IK Online Electronics ID5001P User manual

ONLINE ELECTRONICS LTD

ID5001P_5001_B00

Page 0 of 36

Online Electronics Ltd

Online House

Blackburn Business Park

Woodburn Road

, Blackburn

Aberdeen

AB21 0PS

UK

+44 (0)1224 714 714

www.online

-electronics.com

sales@online

-electronics.com

NON-INTRUSIVE PASSIVE ULTRASONIC

TOPSIDE PIG SIGNALLER

OPERATING MANUAL

The ID5001P is a fully ATEX and IECEx certified, Exd flameproof,

non-intrusive pig signaller which detects, signals and logs the passage

of pigs at critical points along a pipeline both on land and offshore

Inline Services, LLC. 27731

Commercial Park Rd.

Tomball TX 77375

p.. 281.401.8142 | 888.973.0

e.. sales@inlineservices.com

w.. inlineservices.com

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 1 of 36

ID5001P_5001 MANUAL

Rev

Date

By

Summary of change

A00

02/05/19

GH

CR00570: Initial release.

A01

23/05/19

GH

CR00570: Section 2 & 9: Certificate numbers corrected.

B00

14/01/20

GH

Various graphics updated throughout (IK Rebranding).

CR00264.

Section 2: Specifications added for high temperature pipelines.

Section 2: Specifications for battery options added.

Section 5.3 & 5.4: High temp pipeline mounting instructions added.

Section 4.3: Added instructions for latched detection operation.

Section 10: Notified Body number updated.

Added section to cover Config Software installation and operation.

COMMENTS:

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 2 of 36

CONTENTS Page

1. General Description ..............................................................................................3

2. Specifications ...................................................................................................... 4

3. Rules For Safe Operation .......................................................................................5

4. Operation............................................................................................................6

4.1. Turning On ......................................................................................................6

4.2. Listening .........................................................................................................7

4.3. Detection ........................................................................................................ 7

4.4. Detection Algorithm .......................................................................................... 8

4.5. Single Button Menu Interface ........................................................................... 10

4.5.1. Main Menu................................................................................................. 11

4.5.2. Events Menu .............................................................................................. 12

4.5.3. System Info Menu ...................................................................................... 13

4.5.4. Live Display Menu....................................................................................... 13

4.5.5. Output Config Menu .................................................................................... 14

4.5.6. Detect Config Menu..................................................................................... 15

4.6. RS485 Serial Interface .................................................................................... 16

4.6.1. MODBUS Register Map ................................................................................ 16

5. Installation ........................................................................................................ 18

5.1. Main Housing Mounting Plate............................................................................ 18

5.2. Main Housing Post Mounting............................................................................. 18

5.3. Main Housing Pipeline Mounting........................................................................ 19

5.4. Sensor Mounting ............................................................................................ 19

5.5. Sunshade Post Mounting.................................................................................. 20

5.6. Sunshade Pipeline Mounting............................................................................. 20

5.7. Opening The Housing ...................................................................................... 21

5.8. Closing The Housing ....................................................................................... 21

5.9. Battery Removal............................................................................................. 22

5.10. External Connections ...................................................................................... 23

5.10.1. Relay Output.............................................................................................. 23

5.10.2. EX Connections .......................................................................................... 24

5.10.3. RS485 Serial Interface ................................................................................ 24

5.10.4. 0V Connection............................................................................................ 24

5.10.5. Enclosure Connection .................................................................................. 24

5.10.6. Remote Switch Connection........................................................................... 24

5.10.7. Switch Connection ...................................................................................... 24

5.10.8. Current Loop Output ................................................................................... 25

5.10.9. VBAT Connection ........................................................................................ 25

5.10.10. External Power Connection ....................................................................... 25

6. ID5001P Config Software..................................................................................... 26

6.1. Software Installation ....................................................................................... 27

6.1.1. Microsoft .NET Framework Installation ........................................................... 27

6.1.2. ID5001P Config Software Installation ............................................................ 27

6.2. Using The Config Software ............................................................................... 28

6.2.1. Setup Tab.................................................................................................. 28

6.2.2. Read/Write Tab .......................................................................................... 29

6.2.3. Read Only Tab ........................................................................................... 29

6.2.4. Booleans Tab ............................................................................................. 30

6.2.5. Events Tab ................................................................................................ 30

6.2.6. Live View Window ....................................................................................... 31

6.2.7. Event View Window..................................................................................... 31

7. Recommended Maintenance & Storage .................................................................. 32

8. Disposal Of Unit ................................................................................................. 33

9. Warranty........................................................................................................... 34

10. Certification Appendix ......................................................................................... 35

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 3 of 36

1. GENERAL DESCRIPTION

The ID5001P (Passive) pig signaller is a fully ATEX and IECEx certified, Exd flameproof, non-

intrusive, pig signaller which detects, signals, and logs the passage of pigs at critical points along

a pipeline both on land and offshore.

