of settings to be made.

Low light % sets up the intensity of the lowes light level, also called setup light.

Sync fail trailling time will keep the light switched on for some time after an external sync signals

stops (potentially fails). It is a good feature for crash test scenarios, but it is unwanted at test

stands, where a camera controls the light on/off by its sync output. Therefore it is configurabe by

the user.

Light ON time after START sets the duration of an internal timer. Light will be switched off after

this duration. START light cqan be done from an ethernet command or from a contact signal.

Device shutdown controls that the device will shut down (switch itself off) after some time of

inactivity and when diconnected from external power supply. It prevents a forgotten device to draw

the battery empty. A special value 255 can be used, if the device should never switch off. It is a

responsibility of the user, to switch it off manually, after work is done.

Delay broadcast answer is a setting for helping to find devices with the SRCH command. All

devices in an RS-485 network should be set to different delays, so after a broadcast they will

respond one after another, making it likely to be found. If all devices would respond

simultaneously, only garbage answers will be produced an finding is difficult.

Special function settings is a bitmask for special functions. These are device specific and

explaned in the hardware chapters.

Sync freq is a setting for the internal sync generator.

Pulse width is a setting for the output pulse width of sync signal, that is given to the cameras and

the LED light. Preferably use a pulse width lower than 50% of the frame period to have maximum

power output from LED heads. If using more than 50% duty cycle, power is automatically reduced.

Start is signal controlled is a selection between timer control of LED light or direct control from a

hardware signal. If not checked, the external START signal start the internal timer, which controls

the light on duration. If checked, the external START signal controls the light output directly, so the

duration of the signal is used for switching on the light (as opposed to the timer duration).

Make non volatile, if checked, makes the settings nonvolatile after the Store in Device button is

clicked. If not checked, the Store in Device button sends the new settings to the device, and

device uses them, but will forget the changes at power off. This volatility is good for experimenting,

for temporary setups or when a controlling software sets up the LED controllers prior to each test.

The non volatile storage option is good for stand alone applications.

4.4 Battery-Tab

This tab shows the state of charge in percent, the load current and the individual cell voltages. Cell

voltages are colored green, if they are in a normal range, and colored orange, if abnormal.

The values are only updated on entering the tab, not polled automatically.

4.5 IP-Settings -Tab

This tab displays the IP setting of the device. It may be changed and written into the device using

the "change..." button. A password dialog comes up. The password is currently empty.

After a change and write into the device, the device keeps using its old IP until a fresh power up is

done.

4.6 Status -Tab

This tab provides status information about the LED controller. The status is read from the device

on entering the tab (when displayed first). It is also possible to periodically update the status by

checking the Poll GSTS and/or PollLGIN boxes. The periodical refresh causes communication

traffic every second and fills the "answer" textbox (on CMD tab) quickly. It is not a general problem,

but may not be wanted for diagnostic purposes. This is why polling can/must be checked yes/no.

Polling GSTS (GSTS is the command used for this poll, it is a mnemonic for "get status") delivers

- the maximum temperature of all connected LED heads

- the state of charge of the battery

- the ready state of the device

- a SUPAVL flag indicating external power supply is present

- status of OPTO IN input (signal from CTL/STS connector), used for switching on the light

- error indication for config memory (Teds)

- ENA flag, if set, the light is logically ON, but may be dark, if waiting for sync signal

- LED fail flag, indicating an LED head failed to illuminate (requires proper setup SLJB)

- temperature limit flags (see functional description)

- SYNCEXT flag indicating an external sync signal

Polling LGIN (lamp group information) delivers the temperatures for every LED head and the so

called "ready bits" for every LED head. This bit is set, if the light is illuminated.

The LED controller 4416 has three lamp groups, LG001, LG010 and LG100. The diag software

polls all three (if polling is checked), but displays only the one selected to keep the display

compact.

Table of contents

Popular Control Unit manuals by other brands

Lenze

Lenze L-force 9400 Series Mounting instructions

nVent RAYCHEM

nVent RAYCHEM Elexant 5010i installation instructions

Samsung

Samsung MIM-F10N installation manual

suprema

suprema OM-120 installation guide

Cameron

Cameron NAVCO S30 Installation, operation and maintenance manual

Siemens

Siemens SINUMERIK user manual