IGM Laguna Fusion 3 User manual

Producer / Hersteller / Výrobce / Výrobca / Gyártó / Producent:

Laguna Tools Inc

2072 Alton Pkwy

Irvine, CA 92606,

USA

Phone: +1 800-234-1976

Website: www.lagunatools.com

Distributor / Distributor / Distributor / Distribútor / Forgalmazó / Dystrybutor:

IGM nástroje a stroje s.r.o.

Ke Kopanině 560, 252 67, Tuchoměřice, Praha-západ

Česká republika

+420 220 950 910

www.igm.cz

CEF33623003 2019-30

Table Saw

Tischkreissäge

Kotoučová pila

Kotúčová píla

Körfűrészgép

Pilarka tarczowa

Fusion3

man_151-Fusion3_A4ob_kotoucova-pila_EN+DE+CZ+SK+HU+PL_v1.6

EN Operating Instructions

(ofcial Laguna text)

DE Gebrauchsanweisung

(Übersetzung der Originalgebrauchsanweisung)

CZ Návod k obsluze

(překlad původního návodu)

SK Návod na obsluhu

(preklad pôvodného návodu)

HU Használati útmutató

(eredeti használati útmutató fordítása)

PL Instrukcja obsługi

(tłumaczenie oryginalnej instrukcji)

-2-www.igmtools.com

CE-Declaration of Conformity

Product: Table Saw

FUSION3

Type number: CEF33623003

Brand: Laguna

Manufacturer:

Laguna Tools Inc

2072 Alton Pkwy, Irvine, CA 92606, USA

Declare under our sole responsibility that this product is in conformity with the following directives:

- Machinery Directive 2006/42/ES

- Low Voltage Directive 2014/35/ES

- Electromagnetic Compatibility Directive 2014/30/ES

Designed in conformity with:

** EN 1870-19:2013

EN60204-1:2006+AC:2010

Technical documentation processed by:

TUV Rheinland LGA Products GMBH

Certicate number: BM50418591 & BM50418592

2019-09 Ivo Mlej, CEO

IGM nástroje a stroje s.r.o., Ke kopanině 560, 252 67 Tuchoměřice, Česká republika

-3-www.igmtools.com

Contents

1. Declaration of conformity

1.1 Warranty

2. About this manual

3. Fusion 3 Specications

3.1 Contents

3.2 Technical

3.3 Main Features

4. General Safety

4.1 Intended Use

4.2 Work Area

4.3 Personal Safety

4.4 Tool Use

4.5 Guarding Related Warnings

4.6 Work Related Warnings

4.7 Kickback Causes and Related Warnings

4.8 Table Saw Operating Prodedure Warnings

4.9 Electrical

4.10 Noise emissions

4.11 Grounding

4.12 Rulings

4.13 Notice on safe use of the machine

5. Machine overview

5.1 Controls

6. Setup

6.1 Receiving and unpacking

6.2 Inventory

6.3 Loose parts & overview

6.4 General setup

6.5 Installing/removing the throat plate

6.6 Installing/removing safety accessories

6.7 Installing/removing the blade

7. Adjustments

7.1 Fence adjustments

7.2 Table adjustments

7.3 Arbor and tilt adjustments

7.4 Accessory adjustments

7.5 Push block and push stick

8. Type of cut

8.1 Ripping

8.2 Bevel ripping

8.3 Ripping small workpieces

8.4 Cross cutting

8.5 Bevel cross cutting

8.6 Mitre cuts

9. Maintenance

9.1 Internal Components Map

10. Trouble-shooting

1. Declaration of conformity

We declare that this product is in compliance

with the directive and the standard mentioned

on the previous page of this manual.

1.1 Warranty

IGM Tools & Machinery strives to always

deliver high-quality machinery. The warranty is

governed by the valid terms and conditions of

IGM Tools & Machinery available at

www.igmtools.com.

2. About manual

This manual is intended to thoroughly cover the

setup up, maintenance, and proper adjustments

of your new purchase. Aside from the

proceeding general safety considerations,

this manual DOES NOT cover woodworking

or metalworking techniques that are possible

with this product and the appropriate safety

precautions necessary for safe practices. There

are several organizations with published safe

practices, techniques, and proper operation of

this tool. Or look for handy tips and instructions

at www.igmtools.com.

3. Fusion 3 specications

3.1 Contents

Professional Square Zero Clearance Throat

Plate (pre-installed)

250 mm Saw Blade (pre-installed)

Riving Knife (pre-installed)

Mitre Gauge (ships in tool holder)

Tool Holder (pre-installed)

Fence

Blade Guard

Arbor Wrench

Installation and Adjustment Tools

Pic. 1

3.2 Technical Data

Power 230V / 50 Hz / 1 Phase

Motor Type

TEFC Capacitor Start AC Induction

Power Input 2200 W

Motor Speed 2850 /min-1

Full Load Amperage 14.5 A

Start Capacitor 400 µF-U

Run Capacitor 50 µF-U

Switch Type

Magnetic with Overload Protection

Power Transfer Single V-Ribbed 142J FJ

Power Cord 2 m / H07RNF

Power Plug Included CEE 7/7

Breaker Recommendation 16 A,

tripping characteristic C (16/1/C)

General

Footprint (LxW) 503 x 520 mm

Overall Dimensions (LxWxH)

1663 mm x 1652 mm x 1081 mm

Shipping Dimensions (LxWxH)

1130 mm x 1100 mm x 1190 mm

Weight (No Accessories) 157 Kg

Shipping Weight: 202 Kg

Dust Collection: Outlet Dia. 101.6 mm

Dust Collection m3/h, min. 934 m3/h

Sound Emissions N/A

Specics

Blade Diameter 250 mm

Bore Diameter 30 mm

Arbor Speed 3800 /min-1

Blade Rotation Counter-Clockwise

(face arbor)

Rip Capacity, with Fence

914,4 mm Right (1 320,8 mm w/ accessories)

Max. Depth of Cut 90° 79 mm

Max. Depth of Cut 45° 56 mm

Blade Tilt 45° Left, 3° Arbor Adjustment

Table Dim., with Extensions (LxW)

1117 mm x 1663 mm

Wing Dimensions (LxW) 792 x 305 mm

Mitre Slot 19 and 23 mm, T-Slot

Fence Type

Sliding Cam Action Fully Adjustable

Fence Dim (LxWxTh.) 670 x 80 x 17 mm

Throat Plate Type Zero Clearance

Throat Plate (LxWxTh.) 372 x 104.5 x 13 mm

Floor to Table Height 887 mm

Pic. 2

Pic. 3

EN - English

Operating Instructions (Laguna manual)

Dear Woodworker,

Thank you for your purchase and welcome to the Laguna Tools group of discerning woodworkers. We understand that you have a

choice of where to purchase your machines and appreciate the condence you have in the Laguna Tools brand.

Every machine manufactured by Laguna Tools has been carefully designed and well thought through from a woodworker’s perspective.

Through hands-on experience, Laguna Tools is constantly working hard to make innovative, precision products. Products that inspire

you to create works of art, are a joy to run and work on, and encourage your performance.

-4-www.igmtools.com

Pic. 4

3.3 Main Features

• Robust cast-iron trunnion.

• Cast-iron control wheels.

• Two T-slots on the side of the blade.

• Smooth control of the blade height and tilt.

• Lever for a quick blade swap.

• Adjustable control panel.

• Quick clamping riving knife.

• Integrated wheel for simple mobility.

• Includes rear table.

4. General Safety

Warning: Read all safety considerations.

Failure to follow this set of guidelines can result

in unwarranted damage to the machine and

serious injury to the operator and bystanders.

Save all warnings and instructions for future

reference.

4.1 Intended Use

• Table saw and the workpiece guide equipment

supplied with it are intended to be used

exclusively for the following purposes:

- Laminated and non-laminated board materials

(e.g. chipboard, coreboard, MDF board,...)

- Solid wood

- Gypsum plasterboard, Cardboard, Veneer with

a suitable clamping device

- Dimensionally stable plastics (thermoset

plastics, thermoplastics).Sawing these materials

does not normally involve any risks in respect of

dust, chips, and thermal degradation products.

Tools:

• The chosen saw blade must be suitable both

for the specic work cycle and for the specic

material.

• Only circular blades made of tungsten carbide

and have a diameter of 250 mm, arbor size 30

mm are allowed to be used.