The unit uses Passive (listening) techniques to detect pig passage events. Events are signalled

as they occur via a 3” graphical LCD display and high brightness LEDs positioned above and

below the display. Events can also be signalled remotely using several optional outputs.

The unit logs the time and date of up to 99 events which can be viewed at any point using the

local display. The user can turn the unit ON and OFF as well as modify several settings using a

single control button and intuitive menu system.

The unit has two basic parts as shown below. The sensor is permanently connected to the main

housing via a cable and can be quickly and easily attached to the pipeline using ratchet straps

or steel banding. The main housing contains all electronics, batteries (if fitted), display and the

control button and can be mounted onto the pipeline using a mounting plate and straps in a

similar fashion to the sensor or mounted on a wall or post.

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 4 of 36

2. SPECIFICATIONS

GENERAL

External Supply ..................................................................................... 24.0VDC, <2.0W

Battery type ................................................................. 7x Alkaline DURACELL ID1300 cells

Battery life (Alkaline) in LISTENING/LOW POWER MODE at +20°C ............................. 15 days

Battery type ....................................................................... 7x Lithium SAFT LS33600 cells

Battery life (Lithium) in LISTENING/LOW POWER MODE at +20°C.............................. 30 days

Housing Ambient Temperature range (External supply) ...... -40°C to +85°C (-40°F to +185°F)

Housing Ambient Temperature range (Alkaline) .................. -20°C to +54°C (-40°F to+130°F)

Housing Ambient Temperature range (Lithium) ................. -40°C to +85°C (-40°F to +185°F)

Sensor Ambient Temperature Range ......................................................... -55°C to +110°C

Maximum Allowable Pipeline Surface Temperature ............................................ +150°CNOTE1

Typical minimum pig speed .............................................................................0.1m/sNOTE2

Main Housing Ingress Protection................................................................................ IP66

Sensor Ingress Protection......................................................................................... IP68

ATEX/IECEx code .............................................. II 1/2 G Ex d ia [ia Ga] IIC T4..T6 Gb

EU Type Examination Certificate Number ............................................ TRAC 13 ATEX 0008X

IECEx Certificate Number .................................................................. IECEx TRC 13.0006X

Weight in Aluminium .................................................................................................8kg

Weight in Stainless Steel .......................................................................................... 13kg

OUTPUTS

DPDT Relay Output (Volt Free Contacts) .................................................... 2A @ 30VDCNOTE3

Current Loop Output......................................................................................4-20mANOTE4

Serial Data Interface ............................................................................... RS485 MODBUS

NOTE1 Maximum allowable pipeline surface temperature depends on ambient air temperature

and mounting configuration. Only the sensor may be mounted on the pipeline.

NOTE2 Minimum pig speed depends on pig type, pipeline configuration and installation position.

NOTE3 DPDT is equivalent to 2x SPDT.

NOTE4 Current Loop levels are configurable between 4mA and 20mA. Default set state 20.0mA.

Default reset state 4.0mA. Tolerance ±1.0mA.

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 5 of 36

3. RULES FOR SAFE OPERATION

⚠WARNING: The Special Conditions for Safe Use as detailed in section 10 CERTIFICATION

APPENDIX must be followed.

⚠WARNING: The purchaser of this equipment is responsible for the training and competence

of operators and the way in which it is used. This manual should be read through and understood

before installation and commissioning so that the operator is familiar with the equipment.

Contact Online Electronics Ltd immediately should any difficulty arise in the use of this

equipment.

⚠CAUTION: If the equipment is to be placed in storage, always ensure that it is turned OFF

and the batteries (if fitted) are removed and stored separately.

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 6 of 36

4. OPERATION

Familiarise yourself with all of the rules for the safe operation of this equipment as described in

section 3 RULES FOR SAFE OPERATION.

4.1. TURNING ON

If powered from 24.0VDC power supply via

the VEXT connection the unit will turn on

automatically as soon as power is applied. If

powered from batteries simply press and hold

the control button until the COMPANY LOGO

appears on the display and then release, this

takes approximately 5 seconds.

The COMPANY LOGO will be displayed for 5

seconds as shown by the COUNTDOWN

INDICATOR located at the top left-hand side

of the display.

When the COUNTDOWN INDICATOR reaches

zero or the CONTROL BUTTON is pressed, the

next screen will appear.

The next screen shows the PRODUCT LOGO

and firmware version at the bottom of the

screen.

The next screen shows the current system

date and time. If the date and time are blank

as shown then the date and time will require

setting via the menu system or RS485

MODBUS serial interface.

