Hardinge 16C User manual

1

16C Low-Pressure Dead-Length Collet Blocks Instructions B-145

Hardinge Inc. One Hardinge Drive, Elmira, NewYork U.S.A. 14902-1507 800.843.8801 (Canada 800.468.5946) www.hardingetooling.com

Part No. B -0009500-0145

16C Collet Block

Low-Pressure, Pneumatic or Hydraulic, Double Acting, Dead-Length

Part No. 7799-00-00-000096

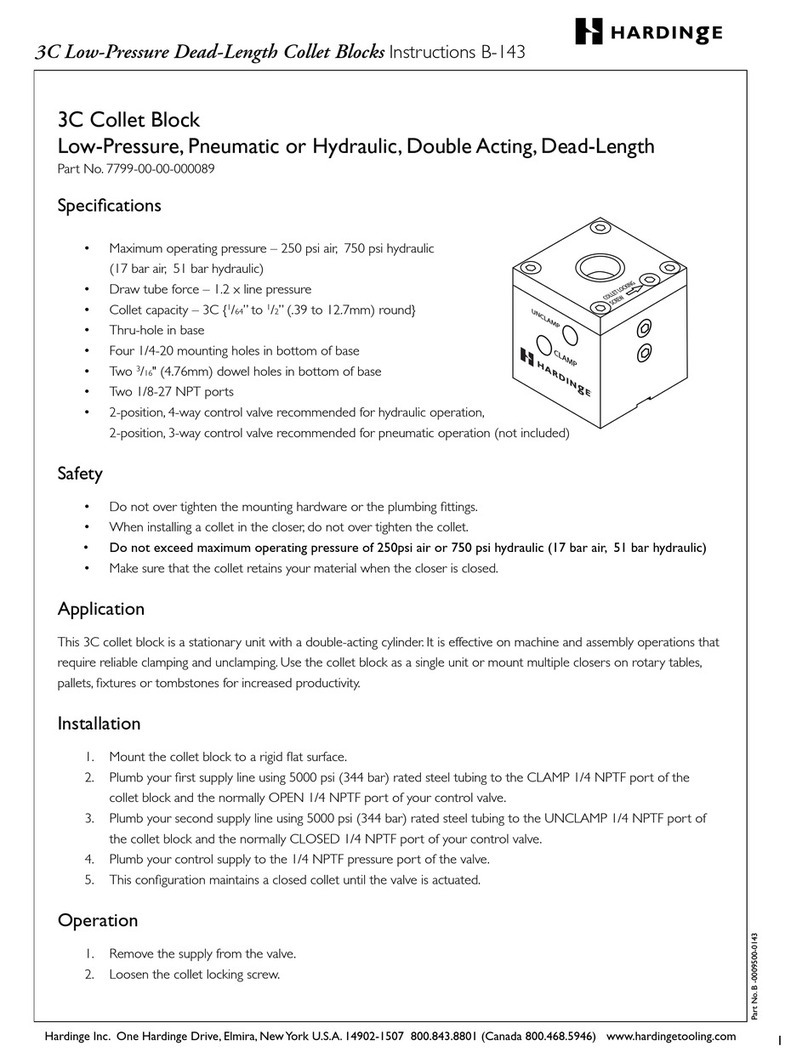

Specifications

• Maximum unit operating pressure – 250 psi air, 2000 psi hydraulic

(17 bar air, 137 bar hydraulic)

• Draw tube force – 5.8 x line pressure

• Collet capacity – 16C {1/64" to 15/8" (.39 to 41.27mm) round}

• Thru-hole in base

• Four 1/4-20 mounting holes in bottom of base

• Two 3/8" (9.52mm) dowel holes in bottom of base

• Two 1/4"-18NPT ports

• 2-position, 4-way control valve recommended for hydraulic operation,

2-position, 3-way control valve recommended for pneumatic operation (not included)

Safety

• Do not over tighten the mounting hardware or the plumbing fittings.

• When installing a collet in the closer, do not over tighten the collet.

