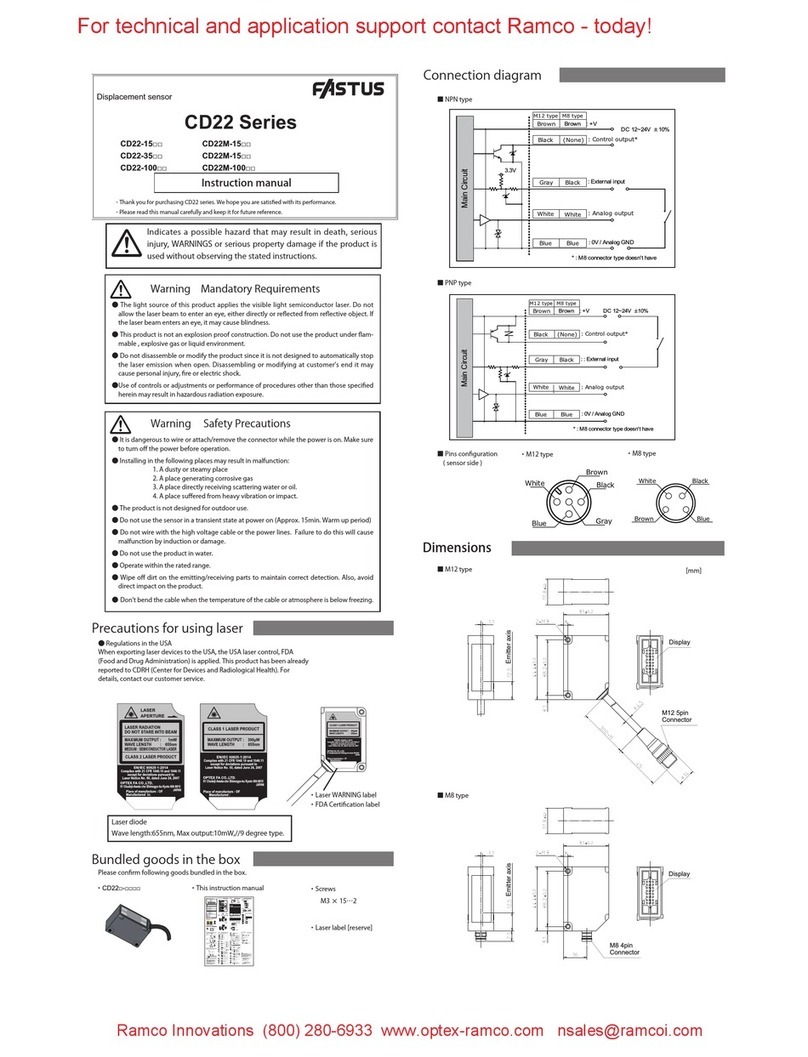

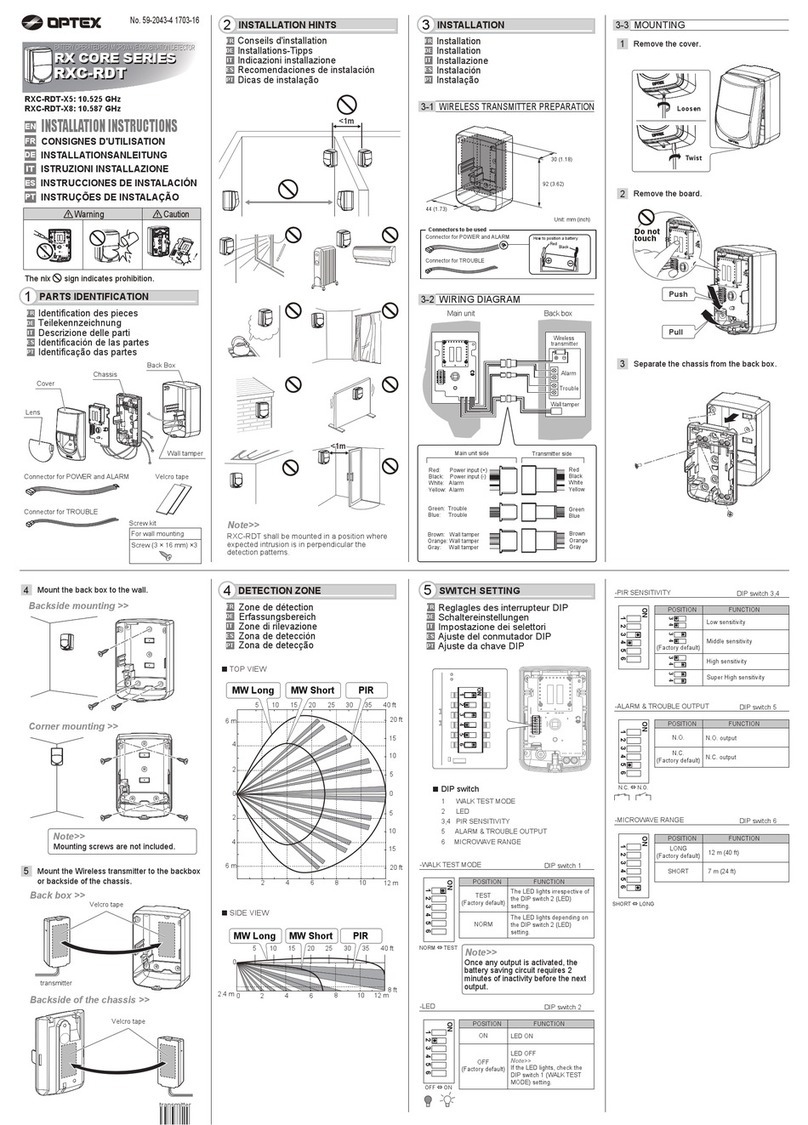

Wire size Power supply voltage

12VDC 24VDC

AWG22

(0.33mm2)1600ft.(500m)7800ft.(2400m)

AWG20

(0.52mm2)2200ft.(700m)11400ft.(3500m)

AWG18

(0.83mm2)3600ft.(1100m)18000ft.(5500m)

AWG16

(1.31mm2)5500ft.(1700m)26200ft.(8000m)

Power input

10.5 to 28VDC

Ქ Ყ

Tamper output : (BE) Model only

(it opens when cover is removed)

Non-voltage contact output

Contact capacity: 28VDC and 0.2A (max.)

“For UL Listed applications, the units shall be connected to a UL

Listed control unit or Listed Burglar Power Supply capable of

providing a minimum of 4 hours standby power.”

Note:Non-Voltage contact output

Resistive load only

TAMPER

Power input

10.5 to 28VDC

Ქ Ყ

Tamper output : (BE) Model only

(it opens when cover is removed)

Non-voltage contact output

Contact capacity: 28VDC and 0.2A (max.)