The unit now enters STABILISATION. During

STABILISATION the unit will initialise the

detection filters and acquire the ambient

noise level of the pipeline.

Once STABILISATION is complete the unit

will enter LISTENING mode.In LISTENING

mode, the display will be switched off and the

LEDs will flash every 5 seconds to indicate

that the unit is active. See section 4.2

LISTENING for more information.

COUNTDOWN

INDICATOR

DATE & TIME

NOT SET

STABILISING

PRESS/

TIMEOUT

PRESS/

TIMEOUT

LISTENING

OR

COMPANY

LOGO

PRODUCT

LOGO

SYSTEM

DATE & TIME

PRESS/

TIMEOUT

PRESS/

TIMEOUT

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 7 of 36

4.2. LISTENING

While in LISTENING mode the unit continuously monitors the acoustic energy produced by the

pipeline as it waits for a pig passage to occur. The unit is configured to recognize the unique

sound signature produced by a pig as it passes the sensor. The unit uses the algorithm described

in section 4.4 DETECTION ALGORITHM to detect a pig passage.

While in LISTENING mode the display will be off and the LEDs above and below the display will

flash every five seconds to indicate that the unit is active. The relay and current loop outputs

will be in LISTENING state.

There are two things that may cause the display to change:

CONTROL BUTTON – If the control button is pressed the unit will enter the MENU system.

The menu system is described in section 4.5 SINGLE BUTTON MENU INTERFACE.

PIG APPROACH – If the unit detects a possible pig approaching

the sensor then the display will show a PIG APPROACH message

as shown. From this point the unit will continue running through

the detection algorithm until either the approach is cancelled, in

which case the display shall turn off, or it will signal pig detected

as per section 4.3 DETECTION.

4.3. DETECTION

When a pig is detected the display will show a PIG DETECTED

message including the time and date of the event as shown. The

LEDs above and below the display will flash every second and the

relay and current loop will be in the DETECTION state. The time

and date of the pig passage are stored in internal memory and

can be viewed later using the menu interface.

The unit will remain in the DETECTION state for the length of time defined by the OUTPUT DELAY

before returning to LISTENING mode. The OUTPUT DELAY can be bypassed by pressing the

CONTROL BUTTON.

OUTPUT DELAY – The OUTPUT DELAY controls how long the unit will signal an event for. Usually

it will be configured to give the pig enough time to get out of range of the sensor after it has

been detected to avoid re-trigger. When dealing with pig trains, the expected pig speed and

separation should be used to configure a suitable value for the OUTPUT DELAY such that the unit

will not detect the same pig twice but will enter LISTENING mode in time to detect the next pig.

LATCHED DETECTION – If the OUTPUT DELAY HH (hours) field

is set to 99 then when an EVENT occurs the unit will LATCH in

DETECTION mode showing the EVENT information and flashing

the LEDs every 1 second. To begin LISTENING again the CONTROL

BUTTON must be pressed or the detection reset using the serial

interface.

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 8 of 36

4.4. DETECTION ALGORITHM

Below is a simplified flowchart for the ID5001P detection algorithm which is running while the

unit is in LISTENING mode.

Periodically calculate 100 bin FFT

(200Hz per bin)

Calculate Power In Band (PIB) between Lower

Frequency bin (LF) and Upper Frequency bin (UF)

Calculate Average Noise (AN)

over Average Noise Time (ANT)

period in minutes

Calculate Average Value (AV)

over Average Value Time (AVT)

period in seconds

Calculate Difference Level (DL)

= Average Value (AV) – Average Noise (AN)

DL > HT?

Display

“PIG APPROACH”

DL < LT?

Was DL > HT for

longer than DT?

PIG DETECTED

YES

YES

YES

NO

NO

NO

Clear

“PIG APPROACH”

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 9 of 36

Below is a graphical representation a typical pig passage.

PIB = Power In Band (between Lower Frequency bin (LF) and Upper Frequency bin (UF))

AN = Average Noise (PIB averaged over Average Noise Time (ANT) period in minutes)

AV = Average Value (PIB averaged over Average Value Time (AVT) period in seconds)

DL = Difference Level (Average Value (AV) – Average Noise (AN))

HT = High Threshold (user set High Threshold)

LT = Low Threshold (user set Low Threshold)

DT = Delta Time (time DL goes above HT before returning below LT in seconds)

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 10 of 36

4.5. SINGLE BUTTON MENU INTERFACE

While LISTENING, the control button can be pressed to enter the menu interface. From the menu

system the user can configure several parameters which are discussed in this section.

When any menu screen is loaded the cursor will initially be located at the home position at the

top right corner next to the page number to indicate that the BACK action will occur when the

countdown expires.

