Igema NA7-45 User guide

Edition 07/2021

D-06-B-51014-EN-00

INSTALLATION AND OPERATING INSTRUCTION

NA7-45 / NA7-130

Magnetic level indicator

2

Product philosophy

Thank you for placing your trust in IGEMA and deciding in favour of one of our

high-quality products.

For more than 100 years, measuring and control systems have been developed,

produced and sold worldwide under the IGEMA brand name.

“Steam is our passion” and we offer you the entire programme for the safe and

economic operation of your plants, especially in the steam and condensate sector.

Please read the installation and operating instructions carefully to ensure a safe and

reliable operation.

In addition to the information on installation and operation, you will also find important

information on maintenance, care, safety and value retention of your measuring and

control system.

3

Table of contents

1. Important safety instructions.............................................................................6

1.1 Symbols used in these instructions.................................................................6

1.2 Intended use of the device..............................................................................7

1.3 Safety at work.................................................................................................8

1.4 Safety instructions for this device....................................................................9

1.5 Exclusion of liability.........................................................................................9

2. Contents of packing..........................................................................................10

3. Important information.......................................................................................10

3.1 Intended use.................................................................................................10

4. Explanations......................................................................................................10

4.1 System description........................................................................................10

4.2 Function........................................................................................................10

5. Technical data ...................................................................................................11

5.1 Versions........................................................................................................11

5.2 Type of connection........................................................................................12

5.3 Materials.......................................................................................................12

5.4 Application limits...........................................................................................12

5.5 Corrosion resistance.....................................................................................12

5.6 Identification plate / Marking.........................................................................12

6. Construction......................................................................................................13

4

Table of contents

7. Assembly...........................................................................................................13

7.1 Version with flange........................................................................................13

7.2 Version with welding end..............................................................................14

7.3 Heat treatment of weld seams ......................................................................14

7.4 Flap indicator ................................................................................................14

7.5 Float installation............................................................................................14

7.6 Drain piping...................................................................................................14

7.7 Assembly of additional equipment (for retrofitting, otherwise already

pre-installed).................................................................................................15

8. Electrical connection........................................................................................15

8.1 Magnetic switch ............................................................................................16

8.2 Primary element............................................................................................16

9. Commissioning .................................................................................................16

9.1 Adjustment of indicating flaps.......................................................................16

9.2 Commissioning of unit together with the boiler .............................................16

9.3 Commissioning of unit if boiler is already in operating condition...................17

9.4 Anti-frost device............................................................................................17

10. Maintenance ......................................................................................................17

10.1 Cleaning of standpipe (2) and float (2.1).......................................................17

10.2 Tightening torques........................................................................................18

5

Table of contents

11. Drain valve.........................................................................................................19

11.1 Construction..................................................................................................19

11.2 Assembly ......................................................................................................20

11.3 Commissioning .............................................................................................21

11.4 Maintenance .................................................................................................21

12. Spare parts ........................................................................................................22

12.1 Magnetic level gauge....................................................................................22

12.3 Drain valve....................................................................................................22

13. Decommissioning .............................................................................................23

13.1 Disposal........................................................................................................23

14. Warranty.............................................................................................................23

15. Manufacturer´s Declaration..............................................................................24

6

1. Important safety instructions

KEEP THESE INSTALLATION AND OPERATING INSTRUCTIONS IN A SAFE PLACE!

Commissioning as well as maintenance and repair work may only be carried out by qualified

persons in compliance with the installation instructions given in this operating manual. The

correct installation, commissioning, maintenance and operation of the device presupposes that

the person in charge is familiar with measurement and control systems and complies with the

general installation and safety instructions. In addition, the correct and intended use of tools

and the handling of safety devices must be ensured. Unqualified personsmust not be assigned

the above tasks!

IGEMA GmbH accepts no liability for damage to property or personal injury caused by

unqualified persons or by failure to observe these installation and operating instructions. If no

sufficiently qualified person can be found, IGEMA GmbH can be commissioned with the

installation/maintenance.

1.1 Symbols used in these instructions

In the following installation and operating instructions, safety instructions are marked with the

following symbols:

Danger

This symbol and signal word refer to a potentially

hazardous situation which could result in death or

injuries if ignored.