• Saw blades made of high-alloy high-speed

steel (HSS) or chrome are not allowed to be

used.

• Saw blades and their xing devices shall

conform to EN 847-1:2013.

Site of installation/use:

• The machine is not suitable for use outdoors,

or in rooms that are subject to moisture or the

risk of explosions.

• The intended use of the machine involves

connection to suitable dust collection.

• The intended ambient temperature used of the

machine: +10 °C to +35 °C.

• The intended altitude used of the machine :

shall be at altitudes up to 1000 m above mean

sea level.

• The intended Relative humidity used of the

machine : not exceed 50% at 35°C.

• Intended use also involves compliance with

our specied operating, maintenance and repair

conditions and the safety information contained

in the operating instructions.

• The table saw may only be used, set up and

maintained by persons who are familiar with the

machine and aware of the dangers.

• The pertinent accident prevention regulations

as well as any other generally recognized

technical safety and industrial medicine rules

must be observed.

• Repair work must be carried out by our own

customer service or by an organization that we

have authorized. Only original spare parts are

allowed to be used for this. we will assume no

warranty for any damage that is caused by using

non-original spare parts.

Warning: The machine is prohibited to be used in

a potentially explosive atmosphere!

4.2 Work Area

• Keep all children and untrained persons away

from the machine. Do not allow bystanders to

touch the machine or power cord. All people but

the operator should be away from the work area.

• Keep work area clean and well lit. A cluttered

area can limit the range of motion needed by the

machine and cause serious injury to the operator

or damage to the machine.

• Make sure the work area is child-proof

and inaccessible to untrained persons. Use

padlocks where possible and keep all machines

unplugged when not in use.

• Do not keep or place tools in outdoor, damp, or

dangerous environments. Never operate the tool

under wet or damp conditions; there is a serious

risk of electrical shock. Exposing this product to

those environments may result in damage to the

tool and operator injury. Do not use tool in the

presence of ammable liquids or gasses.

• Do not operate machine in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust. Machine create

sparks which may ignite the dust or fumes.

4.3 Personal Safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool. do

not use a power tool while you are tired or under

the inuence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

• Use personal protective equipment. always

wear eye protection. Protective equipment such

as a dust mask, non-skid safety shoes, hard

hat or hearing protection used for appropriate

conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to

power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

nger on the switch or energizing power tools

that have the switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. do not wear loose clothing or

jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a

second.

• Know your machine. Read and understand the

owner’s manual and labels afxed to the tool.

Learn its application and limitations as well as

the specic potential hazards peculiar to this

tool.

• Use safety goggles. Some machines require

additional face shielding than offered by safety

goggles alone. Know your machine and the

proper PPE to use.

• Use ear protection. Some machines operate at

very high noise levels. To prevent harm, be sure

to use ear protection always.

• Guard against electric shock. Prevent all bodily

contact with grounded surfaces and parts of the

machine that pose electrical threats.

• Avoid accidental starting for machines without

magnetic or automatic shut-off switches.

Make sure the tool is in the off position prior to

plugging it in.

• Keep guards in place. Machine parts like

riving knifes, blade guard, cutter-head guards,

feather boards, push sticks, etc. are designed

to minimize possible injury. Keep those parts

in place unless a safer means of operation is

available.

• Be alert always and give 100% of your

attention to the operation of this tool. Failure

to do so can result in serious injury to both the

operator and bystanders.

• Do not rely on guards. The operator of this tool

is 100% responsible for his/her own safety. The

guards and safety components sold with this

machine are not enough to ensure safety.

• Check for damaged parts. Before every use

of this tool, makes sure the machine and any

components of the machine are not damaged

or at the risk of being damaged. If a damaged

part is discovered, stop immediately and put the

machine out of service until the part is replaced.

Warning: All repairs should be done by trained

repairmen. Contact your supplier or a competent

repair service.

Warning: Use only supplier Tools or compatible

and marked replacement parts. All others may

cause damage or harm.

Warning: Use only manufacturer-recommended

accessories. Some accessories may cause

damage or harm.

4.4 Tool Use

• Do not force the power tool. use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

-5-www.igmtools.com

• Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any

adjustments, changing accessories, or storing

power tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

• Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

• Maintain power tools and accessories. check

for misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation. If

damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

• Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power

tool for operations different from those intended

could result in a hazardous situation.

• Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow

for safe handling and control of the tool in

unexpected situations.

• Use proper speed. A machine will do a better

and safer job when operated at the proper

speed.

• Use the correct tool for the job. Know

the limitations and capabilities of your new

purchase. Do not try to “t a square peg in a

round hole.

• Secure the work piece. For all woodworking

and metalworking applications, the workpiece

should be secured correctly by the operator

using appropriate clamps and vises. Always

use a clamp or vise when available — it is safer

than using your hands.

• Feed direction. If feed rate is applicable, then

there is only one direction of feed rate for the

tool. Do not force the workpiece in the wrong

feed direction.

• Never leave tool running unattended. Do not

leave the tool until it comes to a complete stop.

When unattended, unplug the tool.

• Maintain tools with care. Keep cutting

tools sharp and clean for better and safer

performance.

• Follow instruction for lubricating and changing

accessories. Inspect tool cords periodically

and if damaged have then repaired by an

authorized service facility. Inspect extension

cords periodically and replace if damaged.

Keep hand dry, clean and free from oil and

grease.

• Illumination. Adequate general or localized

lighting shall be provided.

• Dust Collection. During use the saw benches

shall be connected to an external chip and dust

extraction system.

4.5 Guarding related warnings

• Keep guards in place. Guards must be in

working order and be properly mounted.

A guard that is loose, damaged, or is not

functioning correctly must be repaired or

replaced.

• Always use saw blade guard and riving

knife for every through–cutting operation. For

through-cutting operations where the saw blade

cuts completely through the thickness of the

workpiece, the guard and other safety devices

help reduce the risk of injury.

• Make sure the saw blade is not contacting

the guard, riving knife or the workpiece before

the switch is turned on. Inadvertent contact of

these items with the saw blade could cause a

hazardous condition.

• Adjust the riving knife as described in

this instruction manual. Incorrect spacing,

positioning and alignment can make the riving

knife ineffective in reducing the likelihood of

kickback.

• For the riving knife to work, it must be

engaged in the workpiece. The riving knife is

ineffective when cutting workpieces that are

too short to be engaged with the riving knife.

Under these conditions a kickback cannot be

prevented by the riving knife.

• Use the appropriate saw blade for the riving

knife. For the riving knife to function properly,

the saw blade diameter must match the

appropriate riving knife and the body of the saw

blade must be thinner than the thickness of

the riving knife and the cutting width of the saw

blade must be wider than the thickness of the

riving knife.

4.6 Work related warnings

• Danger: never place your ngers or hands

in the vicinity or in line with the saw blade. A

moment of inattention or a slip could direct

your hand towards the saw blade and result in

serious personal injury.

• Feed the workpiece into the saw blade or

cutter only against the direction of rotation.

Feeding the workpiece in the same direction

that the saw blade is rotating above the table

may result in the workpiece, and your hand,

being pulled into the saw blade.

• Never use the mitre gauge to feed the

workpiece when ripping and do not use the rip

fence as a length stop when cross cutting with

the mitre gauge. Guiding the workpiece with the

rip fence and the mitre gauge at the same time

increases the likelihood of saw blade binding

and kickback.

• When ripping, always apply the workpiece

feeding force between the fence and the saw

blade. Use a push stick when the distance

between the fence and the saw blade is less

than 150 mm, and use a push block when this

distance is less than 50 mm. Work helping

devices will keep your hand at a safe distance

from the saw blade.

• Use only the push stick provided by the

manufacturer or constructed in accordance

with the instructions. This push stick provides

sufcient distance of the hand from the saw

blade.

• Never use a damaged or cut push stick. A

damaged push stick may break causing your

hand to slip into the saw blade.

• Do not perform any operation “freehand”.

Always use either the rip fence or the mitre

gauge to position and guide the workpiece.

“Freehand” means using your hands to support

or guide the workpiece, in lieu of a rip fence

or mitre gauge. Freehand sawing leads to

misalignment, binding and kickback.

• Never reach around or over a rotating saw

blade. Reaching for a workpiece may lead to

accidental contact with the moving saw blade.