Pressing the control button causes the CURSOR to move down to the next menu item and the

COUNTDOWN INDICATOR will be reset to 5. Once the CURSOR is pointing at the desired item

the user simply allows the COUNTDOWN INDICATOR to reach 0 and the selected item will be

executed. This simple behaviour is used throughout the menu interface to modify settings and

interact with the unit.

If the active menu has multiple pages, as indicated in the top right-hand corner then when the

last item is reached the next button press will load the next page and the cursor will return to

the home position. When the end of the last page is reached then the unit will loop back to page

1 of the active menu.

If the selected item is a menu then when the countdown expires the new menu is loaded,

otherwise if the item is an editable field then the display will go into edit mode to allow the value

to be changed. In edit mode the part of the field actively being edited is enclosed in a box to

highlight it. Some parameters will provide additional information on screen while editing such as

min and max values. All parameters are incremented by pressing the CONTROL BUTTON until

they are at the desired value. Allowing the COUNTDOWN INDICATOR to reach 0 either selects

the next editable digit in the field if there is one, otherwise edit mode will exit and the new value

will be saved.

If while editing a parameter value you wish to cancel the edit operation, then press and hold the

CONTROL BUTTON until the cursor returns to the home position.

If an item was selected accidentally then simply press and hold the CONTROL BUTTON until the

cursor returns to the home position or allow the COUNTDOWN INDICATOR to reach 0 without

pressing the CONTROL BUTTON.

The menu system is designed so that the unit will always return to LISTENING mode if the

CONTROL BUTTON is left released for a long enough time.

Below is the typical layout of a menu screen:

CURSOR

HOME

PAGE

INDICATOR

EDITABLE

VALUES

FURTHER

MENU

COUNTDOWN

INDICATOR

SELECTABLE

MENU ITEMS

MENU

TITLE

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 11 of 36

4.5.1. MAIN MENU

The MAIN MENU is the initial entry point to the menu system.

This menu consists of three pages as shown.

DATE – Select this item to edit the system date. Ensure that

a valid date is entered in DD/MM/YY format.

TIME – Select this item to edit the system time. Ensure that

a valid time is entered in 24hour HH:MM format. Seconds

will be set to 0 when the time edit completes.

EVENTS – Indicates the number of stored events. Select

this item to view or delete events via the EVENTS menu. See

section 4.5.2 EVENTS MENU.

SHUTDOWN – Select this item to switch off the unit. The

unit has memory backup and will remember all settings until

next time the unit is switched on. It is imperative that the

unit is turned off using this command rather than simply

disconnecting the external power supply to allow any

memory storage processes to complete prior to turning OFF.

Once turned off the unit can be turned back on either by

pressing the CONTROL BUTTON for 5 seconds or by cycling

the external power supply.

SYSTEM INFO – Select this item to access the System Info

menu. See section 4.5.3 SYSTEM INFO MENU.

LIVE DISPLAY – Select this item to access the Live Display

menu. See section 4.5.4 LIVE DISPLAY MENU.

LOW POWER MODE – Select this item to turn Low Power Mode ON or OFF. Low power mode

only has an influence when the unit is being powered from the internal battery pack.If low

power mode is ON, then while the pipeline is quiet the sensor will sample at a reduced frequency

and the RS485 MODBUS interface will be disabled to preserve battery life.

OUTPUT CONFIG – Select this item to configure the output functionality of the unit. See

section 4.5.5 OUTPUT CONFIG MENU.

DETECT CONFIG – Select this item to configure the detection parameters used by the unit to

detect pig passages. See section 4.5.6 DETECT CONFIG MENU.

MODBUS ADDRESS – Select this item to edit the RS485 MODBUS slave address (1 – 247).

LANGUAGE – Select this item to change the system language.

FORMAT SD CARD – Select this item to format the internal SD card (if fitted).

The following LCD parameters will require the user to press the CONTROL BUTTON within 5

seconds, to save after editing the value. This feature is to try and prevent the display becoming

unreadable. If after editing a value the display is unreadable then just let the countdown timeout

and the previous value will be reloaded.

LCD CONTRAST – Select this item to edit the LCD contrast (65 – 99%).

LCD BL FREQ – Select this item to edit the LCD backlight frequency (100 – 200Hz).

LCD BL DUTY – Select this item to edit the LCD backlight duty cycle (1 – 99%).

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 12 of 36

4.5.2. EVENTS MENU

The EVENTS MENU allows the user to view and erase the EVENTS stored in the unit memory.

VIEW EVENTS – Selecting this item will allow the user to cycle through all logged EVENTS from

oldest to newest. The EVENT number, date and time are shown. Pressing the CONTROL BUTTON

will cycle to the next event. The CONTROL BUTTON can be held to pause at any event. If the

COUNTDOWN INDICATOR reaches 0 then the unit will return to the EVENTS MENU.