Caution electrical voltage

This symbol and signal word indicate live parts

with an immediate danger of death from electric

shock.

Caution hot

This symbol with a signal word indicates a

potentially hazardous situation that can result in

severe burns and scalds all over the body.

7

Caution

This symbol and signal word refer to a potentially

hazardous situation which could result in

personal injury, property and environmental

damage if ignored.

Caution

This symbol and signal word refer to a potentially

hazardous situation which couldresult in damage

to the equipment if ignored.

Info

This symbol indicates useful information and

recommendations as well as measures that will

prolong the value of your measuring and control

system.

1.2 Intended use of the device

Use these installation and operating instructions, the identification on the rating

plate (see 5.6) and the technical data sheet to check whether the device is

suitable for the intended use/application. The device complies with the

requirements of the European Pressure Equipment Directive 2014/68/EU.

The device may only be used to indicate fill levels on containers.

The maximum values of the pressure and temperature range of the device must be checked

before installation. If the maximum allowable operating values of the device are lower than

those of the system on which it is to be installed, protective instruments for the device, such

as pressure reducers or similar, must be provided to avoid limit situations. The device may

only be used in accordance with the information in these installation and operating instructions

or for the parameters and applications agreed in the supply contract. (see rating plate, 5.6)

The operator of the direct water level indicator is obliged to familiarise himself on the

compatibility of the medium and the device. In case of doubt, contact the relevant installation

manager or site manager.

The correct installation position, alignment and flow direction of the device must be observed!

Before installing the IGEMA product on boilers or containers, it is essential to remove all

protective covers and, if necessary, the protective film from rating plates and sight glasses.

Caution

8

1.3 Safety at work

Before installation or carrying out maintenance work on the device, safe access

must be ensured and a secure working area with sufficient lighting must be

defined and marked out. Always use lifting equipment for heavy loads!

Before starting any work, carefully check which liquids or gases are or have been in the

pipeline. (flammable substances, irritating substances,substances hazardous tohealth) When

opening or dismantling the device, residues of the medium can escape. Subsequent fumes

are also possible in unpressurized and cold systems. Use designated PPE such as safety

goggles and respiratory protection!

Special attention must be paid to the condition of the environment around the installation or

maintenance site. Be aware of e.g.: potentially explosive atmospheres, lack of oxygen in tanks

and pits, dangerous gases/liquids, extremetemperatures, hot surfaces,fire hazard (e.g. during

welding) and moving machine and system components. Protect yourself from excessive noise

by taking the required protective measures.

For all maintenance work or new installations, on new or existing boilers or vessels, it is

imperative to check that the boiler or vessel has been depressurised andthat the pressure has

been safely reduced to atmospheric pressure. In principle, no system should be regarded as

unpressurized even if indicated by pressure measuring devices such as pressure gauges or

sensors. When releasing the pressure, make sure that no persons are in the release area.

Carefully check whether you and/or other persons in the vicinity need PPE to protect yourself

from external influences such as high and low temperatures, radiation, noise, danger to eyes,

loose objects that can fall down or chemicals.

There is always a risk of injury when handling large and/or heavy equipment. Observe the load

handling regulation as a minimum requirement for working with loads. Avoid handling the

device with your own physical force, e.g. by lifting, pulling, carrying, pushing or supporting it,

especially to prevent back injuries. Use lifting equipment to move heavy and bulky equipment

in accordance with Article 1, Section 2 of the German Load Handling Regulation

(LasthandhabV).

Under normal operating conditions the surface of the device can become very

hot! Under the maximum operating conditions, the surface temperature can

exceed 350°C. After shutting off or, if necessary, shutting down the boiler, wait

until the temperature has normalized to room level. To avoid the risk of burns

and scalds, always use PPE including safety goggles!

Danger

Caution

hot!

9

1.4 Safety instructions for this device

These installation and operating instructions are an integral part of the device

and must be forwarded to the responsible departments "Goods inward,

Transport, Installation, Commissioning and Maintenance". They must be kept in

such a way that the technical staff have access to these documents at all times.

If the device is passed on to a third party, these installation and operating

instructions must also be included in the national language of the third party.

Avoid shocks and hard contact during transport, as this can lead to damage. During

intermediate storage, the device must be kept dry and secured against damage.