• Provide auxiliary workpiece support to the

rear and/or sides of the saw table for long and/

or wide workpieces to keep them level. A long

and/or wide workpiece has a tendency to pivot

on the table’s edge, causing loss of control, saw

blade binding and kickback.

• Feed workpiece at an even pace. Do not

bend or twist the workpiece. If jamming occurs,

turn the tool off immediately, unplug the tool

then clear the jam. Jamming the saw blade by

the workpiece can cause kickback or stall the

motor.

• Do not remove pieces of cut-off material while

the saw is running. The material may become

trapped between the fence or inside the saw

blade guard and the saw blade pulling your

ngers into the saw blade. Turn the saw off and

wait until the saw blade stops before removing

material.

• Use an auxiliary fence in contact with the table

top when ripping workpieces less than 2 mm

thick. A thin workpiece may wedge under the rip

fence and create a kickback.

4.7 Kickback causes and related warnings

• Never stand directly in line with the saw blade.

Always position your body on the same side

of the saw blade as the fence. Kickback may

propel the workpiece at high velocity towards

anyone standing in front and in line with the

saw blade.

• Never reach over or in back of the saw blade

to pull or to support the workpiece. Accidental

contact with the saw blade may occur or

kickback may drag your ngers into the saw

blade.

• Never hold and press the workpiece that is

being cut off against the rotating saw blade.

Pressing the workpiece being cut off against the

saw blade will create a binding condition and

kickback.

• Align the fence to be parallel with the saw

blade. A misaligned fence will pinch the

workpiece against the saw blade and create

kickback.

• Use extra caution when making a cut into

blind areas of assembled workpieces. The

protruding saw blade may cut objects that can

cause kickback. Note, the above safety warning

only applies to tools where such cuts are

permitted by design and instruction.

• Support large panels to minimise the risk of

saw blade pinching and kickback. Large panels

tend to sag under their own weight. Support(s)

must be placed under all portions of the panel

overhanging the table top.

• Use extra caution when cutting a workpiece

that is twisted, knotted, warped or does not

have a straight edge to guide it with a mitre

gauge or along the fence. A warped, knotted,

or twisted workpiece is unstable and causes

misalignment of the kerf with the saw blade,

binding and kickback.

• Never cut more than one workpiece, stacked

vertically or horizontally. The saw blade could

pick up one or more pieces and cause kickback.

• When restarting the saw with the saw blade

in the workpiece, centre the saw blade in the

kerf so that the saw teeth are not engaged in

the material. If the saw blade binds, it may lift

-6-www.igmtools.com

up the workpiece and cause kickback when the

saw is restarted.

• Keep saw blades clean, sharp, and with

sufcient set. Never use warped saw blades or

saw blades with cracked or broken teeth. Sharp

and properly set saw blades minimise binding,

stalling and kickback.

4.8 Table saw operating procedure warnings

• Turn off the table saw and disconnect the

power cord when removing the table insert,

changing the saw blade or making adjustments

to the riving knife or saw blade guard,

and when the machine is left unattended.

Precautionary measures will avoid accidents.

• Never leave the table saw running

unattended. Turn it off and don’t leave the

tool until it comes to a complete stop. An

unattended running saw is an uncontrolled

hazard.

• Locate the table saw in a well-lit and level

area where you can maintain good footing and

balance. It should be installed in an area that

provides enough room to easily handle the size

of your workpiece. Cramped, dark areas, and

uneven slippery oors invite accidents.

• Frequently clean and remove sawdust from

under the saw table and/or the dust collection

device. Accumulated sawdust is combustible

and may self-ignite.

• The table saw must be secured. A table saw

that is not properly secured may move or tip

over.

• Remove tools, wood scraps, etc. From

the table before the table saw is turned

on. Distraction or a potential jam can be

dangerous.

• Always use saw blades with correct size and

shape (diamond versus round) of arbour holes.

Saw blades that do not match the mounting

hardware of the saw will run off-centre, causing

loss of control.

• Never use damaged or incorrect saw blade

mounting means such as anges, saw blade

washers, bolts or nuts. These mounting means

were specially designed for your saw, for safe

operation and optimum performance.

• Never stand on the table saw, do not use

it as a stepping stool. Serious injury could

occur if the tool is tipped or if the cutting tool is

accidentally contacted.

• Make sure that the saw blade is installed

to rotate in the proper direction. Do not use

grinding wheels, wire brushes, or abrasive

wheels on a table saw. Improper saw

blade installation or use of accessories not

recommended may cause serious injury.

4.9 Electrical

• Machine plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets

will reduce risk of electric shock.

• Disconnect the power rst. Always disconnect

machine from power supply before adjusting,

changing tooling, or servicing machine.

• Power supply: 230V/50Hz/1 phase.

• Use a qualied electrician for all electrical

connections. Failure to do so may result in

damage to the tool and electrical shock to the

operator and bystanders.

• Power plugs. Your machine may not come

with a power plug because of the variance

in power receptacles. Consult with a local

electrician prior to purchasing a power plug.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

• Extension cords. Consult with or use a

qualied electrician prior to sizing extension

cords for use with this machine.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk

of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a residual current device (rcd)

protected supply.

• Electrical protection. End user should connect

the machine to a circuit protected with a 16 A

circuit breaker, tripping characteristic C (16/1/C)

and overvoltage protection.

4.10 Noise emissions

• Reference standards.

The measurements of noise emission were

conducted according to the EN ISO 11202:2010

for the determination of sound pressure level

at the operation positions. When the measured

sound pressure levels at the operation positions

exceed 80db(a), the measurements of sound

power levels were conducted according to EN

ISO 3746:2010.

• Operating conditions.

The operating conditions for noise

measurement comply with Annex A of ISO

7960:1995.

• Testing results:

A-weighted Sound Pressure - Level 91.3 dB

A-weighted Sound Power - Level 113.8 dB

Associated uncertainty - K=4dB

Background noise of measurement surrounding

is - 55dB

The gures quoted are emission levels and

are not necessarily safe working levels. Whilst

there is a correlation between the emission

and exposure levels, this cannot be used

reliably to determine whether or not further

precautions are required. Factors that inuence

the actual level of exposure of the workforce

include the characteristics of the work room, the

other sources of noise etc. i.e. the number of

machines and other adjacent processes. Also

the permissible exposure level can vary from

country to country. This information, however,

will enable the user of the machine to make a

better evaluation of the hazard and risk.

4.11 Grounding

• Proper grounding of your machines lowers the

risk of injury by electricity.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

• Do not modify the plug. Do not remove any of

the prongs attached to the proper plug for the

machine.

• Use only 3-wire extension cords.

Some extension cords only have two wires,

which does not allow for grounding.

• Always use grounded connections and work

only on a grounded circuit.

4.12 Rulings

Warning: Before connecting this tool to a

power supply (receptacle, outlet, etc.) Make

sure that the voltage supplied is the same

that is specied on the nameplate of the tool.

Also make sure that the power supply is

equipped with the appropriate breaker and

plug according to your local electrical code. If

in doubt, do not plug in the machine. Using this

tool with a voltage different than that stated

on the nameplate can damage the electrical

components of this machine and any such

damage will not be covered by a warranty.

Warning: Some dust created by power sanding,

sawing, grinding, drilling and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paint.

• Crystalline silica from bricks, cement, and

other masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk of exposure varies, depending on how

often you do this type of work. To reduce your

exposure to these chemicals, work in a well-

ventilated area and work with approved safety

equipment, such as face or dust masks that are

specically designed to lter out microscopic

particles.

4.13 Notice on safe use

The machinery sold by Laguna Tools,

distributed by IGM Tools and machinery co.,

are safe when used properly and comply to

with the CE norms, standards and regulations

for safe use. Laguna Tools or IGM is in no

way responsible for injury or death that occurs

while using this product. Your personal safety is

100% your responsibility and using this product

requires 100% of your attention.

If there is any concern related to the application

you are intending to use this tool for, DO NOT

proceed until you have contacted the retailer

you purchased it from and have been advised

on the correct application of the product.

This manual is intended to thoroughly cover

the setup up, maintenance, and proper

adjustments of your new purchase. Aside from

the proceeding general safety considerations,

this manual DOES NOT cover woodworking

or metalworking techniques that are possible

with this product and the appropriate safety

precautions necessary for safe practices. There

are several organizations with published safe

practices, techniques, and proper operation of

this tool.