ERASE EVENTS – Selecting this item will ERASE all logged EVENT data. The user will be

prompted to confirm this action before proceeding with the ERASE as this action cannot be

undone. To cancel the ERASE simply ensure NO is selected before the countdown expires. If

YES is selected, then a message will appear to indicate that the EVENTS have been erased before

returning to the EVENTS MENU.

ERASE

VIEW

YES

NO

PRESS

PRESS

PRESS

PRESS

TIMEOUT

TIMEOUT

TIMEOUT

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 13 of 36

4.5.3. SYSTEM INFO MENU

The SYSTEM INFO MENU is largely read only and is primarily used

to display certain system parameters to the user.

SERIAL NO – READ ONLY – The unit serial number is configured

at time of manufacture.

FIRMWARE –This item shows the currently installed firmware version. Select this item to

upgrade the unit firmware via USB. This action will require confirmation from the user before

proceeding as the unit will be locked up in the bootloader until either a new firmware image is

uploaded, or the unit power is cycled. This procedure should only be undertaken by OEL staff

or following instruction from OEL.

BAT TYPE – READ ONLY – This item indicates the type of batteries that the unit is configured

to work with. This is configured at the time of manufacture.

BAT VOLTAGE – READ ONLY – This item indicates the voltage of the battery pack if fitted

otherwise “NO BAT” will be displayed.

POWER SUPPLY – READ ONLY – This item indicates whether the unit is currently being powered

from and external power supply (VEXT) or from the internal batteries if fitted (VBAT).

4.5.4. LIVE DISPLAY MENU

The LIVE DISPLAY MENU gives the user access to the three available diagnostic screens. These

screens allow the user to view the live signals being monitored by the unit which is useful to

confirm correct operation and when making changes to the detection parameters.

TIME MODE – This mode displays a live graphical plot of the Difference Level (DL) vs time. The

High Threshold (HT) and the Low Threshold (LT) are indicated by the dashed lines. The Y axis

is auto scaling based on the maximum value of Difference Level (DL).

TEXT MODE – This mode shows the following live values in text form: Average Noise (AN),

Average Value (AV), Difference Level (DL) and Power In Band (PIB).

FFT MODE – This mode displays a live graphical plot of the full FFT bandwidth (0 – 20kHz).

FFT Y SCALE – Selecting this item allows the user to edit the Y scale for the FFT plot.

When viewing a live screen, a pig passage is indicated by “PIG DET” in the lower left corner as

shown above. Pressing the CONTROL BUTTON returns the unit to the menu system.

TIME MODE

FFT MODE

TEXT MODE

PRESS

PRESS

PRESS

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 14 of 36

4.5.5. OUTPUT CONFIG MENU

The OUTPUT CONFIG MENU allows the user to configure the

output functionality of the unit. This menu consists of two

pages as shown.

OUTPUT DELAY – Select this item to modify the OUTPUT

DELAY in HH:MM:SS format. The OUTPUT DELAY dictates

how long the unit will indicate DETECTION before returning

to LISTENING mode. This can take any value from 00:00:00

up to 98:59:59.

CL OUTPUT – Select this item to enable or disable the

CURRENT LOOP output functionality. If the CURRENT LOOP

output is disabled the loop current will be 2mA, otherwise,

the loop current will be either the user defined LISTENING

or DETECTION level.

CL LISTEN – Select this item to edit the CURRENT LOOP

LISTENING level (4.0 – 20.0mA).

CL DETECT – Select this item to edit the CURRENT LOOP DETECTION level (4.0 – 20.0mA).

CL IF – This item should not be changed by the user. This will be configured at the time of

manufacture to interface with the ID5000IF unit if required.

RELAY INVERT – Select this item to enable or disable the inverse operation of the relay.

LED FLASH – Select this item to enable or disable the flashing high brightness LEDs fitted above

and below the LCD display.

VAL SD LOG – Select this item to enable or disable logging of the raw data to the internal SD

card (if fitted).

FFT SD LOG – Select this item to enable or disable logging of the FFT data to the internal SD

card (if fitted).

RESET TO DEFAULTS – Selecting this item will reset all output parameters to their default

values. This option requires the user to confirm before it is actioned.

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 15 of 36

4.5.6. DETECT CONFIG MENU

ADJUSTING THESE PARAMETERS WITHOUT FIRST

CONSULTING ONLINE ELECTRONICS LTD MAY CAUSE

THE UNIT TO MISS PIG PASSAGES OR GIVE FALSE

DETECTIONS.

The DETECT CONFIG MENU allows the user to configure the

detection parameters for the unit. This menu consists of

three pages as shown.