TAMPER

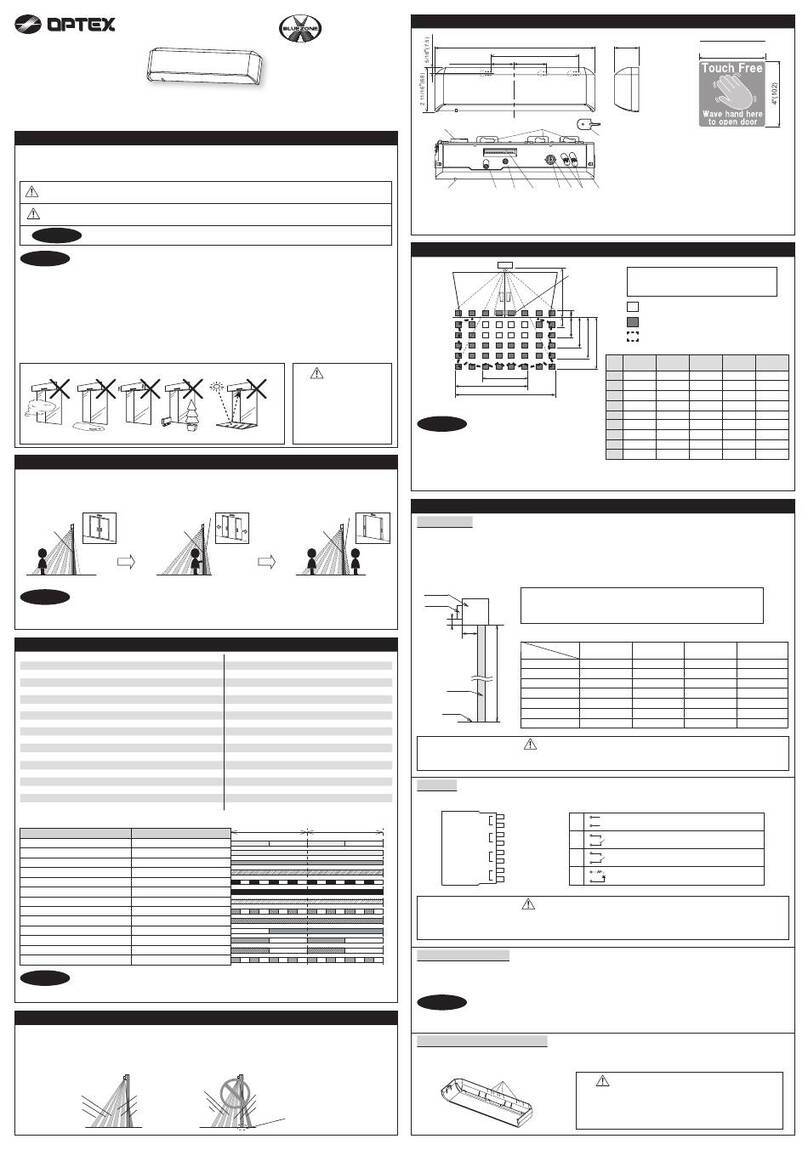

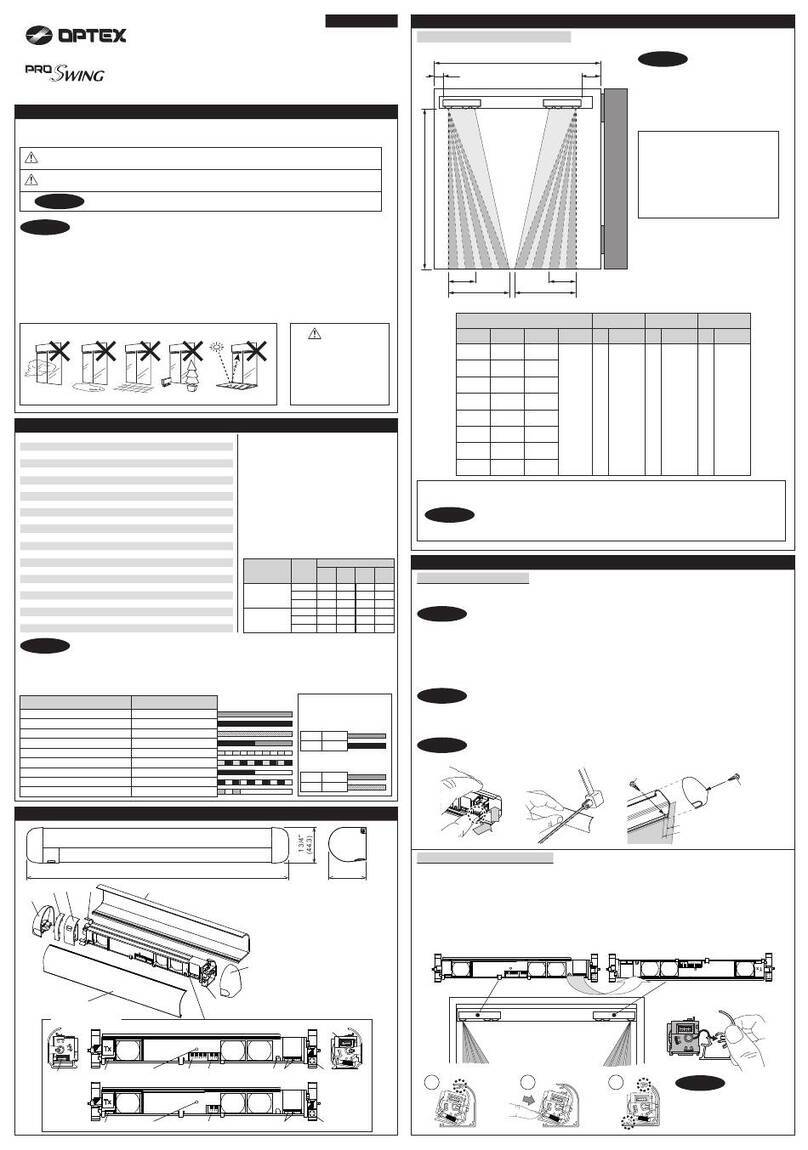

3. Wiring

Use wires in compliance with the following conditions:

1) Wire diameter: φ4 - 7mm

2) When using any other wires than the above, seal the wiring port

with a waterproof agent (silicon, etc.) to prevent water from coming

in through the gap.

3) Number of wires: 3 (max.)

Wiring Hole 1

3 wires can be accommodated in a unit.

Lead-in wire should be as below.

*Wiring hole 2 needs to be punched with a screw driver, etc.

*To have the wiring hole 3, wiring port needs to be cut with a cutter knife,

etc. After inserting the wire, seal the wiring port with a waterproof material

like silicon for leakage prevention.

Wiring Hole 2

Figure 1 Figure 2

Wiring guide should be as below.

Knockout needs to be opened with a nipper, etc.

