CAN BusTester EC2100

2

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

3 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�1 Features at a glance� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�2 Help and additional information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

4 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

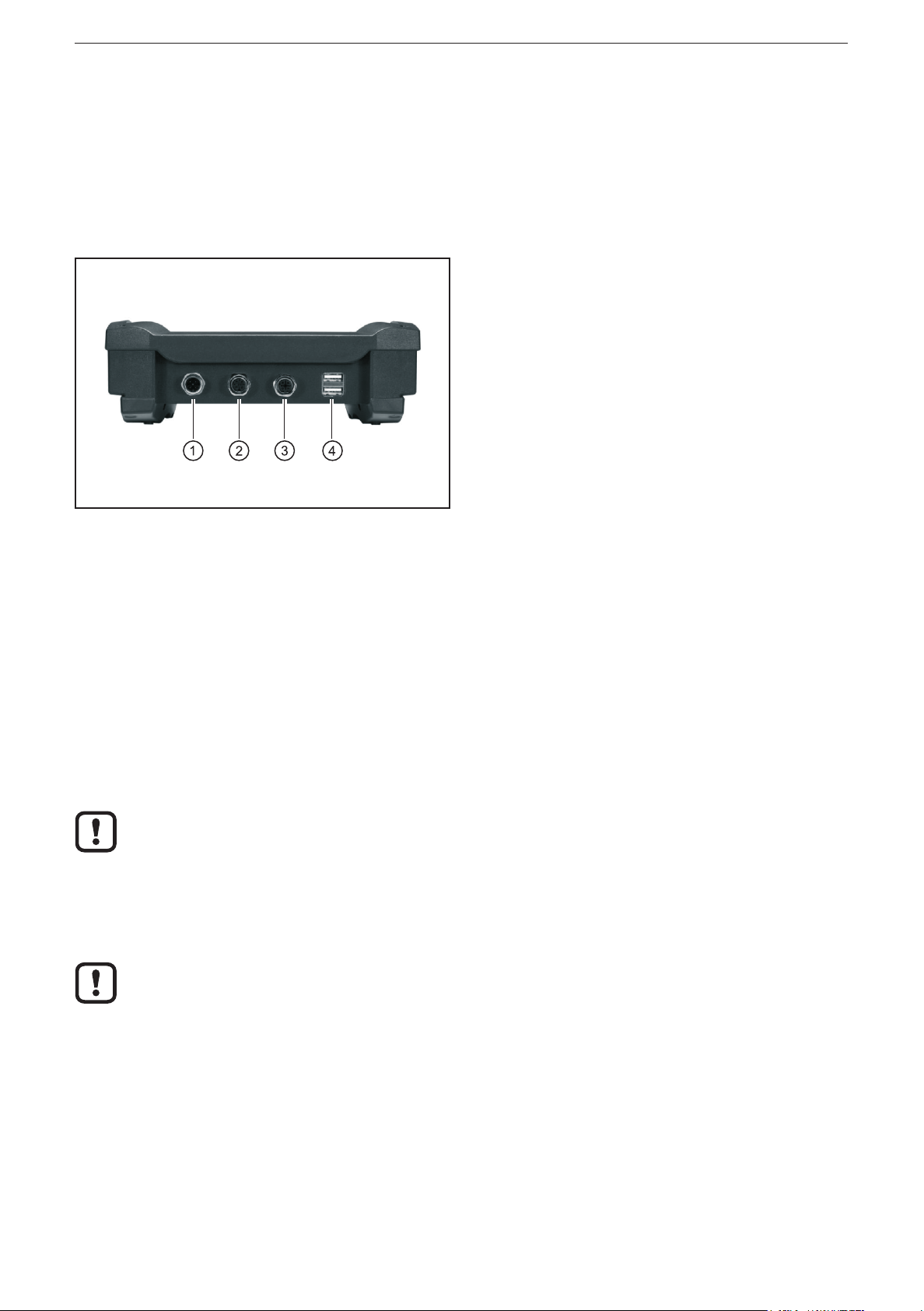

5 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�1 General electrical connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�2 Operating voltage � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�2�1 Battery charging� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�2�2 Battery life � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�3 CAN interface (terminating resistor) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�4 Ethernet interface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�5 USB interfaces � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