HIGH THRESHOLD – The Difference Level (DL) must

exceed this threshold before the unit will consider a possible

pig approach. (0 – 65535)

LOW THRESHOLD – The Difference Level (DL) must fall

below this threshold after being above High Threshold (HT)

to trigger a pig detection. (0 – 65535)

DELTA TIME – The length of time the Difference Level (DL)

must be above the Low Threshold (LT) after exceeding the

High Threshold (HT) before the unit will indicate a detection.

If the time does not exceed this value, then the pig approach

will be cancelled. (1 – 100 seconds)

AV VALUE TIME – The time period the Power In-Band (PIB)

is averaged over to calculate the Average Value (AV).

(1 – 100 seconds)

AV NOISE TIME – The time period the Power In-Band (PIB)

is averaged over to calculate the Average Noise (AN).

(1 – 100 minutes)

AV NOISE OVER – The value of Average Noise (AN) can be over ridden by the user, if this value

is set to zero then the calculated Average Noise (AN) will be used. (0 – 65535)

NUM AVERAGES – The number of samples that will be averaged to calculate the Power In-Band

(PIB). Increasing this value will smooth the resultant PIB output waveform at the expense of

increased processing time to compute the FFTs. (1 – 50)

UPPER FREQ BIN – The highest frequency bin to be included in the Power In-Band (PIB).

200Hz/bin (1 – 100)

LOWER FREQ BIN – The lowest frequency bin to be included in the Power In-Band (PIB).

200Hz/bin (1 – 100)

HARDWARE GAIN – The hardware gain configuration. (1 – 4)

SENSOR GAIN – The sensor gain level. (1 – 12000)

HP FILTER – Enables or disables the hardware high pass filter stage.

RESET TO DEFAULTS – Selecting this item will reset all detection parameters to their default

values. This option requires the user to confirm before it is actioned.

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 16 of 36

4.6. RS485 SERIAL INTERFACE

Communication to the ID5001P, via the RS485 interface, makes use of MODBUS RTU protocol.

All the parameters available in the ID5001P menu system can also be accessed via the MODBUS

interface. The serial interface should be configured as follows:

9600 baud, 8 data bits, 1 stop bit, no parity

⚠WARNING: Care should be taken when remotely controlling/configuring the unit via the

MODBUS interface as values set intentionally, or unintentionally, will immediately affect the

operation of the ID5001P. E.g. enabling relay inversion, although a useful test, will cause the

relay to switch and signal an event when no event is active.

If the ID5001P is powered from batteries, and LOW POWER MODE is enabled, then the RS485

interface will be disabled. If you require to use the RS485 interface while powered from batteries

then LOW power mode must be disabled, although be aware that this will significantly reduce

the battery lifetime.

4.6.1. MODBUS REGISTER MAP

COILS

0

Log Values to SD card

Write 1 to enable or 0 to disable

1

Log FFT to SD card

Write 1 to enable or 0 to disable

2

Invert Relay Operation

Write 1 to enable or 0 to disable

3

Current Loop Enable

Write 1 to enable or 0 to disable

4

Current Loop IF Enable

Write 1 to enable or 0 to disable

5

High Pass Filter Enable

Write 1 to enable or 0 to disable

6

LED Flash Enable

Write 1 to enable or 0 to disable

7

Low Power Mode Enable

Write 1 to enable or 0 to disable

15

Pig Detected

Read Only – Pig detection status

16

Reset Detect Parameters

Write 1 to reset detect parameters

17

Reset Output Parameters

Write 1 to reset output parameters

18

Erase Events

Write 1 to erase the stored events

INPUT REGISTERS

0

Average Noise (AN) High

Upper word (bits 31:16)

1

Average Noise (AN) Low

Lower word (bits 15:0)

2

Average Value (AV) High

Upper word (bits 31:16)

3

Average Value (AV) Low

Lower word (bits 15:0)

4

Difference Level (DL) High

Upper word (bits 31:16)

5

Difference Level (DL) Low

Lower word (bits 15:0)

6

Power In-Band (PIB) High

Upper word (bits 31:16)

7

Power In-Band (PIB) Low

Lower word (bits 15:0)

8

Number of Events

0 - 99

14

Firmware Type

5001

15

Firmware Revision

Major Rev ASCII (bits 15:8) Minor Rev (bits 7:0)

16

Event Year

Selected event date

17

Event Month

Selected event date

18

Event Day

Selected event date

19

Event Hour

Selected event time

20

Event Minutes

Selected event time

21

Event Seconds

Selected event time

22

CPU Temperature

°C

23

Battery Voltage

mV

25

Unit Serial No

0 – 65535

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 17 of 36

HOLDING REGISTERS

0

Upper Freq Bin (UF)

0 – 100 (200Hz/bin)

1

Lower Freq Bin (LF)

0 – 100 (200Hz/bin)