•Do not exceed maximum operating pressure of 250psi air or 1207 psi hydraulic (17 bar air, 83 bar hydraulic).

• Make sure that the collet retains your material when the closer is closed.

Application

This 16C collet block is a stationary unit with a double-acting cylinder. It is effective on machine and assembly operations

that require reliable clamping and unclamping. Use the collet block as a single unit or mount multiple closers on rotary

tables, pallets, fixtures or tombstones for increased productivity.

Installation

1. Mount the collet block to a rigid flat surface.

2. Plumb your first supply line using 5000 psi (344 bar) rated steel tubing to the CLAMP 1/4 NPTF port of the

collet block and the normally OPEN 1/4 NPTF port of your control valve.

3. Plumb your second supply line using 5000 psi (344 bar) rated steel tubing to the UNCLAMP 1/4 NPTF port of

the collet block and the normally CLOSED 1/4 NPTF port of your control valve.

4. Plumb your control supply to the 1/4 NPTF pressure port of the valve.

5. This configuration maintains a closed collet until the valve is actuated.

Operation

1. Remove the supply from the valve.

2. Loosen the collet locking screw.

3. Insert the collet in the top of the collet block.

2

16C Low-Pressure Dead-Length Collet Blocks Instructions B-145

Hardinge Inc. One Hardinge Drive, Elmira, NewYork U.S.A. 14902-1507 800.843.8801 (Canada 800.468.5946) www.hardingetooling.com