When servicing the unit, make sure to use sharp-edged internal parts and avoid shards of

broken glass. There is a risk of cutting hands and arms! Always wear work gloves when

changing packing, valve seat and valve plug.

For units with a dead weight of 30 kg or more, the customer must provide adequate support

(e.g. via a spring suspension device, etc.). This can be attached to the holding strap/eyelet on

the device.

When returning goods to IGEMA GmbH, the applicable safety and environmental laws

according to GGVSEB [German ordinance on the national and international carriage of

dangerous goods by road, rail, and inland waterways] must always be observed. If there are

any risks to health or the environment due to residues or the device has a mechanical defect

this must be indicated when returning the device and the necessary precautionary measures

must be taken. If the returned goods are devices that have come into contact with or contain

hazardous substances, a safety data sheet must be enclosed, and the goods must be clearly

marked. In addition, the hazardous substance must be reported to the logistics service

provider.

Darauf achten, dass die im Gerät eingebrachten Permanentmagnete in der

Magnetisierung nicht verändert werden!

Magnetfelder im Nahbereich der Geräte ausschließen!

1.5 Exclusion of liability

IGEMA GmbH Mess- und Regelsysteme will assume no liability if the above regulations,

instructions and safety precautions are not observed and followed. If they are not expressly

listed in the installation and operating instructions, changes to an IGEMA device are carried

out at the risk of the user.

Der Magnetsperrschalter darf nicht geöffnet werden. Eine Verletzung des

angebrachten Siegels schließt jegliche Gewährleistung aus.

Achtung

Caution

10

2. Contents of packing

1. - Standpipe with indicating ledge

- Float and new gasket are packed on the outside of the unit

- Setting magnet is enclosed

Additional equipment (also possible for existing devices):

- Magnetic switch

- Contact bar with reed contacts (Primary element MRK-…)

- Drain valve

2 Mounting and operating instructions

3. Important information

3.1 Intended use

Magnetic level gauge NA7-45 / NA7-130:

The magnetic level gauge is a liquid level gauge which can be used for steam boilers and

containers.

The indication is made via a float operated magnetic system.

The product corresponding to the EU 2014/68/EU.

Applied standards as per EN 13445 / EN 12952 / EN 12953 / AD 2000 or ASME-Boiler.

4. Explanations

4.1 System description

The level gauge indicates the level in the boiler indirectly.

4.2 Function

The unit works according to the physical law of the communicating tubes.

The liquid level in the standpipe (2) is the same as the one in the boiler. The liquid level is

transmitted to the indicating ledge on the outside of the standpipe via a float with inner

magnetic system located inside of the standpipe. The magnetic system actuates

simultaneously additionally mounted switches (4) on the standpipe and/or a sensor (5) for

remote liquid level transmission.

Design sketches see chapter 6

11

5. Technical data

5.1 Versions

NA7 (version flange/cap)

> 2,6m

> 6m

Possible vent connections

Vent cap

Flange

Flange with vent flange

Possible drain connections

Flange with drain flange

Flange with drain valve

12

•To indicate a range > 2,6 m it is necessary to use 2 or more superposed indicating ledges.

•For level gauges longer than 6 m, the unit will be delivered in divided version with

intermediate flanges.

5.2 Type of connection

Standard : flanges according to DIN or ASME

On request : welding end or Socket Welding according to DIN or ASME

5.3 Materials

•Fluid side in stainless steel according to DIN or ASME.

•Float made of stainless steel; for low medium density, the float is made of titan

•Other components in contact with the medium and pressure-retaining components made

of carbon steel according to DIN or ASME.

5.4 Application limits

Max. all. pressure PS

[bar]

32

50

80

130

Max. all. temperature TS

[°C]

239

265

296

340

5.5 Corrosion resistance

The safety of the unit is not influenced by corrosion if it is used as intended.