2

Number of Averages (NA)

1 – 50

3

Average Noise Time (ANT)

1 – 100 minutes

4

Average Value Time (AVT)

1 – 100 seconds

5

Hardware Gain (HG)

1 – 4

6

Delta Time (DT)

1 – 100 seconds

7

Output Delay Hours

0 – 99 hours

8

Output Delay Minutes

0 – 59 minutes

9

Output Delay Seconds

0 – 59 seconds

10

High Threshold (HT)

0 – 65535

11

Low Threshold (LT)

0 – 65535

12

Sensor Gain (SG)

1 – 12000

13

Average Noise Override (ANO)

0 – 65535

14

Current Loop Listening Level

Val = (ImA x 65536)/24

15

Current Loop Detected Level

Val = (ImA x 65536)/24

16

LCD Contrast

65 – 99

17

LCD Backlight

Freq = Val/100 Duty = Val%100

18

MODBUS Slave Address

1 – 247

19

Language

0 = ENG, 1 = FRA, 2 = ESP

32

System Year

System date

33

System Month

System date

34

System Day

System date

35

System Hour

System time

36

System Minute

System time

37

System Second

System time

38

Selected Event Number

0 – 99, Input registers selected event number

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 18 of 36

5. INSTALLATION

⚠WARNING: The Special Conditions for Safe Use as detailed in section 10 CERTIFICATION

APPENDIX must be followed at all times.

Normally the unit is used to confirm whether or not a pig has passed a known point of interest

on a pipeline such as a bend or valve. The unit should be mounted approximately 5m after the

point of interest and a test run completed to confirm successful installation and reliable detection.

If the main housing is exposed to direct sunshine, then it is recommended that a sunshade is

installed to prevent unnecessary heating of the unit which may shorten the lifespan of the

equipment. See sections 5.5 SUNSHADE POST MOUNTING and 5.6 SUNSHADE PIPELINE

MOUNTING.

5.1. MAIN HOUSING MOUNTING PLATE

The unit is supplied with a mounting plate as shown

which is suitable for use with ratchet straps or steel

banding and for mounting the unit onto pipelines,

posts and walls.

If the unit is post mounted, then 4x M8x120 coach

bolts should be fitted as per 5.2 MAIN HOUSING POST

MOUNTING prior to attaching the mounting plate.

The mounting plate is attached to the main housing as

shown using 2x M8x16 bolts / 2x M8 spring washers /

2x M8 plain washers / mounting plate / 2x M8x5

spacers / main electronics housing.

5.2. MAIN HOUSING POST MOUNTING

The post mounted unit is supplied with a post mounting assembly as

shown.

1. Prior to fitting the mounting plate as per 5.1 MAIN HOUSING

MOUNTING PLATE pass the 4x M8x120 coach bolts through the

mounting plate.

2. Hold the assembly in position on the post and secure using 4x M8

nuts / 4x M8 washers / post mount clamp / post / mounting plate

/ 4x M8x120 coach bolts as shown (view from above).

3. If equipotential bonding, or earthing is required, then the M4

threads around the perimeter of the display endcap may be used.

ONLINE ELECTRONICS LTD

ID5001P_5001_B00 Page 19 of 36

5.3. MAIN HOUSING PIPELINE MOUNTING

The pipeline mounted unit is supplied with a set of ratchet

straps or steel banding as shown.

1. If the pipeline surface temperature is expected to exceed

the maximum permitted ambient temperature for the

enclosure as per the tables in the Special Conditions for

Safe Use within section 10 CERTIFICATION APPENDIX then

the housing must NOT be fitted on the pipeline.

2. Ensure the mounting plate is securely fitted to the housing

as per 5.1 MAIN HOUSING MOUNTING PLATE.

3. Temporarily place the unit at the chosen location to ensure

that the unit sits in place without rocking excessively.

4. Thread 2x loops of banding through the slots provided in

the mounting plate as shown and then following the

instructions provided with the banding gradually tighten the banding until the unit is held

firmly. Do not use excessive force.

5. If equipotential bonding, or earthing is required, then the M4 threads around the perimeter

of the display endcap may be used.

5.4. SENSOR MOUNTING

The sensor is supplied with a mounting

plate, a mounting stud, a PEEK insulator (if

required) and a length of mounting band.

1. If the pipeline surface temperature is

expected to exceed +85°C then the

sensor must be fitted on the lower half

of the pipeline as shown to minimise

convection heating and a PEEK

insulator must be fitted to thermally

insulate the sensor from the pipeline.

Online Electronics should be contacted

for further guidance. Do NOT exceed 3

N·m tightening torque if using the PEEK

insulator or the threads may be damaged.