Knockout

Cutting

Figure 3

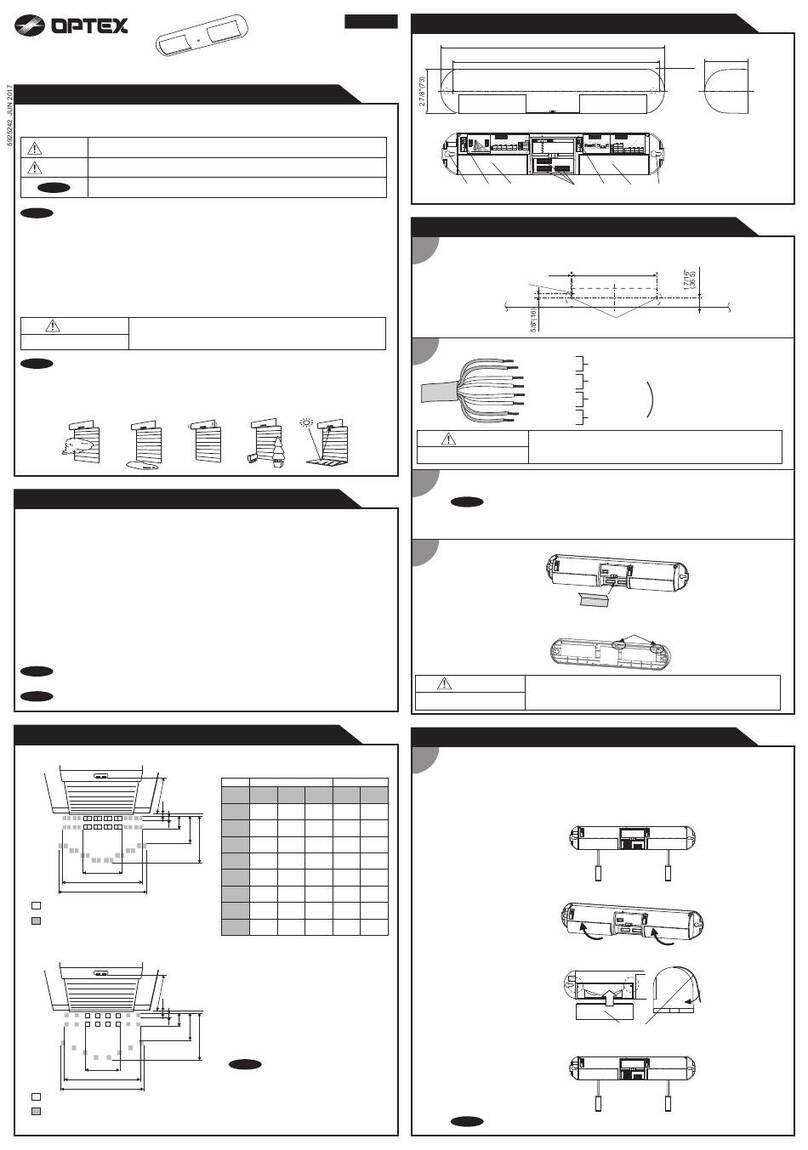

5. Alignment and walk test

4. Mount the unit base

Connect the terminals with reference to “4. WIRE

CONNECTION” and slide the unit base into the mounting

plate from above, then fasten the unit base mounting

screws to ¿x the unit base. Then, push in the waterproof

plug up to the broken line shown in the ¿gure above.

Waterproof Plug

Unit Base

Lock Screw

Align the optical axis to the maximum

receiving level according to “5-1.

OPTICALALIGNMENT”. Then, check

for the operation with reference to “6.

WALK TEST”.

Put the cover and tighten the

cover lock screw.

Make sure that the cover edge

has reached the line prepared

on the side of the unit base

(See the ¿gure left)

Screwdriver Line

Push in up to

this position

Side view of the waterproof plug

WARNING

Do not exceed the voltage

or current rating speci¿ed

for any of the terminals

during installation,

doing so might cause ¿re

or damage to the devices.

<Receiver >

Power input

10.5 to 28VDC

Alarm output (N.C.)

Non-voltage contact output

Contact capacity: 28VDC and 0.2A (max.)

+−ALARM TAMPER

Tamper output

(It opens when cover is removed)

Non-voltage contact output

Contact capacity: 28VDC and 0.2A (max.)

1. Terminal

<Transmitter >

Connect respective wires to the terminals shown in the following ¿gure.

・

Ensure that the wiring distance from the

power supply is within the range shown in

the table on the right.

・

When using two or more units on one wire,

the maximum length is obtained by dividing

the wire length listed below by the number

of units used.

2. Wiring distance between power

supply and detector

4. WIRE CONNECTION

[AX-70/130/200TN]

+−COM.N.O.TAMPER

[AX-100/200TF]

Alarm output: (N.C./N.O.) switch (In case of using N.O., contact is not reversed when power supply is off.)

Non-voltage contact output

Contact capacity: 28VDC and 0.2A (max.)

Use the COM. terminal for both alarm

output and D.Q. circuit.

Knockout

N.C.

Power input

10.5 to 28VDC

Tamper output

(It opens when cover is removed)

Non-voltage contact output

Contact capacity: 28VDC and 0.2A (max.)

Environmental Disquali¿cation (N.C.)

Non-Voltage contact output

Contact capacity : 28VDC and 0.2A (max.)

N.C. / N.O. selection Swich

N.C. ⇔N.O.

3

OFF ON

<Receiver >

<Transmitter >

N.C./