GYT250 specifications

Supplied accessories: Carry case, quick start guide, thermal printer paper,

4GB micro SD card with adaptor, USB SD card reader

Cable length : 1.6m

Power requirements: Uses the power of the battery under test

Dimensions

Tester: 245mm (H) x 108mm (W) x 45mm (D)

Box: 262mm (H) x 354mm (W) x 92mm (D)

Weight

Tester: 730g

Packaged: 1.6kg

Memory storage: External SD card

Display: Full colour graphical display with backlight

Housing material: ABS

Printer: Integrated 56mm roll thermal printer

Battery testing

Testing method: Load free microprocessor-controlled conductance test

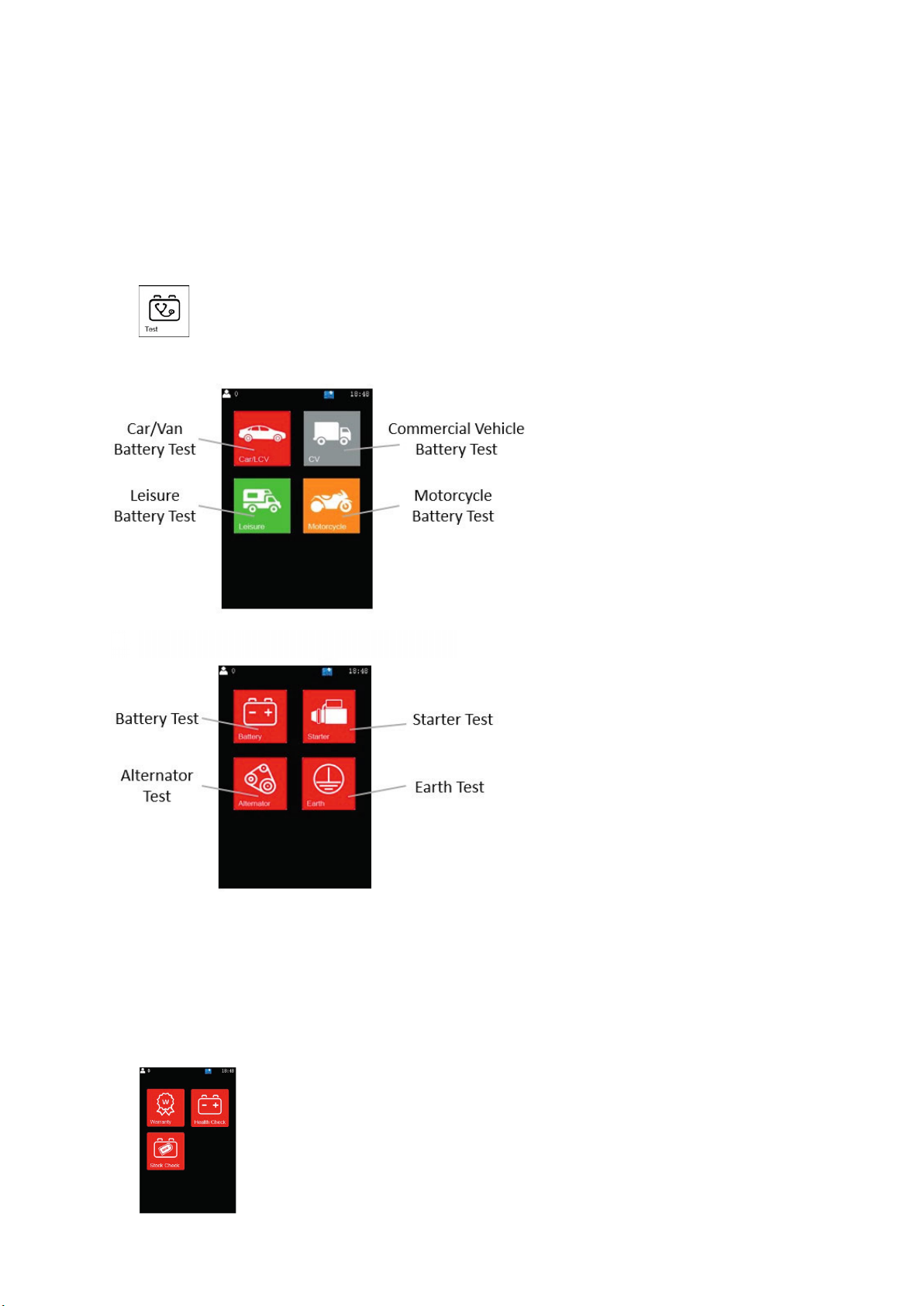

Applications: Automotive, commercial vehicle, motorcycle, powersport & leisure

Test types: Warranty, health check & stock check

Battery technologies : Conventional, EFB & AGM lead acid

Test range: Up to 2000A (EN) CCA

Input Voltage range : 9V to 36V

Starter, alternator & earth testing

Applications: Automotive & commercial vehicles with 12V or 24V electrical

system

Test types: Starter, alternator (diode ripple) & earth test

System technologies : Normal & smart alternators