Part No. B -0009500-0145

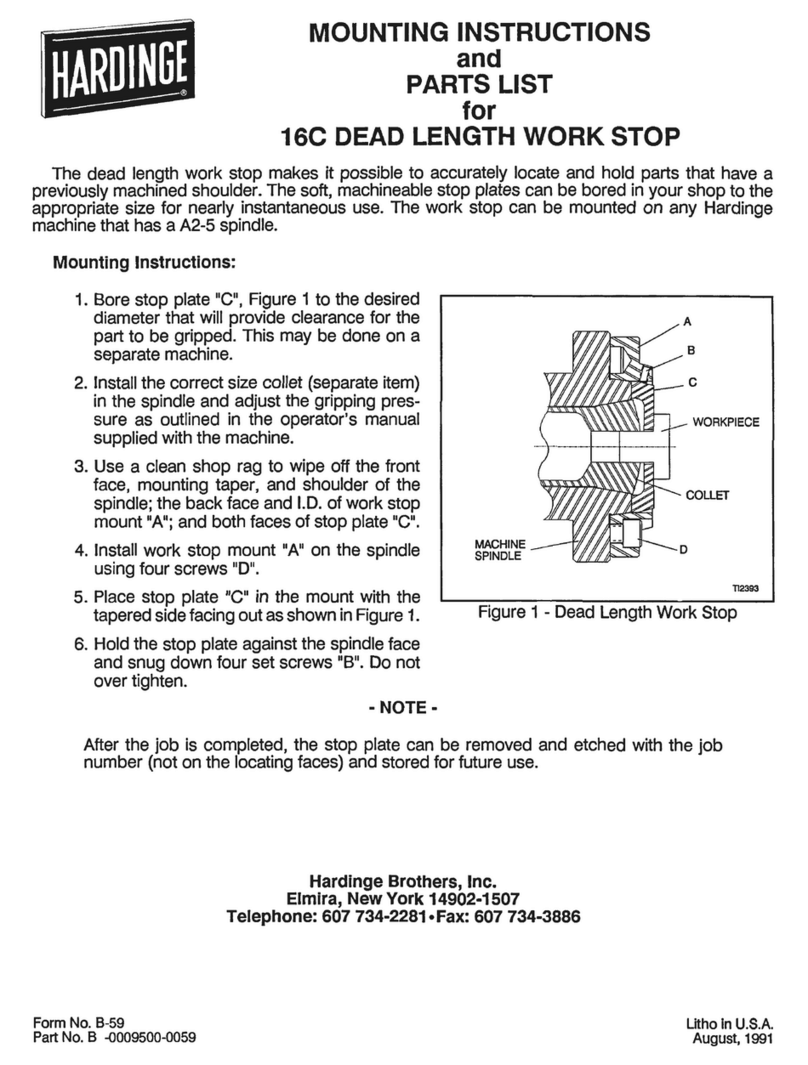

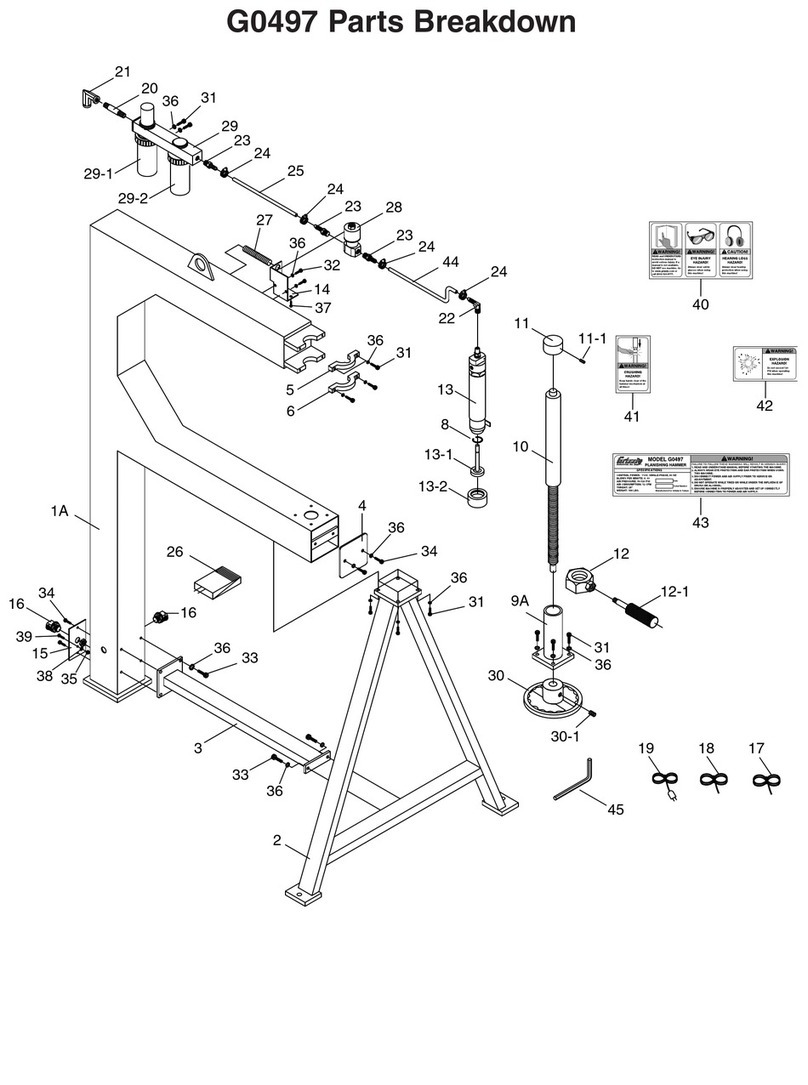

COLLET

LOCKING

SCREW

4.000''

(101.6mm)

4.000''

(101.6mm)

1.062''

(26.9mm)

1/4-18 NPT

SUPPLY PORTS

2X

1/4-20 MOUNTING

HOLES, 4X

.375 (17.1mm) DOWEL

LOCATING HOLES, 2X

3.000''

(76.2mm)

2.8750''

(73.0mm)

+.0010

-.0000

+.0254

-.0000

1.4375''

(36.5mm)

+.0005

-.0000

+.0127

-.0000

3.625''

(92.0mm)

1.125''

(28.5mm)

4.000''

(101.6mm)

4.250''

(107.9mm)

1.094''

(27.7mm)

CONNECTOR BUSHING PORTS, 4X

TOP

VIEW

BOTTOM

VIEW

4. Using the collet wrench, turn the collet clockwise until it contacts the piston taper.

5. Tighten the collet locking screw. Do not overtighten.

6. To close the collet closer, insert a workpiece in the collet, and connect the supply to the control valve.

WARNING: Do not close the closer without the workpiece in the collet.