Warning

The symbols below advise that you

follow the correct safety procedures when using

this machine.

Keep your ngers away from the

saw blade

Environmental protection:

Waste electrical products should not

be disposed of with household waste.

Please recycle where facilities exist.

Check with your local Authority or retailer for

recycling advice.

-7-www.igmtools.com

5.1 Controls

Start/Stop/Fuse

Pic. 6

1. Magnetic switch

2. Overload protector

3. Fuse

CAUTION: Always turn off and unplug the

machine before changing the fuse.

Arbor height control

Pic. 7

The arbor height control adjusts the height of

the blade. Centred in the control is the height

adjustment lock. Behind the control is the tile

gauge. CW to raise, CCW to lower blade.

CAUTION: DO NOT ADJUST HEIGHT WHEEL

WHEN LOCKED.

Arbor tilt control

Pic. 8

The tilt control, located on the right of the

cabinet, adjusts the tilt of the arbor. Centre is

Dusk mask should be worn.

Eye protection should be worn.

Ear protection should be worn.

Disconnect from power supply before

servicing

Fully read manual and safety

instructions before use.

Safety gloves should be worn.

5. Machine Overview

1. Start / Stop

2. Rip Fence

3. Fence Front guide

4. Fence Rear guide

5. Table with mitre slots

6. Cabinet with integrated mobility kit

7. Arbor height adjustment control

8. Arbor tilt adjustment control

9. Dust extraction outlet

10. Moror cover

11. Throat plate

12. Blade

13. Blade guard

14. Riving knife

15. Arbor wrench

16. Push stick

17. Mitre gauge

the tilt lock. CW to tilt left, CCW to tilt the blade

to the right.

CAUTION: DO NOT ADJUST TILT WHEEL

WHEN LOCKED.

Fence clamp lock

Pic. 9

The fence clamp securely locks the fence

anywhere on the rail by a cam action

mechanism.

6. Setup

Use Caution: Your new Laguna Tools machine

is heavy. Use a minimum of two people when

lifting the tool into position and moving the tool

into position.

Warning: DO NOT connect to a power supply

until the setup is complete. DO NOT perform

any of the following steps, installations, or

adjustments with the saw connected to the

power source.

Warning: To avoid set-up problems, to prevent

potential damage to the machine and personal

injury, read through the entire setup section

prior to setting up the machine.

6.1 Receiving and unpacking

If any damage has occurred because of

shipment, note the damage on the bill of lading

or refuse the shipment. Immediately call the

dealer store where the machine was purchased.

TRANSPORTATION AND STORAGE. The

measures of anti-rust and shockproof should

be taken during packing. The machine endures

transportation and store in -25~55°C ambient

temperature.

Be careful not to expose the machine to rain or

damage when transporting or storing.

While transporting or handling the machine,

be careful and let the activity be done by

qualied personnel especially trained for

this kind of activity!

While the machine is being loaded or

unloaded, make sure that no person or

subject gets pressed by the machine!

Select proper transportation device

according to the weight of the machine.

Make sure the lifting capacity of

transportation device is competent for the

weight of the machine.

TRANSPORTATION BEFORE UNPACKING

As standard, the machine is packed in a robust

wooden box. Pic.10 shows the tool that can be

used to transport the packaging.

Pic. 10

UNPACKING

1. Receive your table saw.

2. Unscrew the crate fasteners.

3. Lift crate off pallet.

4. Check Inventory.

5. Wipe off protective oils.

Pic. 5

-8-www.igmtools.com

Receiving your tablesaw

Pic. 11

This is how machine is shipped from the

factory.

Unscrew the crate fasteners

Pic. 12

Use a drill with a #2 Phillips head bit and

remove the bottom screws from carton. These

screws may be discarded.

Lift crate off pallet

Pic. 13

Use two persons to lift the carton away from the

pallet. There should be three packages along

with the table saw.

NOTE: The throat plate, riving knife, and 10”

blade is pre-installed in the machine. The miter

gauge, and blade changing tool are positioned

in the tool holder located on the right side of the

cabinet.

Check Inventory

Pic. 14

1. Fence, install tools, push stick, blade guard

assembly

2. Smaller fence rail sections, hardware kit

3. Longer fence rail sections.

Wipe off protective plastics

Pic. 15

Peel back the protective vinyl plastic and wipe

away the oil with a waste rag.

Use Caution: An oily rag can be a serious re

hazard. Discard in an appropriate manner.

Tech Tip: To help keep your table top clean and

to prevent or clean any rust, we recommend

waxing your tabletop with an appropriate wax

rubbing compound. This will also reduce friction

under operation. Rust can be removed with

WD-40.

6.2 Inventory

Box 1

Fence: PTSF236110175-0130-1-1

Push stick: PTSF236110175-0130-130

Blade guard: PTSF236110175-01302-1

Install Tools

Fence hooks*: PTSF236110175-0130-118

* Fence storage hooks may be pre-installed.

Box 2

Rear Rail 2: PTSF236110175-0130-127.5

Front Rail 2: PTSF236110175-0130-127.6

Hardware kit

Box 3

Rear rail 1: PTSF236110175-0130-127.5

Front rail 1: PTSF236110175-0130-127.6

Pre-installed on machine

Throat plate PTSF236110175-0130-6

Riving knife PTSF236110175-0130-27

250mm blade PTSF236110175-0130-33

Mitre gauge PTSF236110175-0130-3

Arbor wrench PTSF236110175-0130-137

Tool storage PTSF236110175-0130-120

Wings (2x) PTSF236110175-0130-4

Note: The front rail part number is comprised of

two pieces – both long and short. The rear rail

part number is comprised of two pieces – long

and short.

Note.: For safety reasons, this machine is not

sold with a tape-rule for the left side of the

blade. It is not a missing part.

6.3 Loose Parts & Overview

Your new machine has been mostly assembled

at the certied ISO 91001 factory where it was

made. Some parts must be assembled by the

purchaser. Please read all steps rst before

proceeding with step one.

Pic. 16

Blade Guard

Pic. 17

5) M8x1.5+ lock washer + washer + nut

Pic. 18

(5) Square head 8x1.5 + washer + nut

Pic. 19

Fence hooks (step 2)

Pic. 20

Pic. 21

6.4 General Setup

1. Attach the short rear fence support

2. Attach the long rear fence support

3. Level the rear rails and fasten

4. Attach T-Slot bolts to front table

5. Insert long front rail fence support

6. Insert short front rail and switch

7. Join front fence supports

8. Align the entire front rail to blade mark

9. Level and fasten the front rail

10. Insert fence

11. Level the saw by adjusting casters

1. Attach short rear fence support

Use the supplied wrench and Alan key to

loosely fasten (2) bolts, lock washers, washers,

-9-www.igmtools.com

and nuts to the short rear fence guide and

the back left of the table. STOP BEFORE

TIGHTENING: Keep bolts loose until entire rail

assembly is in place to properly level rail.

Pic. 22

2. Attach short rear fence support

Repeat step 1 for the longer rear fence section

with (3) bolts, lock washers, washers, and nuts.

Use the same assembly diagram in Step 1.

NOTICE: If the fence hooks are not yet

installed, now is a good time to do so.

Pic. 23

3. Attach short rear fence support

To level the rear fence with the table top,

place a rigid straight edge on top of the rails.

Apply downward force at both arrow indicators

and simultaneously tighten the bolts with the

supplied Allen key and wrench.

Pic. 24

4. Attach T-slot bolts to front table

Loosely fasten the (5) square headed bolts, (5)

washers, and (5) nuts. A couple revolutions of

the bolt will be tight enough. Prepare to insert

the (2) aluminium front rail sections.

Pic. 25

5.Insert the long front fence support

Insert the long Front Rail. STOP BEFORE

TIGHTENING: Keep these bolts loose until the

entire rail assembly is in place to properly level

the rail.

Pic. 26

6. Insert short rail and switch

Insert the short front rail into the rst square

head bolt. IMPORTANT: Insert the switch

assembly before joining the two front rail

pieces. STOP BEFORE TIGHTENING.

Pic. 27

7. Join front fence supports

Align the pins and join the two front rail pieces

and rmly push together.

Pic. 28

8. Align the front rail with blade

Using the blade notching on the measuring

tape, align the entire front rail section to the

blade.