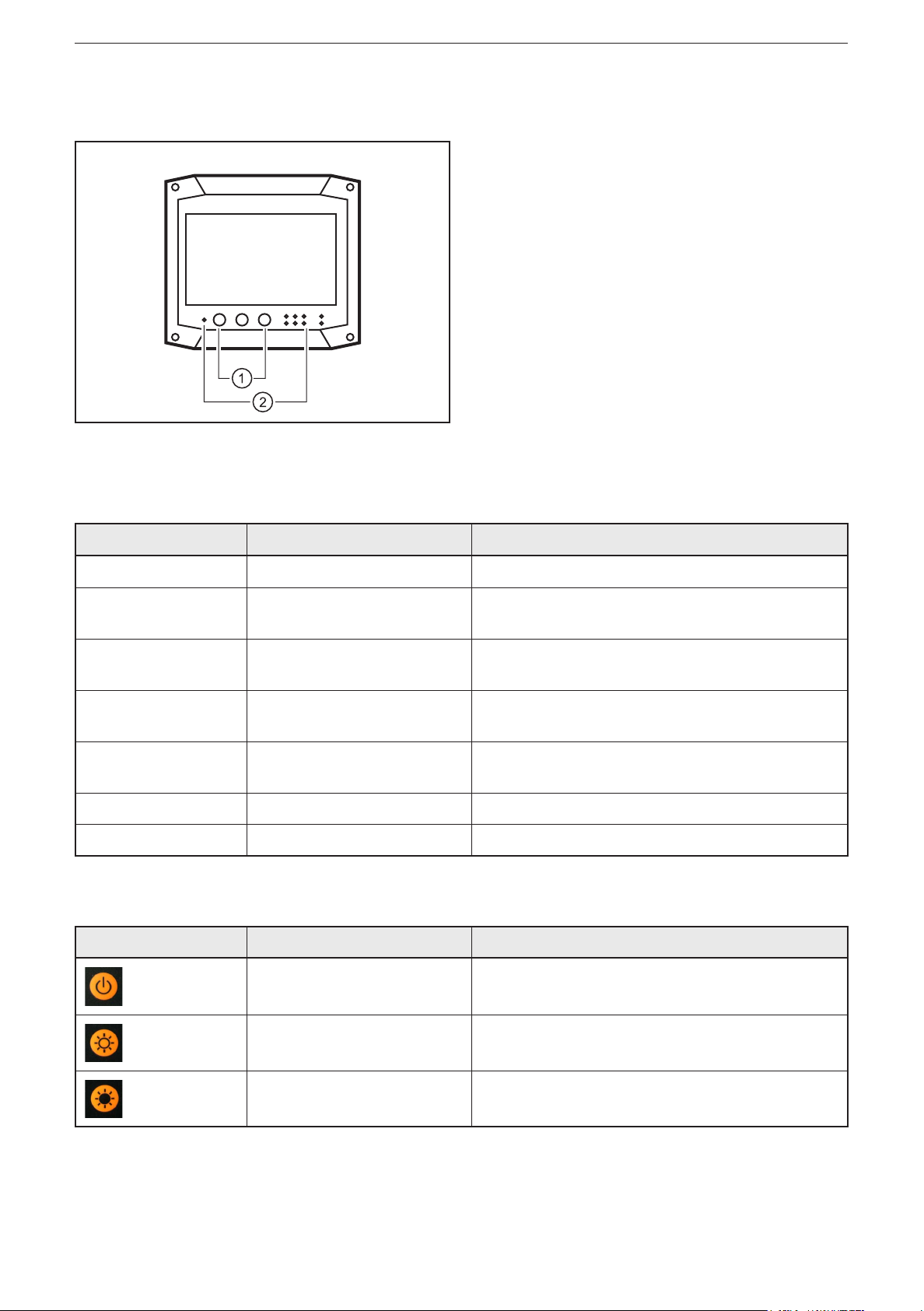

6 Operating and display elements � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

6�1 Display � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

6�2 Operating elements � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

7 Setup � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

7�1 General notes� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

7�1�1 Notes on the touch screen � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

7�2 Switch on the device � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

7�3 Switch off the device � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

7�3�1 Switch off via the ON/OFF key� � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

7�3�2 Switch off via softkey � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

7�4 Set the screen contrast � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

7�5 Switch the screen on/off � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