5.6 Identification plate / Marking

The following data are indicated on the identification plate according to EN 19:

* Marking depending on the realization

A Date of manufacture D Max. all. temperature

B Type of unit E Nominal pressure (not specified)

C Max. all. Pressure F Nominal diameter

13

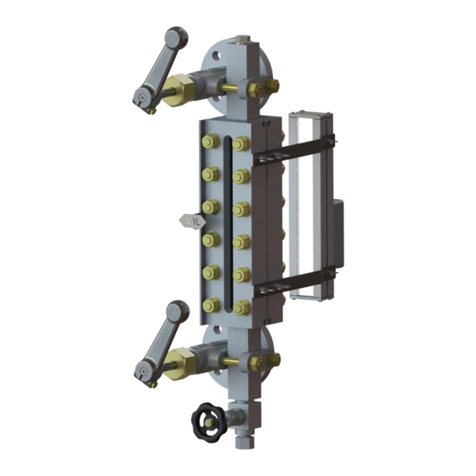

6. Construction

NA7

Legend

(1)

(2)

(2.1)

(2.2)

(2.3)

(3)

(3.1)

(3.2)

(4)

(5)

(6)

(A)

(D)

(W)

Connection studs

Standpipe

Float

Sealing

Cover flange

Flap indicator

Bolt spring

Stop clamp

Magnetic switch (optional)

Contact bar with reed

contacts (optional)

(Primary element MRK-…)

Plug

Drain valve (optional)

Upper shutoff valve

Lower shutoff valve

7. Assembly

Take care that connection of shutoff valves (W+D) is made with a

horizontally orientated spindle. The arrow on the valve indicates the flow

direction “→’’ and must point towards the standpipe (2).

Check mating dimensions between instrument nozzle and boiler nozzle.

Make sure that there are no magnetic materials or magnetic field

generators in close proximity of the standpipe (within 100 mm).

7.1 Version with flange

•Respect installation position!

•Remove protection caps from connection flanges. Caps only serve as transport protection.

•Ensure that sealing surfaces are clean and undamaged.

•Use sealing material according to EN1514 and screws according to DIN2510 or DIN974

(material 1.7709).

•Mount magnetic level gauge stress-free.

Caution

14

7.2 Version with welding end

•Observe installation position!

•Remove protection caps from connection flanges. Caps only serve as transport protection.

•Assembly only by using welding process 111 (manual arc welding) and 141 (tungsten inert

gas welding).

7.3 Heat treatment of weld seams

Supplementary temper tests of weld seams are not required.

7.4 Flap indicator

•The centre of the lower process connection is the reference point for the zero mark of the

flap indicator (3).

•The flap indicator fixed by bolt springs (3.1) with stop clamp (3.2) to the standpipe (factory-

made) can be turned into desired position.

Also turn stop clamp!

7.5 Float installation

•The float (2.1) with inner magnetic system and the new gasket (2.2) are packed and fixed

outside of the standpipe (2) when the unit is supplied.

•Open cover flange (2.3)

•Carefully remove float packing

•Insert float with top-heavy side upwards intostandpipe (top-heavy side with colour marking)

•Tighten cover flange (2.3) and associated gaskets (2.2) with standpipe using successively

opposite diagonal tightening (see chapter 9.2)

The pressure test of the tank must be carried out without the float!

The float may remain in the standpipe if there are valves between the

boiler and the standpipe which are shut off during the test.

7.6 Drain piping

•Check bolting drain valve (A) / standpipe (2) and retighten if necessary.

•Mount drain piping on drain valve (A) (to be provided by the customer).

Ensure that drain piping has free outlet to atmosphere and is protected

from pressure peaks!

•Close valves.

Caution

Caution

15

7.7 Assembly of additional equipment (for retrofitting, otherwise already

pre-installed)

•Remove indicating ledge before assembly of additional equipment

•Magnetic switches and/or primary element are fixed without obscuring the indication by

means of integrated pipe saddle

Assembly of magnetic switches or sensor may only be carried out in a

maximum angle of 90° to the centre of the flap indicator.

Never insulate additional equipment.

•The magnetic switch is continuously adjustable in the whole indication area “E”. (See

special data sheet)

•The centre of the lower process connection is the reference point for the zero mark of the

sensor (marked in red)

(see special data sheet and operating instruction for primary element MRK-..).

8. Electrical connection

Only skilled and qualified personnel may carry out the electrical

connection according to the wiring diagram!

Respect the instructions of the VDE (Association for Electrical, Electronic

& Information Technologies) and of the local network operators for the

installation to be provided by the customer!

Only use cables that are suitable for the operating range!