7. Adjust your supply pressure to a level that assures effective workholding only. Continuously operating the closer at

maximum pressure will decrease the service life of the seals and collet.

WARNING: Pressure to this closer above 250 psi air or 1207 psi hydraulic (17 bar air, 83 bar hydrualic)

may overstress the 5C collet.

8. To open the collet, actuate the valve.

Maintenance

If, over a period of time, you experience a decrease in clamping force even though pneumatic or hydraulic pressure remains

unchanged, remove the collet block from service, disassemble, and replace any damaged or worn o-rings.

Warranty

The products furnished hereunder are guaranteed by Hardinge Inc. against any defect in material or workmanship for a

period of one (1) year from date of shipment when owned by original buyer or first user, and maintained and operated

under normal conditions. Any products hereunder not manufactured by Hardinge Inc. are warranted only to the extent of

the original manufacturer’s warranty. Parts found to be defective in material or workmanship under this guaranty shall be

repaired or replaced without charge, F.O.B., original point of shipment provided prompt notice of the defect is given and

compliance with the terms of this guaranty are established. HARDINGE INC. SHALL BE LIMITED STRICTLY AND

WHOLLY TO THE FOREGOING.

In no event shall Hardinge Inc. be liable for consequential or incidental damages or for other costs, expenses, or damages

incurred by you attributed to any item sold hereunder.

3

16C Low-Pressure Dead-Length Collet Blocks Instructions B-145

Hardinge Inc. One Hardinge Drive, Elmira, NewYork U.S.A. 14902-1507 800.843.8801 (Canada 800.468.5946) www.hardingetooling.com