2. Pass the mounting stud or insulator (if required) through the ø6mm hole in the mounting

band and then screw into the mounting plate approximately 4 full turns. Do not tighten

further at this point.

3. Loop the mounting band around the pipeline and then following the instructions provided

with the banding gradually tighten the banding until the mounting assembly is held firmly.

Do not use excessive force.

4. Ensure that the mounting plate is positioned to form a cross with the mounting band and

the mounting band has been firmly tightened before fully tightening the mounting stud into

the mounting plate using a 21mm AF wrench or the insulator (if required) using a 15mm AF

wrench. Do NOT exceed 3 N·m tightening torque if using the PEEK insulator or the threads

may be damaged. It should not be possible to move the mounting plate at this point.

5. Attach the ID5001P sensor to the mounting stud tightening using a 1” AF wrench. Do NOT

exceed 3 N·m tightening torque if using the PEEK insulator or the threads may be damaged.

Table of contents

Popular Security Sensor manuals by other brands

Notifier

Notifier GL91AMP Installation and operating manual

NuWave

NuWave LumAir LA100 Unloading Guide

System Sensor

System Sensor B501AP Installation and maintenance instructions

THORLABS

THORLABS PDA30B user guide

Dors

Dors 135 user manual

Lutron Electronics

Lutron Electronics Maestro MS-OPS2 1 Series manual

Resolution Products

Resolution Products RE110P+ instructions

MSA

MSA altair 4 Quick start card

Toshiba

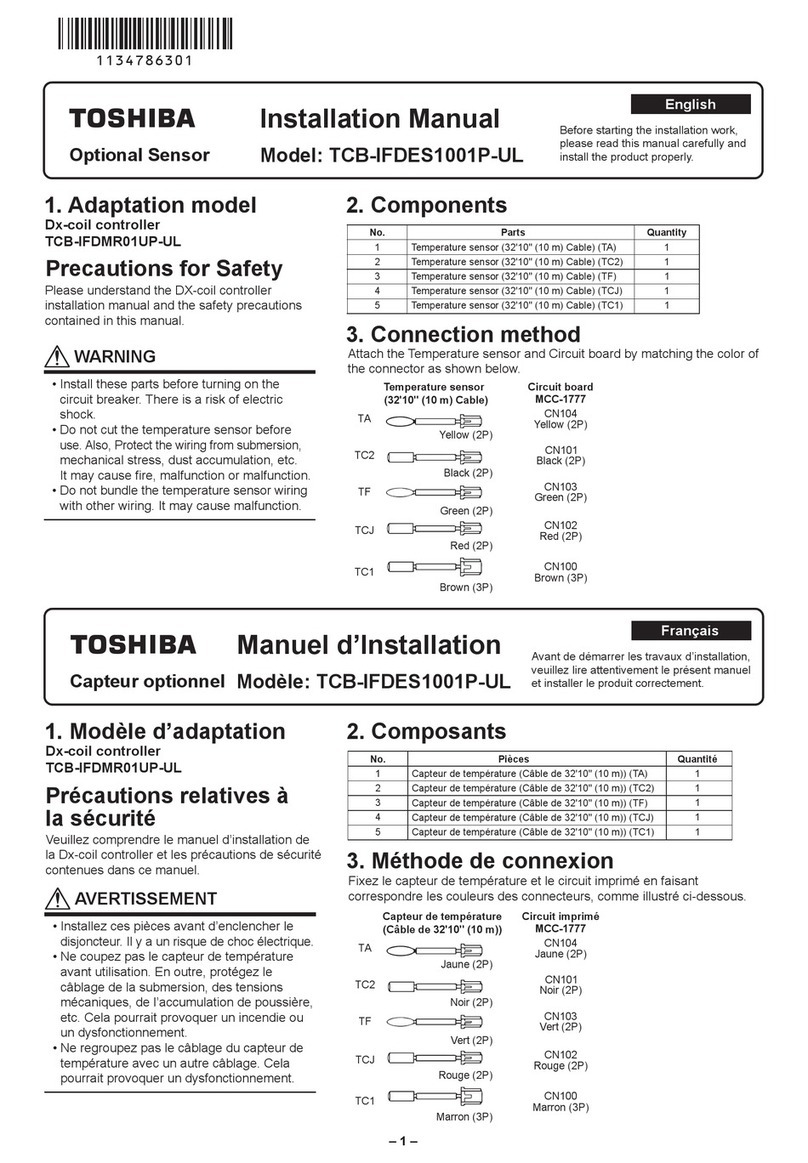

Toshiba TCB-IFDES1001P-UL installation manual

Petzl

Petzl ROLLCLIP A Triact Lock TECHNICAL NOTICE

Honeywell Home

Honeywell Home VISTA-GSM4G Installation and setup guide

Optex

Optex AX-70TN installation manual