Observe the switching time of the magnetic switch when designing a

safety circuit. Adhere to basic and reliable safety principles as per DIN EN

ISO 13849 for electrical components.

Caution

Caution

16

8.1 Magnetic switch

Contact position and wiring diagram:

Float above the switch Float below the switch

We recommend to use customary RC combinations or a suitable Varistor (e.g. 0,1 μF/100 Ω)

as inductive consumer to extend the contact life of the magnetic switch. Resistance value (Ω)

and power rating (W) depend on customer indications.

We suggest to use silicon cables free of acetic acid for the further connection cable in the area

“connecting housing inside”.

8.2 Primary element

see special data sheet and operating instruction for primary element MRK-…)

9. Commissioning

Attention danger of life!

Unit may be hot during commissioning and during operation.

Customer can possibly provide safety device.

9.1 Adjustment of indicating flaps

Pass setting magnet (bottom-up) 3 times along the glass plate. The flaps above the zero mark

are white and the flaps below the zero mark are red.

(See figure in chapter 9.4)

9.2 Commissioning of unit together with the boiler

Check specifications of material, pressure and temperature!

•Close drain valve (A) / plug (6) (see sketch chapter 6).

•Open shutoff valves (W+D).

•Check position of magnetic switch (2) in operating condition and adjust the height if

necessary

Danger

17

9.3 Commissioning of unit if boiler is already in operating condition

•Close drain valve (A) / plug (6) (see sketch chapter 6).

•Open slowly shutoff valve W and then shutoff valve (D)

•Check position of magnetic switch (2) in operating condition and adjust the height if

necessary.

9.4 Anti-frost device

Insulated units which are used in the area of temperatures below 0°C must be provided with

a flap indicator with anti-frost device. Pass setting magnet bottom-up laterally of the anti-frost

device to adjust the flaps.

10. Maintenance

When using viscous or crystallizing media, clean standpipe (2) and float (2.1) inside in regular

intervals and during boiler revision.

Attention danger of life!

Unit may be hot during commissioning and during operation.

Customer can possibly provide safety device.

10.1 Cleaning of standpipe (2) and float (2.1)

Purging of connection pipework including case:

•Close shutoff valves (W+D).

•Slowly open drain valve (A) / plug (6) and drain medium

•Slightly open valve (D) and close after approx. 2 seconds.

•Slightly open valve (W) and close after approx. 2 seconds.

•Close drain valve (A) / plug (6).

•Open the shut-off valves (W+D) a little, the add-on housing is filled up.

•Fully open shut-off valves (W+D) after filling of the standpipe.

Danger

18

If this cleaning was not sufficient, dismount bottom/cover flange (2.3) and remove float (2.1).

Plant must be pressureless for disassembly works!

Wait until unit has cooled!

•Close shutoff valves (W+D).

•Open drain valve (A) / plug (6); unit is drained.

•Caution! When dismounting, residual medium may escape and further evaporation is also

possible.

•Remove cover flange (2.3).

•Remove float and clean standpipe and float.

•Insert float with top-heavy side upwards into standpipe (top-heavy side with colour

marking).

•Always use new gaskets (2.2) when assembling the unit. Tighten bolts of cover flange /

standpipe in several steps using successively opposite diagonal tightening (see table in

chapter 10.2) until reaching tightening torque Mdmax.

Close shutoff valves before carrying out preservation works or chemical

cleaning of the boiler. Or even better: interrupt passage on flange

connection of boiler nozzles by placing blind flanges.

For commissioning see chapter 9.

Design sketches see chapter 6

10.2 Tightening torques

all. pressure PS

[bar]

Tightening torque Md →Mdmax [Nm]

in steps

1

2

3

4

5

6

32

35

50

65

75

-

-

50

50

75

100

125

150

165

80-130

60

90

120

150

180

200

Tightening torques of screw plug (6) Md= 150 Nm

Danger

Danger

19

11. Drain valve

11.1 Construction

AV500, AV520

•Male thread G½“ on input

side

•Output side with cutting ring

connection ø 12 as per DIN

2353 –DS12

AV540, AV550

•Male thread G½”on input

side

•Output side with welding end

•On request other

connections possible

20

AV56x, AV57x

•Male thread G½” on input

side

•Output side with cutting ring

connection ø12 as per DIN

2353 –DS12

•On request other

connections possible

(1) Valve housing (8) Screw cap

(2) Sealing ring (9) Sealing ring

(3) Seat (10) Upper part of valve

(4) Valve spindle with cone (11) Handwheel

(5) Scraper rings (12) Plate OPEN-CLOSED AUF-ZU

(6) Gland packing (13) Cap nut

(7) Stuffing box (14) Drain connection

11.2 Assembly

Ensure that drain piping has free outlet to atmosphere and is protected

from pressure peaks.

