Igema TG200 Owner's manual

Edition 04/2021

D-03-B-51284-EN-02

INSTALLATION AND OPERATION INSTRUCTION

TG200 with LEDSecure Slim

Transparent level gauge

2

Product philosophy

Thank you for placing your trust in IGEMA and deciding in favour of one of our

high-quality products.

For more than 100 years, measuring and control systems have been developed,

produced and sold worldwide under the IGEMA brand name.

“Steam is our passion” and we offer you the entire programme for the safe and

economic operation of your plants, especially in the steam and condensate sector.

Please read the installation and operating instructions carefully to ensure a safe and

reliable operation.

In addition to the information on installation and operation, you will also find important

information on maintenance, care, safety and value retention of your measuring and

control system.

3

Table of contents

1. Important safety instructions.............................................................................6

1.1 Symbols used in these instructions...................................................................6

1.2 Intended use of the device................................................................................7

1.3 Safety at work...................................................................................................8

1.4 Safety instructions for this device......................................................................9

1.5 Exclusion of liability...........................................................................................9

2. Contents of packing............................................................................................9

3. Important information.......................................................................................10

3.1 Intended use...................................................................................................10

4. Explanations......................................................................................................10

4.1 System description..........................................................................................10

4.2 Function..........................................................................................................10

4.3 Versions..........................................................................................................10

5. Technical data ...................................................................................................12

5.1 Dimensions.....................................................................................................12

5.2 Type of connection..........................................................................................14

5.3 Materials .........................................................................................................14

5.4 Application limits .............................................................................................14

5.5 Corrosion resistance.......................................................................................14

5.6 Rating plate / Marking.....................................................................................14

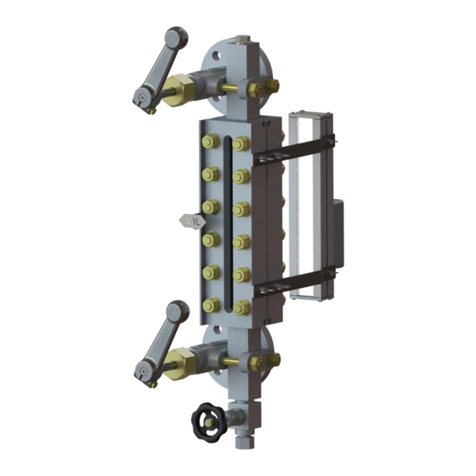

6. Construction......................................................................................................15

4

Table of contents

7. Assembly...........................................................................................................16

7.1 Version with flange..........................................................................................16

7.2 Version with welding end ................................................................................16

7.3 Heat treatment of weldseams .........................................................................16

7.4 Drain piping.....................................................................................................16

7.5 Illumination device ..........................................................................................16

8. Commissioning .................................................................................................17

8.1 Before commissioning.....................................................................................17

8.2 Commissioning of unit together with the boiler................................................18

8.2 Commissioning of the unit when the boiler is under pressure and at

temperature.....................................................................................................18

9. Maintenance ......................................................................................................19

9.1 Leakage..........................................................................................................20

9.2 Cleaning of mica shields.................................................................................20

9.3 Cleaning and purging of level gauge...............................................................21

9.4 Exchange of mica shields ...............................................................................21

9.5 Assembly ........................................................................................................22

9.6 Tightening torques ..........................................................................................22

10. Shutoff valve......................................................................................................22

10.1 Allgemeine Hinweise und Arbeitshinweise..................................................22

10.2 Functional principle.....................................................................................22

10.3 Self-closing ball safety function...................................................................23

5

Table of contents

10.4 Construction................................................................................................24

10.5 Commissioning...........................................................................................27

10.6 Maintenance...............................................................................................28

10.7 Assembly....................................................................................................29

11. Drain valve.........................................................................................................29

11.1 Information..................................................................................................29

11.2 Functional principle.....................................................................................29

11.3 Assembly....................................................................................................30

11.4 Commissioning...........................................................................................30

11.5 Maintenance...............................................................................................31

12. Case of damage.................................................................................................32

13. Spare parts ........................................................................................................32

13.1 Transparent level gauge.............................................................................32

13.2 Shutoff valve...............................................................................................35

13.3 Drain valve..................................................................................................35

14. Decommissioning .............................................................................................36

14.1 Disposal......................................................................................................36

15. Manufacturer´s declaration..............................................................................37

Table of contents

Other Igema Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Test Equipment Depot

Test Equipment Depot GVT-427B user manual

Fieldpiece

Fieldpiece ACH Operator's manual

FLYSURFER

FLYSURFER VIRON3 user manual

GMW

GMW TG uni 1 operating manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

Hanna Instruments

Hanna Instruments HI96725C instruction manual

Nokeval

Nokeval KMR260 quick guide

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Fluke

Fluke 96000 Series Operator's manual

Test Products International

Test Products International SP565 user manual

General Sleep

General Sleep Zmachine Insight+ DT-200 Service manual