Pic. 29

9. Level and fasten front rail

To level the front rail sections to the table top,

use a ridged straight edge atop the loosely

t rail sections. Apply downward force to the

straight edge while keeping the two sections

rmly together. Simultaneously fasten down the

bolts.

Pic. 30

10. Install the fence

Install the fence by placing the front end

rst. Be sure that the handle is in the open,

unlocked, position prior to installing.

Pic. 31

11. Level the table saw with casters and x

Level the table saw with the ground and x the

machine on the oor with screws.

Pic. 32

6.5 Installing/removing the throat plate

1. Unplug the table saw!

2. Insert the throat plate back end rst.

3. Lower the throat plate to the table.

4. Lock the throat plate with the thumb-lock.

5. Level the throat plate with the table using

the cat screws.

Note: This machine is shipped with a zero-

clearance throat plate that has already been

cut at the factory. Because of this, there may be

some residue already in the saw.

Installing the throat plate

Pic. 33

WARNING: MAKE SURE SAW IS

UNPLUGGED. To remove or install the throat

plate, rst set it to the unlock position. Then,

insert the rear end rst and tilt the other end

down into position.

Levelling the throat plate

Pic. 34

To level the throat plate, adjust the leveling

screws.

Note: Make sure the throat plate is lower than

the cast iron table. Having the throat plate

higher at any position can interfere with the

workpiece feed and cause injury or harm and

increase the chance of kickback

6.6 Installing/removing safety accessories

A: Saw blade

B: Riving knife housing

C: Cam action lever

D: Riving knife

E: Blade guard

F: Blade compliant markings

-10-www.igmtools.com

Pic. 35

• Note on the Riving Knife

Pic. 36

Since Riving Knife, other than those offered by

Laguna, has not been tested with this product,

use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only

Laguna, recommended accessories should be

used with this product.

• Note on the saw blade

Pic. 37

Installing/removing the riving knife

1. Unplug the tablesaw!

2. Make sure the lock is in open position

3. Insert the blade guard

4. Position the guard insert

5. Lock the blade guard

6. Reinstall throat plate

CAUTION: Make sure the blade guard is in line

with the blade. If it is not in line, please see the

Adjustment section.

3. Insert the blade guard

Pic. 38

WARNING: MAKE SURE SAW IS

UNPLUGGED.

With the throat plate removed, and the cam lock

mechanism in the open position (pulled up),

insert the blade guard insert into the slot.

4. Position to the left of the casing

Pic. 39

Make sure the guard is positioned correctly and

seated in the bottom of the casing. Grasp the

pawls with one hand, leaving the other hand

free to activate the cam action lock.

5. Lock the blade guard

Pic. 40

Keep rm hold of the blade guard with left hand

and engage the cam lock with the thumb of

your right hand.

6. Reinstall the throat plate

Pic. 41

Grasp the pawls up and out of the way to re-

insert the throat plate. Lock the throat plate.

Pic. 42

CAUTION: Make sure the riving knife is in-line

with the blade. If it is not in line, please see the

Adjustments Section.

6.7 Installing/removing the Blade

1. Unplug the table saw!

2. Remove any blade guards, riving knifes, and

the throat plate to access the blade.

3. Set the arbor tilt to 0 degrees and lock.

4. Raise saw to highest position.

5. Engage blade lock (red component).

6. Remove the arbor nut and ange with arbor

wrench.

7. Remove or install blade.

CAUTION: Make sure the teeth of the blade are

facing the front of the saw as shown.

2. Remove all accessories

Pic. 43

WARNING: MAKE SURE SAW IS

UNPLUGGED. To access the blade remove all

accessories around the blade, including riving

knifes, throat plates, ect.

3. Set arbor tilt to 0 and lock.

Pic. 44

Set the arbor tilt to 0 degrees and lock the arbor

to prevent it from moving when installing or

removing blades.

Limit position of the top guard

Use riving knife only with 250 mm

diameter blade

Riving knife thickness 2,3 mm

Only use this riving knife with 2 mm

and 3 mm teeth thickness

No saw blade should be used where

the maximum marked speed is lower

than the selected rotational speed of

the saw spindle.

5500 max rpm

-11-www.igmtools.com

4. Raise saw blade to highest position

Pic. 45

5. Engage the blade lock

Pic. 46

6. Remove arbor nut and ange

Pic. 47

7. Adjustments

Your Laguna Tools machine comes fully

adjusted from the factory, but it is good practice

to double check these adjustments and make

sure the tool is in safe operating condition.

7.1 Fence Adjustments

Fitting the fence:

You will need to t the fence to the right side of

the blade to use the table saw. You will need to

t the fence to the right side of the blade to use

the table saw.

1. Unplug the table saw!

2. Hold fence with both hands, with cam lock up.

3. Place fence in fence guide

4. Check cam lock action, adjust if necessary.

2. Place fence in fence guide

Pic. 48

While holding the fence and the cam lock, raise

the cam lock to engage the open position.

Insert the fence frame into the front rail.

3. Check Cam lock action

Pic. 49

The fence can slide freely in any position to the

right of the blade. If the fence does not lock,

adjust both blade paralleling set screws.

Adjusting the Scale (rule):

The scale will need to be “zeroed” every

time the fence guide is taken off the table

or adjusted. The fence must be zeroed for

accurate cuts when using the scale.

1. Unplug the table saw!

2. Position the fence up to blade.

3. Loosen the transparent viewport.

4. Adjust the view as needed.

5. Tighten the view screws.

Place fence in fence guide

Pic. 50

WARNING: MAKE SURE SAW IS

UNPLUGGED. With the blade in a high

position, bring the fence close to — but not

touching — the blade. Use a folded piece of

paper between the blade and the fence to

ensure good distance.

Adjust the Viewport

Pic. 51

Use a #2 Philips head driver to loosen (but

do not remove) the transparent scale reader.

Adjust the viewport as needed, tighten the

screws. Note: If adjusting the viewport does not

allow enough to zero the scale, see step 8 of

general setup.

Adjusting the Fence Glide Bushings:

You may need to adjust the height of the

bushings on either side or rear of the fence. The

fence should be between 1-3 mm off the table

to prevent scratches.

1. Unplug the table saw!

2. Unlock the fence.

3. Use a hex key to adjust the front bushing

height.

4. Use a wrench to adjust the rear bushing

height.

Front Bushings

Pic. 52

To adjust the front bushings, use the included

hex key to raise or lower the nylon bushings

that make contact with the front fence rail.

Rear Bushings

Pic. 53

Adjusting the Fence to be parallel with the

Blade: It is very important to only operated this

saw with the blade parallel to the fence. Note: If

this section does not help, please see the table

adjustments section: Adjusting the Table to be

Parallel with the Blade. The blade needs to be

parallel to the table (mitre slots) to effectively

make the fence parallel to the blade.

1. Unplug the table saw!

2. Position the fence to access the fence

adjustment screws.

3. Use a hex key to adjust each side

4. Make small increments and check

Use caution: It is not guaranteed that the fence

will be parallel to the saw blade when shipped

from factory. Make sure to make all required

adjustments to make the fence parallel to the

saw blade prior to operation.

Position fence to access adj. screws

Pic. 54

WARNING: MAKE SURE SAW IS

UNPLUGGED. Take the fence out of position

and ip it on its back side to access the cat

screws that push the nylon supports in/out.

-12-www.igmtools.com

Use a hex key to adjust

Pic. 55

Use the included hex key to adjust the depth of

each nylon support. Do small increments and

check.

7.2 Table Adjustments

Adjusting the Table to be Parallel with the

Blade: It is good practice to make sure that the

table is always parallel to the blade by checking

it often. You can do this with a combination

square or with a dial indicator on an appropriate

mount. Check the IGM website for these tools.

Good

Pic. 56

Combination Square. Notice: This method may

leave scratched.

Better

Pic. 57

A dial indicator on a mitre gauge.

Best

Pic. 58

A dedicated saw dial indicator. Such as this one

by ‘Iagging’.

1. Un-plug the tablesaw!

2. Take initial measurement.

Pic. 59

WARNING: MAKE SURE SAW IS

UNPLUGGED. With the throat plate and all

attachments removed, raise the blade to the

highest position at 90 degrees with the table.

Take an initial measurement about 1 cm from

the ground edge of the blade as shown.

3. Take relative measurement

Pic. 60

Keep the mitre gauge against the left rail

and slowly move crossed the blade. Take

the second measurement and compare with

the initial measurement. Adjust the table to

compensate false measurements. There are 3

bolts to loosen prior to adjusting the table, see

step 4.