•Firmly screw on drain valve with sealing ring (2) on existing unit.

•Cutting ring connection: Assemble drain piping (tube ø 12x1 material

P235GH) on provided drain connection (14) as

per DIN 2353 (AF24) (on the part of the builder).

Welding end: weld on

Flange: screw on

Danger

This manual suits for next models

1

Table of contents

Other Igema Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Greyline Instruments

Greyline Instruments PDFM 5.1 user guide

Leister

Leister 142.723 operating instructions

VALLEY FORGE & BOLT

VALLEY FORGE & BOLT SPC4 406A user manual

Pitney Bowes

Pitney Bowes MAILSTATION 2 Quick install guide

International Light Technologies

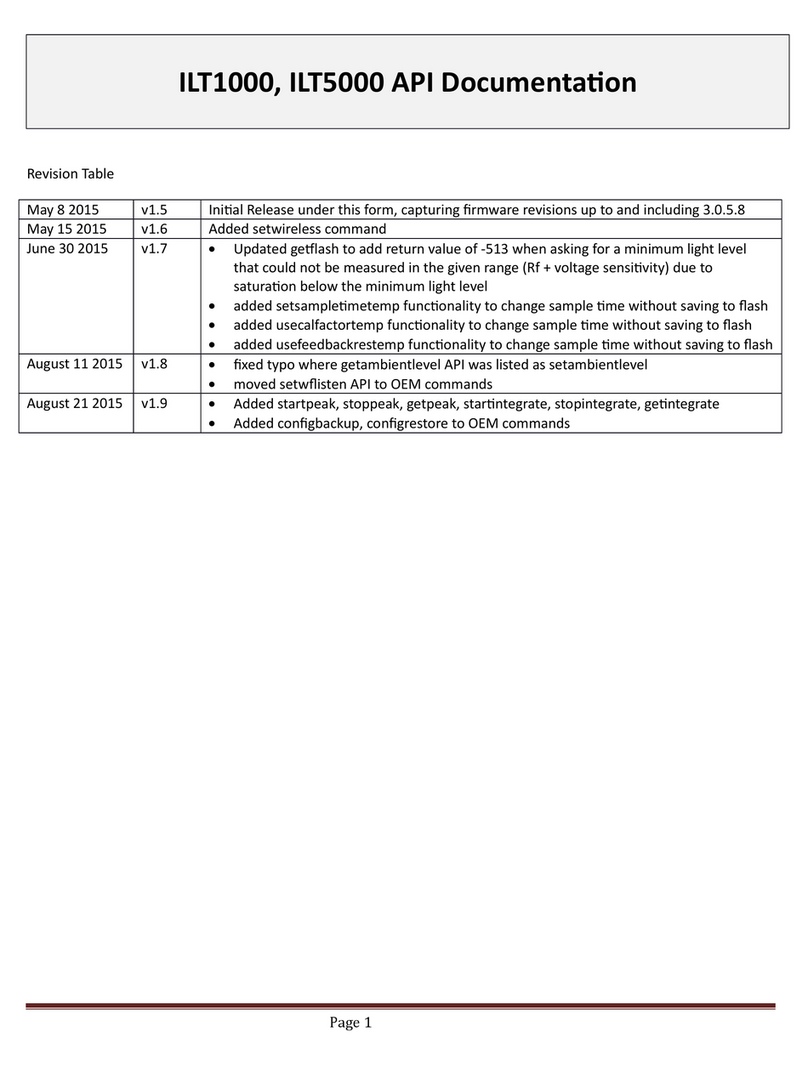

International Light Technologies ILT1000 API Manual

HydroPoint

HydroPoint WaterCompass FM300 installation instructions