Part No. B -0009500-0145

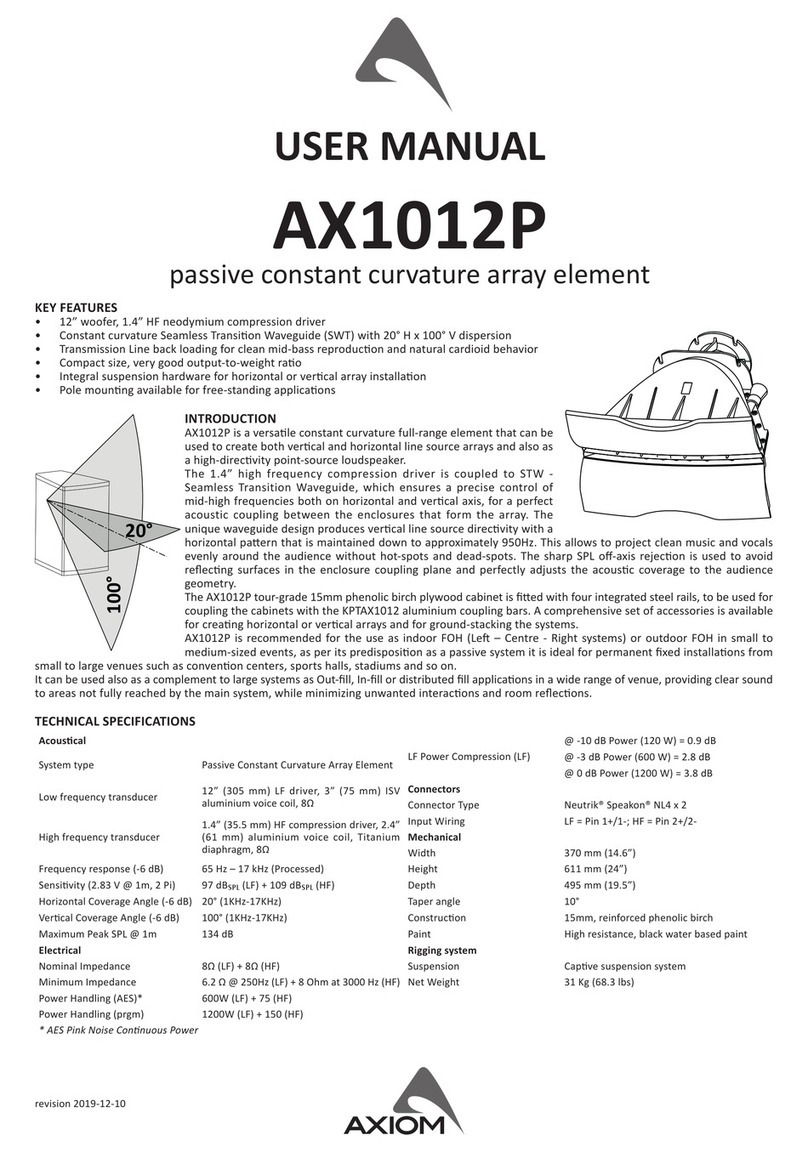

CLAMP

UNCLAMP

PNEUMATIC

CONTROL VALVE

#7799-00-00-000065

PNEUMATIC

COLLET CLOSERS

(double-acting) AIR SUPPLY

FIXTURE PLATE

Example of a simple pneumatic configuration

Components include a control valve and three pneumatic collet blocks supplied by Hardinge mounted on a customer

machined fixture plate. Two connector bushings are used between each collet block for internal plumbing. A total of four

connector bushings would be used in this example. (schematic shown in clamp position)

Dimensions for mounting holes are available on the installation instructions online at www.hardingetooling.com

4

16C Low-Pressure Dead-Length Collet Blocks Instructions B-145

Hardinge Inc. One Hardinge Drive, Elmira, NewYork U.S.A. 14902-1507 800.843.8801 (Canada 800.468.5946) www.hardingetooling.com

Part No. B -0009500-0145

AIR SUPPLY

4-WAY, 2-POSITION

CONTROL VALVE

#7799-00-00-000071

AIR DRIVEN HYDRAULIC PUMP

1500 PSI #7799-00-00-000070

2500 PSI #7799-00-00-000069

PRESSURE

RETURN

CLAMP

UNCLAMP

HYDRAULIC

COLLET CLOSERS

(double-acting)

AIR SUPPLY

PRESSURE

RETURN

AIR DRIVEN HYDRAULIC PUMP

1500 PSI #7799-00-00-000070

2500 PSI #7799-00-00-000069

HYDRAULIC

COLLET CLOSERS

(double-acting) ACCUMULATOR

#7799-00-00-000068

HORIZ MOUNT

#7799-00-00-000067

QUICK

DISCONNECT

HANDLE

#7799-00-00-000075 STD. MANIFOLD

WITH CHECK VALVE

#7799-00-00-000074

FIXTURE

PLATE

CLAMP

UNCLAMP

4-WAY, 3-POSITION

CONTROL VALVE

#7799-00-00-000072

Example of a typical hydraulic configuration

Components include a pump, control valve and three hydraulic collet blocks supplied by Hardinge mounted on a customer

machined fixture plate. (schematic shown in clamp position) 5000 psi (344 bar) rated hose/tubing is recommended.

Dimensions for mounting holes are available on the installation instructions online at www.hardingetooling.com

Example of a quick disconnect hydraulic configuration

Components include a pump, control valve, accumulator, quick disconnect handle, manifold with check valve and three

hydraulic collet blocks supplied by Hardinge on a customer machined fixture plate. The control valve should mount outside

of the machine with the pump or on the outside wall of the machine. The quick disconnect with check valve allows you to

remove the hydraulics while in the clamp mode – ideal for preloading pallets. An accumulator is required when using the

quick disconnect product. (Schematic shown in the clamp position) 5000 psi (344 bar) rated hose/tubing is recommended.

Dimensions for mounting holes are available on the installation instructions online at www.hardingetooling.com

Other Hardinge Tools manuals