nVent.com/RAYCHEM

|

5

ENGLISH

Warning:

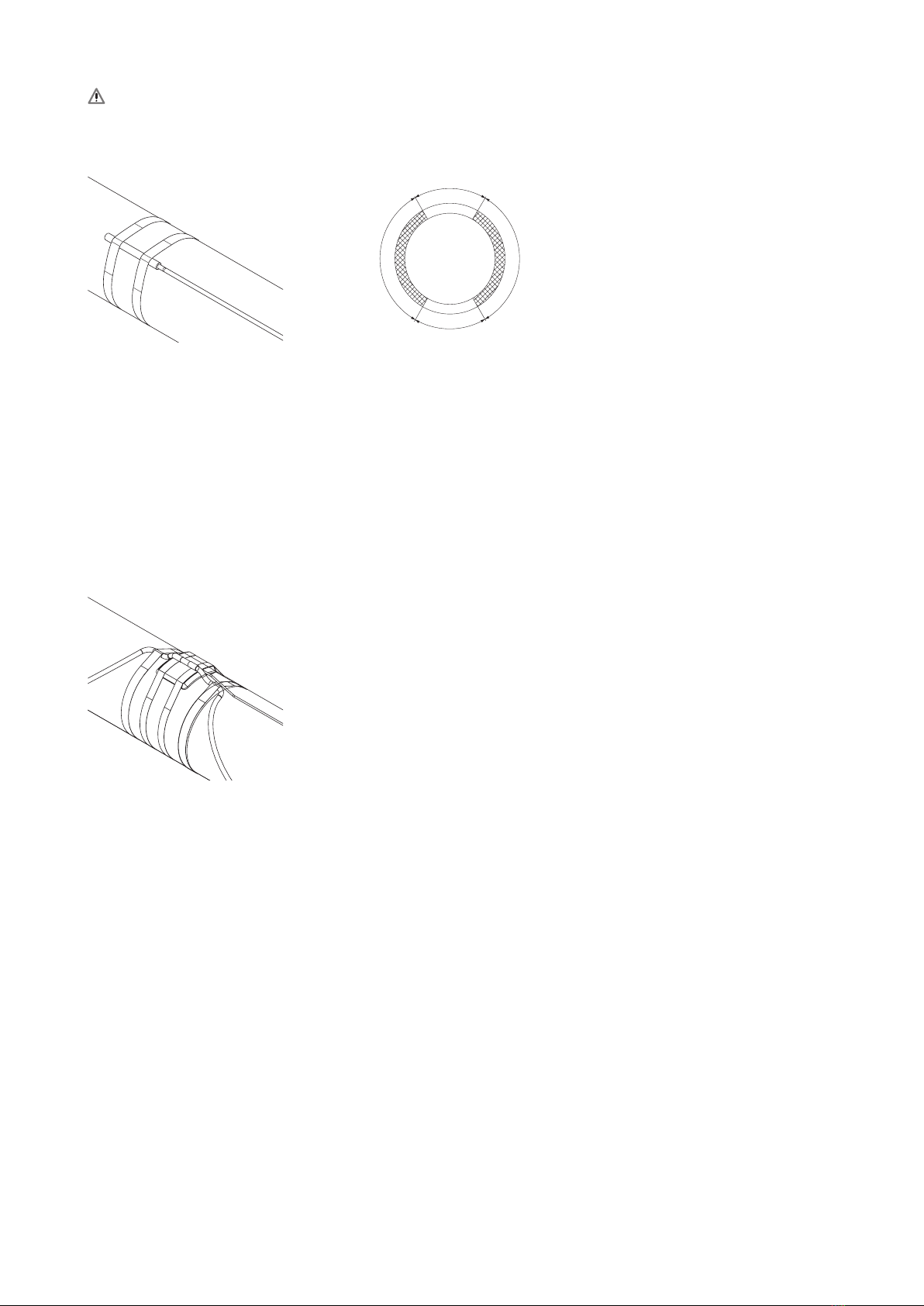

The purchaser should make the manufacturer aware of any external effects or aggressive substances that the equipment may be

exposed to.

The cable glands shall only be used for fixed installations, the cables must be fixed to prevent pulling or twisting.

Important Notice: In case a failure of the safety system is detected either during operation or during routine maintenance when

executing a function test the unit should be switched off and taken out of service. Defects in the safety system cannot be repaired

in the field. Defective units are to be replaced and returned to the manufacturer for investigation. Please contact your nearest nVent

representative for more instructions. A list of worldwide representations can be found on the last page of this document or on

nVent.com/RAYCHEM

Please read all instructional literature carefully and thoroughly before starting.

Notice: The information contained in this document is subject to change without notice. Please read these Installation Instructions

before commissioning the instrument. Keep the instructions in a place which is always accessible to all users. Please assist us to

improve these instructions, where necessary. We are always grateful for your suggestions. Should any difficulties arise during

start-up, you are asked not to carry out any unauthorized manipulations on the instrument as this could affect your warranty rights!

Please contact the nearest nVent subsidiary or the head office. If any servicing is required, the instrument must be returned to the head

office.

