BasicController / BasicController plus

2

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�1 General� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�2 Target group � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�3 Electrical connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�4 Tampering with the device � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Overview of the common characteristics � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�2 Application example � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�3 Devices of the Basic series (examples) � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�1 General installation instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�1�1 Protection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

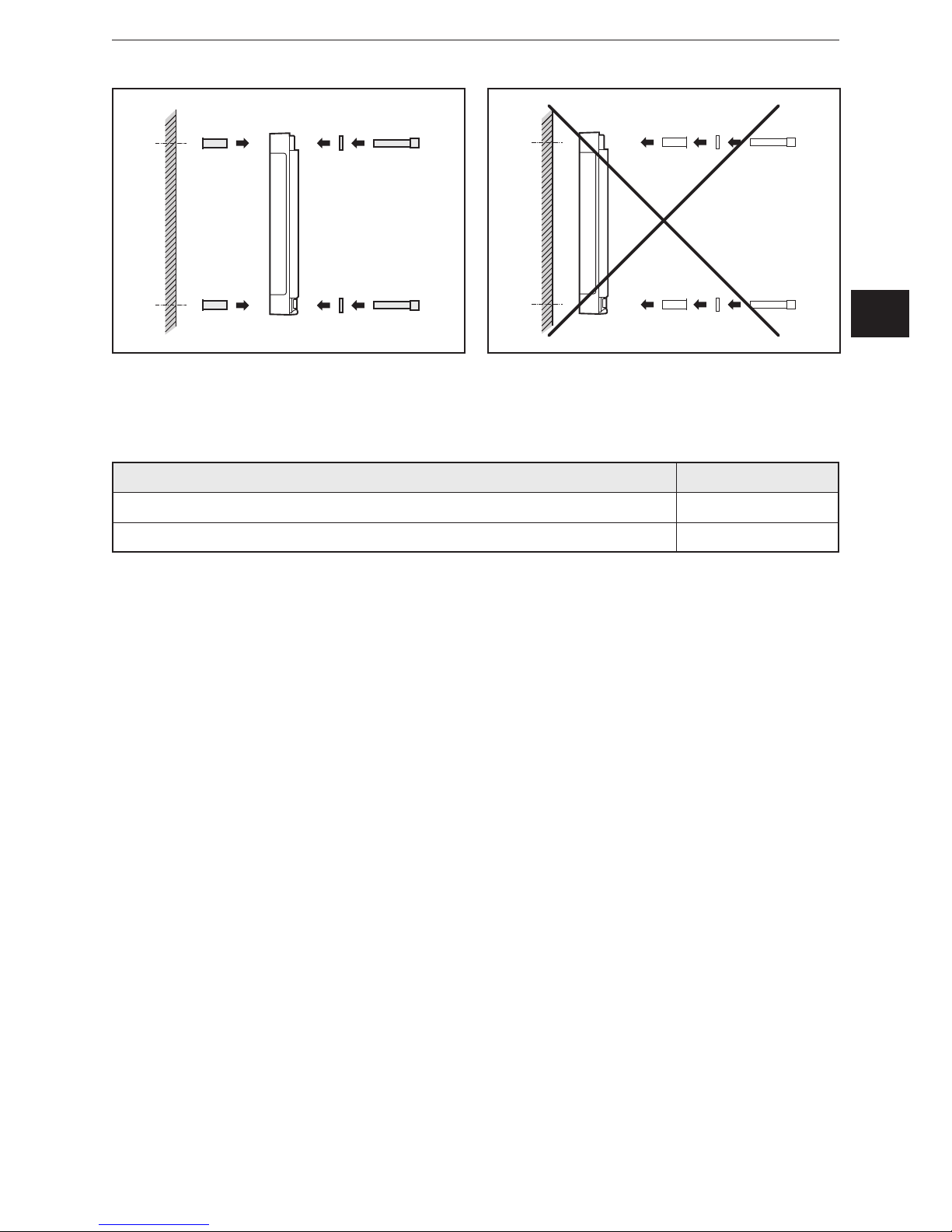

4�1�2 Mounting surface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2 Fastening � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�3 Cover and cable seal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�3�1 Installation of the cable seal� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�3�2 Removal of the cable seal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�3�3 Installation of the cover � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

4�3�4 Removing the cover � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

5 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

5�1 General electrical connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

5�2 Connection accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�2�1 Example accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�3 Frequency inputs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�4 Fuses � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

6 Indicators � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

7 Set-up � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

7�1 Programming � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

7�2 Required documentation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

7�3 Required hardware� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

8 Technical data� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

8�1 CR0401 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

8�2 CR0403 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

8�3 CR0411 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

9 Maintenance, repair and disposal� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

9�1 Maintenance� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

9�2 Cleaning the housing surface� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

9�3 Repair� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33