2Introduction

KVD-700

1.2 Circuit Description

1.2.1 Model

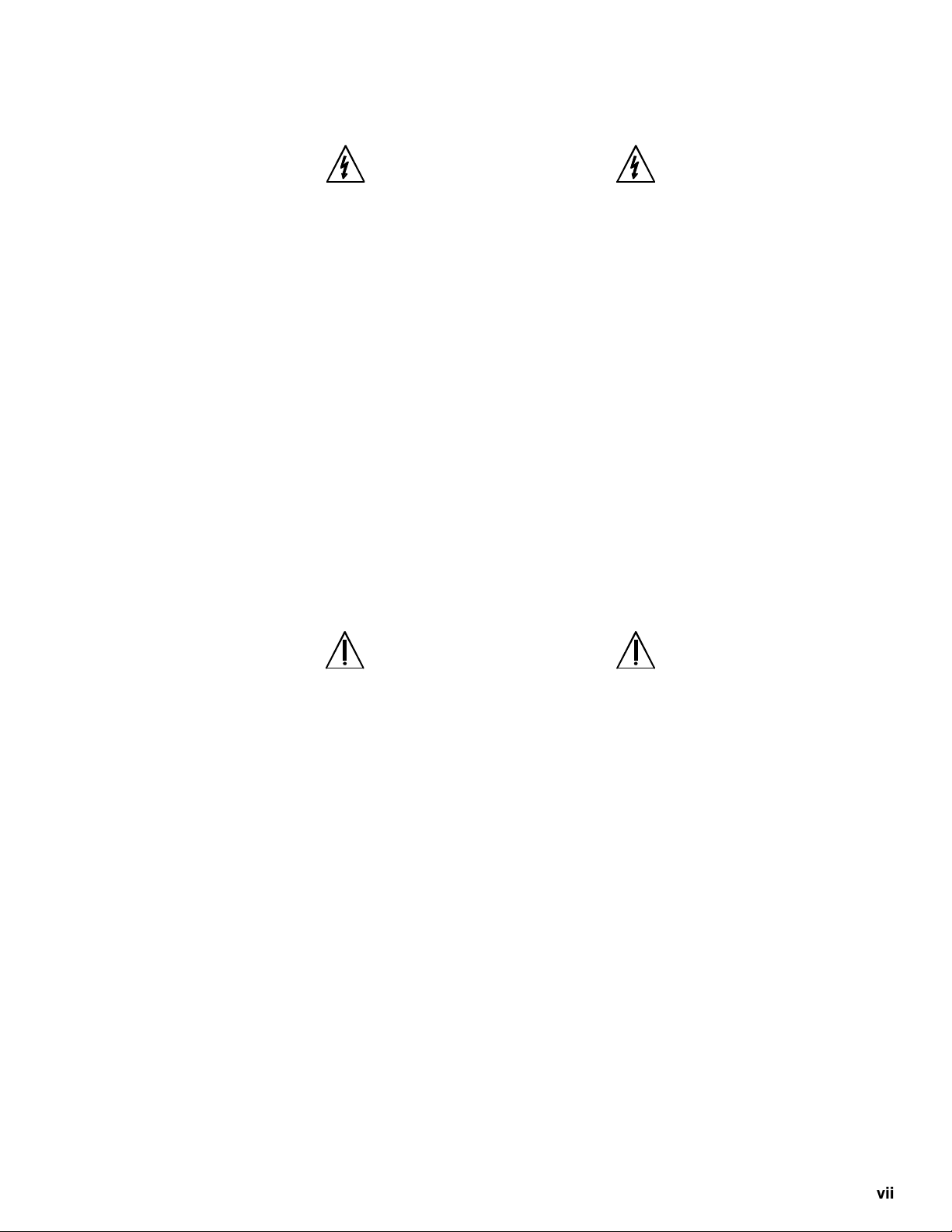

AKelvin-Varley voltage divider may be thought of as

being equivalent to a digital potentiometer, except that

it has an additional, but variable resistance in series

with the wiper arm. Such a circuit model of the KVD-

700 may be seen in Figure 1.2. In the case of the

KVD-700, the resistance between the input termi-

nals 1 and LOW is 100 kΩ.

An actual digital potentiometer uses decades of re-

sistor steps each decreasing by factor of ten. The

problem with such a digital potentiometer, however,

is that its resolution becomes limited by the value of

ever smaller resistors. They become difficult to imple-

ment as the contact resistance of switches and con-

nections become significant. AKelvin-Varley circuit

overcomes this problem with its special design, de-

scribed later.

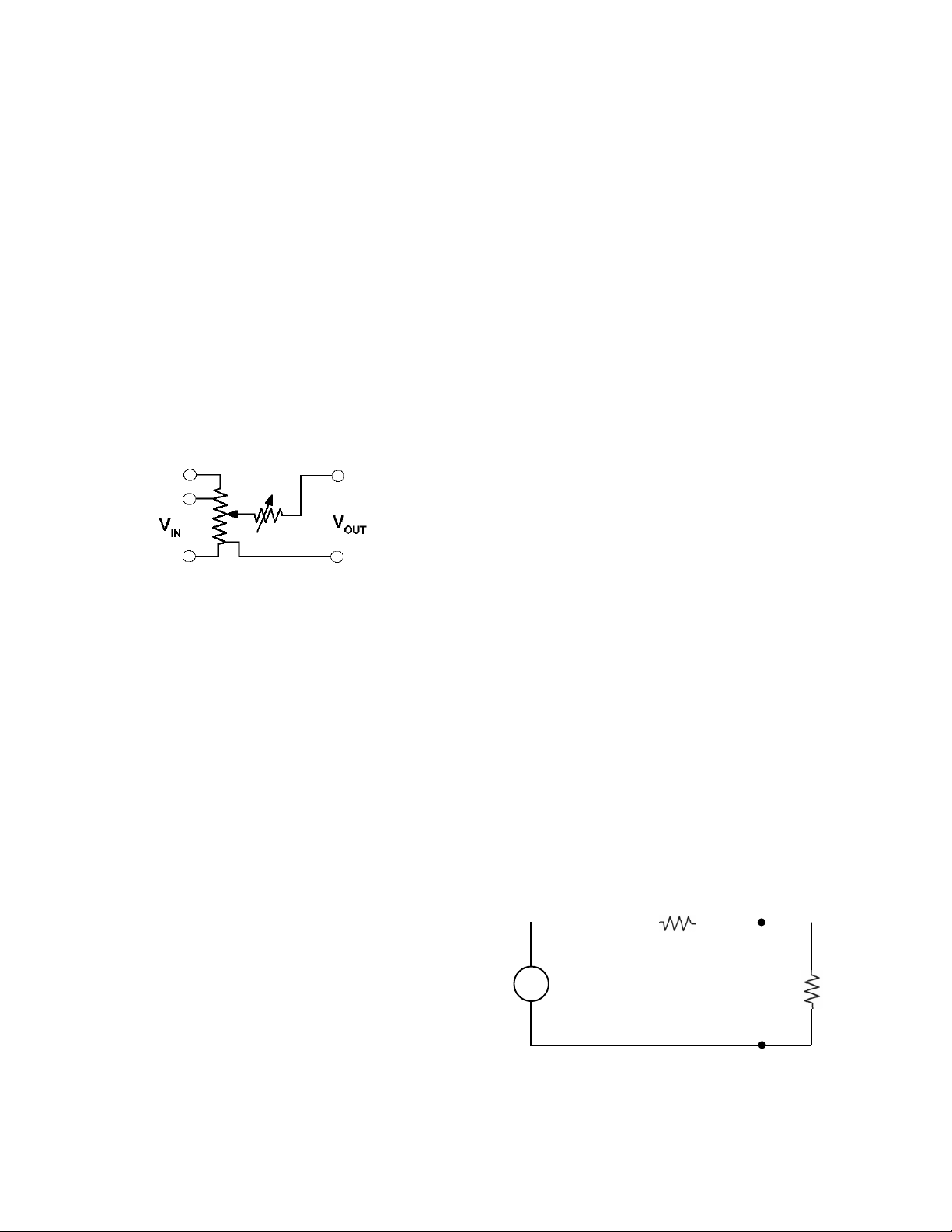

Another way to model the KVD-700 is with the

Thevenin equivalent circuit shown in Figure 1.3, where

S is the dial setting. Note that if the output is being

fed into a very high impedance, then the output im-

pedance RO, may be ignored. In general, however,

the effect of load impedance, RLmust be taken into

consideration, as will be discussed below. The ap-

proximate value of ROis shown in Figure 1.4. It may

be seen that the output impedance is maximum at

about the dial setting of 0.5 and drops to zero at both

ends, 1.0 and 0. It is the value of ROwhich will influ-

ence the effect of loading.

Note, however, that in general bridge applications,

nominally zero current flows out of the divider as the

bridge comes into balance, and therefore the divider

effectively “sees” an infinite impedance, and the ef-

fect due to ROmay be safely ignored.

1.2.2 Theory of Operation

The actual circuit diagram of the KVD-700 is shown

in Figure 1.5. This circuit is capable of dividing the

input into 107parts, i.e. 0.1 ppm. It consists of seven

decades, each of which divides its input voltage into

10 equal parts.

The implementation of this division may be seen as

follows: The input voltage across each decade is di-

vided by 10 equal resistances. Placing the resistance

of the succeeding decade in parallel with a portion of

the upstream decade reduces the effective resistance

of that portion. In particular, examine the figure and

note that first decade has 11 - not 10 - resistors (ig-

noring the 1.1 input resistor). The divider wipers from

the second decade encompass two resistors totaling

20 kΩ. This 20 kΩis shunted by 20 kΩ, the effective

total resistance of the second decade with all the

shunting in parallel with it, resulting in a total effec-

tive resistance of 10 kΩfor that step.

The 11 steps become equivalent to 10 steps of 10 kΩ

each, and in this way all the steps are kept equal.

1.1

1.0

LOW

HIGH

LOW

Figure 1.2. Digital Potentiometer Model for a Kelvin-

VarleyVoltage Divider

INPUT OUTPUT

SVIN V

OUT RL

RO

Figure 1.3.Thevenin Equivalent Circuit of a Kelvin-

VarleyVoltage Divider

R0