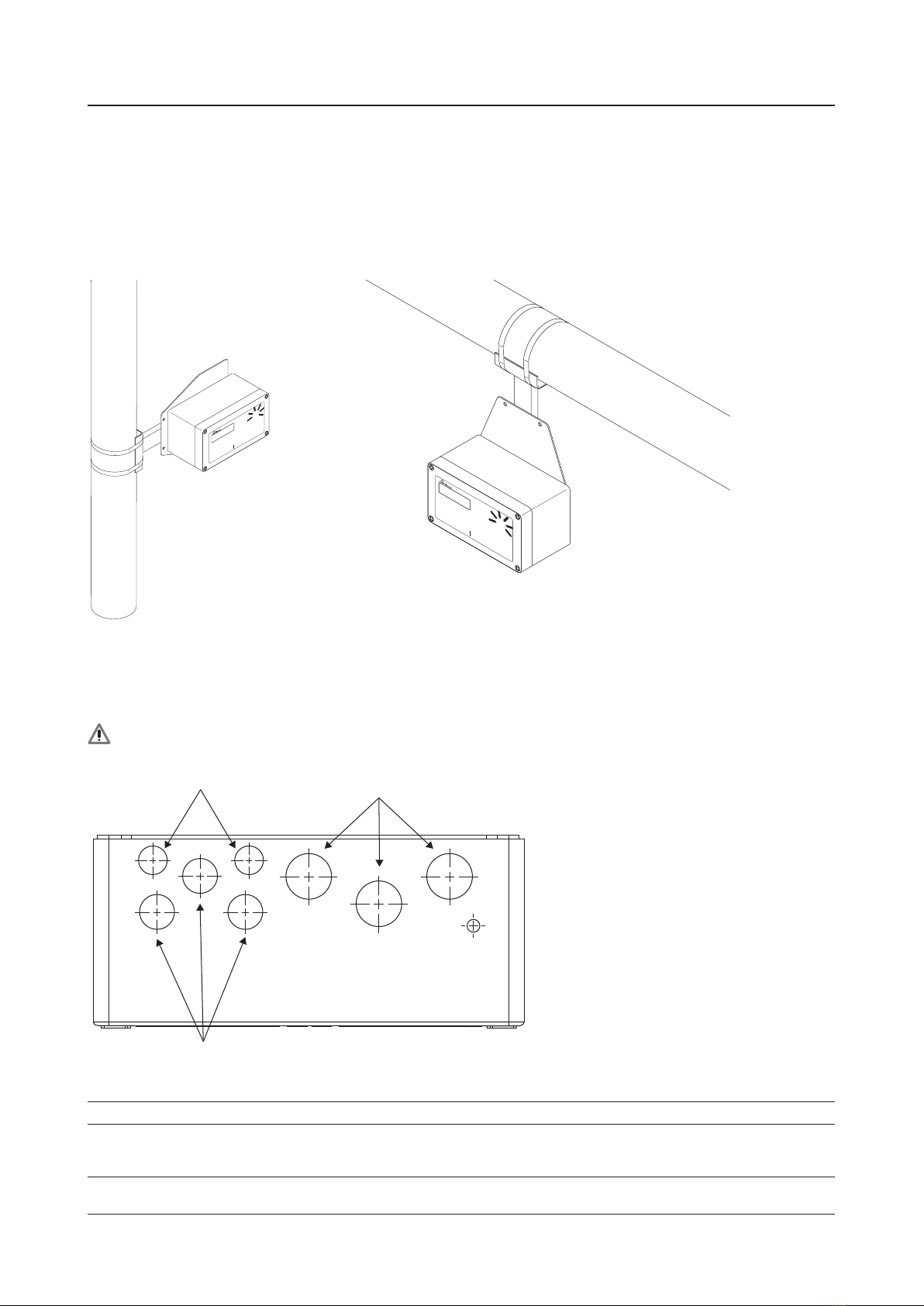

Special conditions for safe use

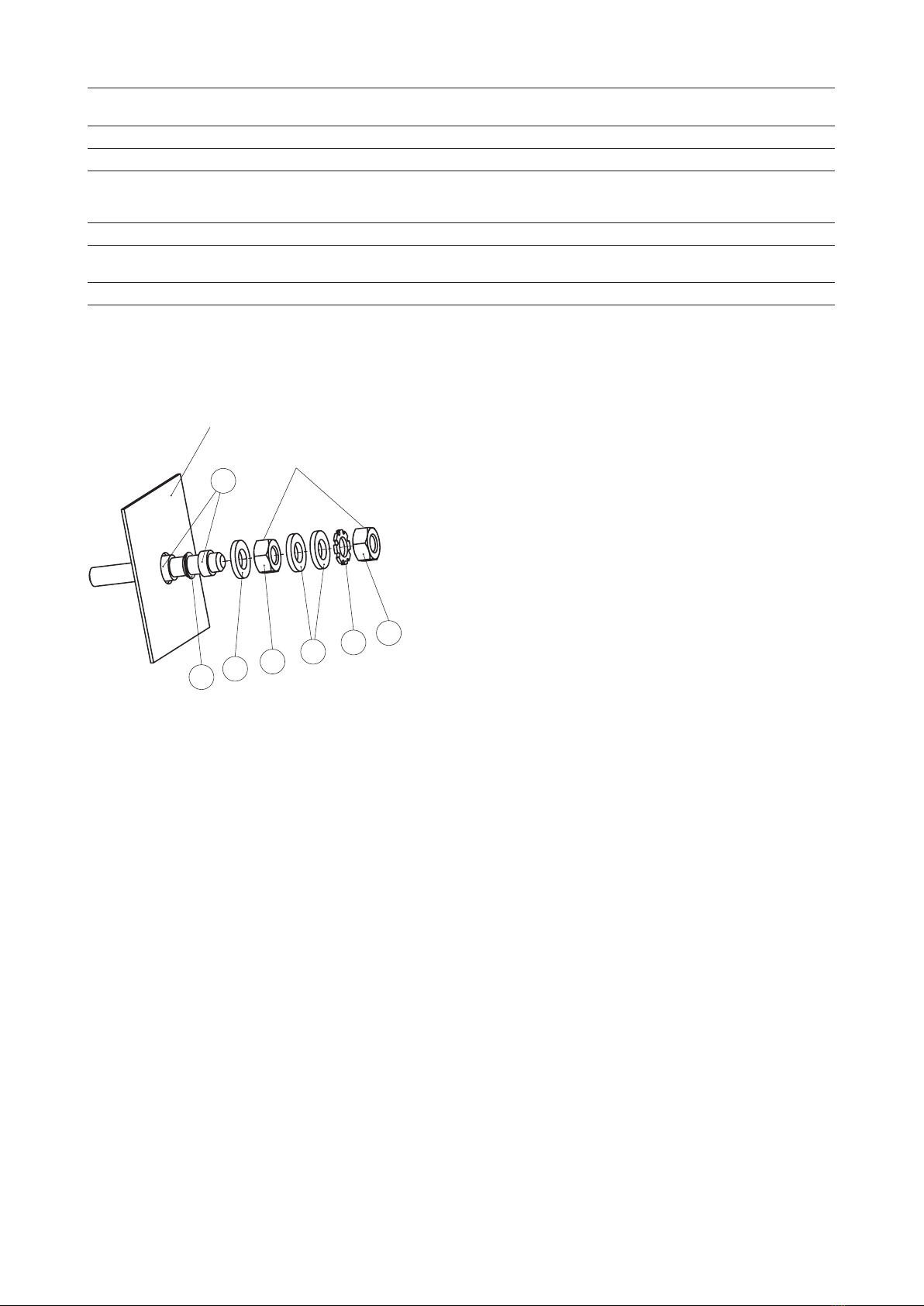

• Cable entry shall be Ex eb and tb ATEX certified and rated minimum IP66 to maintain the IP66 rating of the enclosure. Cable entry

devices must have a seal or gasket to provide sealing with the enclosure.

• Unused cable entries must be filled with Ex eb and tb ATEX certified and rated minimum IP66 stopping plugs to maintain the IP66

rating of the enclosure. Cable entry plugs must have a seal or gasket to provide sealing with enclosure.

• Not more than one single or multiple strand wiring lead shall be connected into either side of the terminals.

• Leads connected to the terminals shall be insulated for the appropriate voltage and this insulation shall extend to within 1 mm of the

metal of the terminal throat.

• The maximum permitted current of the non-IS alarm contacts is 3 A.

• The earth pillar adjacent to the RTD connectors must be used only for RTD cable screens.

• The external RTDs must be capable of withstanding a 500 V test to earth.

Certification

nVent certifies that this product met its published specifications at the time of shipment from the factory.

Warranty

This nVent product is warranted against defects in material and workmanship for a period of 12 months from the date of installation

or 30 months maximum from the date of shipment, whichever occurs first. During the warranty period, nVent will, at its option, either

repair or replace products that prove to be defective. For warranty service or repair, this product must be returned to a service facility

designated by nVent. The Buyer shall prepay shipping charges to nVent and nVent shall pay shipping charges to return the product to the

Buyer. However, the Buyer shall pay all shipping charges, duties, and taxes for products returned to nVent from another country. nVent

warrants that the software and firmware designated by nVent for use with a product will execute its programming instructions properly

when installed on that product. nVent does not warrant that the operation of the hardware, or software, or firmware will be uninterrupted

or error-free.

Limitation of warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse, operation outside of the specifications for the product, or improper

installation.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. NVENT DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

Exclusive remedies

THE REMEDIES PROVIDED HEREIN ARE THE BUYER’S SOLE AND EXCLUSIVE REMEDIES. NVENT SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER

LEGAL THEORY.

Statement of compliance

This equipment has been tested and found to comply with the low voltage directive 2014/35/EU, the ATEX directive 2014/34/EU and

the electromagnetic compatibility directive 2014/30/EU. These limits are defined to provide reasonable protection against harmful

interference in a residential installation (technical data mentions industrial application). This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures: