ILE AGF2B User manual

NOTES OF OPERATION OF DEVICE

AGF2B

AGF2

Index

Overview...........................................................................................................................................................3

Main unit...........................................................................................................................................................6

Magnetic Sensor and permanent Magnet:........................................................................................................ 7

Adapter module:................................................................................................................................................7

Optical heads:....................................................................................................................................................8

Use of the main unit. ........................................................................................................................................

Foreman password.......................................................................................................................................... 12

Install of the main unit ................................................................................................................................... 13

Instructions for the assemblage of the optic head...........................................................................................14

Memorization of reference data......................................................................................................................15

Regular operation and stop of the production................................................................................................ 16

Cleaning of the heads......................................................................................................................................16

Turning off the main unit................................................................................................................................16

Output relay blink........................................................................................................................................... 16

There is a page in which is possible to choose if, in condition of stop, the output relay must have

maintained turned on or has to blink (to give greater visibility to connected lamp). ....................................16

List of part numbers and description.............................................................................................................. 1

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

2

Overview

The device AgoFototex AGF2B and AGF2 is installed on Circular textile machines with the purpose to

notice the breakup of the heads of the needles and to stop the production.

It is born as fusion of two instruments, the FM8/10 and the AG14. It in fact it unites the functionalities of

both allowing the analysis of the fabric produced for check of holes or dropped stitches (FM8/10) and

the survey of the breakup of needles hook (AG-14).

It is composes of:

•an electronic main unit AGF2 or AGF2B with display and keyboard, to which the other parts are

connected directly:

AGF2B

AGF2

•A magnetic sensor of precision, that is activated by a permanent magnet

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

3

•One or two optic needle scanner placed close to the hook of the needles and hold by special supports,

one optic needle scanner for each series of needles to be checked. These scanner serve to count the

number of needles hook .

•One Adapter module or amplifier which connect one or two optic needle scanners to the main. It act

as an electric and mechanic adapter and contain a trimmer-based sensitivity regulation .

•One optic head for the check of holes and dropped stitches in the produced fabric. The optic head is

placed directly onto the produced fabric to see holes and dropped stitches .

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

4

The magnetic sensor points out the conclusion of a turn to the main unit .

The microcontroller in the principal unit handles to count, to memorize and to verify the number of

present needles in two turns of the textile machine (two turns to increase tolerance ).

When the device individualizes some needles with the broken hook it points out on the display the

number and stops the loom.

The data and the settings of the tool can be protected with a secret code or password .

Technical characteristics

-Power supply voltage from 22 to 26 VAC

-Power consumption 10W

-Output port 2A 250V

-Indication on the display of the broken needles number

-optional password for data and set-up

-It counts up to 40000 needles for head and it works fine on speeds between 10 and 70 turn-minute.

-Languages Italian, English and French .

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

5

Main unit

The AGF2B main unit is smaller than AGF2 main unit, but it works the same way.

Also user interface and connections are the same , just two redundant key are removed.

There are two versions of AGF2B main unit :

1. One is the 'BLU' version , recognizable from blue paint on connector and from power-on message. This

BLU main unit use specific BLU-type optic heads, which are better then standard non-BLU ones .

2. The other is the non-BLU version , or normal one, just the standard type compatible with optic heads

previously used .

The present messages on the display vary according to the state of operation. When the loom regularly

turns the display it shows the message 'Counting.. .OK' and to the left it points out the present heads (up

to 4 heads). The count and the relative verify take place in two following turns of the textile machine.

What the tool shows after power on, without pressing keys, is called 'initial page.'

The principal functions of the keys are the followings :

•'Page' key used to flow the various visualizations or pages .

•Key 'R' , it restores the normal operation of the device after a block and if pressed for a long time

(6 seconds ) it disable the device.

•The keys '+', '- ', they serve for planning the data in the various visualizations or pages (delay arrest

needle, password...).

•The key 'C' on AGF2 and the key 'J' on AGF2B serve for planning the data in the various

visualizations or pages (delay arrest needle, password...).

•The key 'C' on AGF2 and the key 'J' on AGF2B also serves for memorizing the number of needles

to count when the instrument show the relative page.

•The key ‘J ' allows to enable or to disable the jump of the discarded initial needle. When the jump

is enabled the message ‘Jump ' appear in the inferior line of the display, this immediately

implicates the skip of the control of the zones of fabric following to the magnetic sensor . If the

present message is then ‘No J. ' , then the whole fabric is checked.

There are some connector in the lower side :

•the most left connector type DB9 must be connected to the optic head of the proper type ; connect

BLU type optic heads if the main unit is BLU type . Otherwise connect standard optic head if the

main unit is a normal or standard one.

•The middle connector must connect to the adapter module or amplifier, one or two optic needle

scanner are then connected to the adapter.

•To the most right connector type DB15 must be connected the power supply cable, furnished.

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

6

Magnetic Sensor and permanent Magnet:

Install the sensor on a firm part of the machine, in protected position from the bumps. Position the

magnet on a rotating part in such position to activate the sensor to every turn of the loom. The distance

between sensor and magnet has to be around 4 mm.

Pay attention to the obligatory polarity of the magnet.

Attention to the obligatory polarity of the agnet, and that the support is not vibrations subject!

The cable of the sensor finishes with a connector to insert in the circuit of command. If the sensor is

correctly installed it will be noticed on the display the writing 'Magnet! to the conclusion of every turn.

Please note that this magnetic sensor to be used with AG14 is a special one, different from FM8 or C8 's

magnetic sensors.

Adapter module:

It connects the optic needle scanner to the main unit and it is furnished with a regulation of sensibility for

each optic head .

The red and green lights ( LEDS ) present on its front serve for the regulation of the sensibility of the

heads, regulation to be performed during the installation.

Inside the adapter there are some dip-switches, two for each optic needle scanner . These dip-switches

must be set to 'ON' when the type of fabric produced is made with some very long voids between groups

of needles.

The switches 1 and 2 are used for the optic needle scanner 1, the switches 3 and 4 for the second one .

Then if there are some long voids on the optic needle scanner 1 try to put the switch 1 on ON, and if the

count is not correct try to put 1 and 2 on ON.

For the optic needle scanner 2 try to set on ON the switch 3 or the switches 3 and 4.

Therefore with total presence of needles, both in coasts 1:1, such switches will stay in the position OFF.

When inserting the heads into the form adapter it is necessary to respect the position of entrance of the

connector (stings red probe with point red form). Handle with care and avoid to force the connectors .

Top view of adapter module

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

7

Optical heads:

The optic heads (probes) must be set with a lot of care in proximity of the head of the needles, and once

individualized the positioning (see underlying figure) their support must be held to avoid moves during

the workmanship.

The head of the probe must be placed so that it surmount the head of the needle to a distance that

depends on the type of used head:

For heads produced before 2007 the distance it has to be among 1,5 and 2,5mm.

For heads produced in 2007 the distance it has to be among 2 and 4mm.

Recognize the 2007 new heads from the date written on the connector, the date show week and year, this

way: 05-07

The dates week-year with second figure 07 (2007) or following means heads of the new type, that must

be set to 5mm apart from the needle.

The position of the probe has to favor the vision of the head but not the stem of the needle.

The present green lights on the adapter must partially have turned on when the probe surmounts the head

of a needle, and they have to be turned off when the probe point on an empty space between needle and

needle. (To make sure of this correct positioning make to advance the loom through hand lever or with

brief pressures on the button 'slow' or 'pulse').

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

8

Use of the main unit.

The instrument (device) is endowed with various pages that allow to plan all the necessary parameters

for a correct operation.

The various pages are flowed in sequence using the special key 'Page' having the sketch of the pages.

Here following the description of the various pages, where the pages can be recognized from the writing

on the superior line of the display.

Note that this description refers to the simplest situation or without foreman password, which is

described subsequently.

Page Description

Initial This page appears at power-on .

From the upper line it is possible to understand the state of the device;

•the writing appears 'Wait for Work' if the device doesn't receive the

signal of activity from the textile machine, because it is stopped, or

the wire is not connected

•the writing appears 'Magnet' if the magnetic sensor has given an

impulse, which is when a turn of the textile machine is finished

•the writing appears 'CountS =. OK' if there is the signal of activity,

the textile machine is regularly turning and the number of needles

match the programmed number .

To the left appear the number of optic needle scanner connected; if the

scanner is connected then appear its number, 1 or 2; if a dot appear the

corresponding scanner is not connected. For example:

“1.” mean that optical needle scanner 1 is connected

“.2” mean that optical needle scanner 2 is connected

“12” mean that optical needle scanner 1 and 2 are connected

In the lower line sensibility to holes and dropped stitches is visualized ,

shown as two numbers between 1 and 100:

•to the left the sensibility to the holes

•to the right the sensibility to the dropped stitches.

Such sensibilities can be modified through 2 couples of keys ‘- ‘and ‘+, sets

in proximity of the aforesaid numbers.

There is then the key ‘J ' that it allows to enable or to disable the jump of the

discarded initial needle. When the jump is enabled the message ‘Jump '

appear in the inferior line of the display, this immediately implicates the

skip of the control of the zones of fabric following to the magnetic sensor .

If the present message is then ‘No J. ' , the whole fabric is checked.

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

Page Description

Memory= It points out the number of needles memorized for each head. For every

head or probe it show her own number of needles to count and verify. This

page serves only to read such number (you cannot modify it here, but then in

other pages). This page repeats so many times how many the present

(connected ) probes are, if any.

CountS1=

CountS2= Here the device counts the needles for the suitable probe on the display and

visualizes the total number of it every 2 turns of the machine. When the

device shows this 'pages of installation' it doesn't verify the number of

needles (it doesn't stop the machine), but it count them and eventually

memorize the number. In fact pressing the key 'C' or 'J' the display writes

'MEMORIZZ', and the number of needles counted is set in 'memory needles'

for the visualized probe. This page repeats so many times how many the

present probes are.

Pressing the keys '-and '+' you can decreased or to increase the sensibility of

the optic needle scanner actually visualized. Such sensibility must be

measured while the textile machine turns, and planned to such a value that

one or two green lights have turned on. You can sometimes try to vary the

sensibility so that the number of needles counted is more correct, if the optic

needle scanner is correctly positioned .

OPTICAL HEAD

STOP AT x HOLES It allows to plan the number of holes of small dimensions to count before

stopping the machine. Choice happens through the keys ‘+ and ‘- ‘related to

the error hole.

AMOUNT OF HOLES It visualizes the total number of holes that have caused the stop of the machine.

Such number accumulates that due to the survey of holes of big dimensions with

that due to the attainment of the quantity of holes of small dimensions planned into

the preceding page. The number can be reset by the ‘R ' key.

STOP FOR LITTLE

HOLES .. It visualizes the total number of machine stop for little holes . The number can be

reset by the ‘R ' key.

AMOUNT LADDERS It visualizes the total number of machine stop dropped stitches. The number can be

reset by the ‘R ' key.

D. STITCHES STOP

NO BLINK /BLINK It allows to select if during the stop due to dropped stitches the output relay

is always active or intermittent at 50% duty cicle. This can help to recognize

the stop due to broken needle. Change option with 'C' or 'J' key.

NEEDLE NUMB.STOP

NO BLINK / BLINK It allows to select if during the stop due to needle number error the output

relay is always active or intermittent at 30% duty cicle. This can help to

recognize the stop due to broken needle. Change option with 'C' or 'J' key.

SPEAK

ENGLISH/ITALIANO Imposes the language (English or Italian or French). To application other

languages can be included.

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

10

Page Description

NEEDLE JUMP

LENGHT ... In this page it is possible to specify the duration of the jump of needle that

effects after received the signal by the magnet. During such jump the control

of the fabric is suspended, so that possible lacks of needles foreseen in the

fabric doesn't cause a block. The value are the maximum duration (100ms)

while 1 are the least duration (11ms). The value 2 correspond to 22ms, and

so on . Change value with '+' and '-' keys.

Maintenance A number of turns can be input here, at which the device stops the car to

ask for a maintenance. With the key 'C' the number is modified, the key ‘+ it

increases the number pointed by the cursor while with the key ‘- ‘makes

flow the cursor to the following figure. Pressing the key 'C' the number is

memorized. A number equal to Zero disables this function.

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

11

Foreman password

The password foreman serves to limit the access to the configuration pages of the device.

If the password is trained then the initial page is always on top while to visualize the other pages the

password is required.

To specify and to train the password, act as it follows:

1. While the device is turned on and display the initial page, unplug the connector of the optic head

and insert the key of password furnished with the tool. The machine has to be stopped , or on the

signal in entry of 'activity' it doesn't have to be any voltage.

2. The special page will appear. The password is a decimal number of 4 digit . The key ‘+' increase

the number pointed by the blinking cursor . The key '-' move the blinking cursor to next digit.

Pressing the key page the password is memorized and the writing ‘new inserted password is

visualized.

3. Unplug the key of password so the device return to the initial page and the password is

memorized. .

The password is trained if different from '0000.' Then to disable the password protection just input a

new password equal to '0000.'

The device is furnished with password of default planned to ‘0000, such password allows the

unconditional access to all the pages.

When the password is trained, pressing the key 'page' make the tool require the password :

To insert the password use the same keys described above . Pressing the key page, the tools goes to the

following pages if the password is correct.

When the password is trained, there are one or two new pages :

Page Description

LOCK KEYS +,-,J

WITH PASS. ? In the initial page the keys + and- allow to regulate the sensibility of the optical

head for holes and tears. If it is wanted that such keys are protected with password,

to specify 'Yes' in this page. In such case the initial page serves only to read such

values, and the page described below is used for modifying them.

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

12

Install of the main unit

1. Choose a position for the main unit that is firm and visible. Unscrew the two screw placed on the

sides, and separate the front panel of the device from the hull in black metal, making slip

downward the front panel . Put aside the Front panel, handle with care.

2. Fix the black metal hull to the select place, avoiding leaning screw toward the inside of the

device. Clean possible metallic shavings due to the workmanship, and insert again the front panel

in the metallic hull. Fix the front panel with the screw previously removed.

3. Plug the power supply cable to the main unit; the black cable with 3 wires and the terminal block

in head must be connected to the magnetic sensor, connecting the white to the white, the brown

one to the brown one, the screen to the screen; the grey cable with 7 wires must be connected

here according to the suitable instructions following and to manual end.

Wire Function Connection

Brown power supply input - to the 0V of the transformer of the services of the

loom

Red with fuse power supply input + to the 24V of the transformer of the services of the

loom

Black or Orange Activity Input signal to 12V o 24V available only when the machine is

turning

Yellow connection to GND to protection earth (PE) or ground

Green Needle protection Input to Needle protection device (option )

Blue with fuse Stop output relay + Note 1

Bianco Stop output relay + Note 1

Note 1 : the “Stop output relays” are the two pins of a contact of relay, selectable NC or NA

through the pages of the device. Such contact of the relay doesn't have inside connections to the

device, and it is isolated therefore from GND and from any other signal. Use to stop the

machine.

Note 2 : The 'Activity' signal is required to tell the instrument that the machine is turning. In the

absence of that signal the quality check is not performed because the machine is assumed to be

stopped.

Warning: Avoid to make the cables run near the cables of power supply to the loom (380 V ) and avoid

to pick up the excesses of length rolling up her. Stretch well the cables.

Assemblage of the optic needle scanner for the count of the needles

1. Install the cylindrical supports of the optic needle scanner in stable way (eventually through

perforation on the sector).

2. Install the optic needle scanner according to the suggestions statements in the description of the

parts. Their supports allow any movement. For every loom it will be opportune to adapt the

wands of metal so that to make her the shortest possible. We remember that the heads don't have

to prevent the access the needles from the special counters, they don't have to hamper the

movements of the guide-threads and don't have to be one with the ring of the guide-threads, so

that to avoid that the adjustments of the same don't alter the distances between scanner and

needles.

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

13

3. Connect the optic needle scanner to the main unit. Power on and go to chapters about regulation

of the device and memorization of reference data.

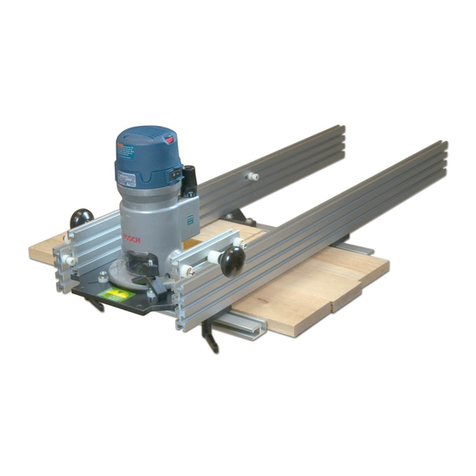

Instructions for the assemblage of the optic head

1. The optic head has a black plastic front with a transparent window, as visible in the following

image, and a plastic cork on the back. Mount one or two sleighs of metal on the optic head so

that sticks out of around two millimeters from the front. Then mount the optic head with the

sleighs in contact with the fabric, so that the front of the head is firmly two millimeters apart

from the cloth.

2. The head must be placed on top, next to the needles, where the fabric is formed. It is generally

fixed on the yarn guide. The transparent window of the front , visible in the following image, has

to be parallel to the defects of the fabric as the dropped stitches. Mainly the head is placed

standing in portrait (not landscape), exactly as in the image.

3. If the head is very near to the needles, only the lower sleigh is

necessary.

4. Check that the fans don't make to tremble the cloth at their

passage. This could cause some stop not necessary.

5. To make the jump of discarded needle then position the loom so

that the discarded needle is placed one inch before the optic head

and mount paired the couple of magnet and magnetic sensor. This

to be able to effect the jump of needle, that happen immediately

after received the signal by the magnetic sensor. During such jump

the control of the fabric is suspended, so that possible lacks of

needles programmed in the fabric doesn't cause a stop.

6. Connect the head to the main unit, turn on and regulate the

sensibility using the keys as previously exposed.

7. In the regulation of the sensibility keep in mind that can be increased or decrease acting on the

jumper put inside the main unit, previously described.

8. The sensibility must be increased until the tool stops the machine in presence of defects, but not

too much to stop the machine without motive. And' profit in this the distinction between holes

and dropped stitches :

1. The sensibility to dropped stitches (shown on the right on the display) can relatively be kept

high without a negligible defect stop the machine; in fact the defect of dropped stitches has to

present three consecutive times in the same point to cause a stop.

2. The sensibility to the holes (shown on the left on the display) must relatively be held low

so that to stop only when necessary.

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

14

Memori ation of reference data

The main unit counts the present needles in two turns of the loom and compares them with the

memorized datum, this for every probe or connected optic head.

To memorize the correct number of needles it is necessary to use the keyboard and the display of the

main unit so that to access the special pages of installation heads.

We recommends to read the part 'use of the main unit' first exposed.

Then follow the indications here available:

•To begin the installation, power on the instrument .

•Press the key 'Page' to flow the various present pages, until it reaches the page 'ContaS1 =..... '. This

message points out a 'page of installation'. It can be necessary to insert the password , as described

later in this document.

•The device counts the needles for the suitable probe on the display and visualizes the total number of

it every 2 turns of the machine. When the device shows these 'pages of installation' it doesn't verify

the number of needles, but it limits to count them and eventually to memorize them.

•Press the key 'page' until appear the 'page of installation' related to the probe that is desired to install.

•Start the machine .

•In such page at every couple of turns the number of counted needles remains on display for 2 seconds

; pressing the key 'C' or 'J' then the display writes 'MEMORIZZ', and the number of needles counted is

set in 'memory needles' for the visualized probe.

•If the number of needles shown doesn't correspond to the reality, intervene on the present

potentiometer inside the adapter that corresponds to the visualized probe; then increase or decrease

the sensibility of the probe until the instrument count the exact number.

•If he doesn't succeed in getting the exact number it will be useful to check or modify the positioning

of the probe and the distance from the needles .

•When the counter is correct press again the key 'C' or 'J' , the display writes again 'Memory =

visualizing the new amount just saved.

•The installation of this probe is complete, others of it can be installed or return to the normal page

with the key 'Page.' After a time-out the device returns itself to the normal operation.

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

15

Regular operation and stop of the production

The block of the machine happens if the device notices for two couples of consecutive turns a greater

difference of 1 among the number of counted needles and the data saved in memory.

The device counts and verifies the needles regardless of any operation that is performing through

keyboard , except in the following cases:

1. the instrument show a 'Page of installation.'

2. the instrument is disarmed through the key 'R', see relative paragraph.

3. the instrument doesn't receive the signal of activity, and in such case the display shows the message

'WaitForWork'

When the device notices the breakup of the head of a needle the block of the machine can be immediate

or delayed so that the broken needle is placed in a pre-arranged position.

Opportunely programming the device in the page 'Stop Machine' it will involve in the select way during

the stop.

Cleaning of the heads.

With the progress of the job in the time, in case of dusty yarns, there is the danger that the dust obscure

progressively the heads, causing a lowering of sensibility (this is underlined by a decrease of brightness

of the leds on the form adapter).

It is useful to handle the cleaning of the heads with regularity, for instance every piece, with spun of

middle cotton. Or clean the heads blowing with compressed air or, if dirty of paraffin, clean the optic

part brushing with a clean and soft rag.

Turning off the main unit

The device can be disarmed pressing for a long time the key 'R.'

The display shows the writing 'turned off by operator.' To reactivate press the same key for a long time.

The device remains turned off indefinitely even if powered off and on .

Output relay blink

There is a page in which is possible to choose if, in condition of stop, the output relay must have

maintained turned on or has to blink (to give greater visibility to connected lamp).

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

16

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

17

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

18

List of part numbers :

809 OPTIC HEAD 40X60

810 OPTIC HEAD BRACKET

811 LARGE SLEIGH

822 AG12/AG14/AGF OPTIC NEEDLE SCANNER

823 BRACKET FOR NEEDLE SCANNER

824 AMPLIFIER AG14/AGF

825 AG14/AGF MAGNETIC SENSOR PLUS MAGNET

826 AG14/AGF POWER SUPPLY CABLE

839 AGF PASS

840 AGF2 MAIN UNIT

841 AGF2B MAIN UNIT

15/01/10

Il presente documento è di proprietà della ditta I.L.E., ogni riproduzione o cessione a terzi è vietata a norma di legge.

1

This manual suits for next models

1

Table of contents

Other ILE Tools manuals