4. Loosen the three table fastener bolts.

5. Adjust as needed.

Loosen Table Bolts

Pic. 61

Locate and loosen right side table to cabinet

bolt (above the tool holder).

Loosen Table Bolts

Pic. 62

Locate and loosen left side table to cabinet bolt

(above the motor cover).

Loosen Table Bolts

Pic. 63

Locate and adjust the rear table to cabinet bolt.

Adjusting or Installing Extension Wings: (may

be pre-installed):

To install or remove the extension wings, an

advised method is provided. This method

makes it easy to make the extension wings at

with the table but requires the use of two ridged

supports and four clamps.

1. Unplug the table saw!

2. Clamp supports to table.

3. Place extension wing on supports.

4. Join or adjust the wing with supplied bolts.

Note: The clamps may scratch the tabletop!

Use a cloth or soft wood between

the clamp and the iron surfaces.

2. Take initial measurement

Pic. 64

WARNING: MAKE SURE SAW IS

UNPLUGGED. Clamp two wooden supports

to the underside of the table saw as shown.

Straight 2x4 lumber will work

3. Take relative measurement

Pic. 65

Place the extension wing on the supports and

place into position.

4. Join or adjust wing

Pic. 66

You will need (4) m10 bolts and (4) washers to

fasten each extension wing to the table top. Be

sure to align the extension wing to the table top

prior to tightening the bolts.

-13-www.igmtools.com

7.3 Arbor and Tilt Adjustments

Adjusting the Blade Tilt Limits

You can check the arbor (blade) tilt limits with

an angle nder or 45-degree triangle. If these

limits are not within 0 degrees and 45 degrees,

use the following steps to adjust.

1. Unplug the table saw!

2. Remove the motor cover.

3. Remove the tool storage cover.

4. Locate tilt adjustment screws.

5. Adjust as needed.

6. Adjust the scale and indicator as needed.

Use caution: From the factory, the tilt limits

are pre-set to 0 and 45 degrees tilt to the left.

Adjusting this limit will slightly alter that amount

which may cause throat plate or fence to

interfere. Adjusting these limits should only be

done to set the tilt limits to 0 and 45 degrees.

2. Remove motor cover

Pic. 67

WARNING: MAKE SURE SAW IS

UNPLUGGED.

To access the left side tilt limit adjustment

screw, remove the motor housing cover using

a #2 Philips head driver. There are 4 screws in

total holding on the motor cover..

3. Remove tool storage cover

Pic. 68

To access the right-side tilt adjustment screw,

remove the tool storage using a #2 Philips head

driver. There are 4 screws in total holding on

the tool storage box.

4. Locate Tilt Adjustment

Pic. 69

Locate the tilt adjustment screw. Screw it in to

expand the tilt range slightly.

5. Adjust as needed

Pic. 70

Locate the tilt adjustment screw. Screw it in to

expand the tilt range slightly.

6. Adjust scale (if needed)

Pic. 71

Adjust the scale and tilt indicator on the cabinet

if needed.

Adjusting the Belt:

It is good practice to check the tension of the

belt often to ensure that the saw is performing

properly. If the table saw blade is slipping or is

feeling underpowered, you may need to tighten

the belt. To do so, follow the steps below.

1. Unplug the table saw!

2. Remove the motor cover.

3. Locate belt adjustment bolt.

4. Tighten or loosen with weight of motor.

Use Caution: DO NOT OVERTIGHTEN BELT!

The weight of the motor is adequate to put

enough tension on the belt. Only tight enough

to prevent slippage.

Remove the motor cover

Pic. 72

WARNING: MAKE SURE SAW IS

UNPLUGGED.

To access the motor, remove the motor housing

cover using a #2 Philips head driver. There are

4 screws in total holding on the motor cover.

Locating Belt Adjustment bolt

Pic. 73

To adjust the belt, set blade to 0° on tilt scale,

then raise or lower blade to approximately 2“

above table. Loosen the belt adjustment bolt.

With the bolt loose, Raise or lower the motor so

that the belt is tight.

Changing the belt:

1. Unplug the table saw!

2. Remove all throatplates, blades, and blade

accessories.

3. Remove the motor cover.

4. Remove the dust shroud.

5. Loosen the Belt adjustment bolt and loosen

belt by raising motor.

6. Remove belt. NOTE: you may need to lower

the arbor height to access the belt.

7. Replace belt.

Use Caution: DO NOT OVERTIGHTEN BELT!

The weight of the motor is adequate to put

enough tension on the belt. Only tight enough

to prevent slippage.

Belt Adjustment bolt

Pic. 74

WARNING: MAKE SURE SAW IS

UNPLUGGED. NOTICE: The drawing shown

is with the top of the table removed. AVOID

removing the table top. The belt can easily be

changed without removing the table top.

Accessing the Belt

Pic. 75

7.4 Accessory Adjustments

Insert Block Adjustments (For all Safety

Accessories):

The Riving knife, blade guard, or splitter must

be aligned with the blade to be used affectively.

The riving knife should only be used with

-14-www.igmtools.com

blades specied on the riving knife. To adjust

the position of the blade safety attachments,

relative to the saw blade: NOTE: if the cam

action lever does not lock or is too hard to lock

– adjust the nut on the back side of the cam

action axil. You will need to remove the motor

cover.

Pic. 76

Loosen the two middle setting bolts. These

two bolts fasten the assembly in-between the

set screws and the arbor block.

Pic. 77

Adjust the set screws as needed to correct

an out of align blade attachment. Do small

adjustments and check.

Pic. 78

As Adjustments are made, the blade

attachments will translate, not rotate, by design.

This ensures that the workpiece will not get

held up. CHECK COMPONENTS BEFORE

EVERY CUT.