7�6 Language selection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

8 Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

8�1 User interface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

8�1�1 Main menu � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

8�1�2 Configuration menu � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

8�1�3 Status Line � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

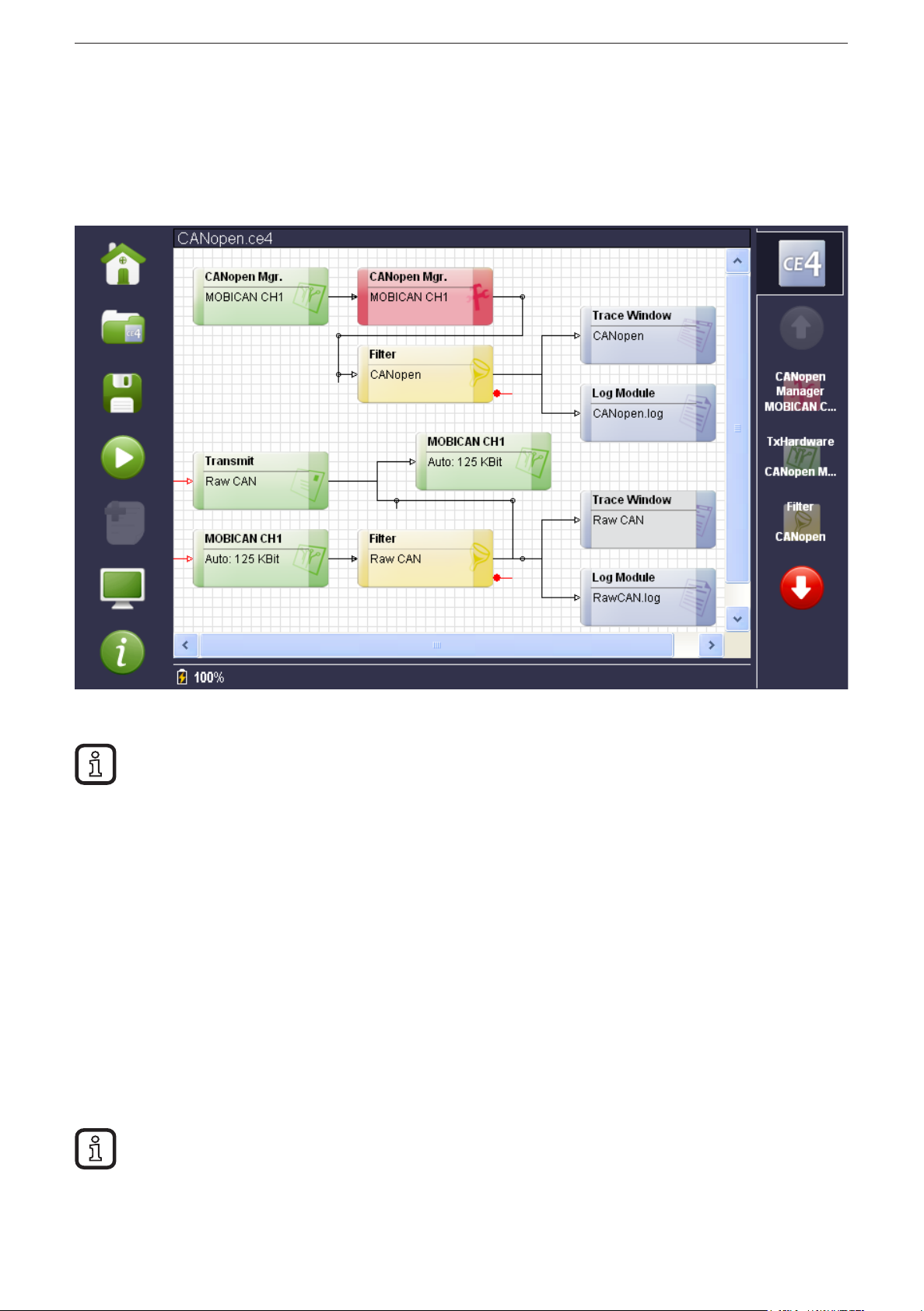

8�2 The most important function elements of the measuring setup � � � � � � � � 14

8�2�1 CANopen Manager (hardware) � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

8�2�2 CANopen Manager � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

8�2�3 Trace panels (RawCAN and CANopen)� � � � � � � � � � � � � � � � � � � � � � 18

8�3 Further function elements of the measurement setup � � � � � � � � � � � � � � � 20

9 Technical data� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22