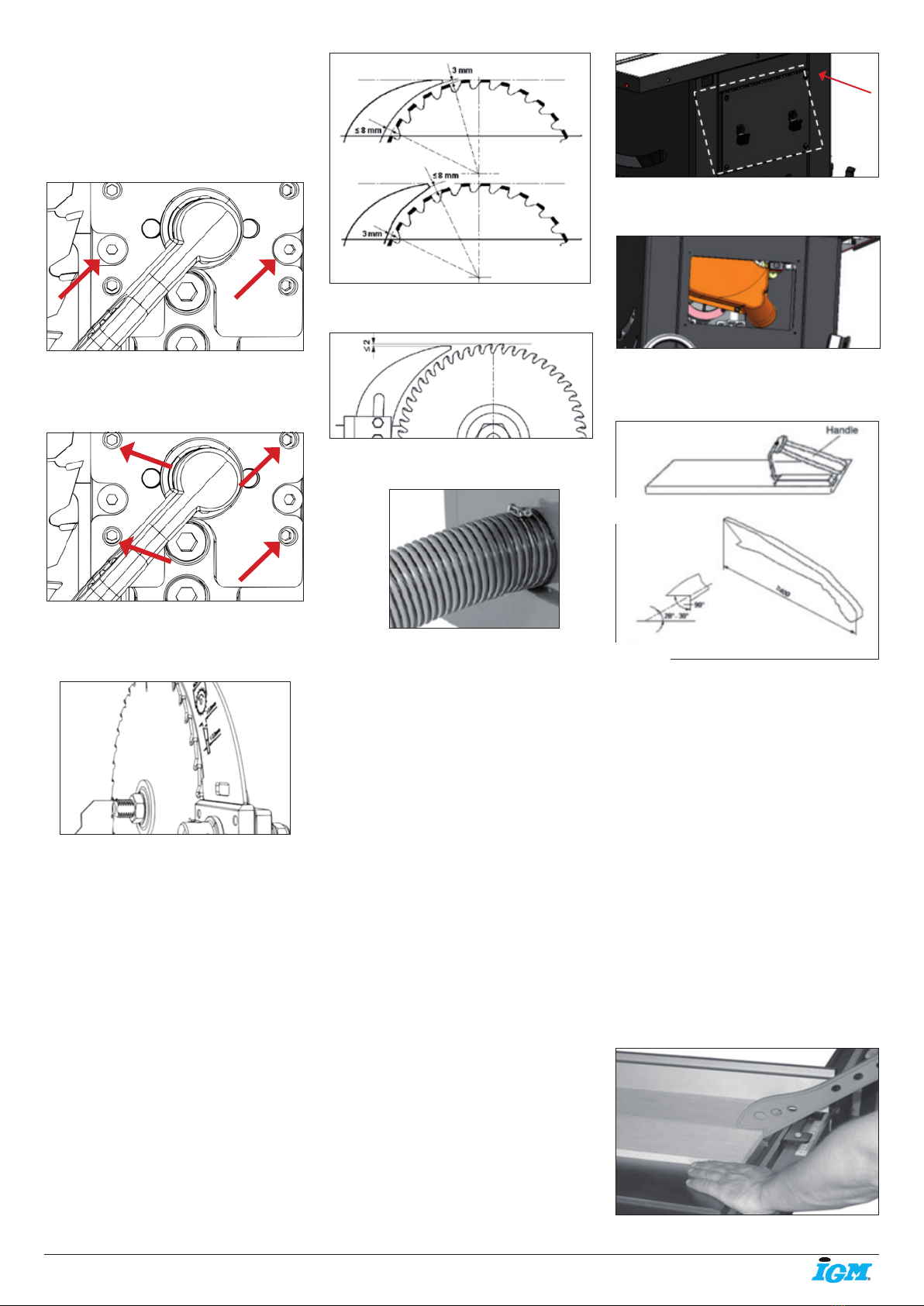

Riving Knife Adjustments::

After changing a saw blade, always check that

the riving knife is correctly set!

The distance of the riving knife from the gear

rim must be between 3 mm and 8 mm.

The highest point of the riving knife must be set

at least 2mm beneath the topmost tooth.

The riving knife must be at least 0.2 mm thicker

than the main saw blade.

Check that the saw blade clamping system is

tight before operating the machine!

Pic. 79

Pic. 80

Dust Collector:

Pic. 81

There is a 100 mm dust outlet located on

the lower left of the saw cabinet allowing for

the connection to a dust collection system

(not included). Air current speed is 20m/s for

vacuum suction dust emission index. When

air current speed of dust collector device (in

accordance with EN 12779:2004+ A1:2009) is

not lower than 20m/s, ensure machine can be

normal exhausted. User must wear dustproof

mask.

1. Fit the 100 mm dust hose over the dust port,

(not included) and secure in place with a hose

clamp.

2. Make sure the hose could not come off.

3. Required air ow: 934 m3/h

4. Ensure pressure drop of each dust collector

outlet carrying air current speed: 1500Pa

5. Wind speed of dust collector tube m/s: dry

chips: 20m/s, water content is equal to18% wet

chips: 28m/s.

Warning: Always turn on the dust collector

before starting the saw and stop the saw before

turning off the dust collector.

Note.: A tight t is necessary for proper

performance.

Warning: Always turn off the table saw before

removing any cover of the machine.

Pic. 82

Remove the side cover, to clean and remove

dust, debris from dust hood.

Pic. 83

7.5 Push block and push stick

A push block (Pic.2) and A push stick (Pic.3)

must be used.

If the workpiece is less then 12 0mm, you must

use the push stick to prevent your hands from

getting too close to the saw blade.

Push block must be used to cut narrow

workpieces and, when necessary, to push the

workpiece against the fence, a push block can

be easily made by the operator as Pic.2.

Warning: Use only the push stick provided by

the manufacturer or constructed in accordance

with the instructions. This push stick provides

sufcient distance of the hand from the saw

blade.

Warning: Never use a damaged or cut push

stick. A damaged push stick may break causing

your hand to slip into the saw blade.

8. Type of Cut

Warning: Always wear safety glasses, a

respirator and hearing protection when

operating this machine.

Note: This saw is only designed to cut wood.

8.1 Ripping

Pic. 86

Pic. 84

Pic. 85

-15-www.igmtools.com

Cutting a wood plank or sheet of plywood

lengthwise to reduce its width is called “ripping”.

To rip stock, hold the work with both hands

pushing it into the blade as well as rmly

against the rip fence so that it is cut straight.

• Never rip or cut wood without using the fence

or mitre gauge to guide it because the stock

could kickback.

• Always use the blade guard and riving knife

assembly when cutting wood. The riving knife

prevents the saw “kerf” (the slit cut by the

blade) from closing and binding the blade,

which can overload and/or stall the motor or

cause the blade to lift and eject the workpiece

towards the front of the saw at very high

speeds. The blade guard keeps your ngers

away from the blade and also reduces the

amount of sawdust ying free.

• Some jobs may require removing the riving

knife along with the cover. Do not forget to put

them back when you are done.

As you complete the rip, the wood will either

remain on the table, tilt up to be caught on

the end of the guard, or fall onto the oor (or

outfeed table). The waste part of the stock

remains on the table to be removed only after

the saw is stopped (unless it is large enough for

immediate safe removal).

If the work to be ripped is narrow, it is safer

to use a push stick, rather than the hands, to

feed it into the blade Push sticks with non-slip

grippers can be purchased, but a shop-made

one works just as well. When ripping extremely

narrow stock that may not clear the width of

the blade guard, or very thin material such

as panelling, which may slip between the

underside of the fence and the table surface,

a strip of wood as an auxiliary guide can be

attached to the fence.

WARNING: Keep the blade guard installed and

in the down position. Failure to do this could

result in serious personal injury or death.

WARNING: Never reach in towards the blade

while the blade is still spinning! whenever a rip

cut is completed, turn off the saw and wait for

the blade to come to a complete stop before

reaching in to remove the workpiece or the

waste material.

8.2 Bevel Ripping

Pic. 87

Bevel ripping is performed the same as ripping

but with the saw blade set to an angle not

perpendicular with the table surface. To tilt the

blade to the left, anywhere between 0° and 45°.

This is used most often when cutting bevels,

compound mitres or chamfers.

After changing the bevel angle verify the

alignment of the guard and splitter; make sure

there is clearance with the saw blade.

8.3 Ripping small workpieces

Do not attempt rip cuts if the work piece is too

small, as this will oblige you to place your hands

too close to the blade and put you at serious

risk of injury. When ripping narrower widths; use

a push block or a push stick in order to avoid

placing hands near the blade.

8.4 Cross cutting

Cutting against the grain, to shorten the length

of a board is crosscutting. With some smaller

sized and rectangular pieces, you often have

the choice of ripping or crosscutting. Always

use the mitre gauge, when crosscutting; never

cut a piece unsupported. The mitre gauge may

be used in either slot, but most operators prefer

the left groove for typical work. When the blade

is tilted for bevel cutting, use the table slot that

does not cause interference with your hand or

the saw blade guard.

To begin crosscutting, place the work on the

mitre gauge and, with the motor OFF, slide it up

close to the blade to align the outer edges of

the teeth with your cut mark (see pic).

Keep a rm grip as you pull the mitre gauge

and the wood back away from the blade. Lower

the blade guard, turn on the saw and make the

cut. When the work is cut through, move one or

both cut pieces.

Pic. 88

Warning: When cross-cutting round stock it

is necessary to secure the workpiece against

rotation by using a suitable jig.

8.5 Bevel cross cutting

This procedure is the same as cross cutting

except that the blade is set to an angle other

than 0. After changing the bevel angle, verify

the alignment of the guard and splitter and

verify that there is clearance with the saw blade.

Pic. 89

8.6 Mitre cuts

This operation is the same as cross cutting,

except the mitre gauge is set to an angle. Hold

the work piece rmly against the mitre gauge

and feed the workpiece slowly into the blade to

prevent it from moving during the cut.

Pic. 90

9. Maintenance

To keep you Laguna Tools machine in top

performance for many years please follow

this maintenance schedule and refer to any

instructions.

Daily Check:

• Loose mounting bolts

• Damaged saw blade

• Damaged riving knifes, splitters, or blade

guards

• Worn or damaged wires

• Any other unsafe condition

Weekly Maintenance:

• Clean table surface and mitre slot grooves

• Clean and protect cast-iron table

• Clean rip fence

Monthly Maintenance:

• Clean/vacuum dust buildup from inside

cabinet and off motors.

• Check/replace belt for proper tension, damage

or wear.

Every 6–12 Months:

• Lubricate trunnion slides.

• Lubricate worm gear.

• Lubricate leadscrew.

• Lubricate gearing and gearboxes.

-16-www.igmtools.com

9.1 Internal Components Map

A. Motor

B. Dust Shroud

C. Trunnion Slides (Support)

D. Upper Trunnion

E. Lower Trunnion

10. Trouble-Shooting

Machine will not start or continues to trip the breaker.

Possible Causes

1. Start capacitor at fault.

2. Motor connection wired wrong.

3. Wiring at fault.

4. Motor Start/Stop switch at fault.

5. Motor at fault.

6. Run capacitor at fault.

7. Wall circuit breaker tripped or at fault.

8. Power supply switched OFF or at fault.

9. Plug/receptacle at fault or wired incorrectly.

Possible Solution

1. Test/replace if faulty.

2. Correct motor wiring connections.

3. Check/x broken, disconnected, or corroded wires.

4. Replace switch.

5. Test/repair/replace.

6. Test/replace if faulty.

7. Ensure circuit size is correct/replace weak breaker.

8. Ensure power supply is on/has correct voltage.

9. Test wires and contacts; correct the wiring.

Machine is excessively loud or is experiencing excessive vibration.

Possible Causes

1. Motor or component loose

2. Blade at fault

3. Motor mount loose/broken

4. Machine incorrectly mounted

5. Arbor pulley loose

6. Belts worn or loose

7. Pulley loose or at fault

8. Arbor bearings at fault

9. Motor bearings at fault

Possible Solution

1. Inspect/replace damaged bolts/nuts, and re-tighten with thread-locking

uid.

2. Replace warped/bent blade; re-sharpen dull blade.

3. Tighten/replace.

4. Tighten mounting bolts; relocate/shim machine.

5. Retighten/replace arbor pulley.

6. Adjust tension of/replace belt

7. Realign/replace shaft, pulley, setscrew, and key.

8. Replace arbor housing bearings; replace arbor.

9. Test by rotating shaft; grinding/loose shaft requires bearing

replacement.

Machine trips the overload, or feels underpowered during operation.

Possible Causes

1. Feed rate/cutting speed too fast

2. Workpiece material unsuitable for machine

3. Pulley/sprocket slipping on shaft

4. Motor bearings at fault

5. Contactor at fault

6. Motor overheated

7. Workpiece crooked; fence not aligned

8. Machine undersized for task; wrong blade

9. Run capacitor at fault

10. Belt is slipping from pulley

11. Motor wired incorrectly

12. Plug/receptacle at fault

13. Motor at fault

Possible Solution

1. Decrease feed rate/cutting speed.

2. Only cut wood; ensure moisture is below 20%.

3. Replace loose pulley/shaft.

4. Test/repair/replace.

5. Test for good contacts/correct wiring.

6. Clean motor, let cool, and reduce workload.

7. Straighten or replace workpiece; adjust fence.

8. Use correct blade; reduce feed rate or depth of cut.

9. Test all legs for power/replace if faulty.

10. Adjust tension of/replace belt.

11. Test/repair/replace.

12. Wire motor correctly.

13. Test/repair/replace.

WARNING:

1. Wiring should only be done by professional electricians. Always make sure the machine is properly earthed.

2. All wirings in the cabinets should be protected against direct contact to at least IP2X when nishing electrical installation.

3. All exposed conductive parts should be connected to the protective bonding circuit.

4. Close and lock the door of cabinets.

WARNING:

1. Enough space around the machine and the cabinets should be kept in order to maintain conveniently.

2. The machine should be installed in a workshop with good illumination and ventilation.

3. Over-voltage protection device should be provided by end user on spot.

F. Arbor Nut

G. Arbor Washer (Flange)

H. Blade

I. Tilt Gearing

J. Height Gearing

K. Belt (behind blade)

L. Worm Screw

M. Tilt Plate

N. Start Capacitor (see spec sheet)

O. Run Capacitor (see spec sheet)

FG

H

B

E

C

N

A

K

D

C

J

I

M

O

-17-www.igmtools.com

CE-Konformitätserklärung

Produkt: Tischkreissäge

FUSION3

Typnummer: CEF33623003

Marke: Laguna

Hersteller:

Laguna Tools Inc

2072 Alton Pkwy, Irvine, CA 92606, USA

Hiermit erklären wir in unserer alleinigen Verantwortung, dass dieses Produkt den folgenden Richtlinien entspricht:

- Machinery Directive 2006/42/EC

- Low voltage Directive 2014/35/EC

- Electromagnetic Compatibility Directive 2014/30/EC

Entworfen in Übereinstimmung mit:

** EN 1870-19:2013

EN60204-1:2006+AC:2010

Technische Dokumentation erstellt von:

TUV Rheinland LGA Products GMBH

Číslo certikátu: 50100405 002

2019-09 Ivo Mlej, CEO

IGM nástroje a stroje s.r.o., Ke kopanině 560, 252 67 Tuchoměřice, Česká republika

-18-www.igmtools.com

Inhaltsverzeichnis

1. Konformitätserklärung

1.1 Gewährleistung

2. Über die

Gebrauchsanweisung

3. Spezikation der Maschine

3.1 Bestandteile der Maschine

3.2 Technische Daten

3.3 Hauptbestandteile

4. Allgemeine Arbeitssicherheit

4.1 Bestimmungsgemäße Verwendung

4.2 Arbeitsbereich

4.3 Persönliche Sicherheit

4.4 Einsatz der Werkzeuge

4.5 Hinweise zu Sicherheitseinrichtungen

4.6 Hinweise zu Maschinenteilen

4.7 Rückstoßursachen und damit verbundene

Gefahren

4.8 Warnungen zur Bedienung der Maschine

4.9 Elektroschaltung

4.10 Lärm

4.11 Erdung

4.12 Regelungen

4.13 Hinweis zur sicheren Verwendung der

Maschine

5. Allgemeine Beschreibung der

Maschine

5.1 Bedienelemente

6. Zusammenbau der Maschine

6.1 Übernahme und Auspackung

6.2 Kisteninhalt

6.3 Lose Teile und Übersicht

6.4 Zusammenbau der Maschine

6.5 Einbau/Entnahme der Tischeinlage

6.6 Einbau/Entnahme der

Sicherheitseinrichtungen

6.7 Einbau/Entnahme des Sägeblatts

7. Maschineneinstellungen

7.1 Einstellung des Sägeanschlags

7.2 Tischeinstellung

7.3 Einstellung der Wellenneigung

7.4 Einstellung der Wellenneigung

7.5 Einstellung der Zubehörteile

7.6 Schiebestock und Schiebeblock

8. Schnitttypen

8.1 Längsschnitt

8.2 Winkellängsschnitt

8.3 Längsschneiden schmaler Werkstücke

8.4 Querschnitt

8.5 Winkelquerschnitt

8.6 Gehrungsschnitt

9. Instandhaltung

Verzeichnis der Bestandteile

10. Störungsbehebung

1. Konformitätserklärung

Wir erklären, dass dieses Produkt im Einklang

mit der auf der vorherigen Seite dieser

Gebrauchsanweisung genannten Richtlinie und

Norm.

1.1 Gewährleistung

Die IGM nástroje a stroje s.r.o. strebt

danach, stets ein hochwertiges und

leistungsfähiges Produkt zu liefern. Die

Inanspruchnahme der Gewährleistung richtet

sich nach den jeweils geltenden Geschäfts- und

Gewährleistungsbedingungen der IGM nástroje

a stroje s.r.o.

2. Über die Gebrauchsanweisung

Der Zweck dieses Handbuchs ist es,

die Einstellungen, Instandhaltung und

Anpassungen Ihrer neuen Maschine zu decken.

Neben allgemeinen Sicherheitshinweisen

gilt dieses Handbuch NICHT für Holz- oder

Metallbearbeitungstechniken und für die

relevanten Sicherheitsvorkehrungen, die

für eine sichere Bedienung erforderlich

sind. Es gibt mehrere Organisationen mit

Veröffentlichungen zur sicheren Handhabung,

zu Techniken und zur ordnungsgemäßen

Verwendung dieser Maschine.

3. Spezikation der Maschine

3.1 Bestandteile der Maschine

Pro-Tischeinlage (in der Tischkreissäge

eingebaut)

250 mm Sägeblatt (in der Tischkreissäge

eingebaut)

Spaltkeil (in der Tischkreissäge eingebaut)

Winkelanschlag (auf Seite der Tischkreissäge)

Zubehörhalter (in der Tischkreissäge eingebaut)

Längsanschlag Sägeblattabdeckung

Mutterschlüssel